2/4 Fixing instructions Doc. version 4.0

FC421CP-I FIRECLASS Fire detection system

Terminals

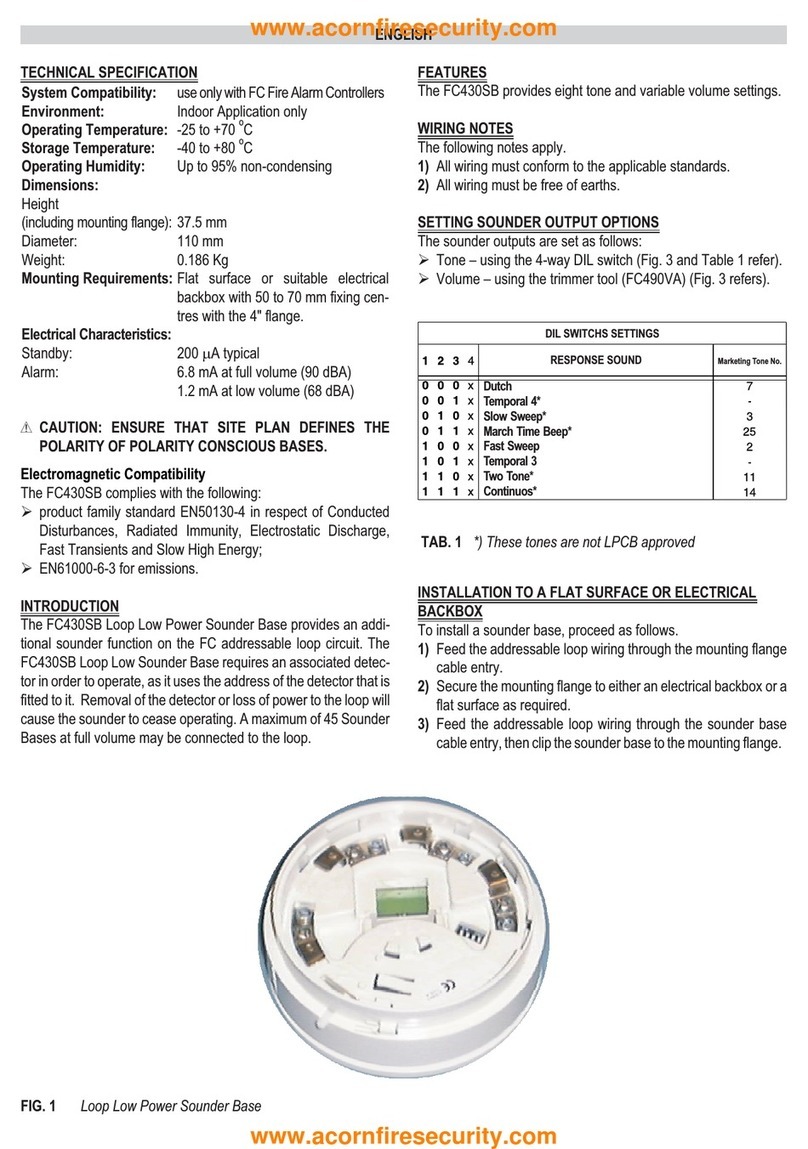

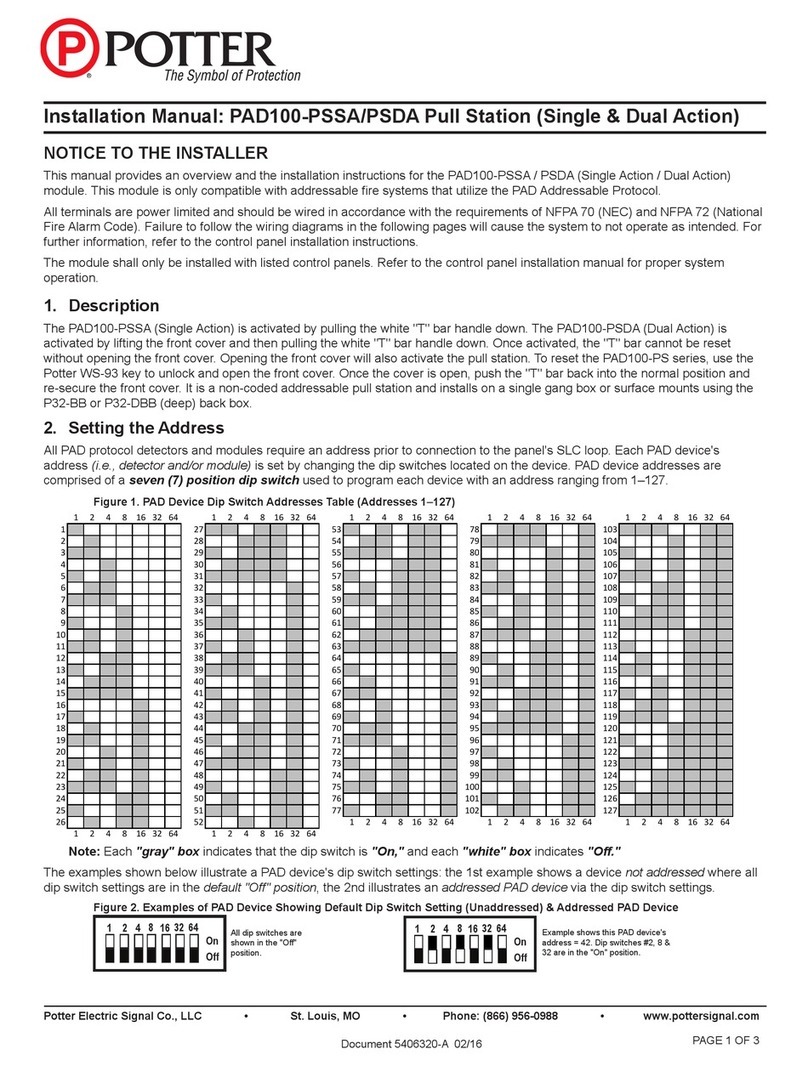

Table 2 shows the terminal information.

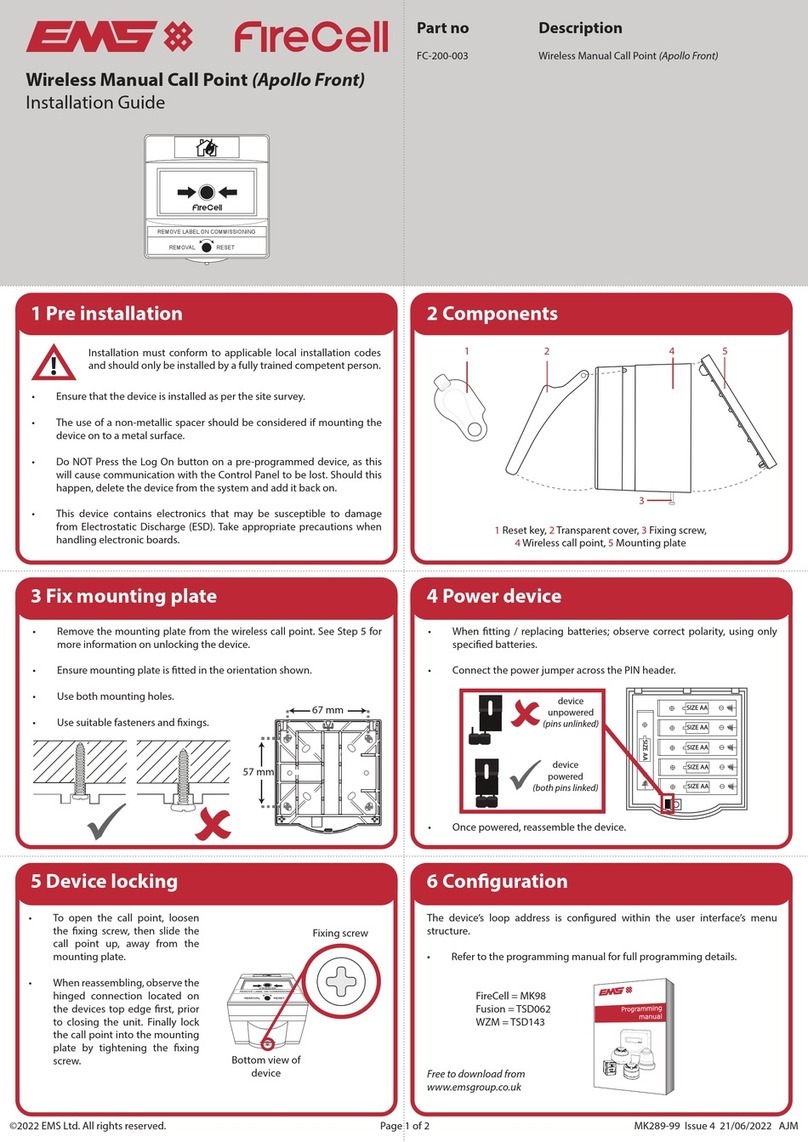

Address Programming

The FC421CP-I has a default factory set address

of 255.

The FC421CP-I is programmed with the address

prior to installation using an address program-

ming tool. The associated ancillary programming

lead plugs into the programming port (see

items 1 and 2 in Fig 2). Refer to Fig 2 for proper

orientation.

Mounting & Cabling

How to mount the FC421CP-I with

earthing plate fitted

1 Mount the backbox to a suitably flat surface in

the required location, using the three fixing

holes and screws provided in the installation

kit.

2 Fit the appropriate cable glands into the

20 mm diameter threaded holes as required.

Description Marking Comment

MX Loop

Interface

1 Loop+ IN

2 Loop- Left

3 Loop+ OUT

4 Loop- Right

Table 2: Terminals

NOTICE

Ensure that the pins of the ancillary

programming lead are inserted

completely into the lower row of the

programming port (see item 7 in Fig 2)

for effective communication with the

Address programming tool.

Site Drawings

Once the address has been pro-

grammed, take note of the device loca-

tion and address number, to include on

site drawings.

Fig. 2: FC421CP-I Rear View and Wiring Information

1– Ancillary Programming Port

2– Ancillary Programming Lead

3– Connected to Loop+IN

4– Connected to Loop-Left

5– Connected to Loop+Out

6– Connected to Loop-Right

7– Programming Lead Orientation

8– Gasket

NOTICE

Ensure that the cable entry holes are in

the vertical plane. The backbox can be

mounted with either the single or the

double entry holes at the top.

6

35

4

2

1

7

8

FIRECLASS Fire detection system FC421CP-I

Fixing instructions Doc. version 4.0 3/4

The 2 hole stoppers with plastic washers are

provided for use where cable glands are not

required.

3 Connection to the FC421CP-I is made via the

4 way terminal connector as shown in Fig. 2,

ensuring correct polarity.

Each terminal can accommodate a conductor

of up to 2.5 mm2.

.

4 Place the callpoint squarely over the backbox

and carefully push the callpoint until the locat-

ing clips have engaged.

Use the four fixing screws to lock the call-

point into place.

5 Select all cables in accordance with local

standards,

6 Couplers are to be used with MICC cable.

Earthing

An Earth Continuity Terminal is situated in the

rear of the backbox. This is designed to accom-

modate 2 conductors of up to 2.5 mm2.

An earthing plate is provided for continuity of

metal conduits. This must be placed behind the

backbox prior to fixing the box to the wall.

If the earthing plate is fitted, fit the 3 spare wash-

ers (supplied with each call point) between the

metal earth continuity strap and the call point

backbox.

Wiring Notes

There are no user-required settings (such as

switches or headers) on the FC421CP-I.

All wiring must comply with local installation

regulations and local fire system design

requirements.

All conductors to be free of earths. For typical

wiring configuration see Fig 2.

Spare Washers

Use only the supplied spare washer(s)

to fit the respective cable gland(s) or

hole stopper(s).

CAUTION

Ensure that the backbox’s cable entry

holes are not expanded to

accommodate cable glands wider than

20 mm in diameter. It must not be

subjected to stress by the cable or

conduit.

Ensure that all the cable entries and

unused entry points are securely sealed

against water and moisture ingress.

Sealant

It is recommended to use Loctite 5331

as sealant.

NOTICE

Ensure that the gasket is correctly

seated in the channel on the rear of the

cover. The gasket should be replaced if

damaged.

WARNING

While installing the FC421CP-I:

Do not overtighten the fixing

screws

Avoid using lubricants, clean-

ing solvents or petroleum

based products.