A

B

A

C

D

6

0.7 0.2

1.2 0.7

10 15 20 25 32

∗Normally closed (NC = b contact), solid state auto switch (D-Y7G/Y7H type) are also available. For details, refer to page 1913.

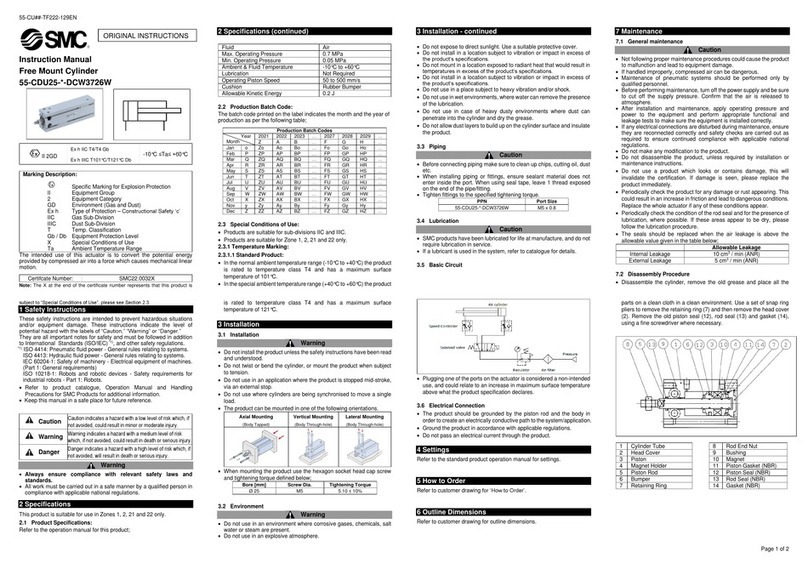

Auto Switch Proper Mounting Position (Detection at Stroke End)

Electrical entry direction:

Inward

Electrical entry direction:

Outward

Operating Range

Dimensions for Mounting of Auto Switch

Auto Switch Mounting

Other than the applicable auto switches listed in “How to Order”, the following auto switches can be mounted.

For detailed specifications, refer to pages 1893 to 2007.

Series CXS

Auto Switch Mounting

673

6

10

15

20

25

32

Bore size

(mm)

15.5

22.5

30.5

38

38

48

A

C

11.5 (10)

18.5 (17)

26.5 (25)

34 (32.5)

34 (32.5)

44 (42.5)

D

0.5 (–1)

3.5 (2)

0.5 (–1)

3 (1.5)

5 (3.5)

5 (3.5)

C

13

20

28

36

36

46

C

5.5

12.5

20.5

28

28

38

D

4.5

7.5

4.5

7

9

9

B

D-Z7/Z8, D-Y7W

D-Y5, D-Y7

D-Y6, D-Y7V

D-Y7WV

D-Y7BA

Lead wire entry is inward prior to shipment.

Note 1) Negative figures in the table D indicate how much the load wires protrude from the cylin-

der body.

Note 2) ( ): Denotes the dimensions of D-Z73.

Note 3) Adjust the auto switch after confirming the operating conditions in the actual setting.

–5.5

–2.5

–5.5

–3

–1

–1

D

2

5

2

4.5

6.5

6.5

D-Z7/Z80

D-Y59, D-Y69D-Y7P/Y7PV

D-Y7W/Y7WV

D-Y7BA

Auto switch model Bore size (mm)

6 10 15 20 25 32

9 7 9 9 9 11

3 3 3.5 3.5 4 4.5

∗Since this is a guideline including hysteresis, not meant to

be guaranteed.

(assuming approximately ±30% dispersion.)

There may be the case it will vary substantially depending

on an ambient environment.

D-Z7, D-Z8

(Reed auto switch)

D-Y5, D-Y6, D-Y7

(Solid state auto switch)

D-Y59A/Y7P/Y59B

D-Y69A/Y7PV/Y69B

D-Y7NWV/Y7PWV/Y7BWV

D-Y7NW/Y7PW/Y7BW

D-Y7BA

D-Z7, D-Z8

Bore size (mm)

A Dimension

Auto switch model

When mounting and securing auto switches, they

should be inserted into the cylinder’s auto switch

mounting rail from the direction shown in the drawing

below.

After setting in the mounting position, use a flat head

watchmaker's screwdriver to tighten the auto switch

mounting screw that is included.

When tightening an auto switch mounting

screw, use a watchmakers’ screwdriver with a

handle of approximately 5 to 6 mm in diameter.

Also, tighten with a torque of about 0.05 to 0.1

N·m. As a guide, turn about 90°past the point at

which tightening can first be felt.

Note)

Auto switch mounting screw

M2.5 x 4 L

(Included with auto switch)

1. Avoid proximity to magnetic objects

When magnetic substances such as iron

(including flange brackets) are in close

proximity to a cylinder body with an auto

switch, be sure to provide a clearance

between the magnetic substance and the

cylinder body as shown in the drawing below.

If the clearance is less than the values noted

in the table below, the auto switch may not

function properly.

Caution

Auto switch

Bore size

0

0

10

10

0

0

ø6

ø10

ø15

ø20

ø25

ø32

X (mm)