PN P85756-002D Page 2

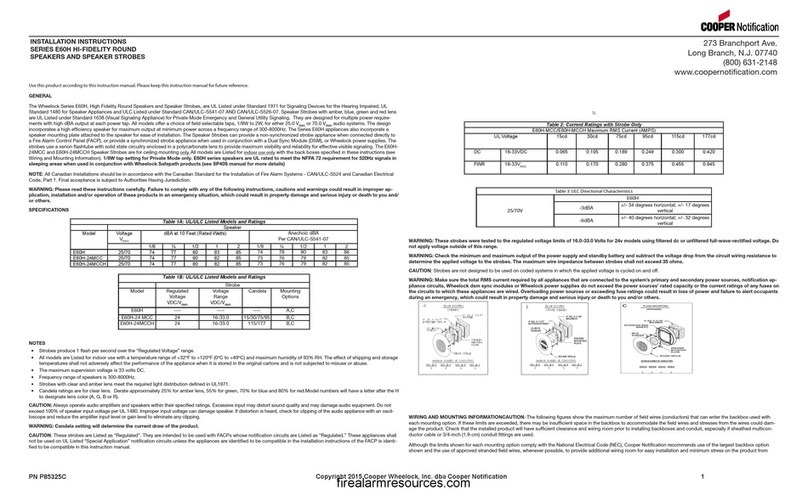

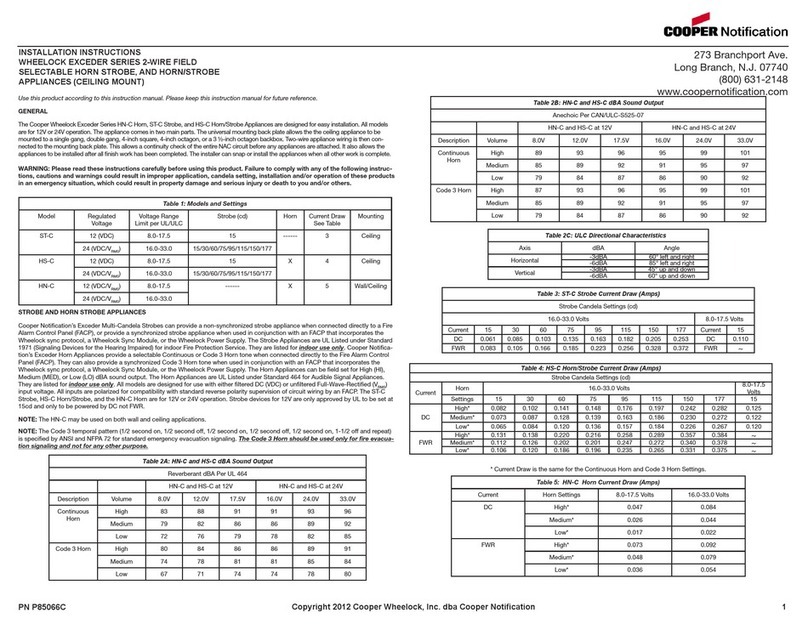

SETTINGS: To set candela, slide the selector switch to the desired setting. See Figure 3.

Figure 3: Settings (Set from rear)

Factory Setting is 5cd.

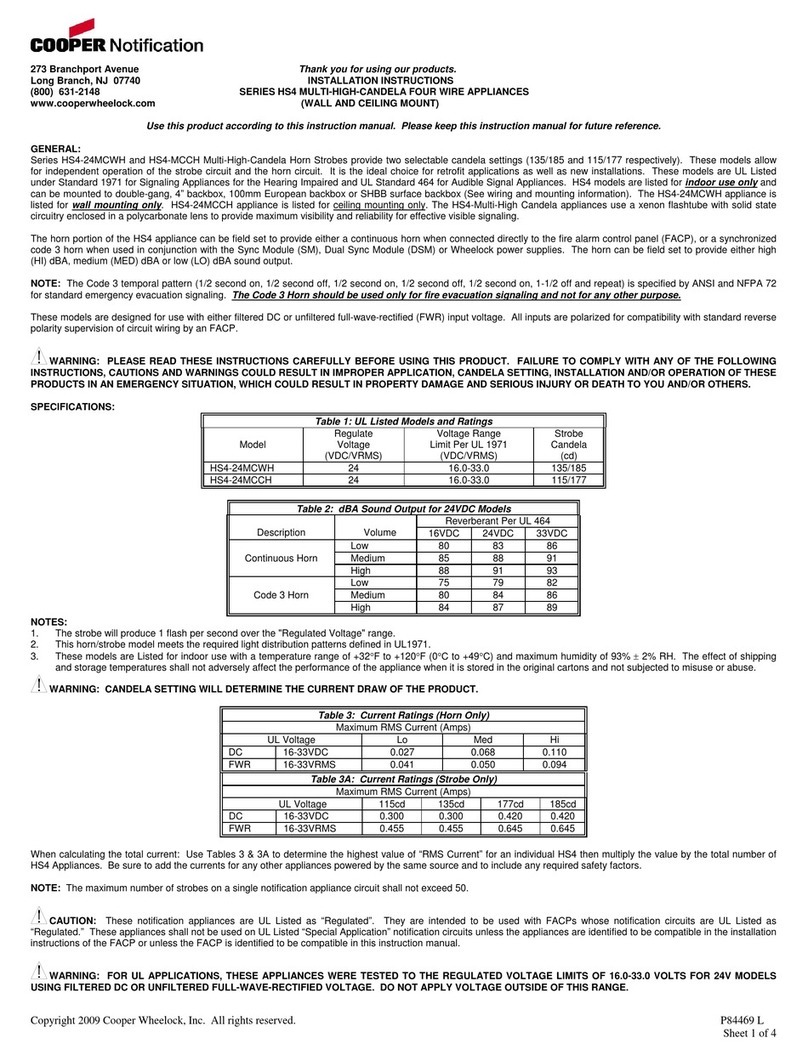

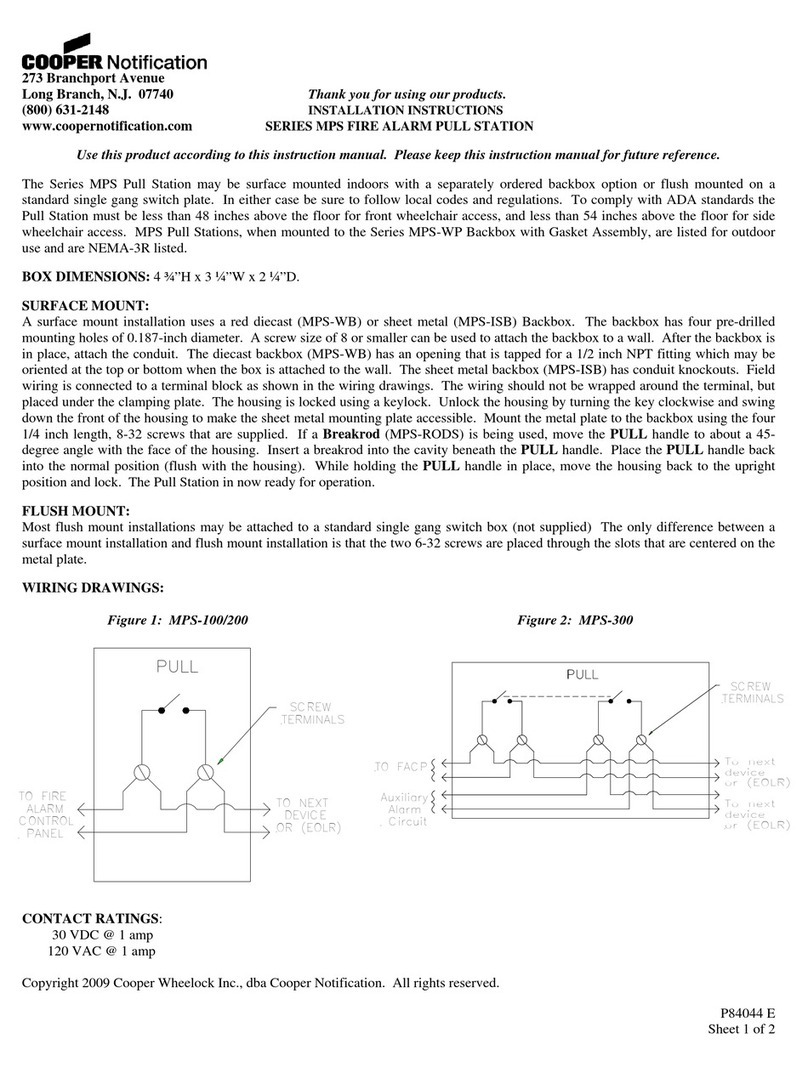

Figure 4: Strobe Light Distribution

Strobe device has only one mounting orientation. LED light element should be oriented toward the floor

NFPA 72/ANSI 117.1 provide means for determining equivalent illumination using fewer, higher intensity strobes within the same area.

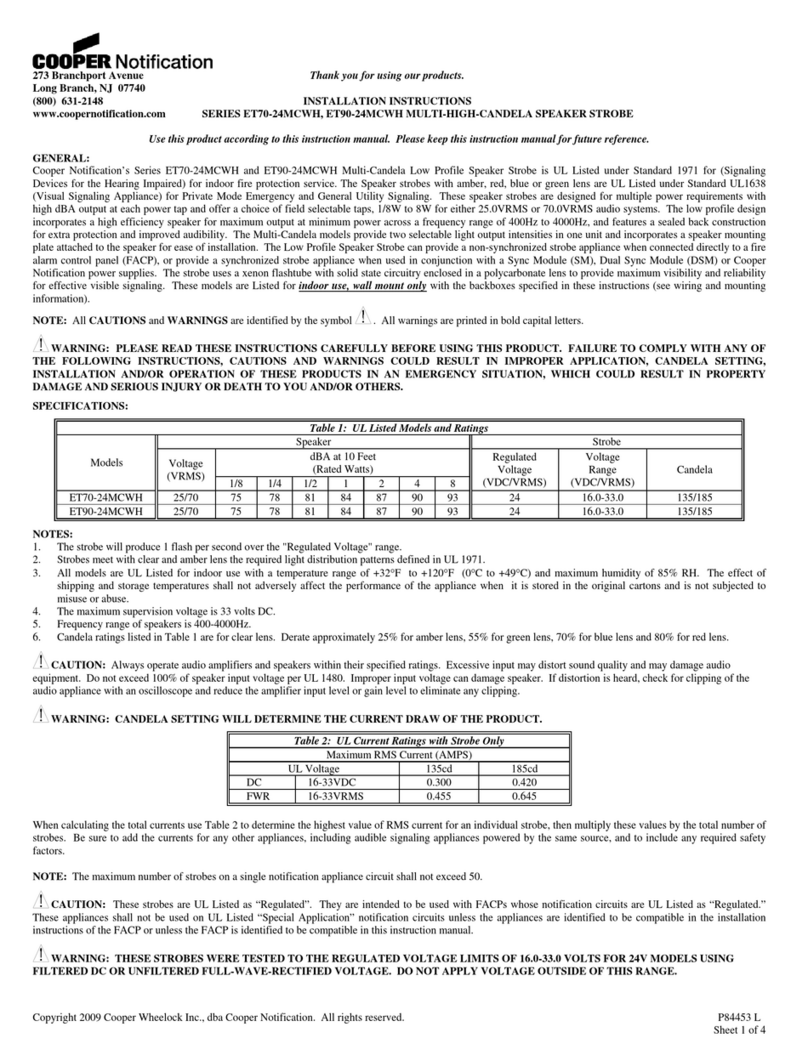

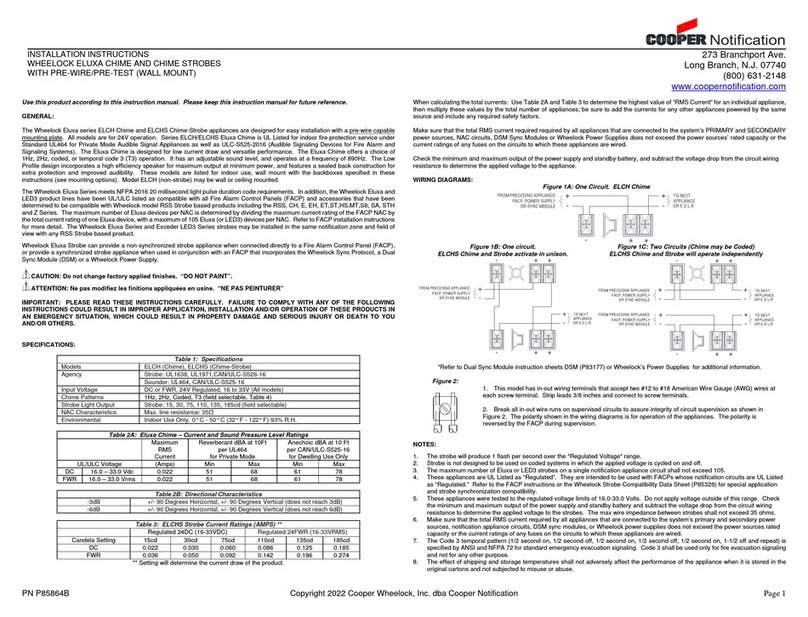

Figure 5: Grille Removal ** Figure 6: Surface BackBox LSPKBB-C

(1)PRESSIN

(2)PULL

INSERT SCREW DRIVER INTO SLOT,

(1) PUSH IN TO RELEASE SNAP, AND

(2) PULL TO REMOVE THE GRILLE

BREAK OFF TABS

FOR 3/4" CONDUIT

METAL STRAP

SUFACE

BACKBOX

WOOD

SCREWS (2)

INSERT

MOUNTING

TABS (2)

** Grille removal: 1) Insert Screwdriver into slot, and push to release snap. 2) Remove the grille.

Check the installation instructions of the manufacturers of other equipment used in the system for any guidelines or restrictions on wiring

and/or locating Notification Appliance Circuits (NAC) and notification appliances. Some system communication circuits and/or audio circuits,

for example, may require special precautions to assure immunity from electrical noise (e.g. audio crosstalk).

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to correct the interference at his own expense.

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations. Cet appareil

numérique de la classe A respecte toutes les exigences du Réglement sur le matériel brouilleur du Canada.

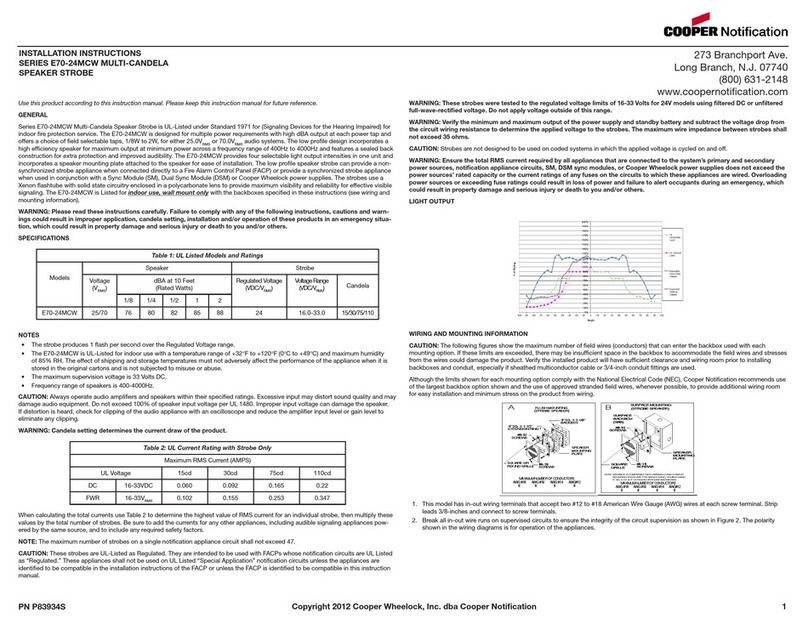

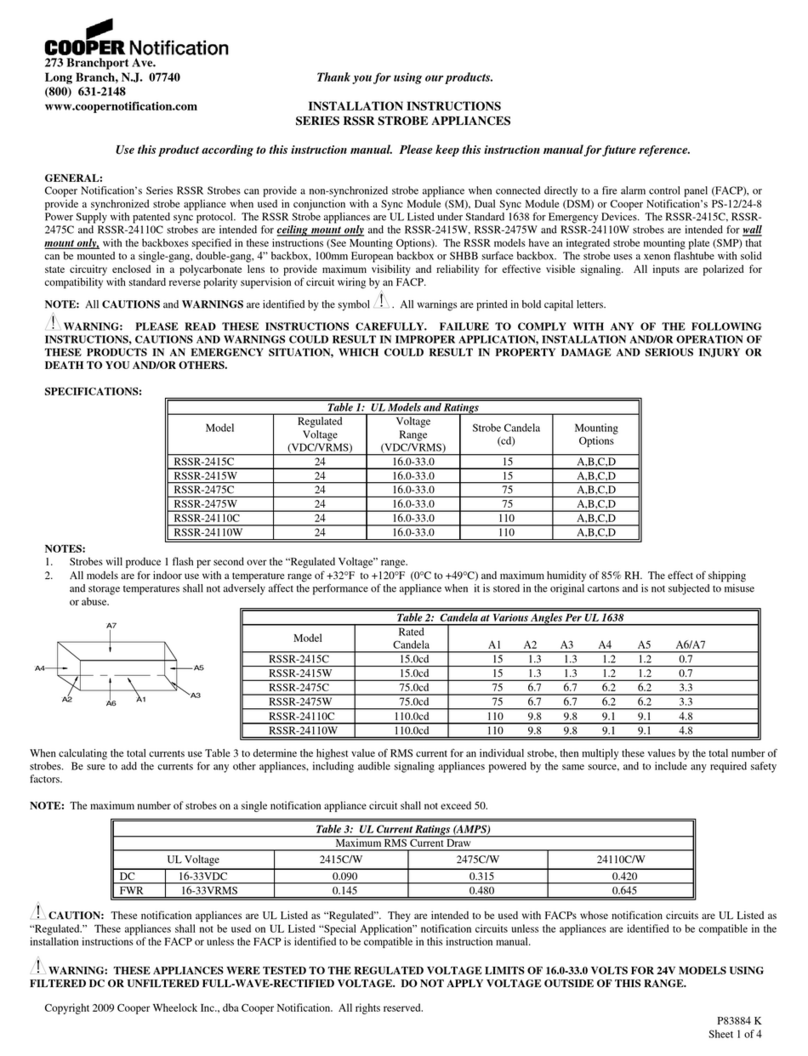

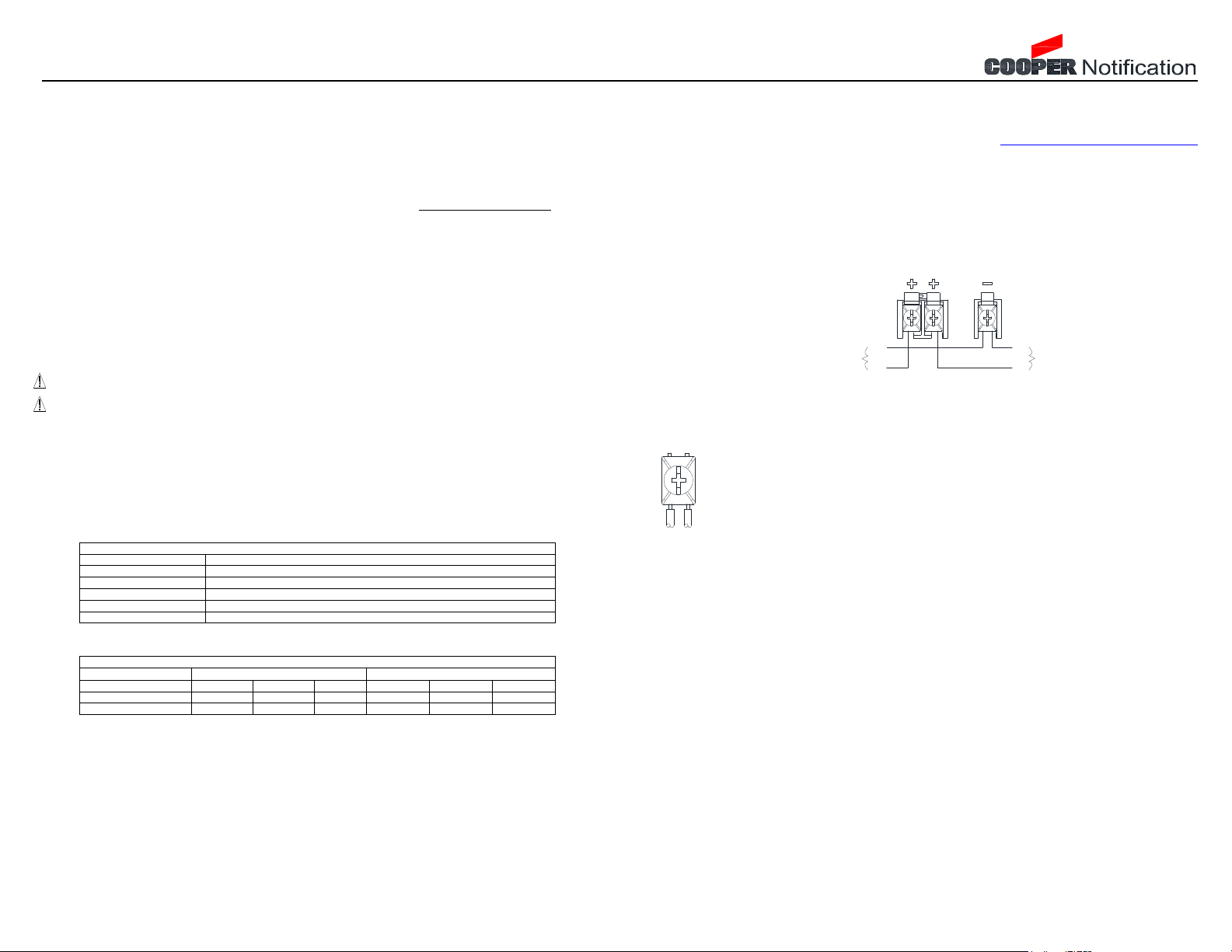

MOUNTING OPTIONS:

The following figures (A thru C) show the maximum number of field wires (conductors) that can enter the backbox used with each mounting

option. If these limits are exceeded, there may be insufficient space in the backbox to accommodate the field wires and stresses from the

wires could damage the product.

Check that the installed product will have sufficient clearance and wiring room prior to installing backboxes and conduit, especially if

sheathed multiconductor cable or 3/4" conduit fittings are used.

Figure A: Flush Mount (4”SQ Box) Figure B: Surface Mount (LSPKBB-C)

(2)#8-32 SCREW

#8 THREAD CUTTING SCREW (2)

Maximum Number of Conductors

AWG #18 #16 #14 #12

4 4 4 4

Maximum Number of Conductors

AWG #18 #16 #14 #12

4 4 4 4

Figure C: Flush Mount (Octal box)

Figure D: Flush Mount (SG box)

(2)#8-32 SCREW

(2)#6-32 SCREW

Maximum Number of Conductors

AWG #18 #16 #14 #12

4 4 4 4

Maximum Number of Conductors

AWG #18 #16 #14 #12

4 4 4 4

All installations shall be in accordance with:

1) In the United States, the National Electrical Code, NFPA 70, and the National Fire Alarm and Signaling Code, NFPA 72.

2) In Canada, CSA C22.1, Canadian Electrical Code, Part I, Safety Standard for Electrical Installations, Section 32; and the Canadian

Standard for the Installation of Fire Alarm Systems - CAN/ULC-S524.

MOUNTING PROCEDURES:

1. Select a mounting option and install the backbox. Conduit entrances to the backbox should be selected to provide sufficient wiring

clearance for the installed product. Do not pass additional wires (used for other than the signaling appliance) through the backbox.

Such additional wires could result in insufficient wiring space for the signaling appliance.

2. Install the Mounting Plate on the backbox. Use 8-32 screws for 4” SQ or Octal; 6-32 screws for SG; or hi-lo screws for LSPKBB.

3. Pre-Wire: Connect field wires to terminals on mounting plate (reference Figure 1 and 2). Use care and proper techniques to position

the field wires in the backbox so that they use minimum space and produce minimum stress on the product. This is especially

important for stiff, heavy gauge wires and wires with thick insulation or sheathing. When terminating field wires, do not use more

lead length than required. Excess lead length could result in insufficient wiring space for the signaling appliance.

4. Pre-Test: Mounting Plate contains a SHUNT between adjacent “+” terminals to facilitate testing before device is attached.

Note: Shunt will open permanently when device is installed on mounting plate.

5. Verify appliance settings are correct for your application. Settings are shown in Fig. 3. Factory settings is 5cd.

6. Place the appliance over the mounting plate. Engage TOP hook on mounting plate, then secure with screw at the bottom. Use care

to prevent damage when driving the screw.

7. Align cover to the ELSTC-B appliance with strobe opening over LED lens. Then, snap the cover in place.

8. To remove the appliance, insert a small flat-bladed screwdriver into the bottom opening ½” as shown in Figure 5. Then remove grille.

9. Accessories: ELUXA Surface back box. LSPKBB-CR (Red); LSPKBB-CW (White).

Important: Do not fully back out terminal screws. Do not over tighten screws or terminals. Excessive torque may affect

operation. When using power tools, ensure the torque is set to the lowest setting available.

NOTE: Final acceptance is subject to Authorities Having Jurisdiction.

Any material extrapolated from this document or from Cooper Wheelock manuals or other documents describing the product for use in

promotional or advertising claims, or for any other use,including description of the product’s application, operation, installation and testing

is used at the sole risk of the user and Cooper Wheelock will not have any liability for such use. IN NO CASE WILL SELLER’S LIABILITY

EXCEED THE PURCHASE PRICE PAID FOR A PRODUCT.

8/22