80-9360-6003-152 Rev. 12/06 Page 5

Interior Exterior

In

Swing

Exterior

Out

Swing

LATCHING

SPEED

VALVE

BACKCHECK

INTENSITY VALVE

BACKCHECK

LOCATION VALVE

OPTION M71

DELAYED

ACTION VALVE

CLOSING

SPEED VALVE

SPRING POWER ADJUSTER

(5/16 WRENCH or SOCKET)"

Size of Door No. of Full

(360°) Turns

Clockwise

of Power

Adjuster

(Approx.)

Equivalent

Closer Size

DC6200 SPRING POWER ADJUSTMENT CHART

2 4 (712)

2 6 (764)

3 0 (915)

3 6 (1067)

'"

'"

'"

'"

4

8

12

16

2

3

4

5

2 6 (764)

3 0 (915)

'"

'"

2 6 (764)

3 0 (915)

3 6 (1067)

4 0 (1219)

'"

'"

'"

'"

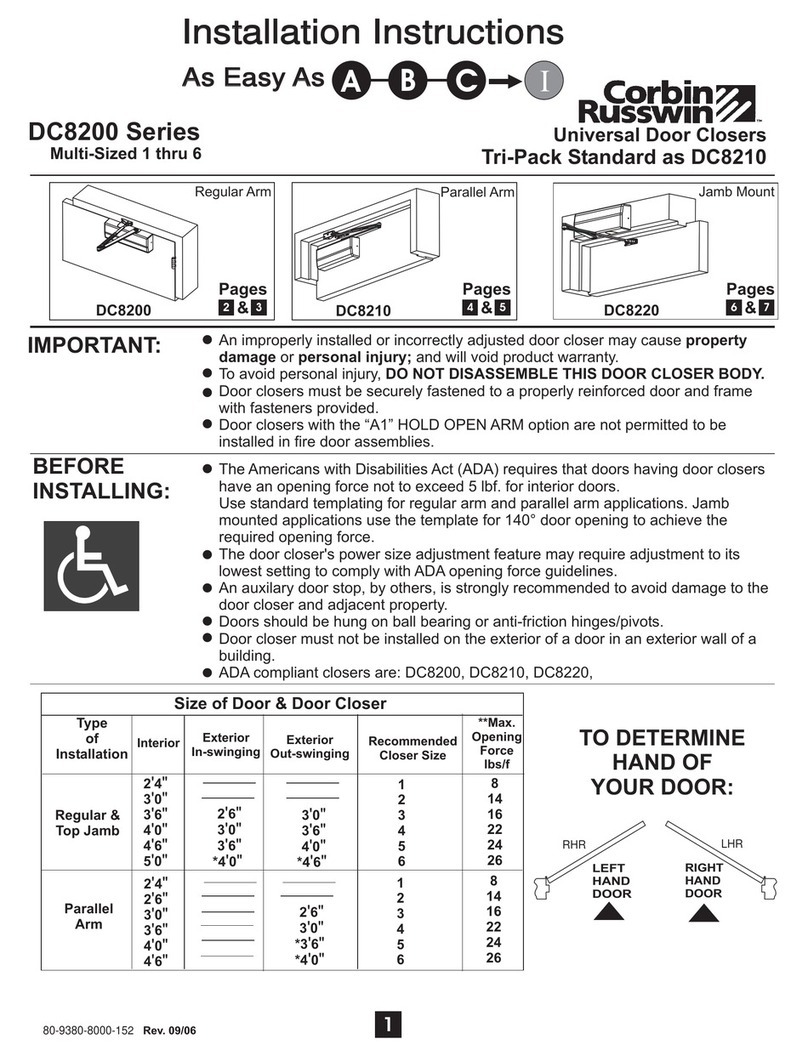

Spring Power Adjustment

DC6400 Half Size Adjustment as Desired

DC6200 Size 1 thru 6 Adjustment See Chart

All DC6200 closers are factory set at an approximate

Adjust closer as necessary for door size using this chart.

Readjustment may be required to suit prevailing conditions.

Size 3.

Locate spring power adjuster from Illustration below

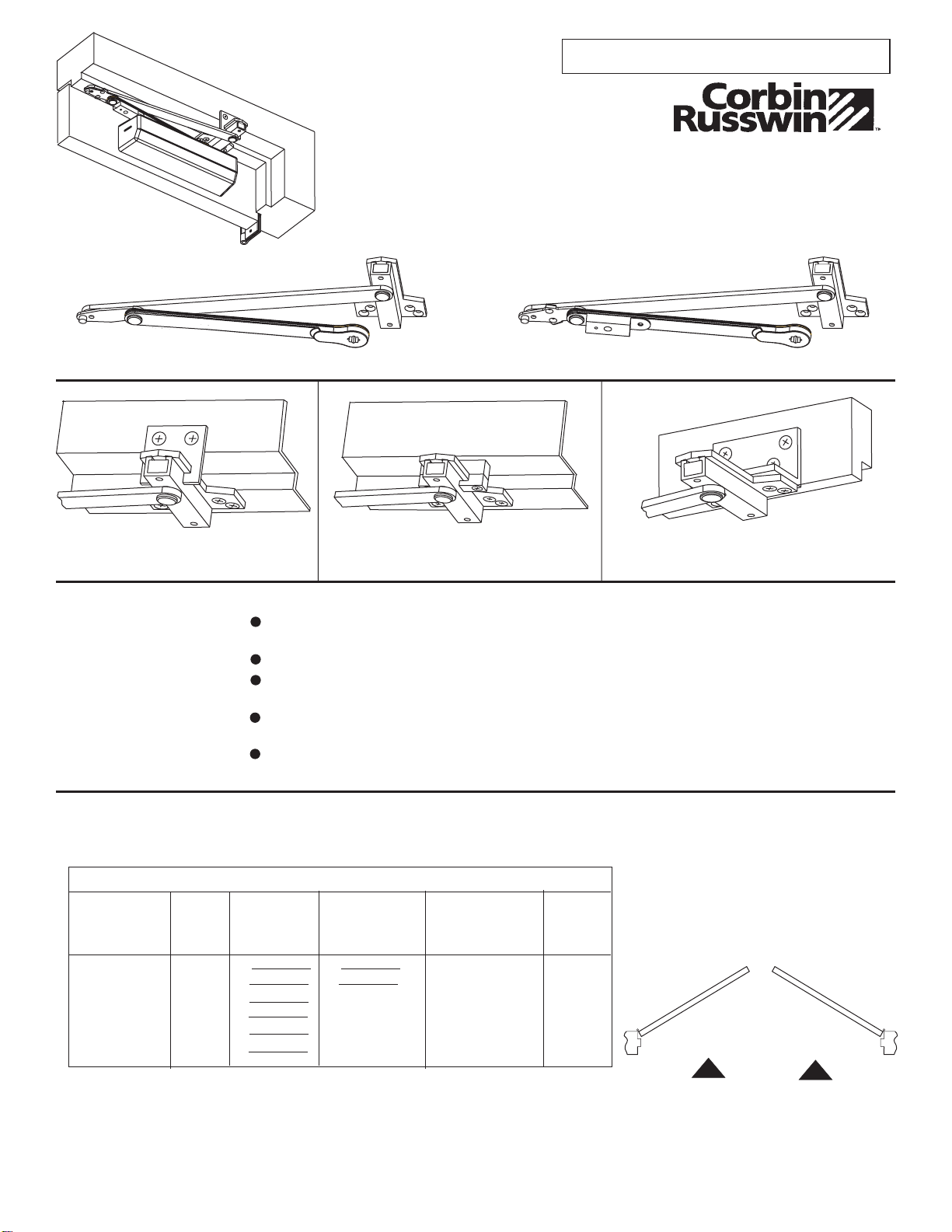

Backcheck Location Valve

Valve is closed, as shipped, from factory. To increase the

degree of door opening where backcheck takes effect, turn

valve counter-clockwise.

Backcheck Intensity Valve

Turn valve COUNTER- CLOCKWISE to reduce backcheck

or CLOCKWISE to increase backcheck. (Backcheck should

be set to give a soft cushioning action, not a sudden stop).

CLOSED

OCCURS AT

OPEN

65°-70°

95°-100°

VALVE

Degrees shown are approximate

(FLAT TIP SCREWDRIVER

W/ 5 (127mm) Min. Shaft Length)

"

Latching Speed Valve

After closing speed has been obtained, turn latching speed valve

CLOCKWISE to SLOW latching or COUNTER-CLOCKWISE to

SPEED latching for last 2 to 5 of door travel.

NOTE: Set combination of CLOSING and LATCHING speeds to

between 3 and 7 seconds Use of door by handicapped,

elderly or small children, may require even greater

closing time.

""

Closing Speed Valve

To adjust speed of door closing from fully open to a position

2 to 5” from closed, turn Closing Speed Valve CLOCKWISE

to SLOW closing, COUNTER-CLOCKWISE to SPEED

closing.

"

Delayed Action Valve

Turn valve CLOCKWISE to SLOW closing, COUNTER-

CLOCKWISE to SPEED closing. Delayed action may be

adjusted from 20 seconds to 90 seconds, depending on

degree of door swing. Delay occurs at the beginning of the

door closing cycle from fully open down to 70°, where the

closing speed valve then begins its control.

Latch

C

l

o

s

i

n

g

S

p

e

e

d

B

a

c

k

c

h

e

c

k

D

e

l

a

y

e

d

A

c

t

i

o

n

Option

M-71

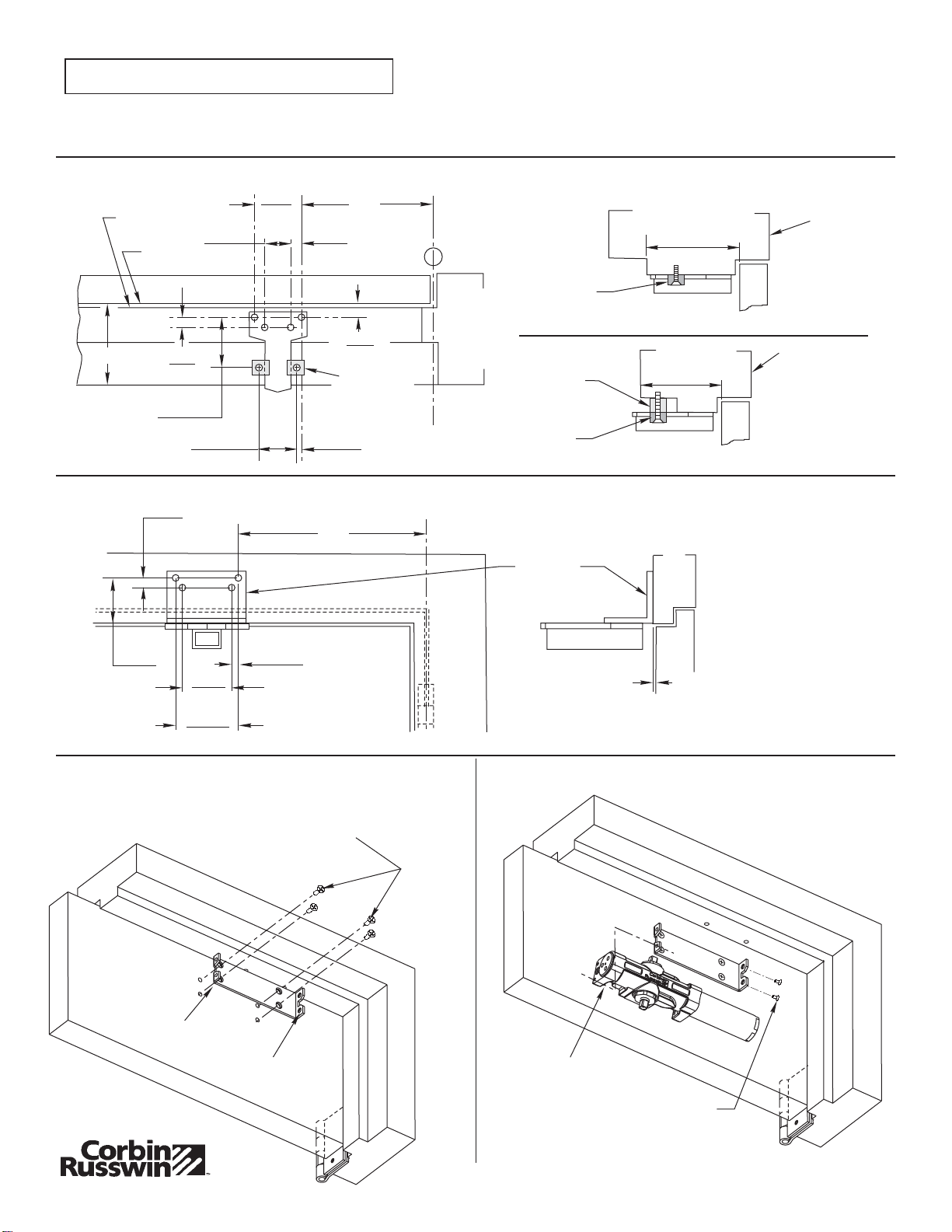

Full Cover

(Standard)

Slim Cover

(Option M76)

Slip cover over closer. Hold tightly

against closer mounting surface.

Secure on each side with 6-32 x 1/4

PBHMS screws. "

Slim Cover Option M76 only

Position spindle cap over unused

spindle and secure with

10-32 x 3/8 PTHMS screw.

(3/32 Allen Wrench Provided)

(3/32 Allen Wrench Provided)

(3/32 Allen Wrench Provided)

(3/32 Allen Wrench Provided)

Installing Cover

Power

Size

Stamp

Date Stamp