BYK-Gardner GmbH Table of Contents

301 200 141 E 2010 wave-scan 3 ROBOTIC 3

Table of Contents

1 Introduction.................................................................................................................................. 5

1.1 Safety Instructions ............................................................................................................................... 6

1.2 Declaration of Conformity.................................................................................................................. 8

1.3 Handling Instructions .......................................................................................................................... 8

1.4 Prerequisites ........................................................................................................................................ 8

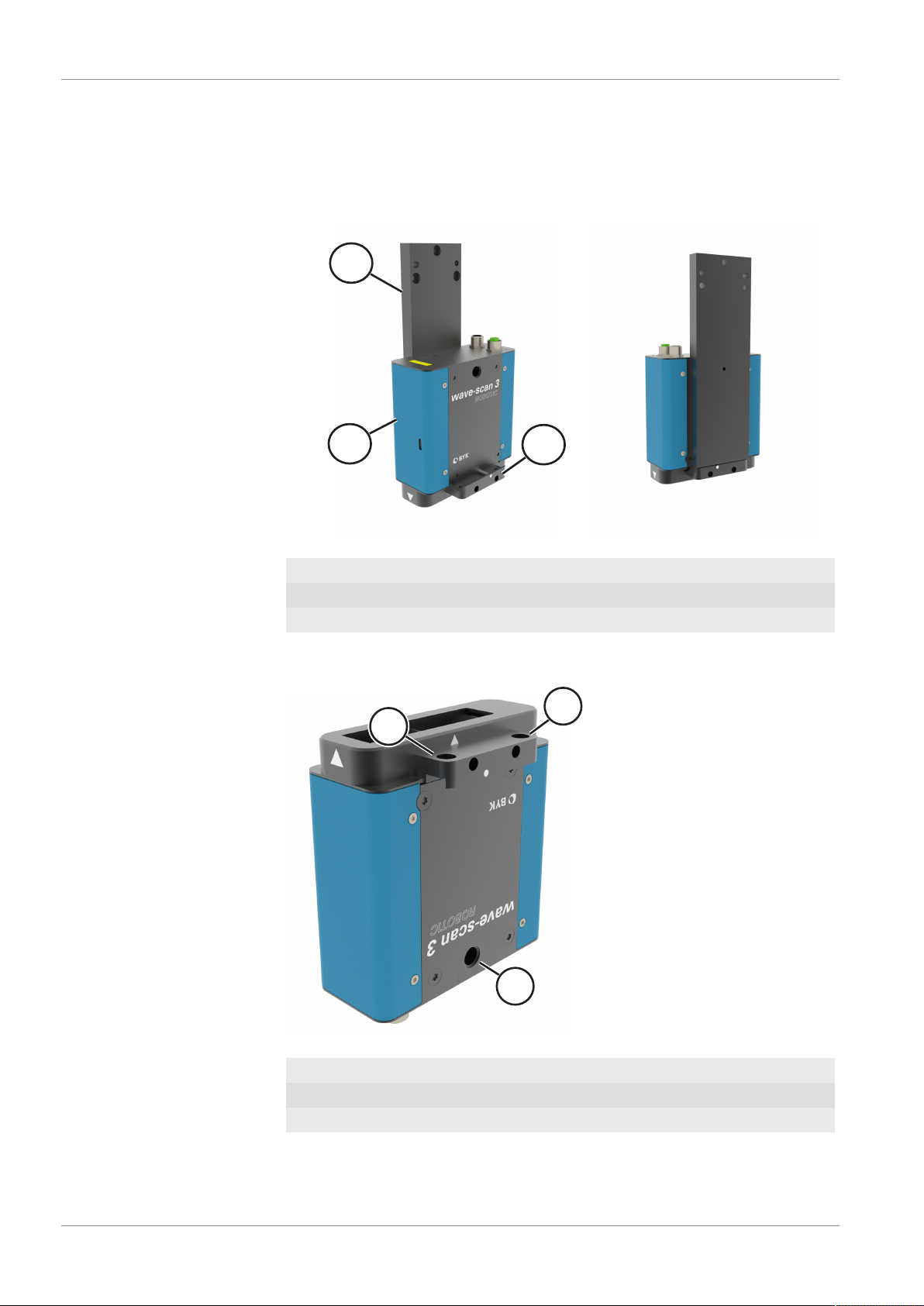

2 Hardware....................................................................................................................................... 9

2.1 Delivery Content.................................................................................................................................. 9

2.2 Mounting Board .................................................................................................................................. 10

2.3 Power Supply ....................................................................................................................................... 11

2.4 Status LEDs........................................................................................................................................... 12

3 Cabling .......................................................................................................................................... 13

3.1 Application Example ........................................................................................................................... 13

3.2 Power Cables ....................................................................................................................................... 14

3.3 Data Cables .......................................................................................................................................... 16

3.4 USB Cable............................................................................................................................................. 18

4 Operation ...................................................................................................................................... 19

4.1 Software Installation........................................................................................................................... 19

4.2 Firmware Update................................................................................................................................. 19

4.3 Device Configuration .......................................................................................................................... 20

4.3.1 Driver Installation ..................................................................................................................... 20

4.3.2 Device Connection.................................................................................................................... 22

4.3.3 Device Test ................................................................................................................................ 23

4.4 Productive System ............................................................................................................................... 24

5 Checking........................................................................................................................................ 25

5.1 Principle ............................................................................................................................................... 25

5.2 Mounting ............................................................................................................................................. 25

5.3 Procedure............................................................................................................................................. 26

6 Appendix....................................................................................................................................... 27

6.1 Cleaning and Maintenance................................................................................................................. 27

6.1.1 Cleaning the Test Tile............................................................................................................... 27

6.1.2 Usage of Reference Tile ........................................................................................................... 27

6.2 Delivery Notes...................................................................................................................................... 28

6.2.1 Product Highlights.................................................................................................................... 28

6.2.2 Product Features....................................................................................................................... 28

6.2.3 Delivery Content....................................................................................................................... 28

6.2.4 Download Links ........................................................................................................................ 29

6.2.5 Accessories List.......................................................................................................................... 29

6.3 Error Messages..................................................................................................................................... 30

6.4 System Requirements .......................................................................................................................... 30

6.5 Technical Data ..................................................................................................................................... 31

6.5.1 Measuring Data ........................................................................................................................ 31

6.5.2 General Data............................................................................................................................. 31