The Form 4C control is equipped with a 24-hour notation

time clock that records the year, month, day, hour,

minute, and seconds of recorded events. The clock

begins operation upon connection to the control’s ac

power or backup power supply.

The clock must be set at the time the control is installed

and reset whenever control power is disconnected.

When the control is first energized, the clock default

month and day are 1/1 and the year is 2001. The clock

must be set prior to programming or interrogation for the

recorded events to be logged to the proper day and

time.

The clock is used in conjunction with the event recorder

and load profile monitor to store events recorded in the

control. No security code is required to set the clock or

change clock settings.

To set, examine, or change clock settings, refer to

Access Codes 153 through 156.

1. Connect the ac supply and the control battery. Four

dashes (----) will appear on the LCD display to indi-

cate that the clock needs to be set.

2. From the keyboard, press DISPLAY ON. The Ready

(rdY) prompt appears indicating the control is ready

for programming.

To set the year:

1. Press the CODE key and the numbers 1-5-3 (for

access code 153). Then press ENTER.

2. Press the CHANGE key. Enter the four digits of the

current year. Press ENTER.

To set the date:

1. Press the SCROLL key to advance the control to

Access Code 154. Code 154 can also be entered

manually.

2. Press CHANGE. Enter four digits for the month (01

to 12) and day (01 to 31). Single-digit months and

days are preceded by a zero. Press ENTER.

To set hour and minute:

1. Press SCROLL to advance the control to Access

Code 155. Code 155 can also be entered manually.

2. Press CHANGE and enter four digits for the hour (01

to 24) and minute (01 to 59). Press ENTER.

To set seconds:

1. Press SCROLL to advance the control to Access

Code 156. Code 156 can also be entered manually.

2. Press CHANGE and enter two digits for the seconds

(01 to 59) and press ENTER.

Use the SCROLL key to review the new calendar and

clock settings. Press ESCAPE to return to the Ready

(rdY) prompt.

6

Kyle Form 4C Microprocessor-Based Recloser Control Programming Guide

SETTING THE CONTROL CLOCK

(Access Codes 153–156)

USING THE KEYBOARD

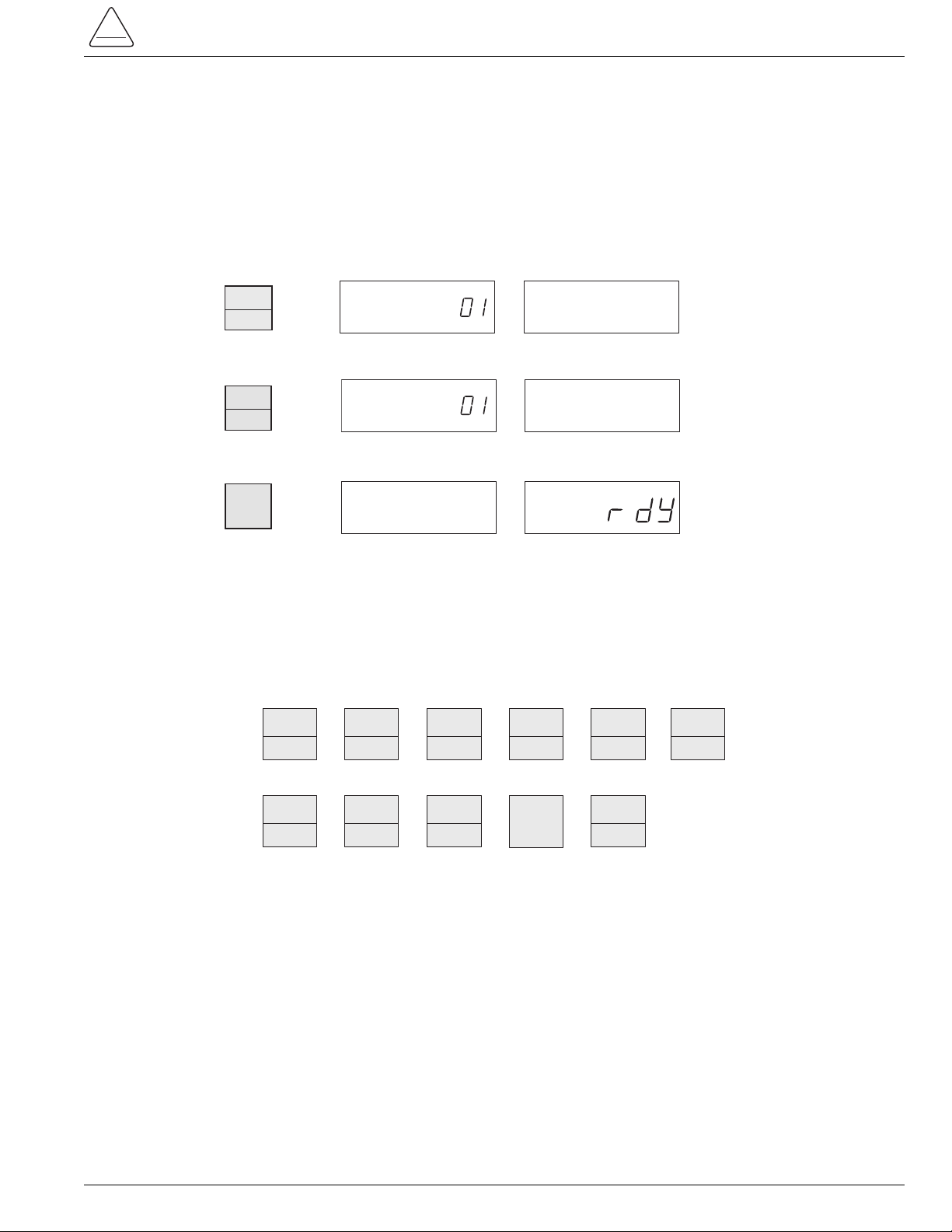

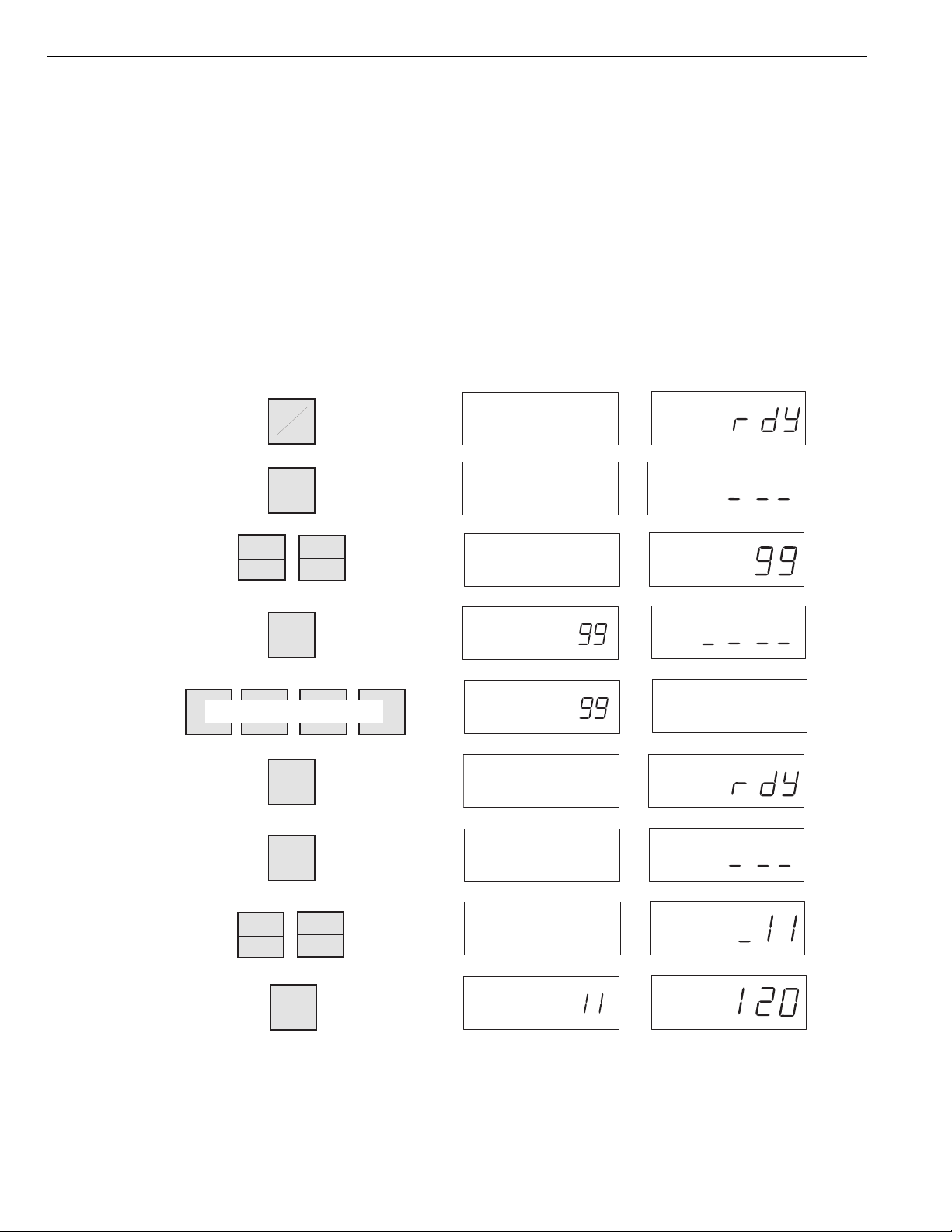

The following example of a Display Test illustrates the use of the keyboard for interrogation. The same basic step-by-

step descriptive procedure is used for all keyboard interrogation and program change operations.

Each step of the procedure is numbered, the appropriate key to be pressed is illustrated, and the resulting keyboard

display is shown.

No. Touch Key

1.

2.

3.