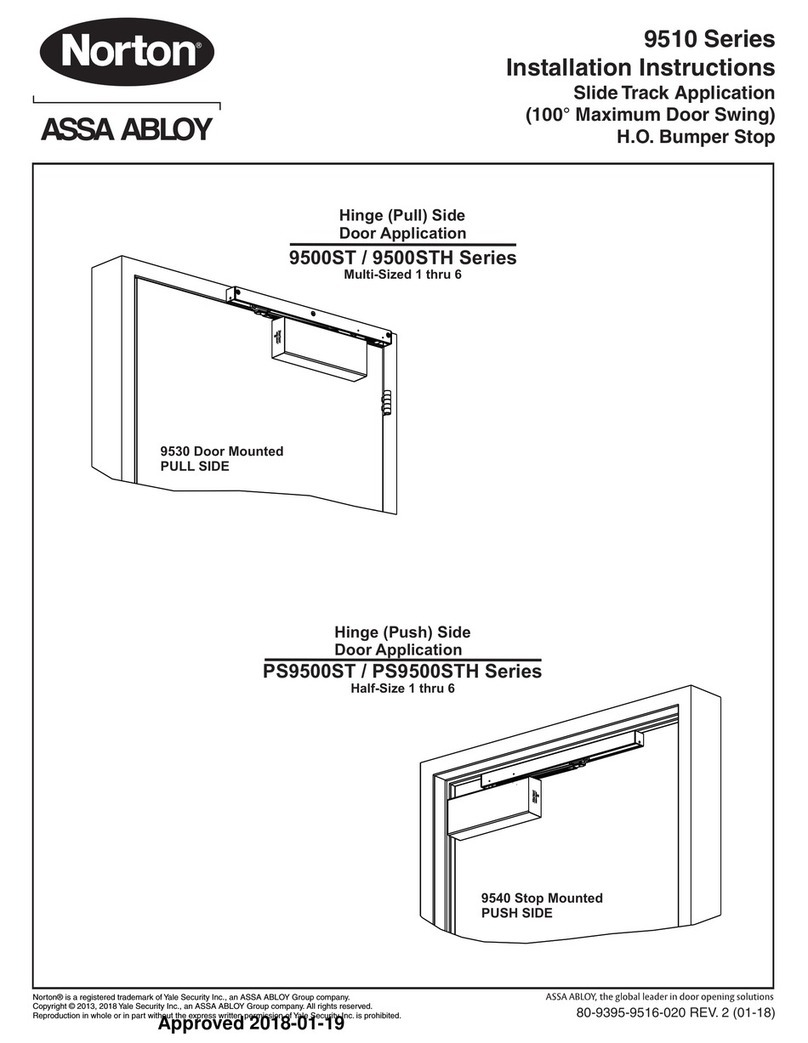

L7714SDSIL Sliding Door Closer

1 x Door Closer

Installation Instructions

Application: Automatically closes sliding doors.

Door Specifications:

• Maximum Door Height 2500mm

• Maximum Door Width 1200mm

• Maximum Door Weight 60kg

• Minimum Reveal Depth

(Door Frame Thickness) 70mm

Tools Required:

• 5mm Hexagonal Allen Key

• Adjustable Spanner

• Drill

• 2.5mm Drill Bit

• 3.0mm Drill Bit

• Phillips Screwdriver

• Flat Head Screwdriver

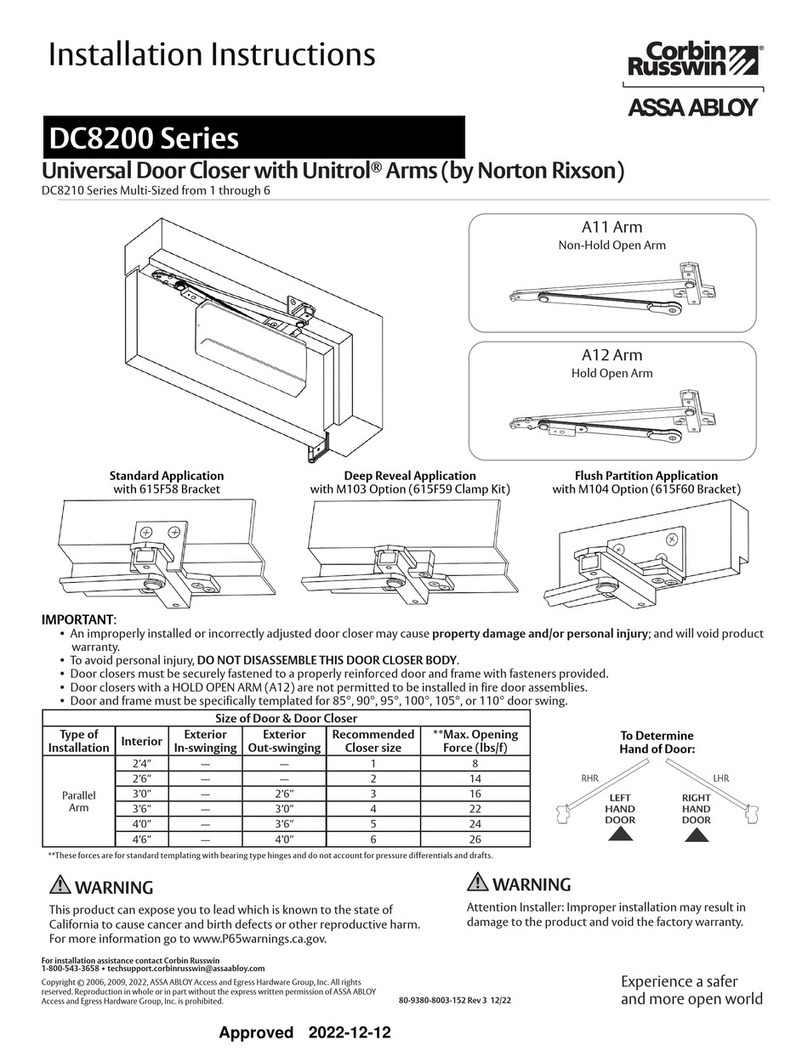

Pack Contents

1 x Bent Arm

1 x Straight Arm

1 x 800mm Track

4 x Track Fixing

Screws

1 x Spacer

4 x Closer

Mounting Screws

1 x Wheel and Axle1 x Wheel Cover

4 x Arm Screws

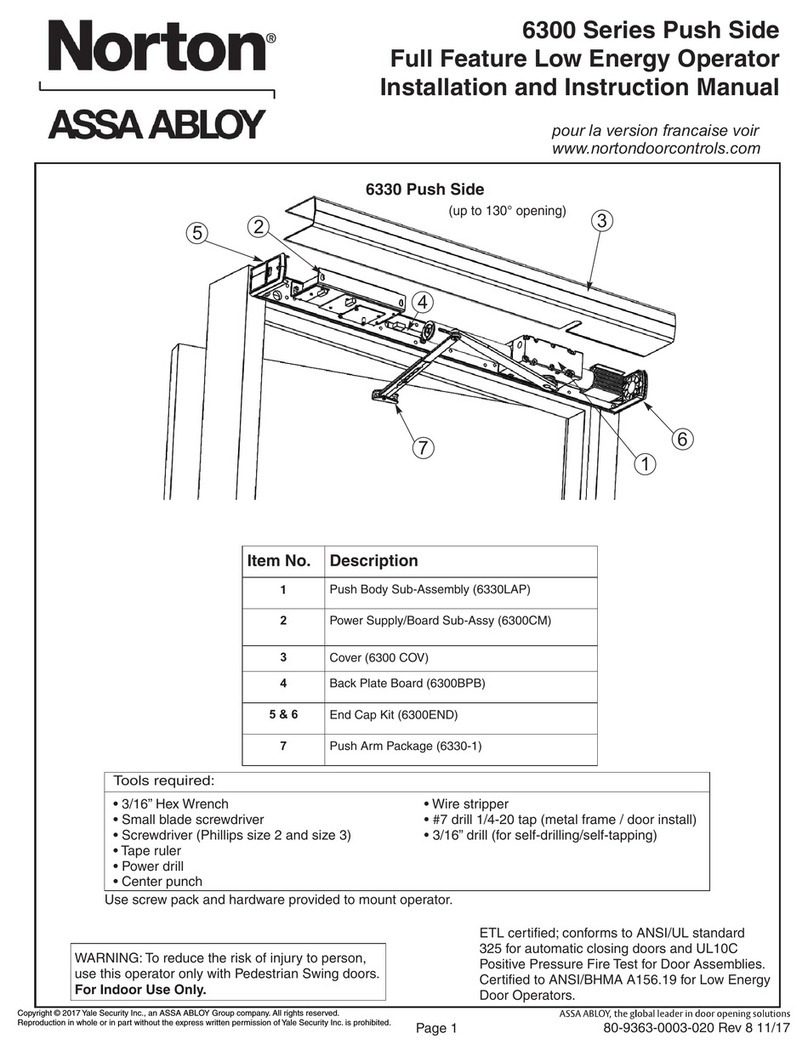

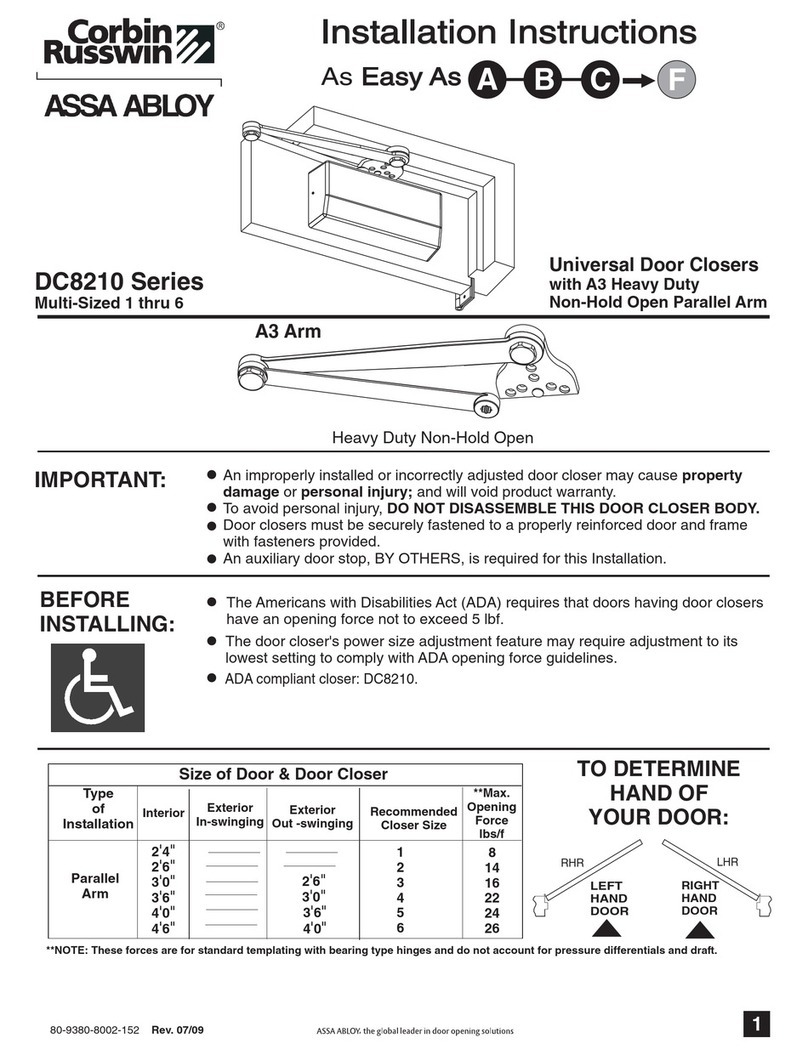

2. ASSEMBLE THE DOOR CLOSER AND

STRAIGHT ARM

• Place the spacer onto the square

drive shaft.

• Secure the straight arm onto the Closer

unit using the arm screw.

Note: Arm Orientation - The Straight Arm

square hole has been designed with a 10º

pre-load. Ensure that the straight arm

points away from the side of the closer that

the cover plate attaches to.

3. MARK POSITION

• Measure half the length of the

stationary panel and with a pencil draw

a line 90˚ on the reveal.

• Cut out the template supplied over

page. Align the edge of the template

against the line you drew on the side

facing away from the sliding panel.

• Mark the position of the screw holes

according to the template and drill

ø3mm holes.

4. INSTALL THE DOOR CLOSER

• Install the Door Closer onto the timber

door reveal using the closer mounting

screws

5. INSTALL THE TRACK

Note: Remove screw cover plug on

the back of the door panel before

attaching track.

• Line up the track with the edge of the

sliding door recess and flush with the

inside surface of the sliding panel.

• Drill four ø2.5mm holes into the back

of the door.

• Secure the top of the track only with

two of the four track fixing screws.

Note: To secure position - A length of

double sided tape will help hold the track in

position while drilling holes.

077704 0807-1

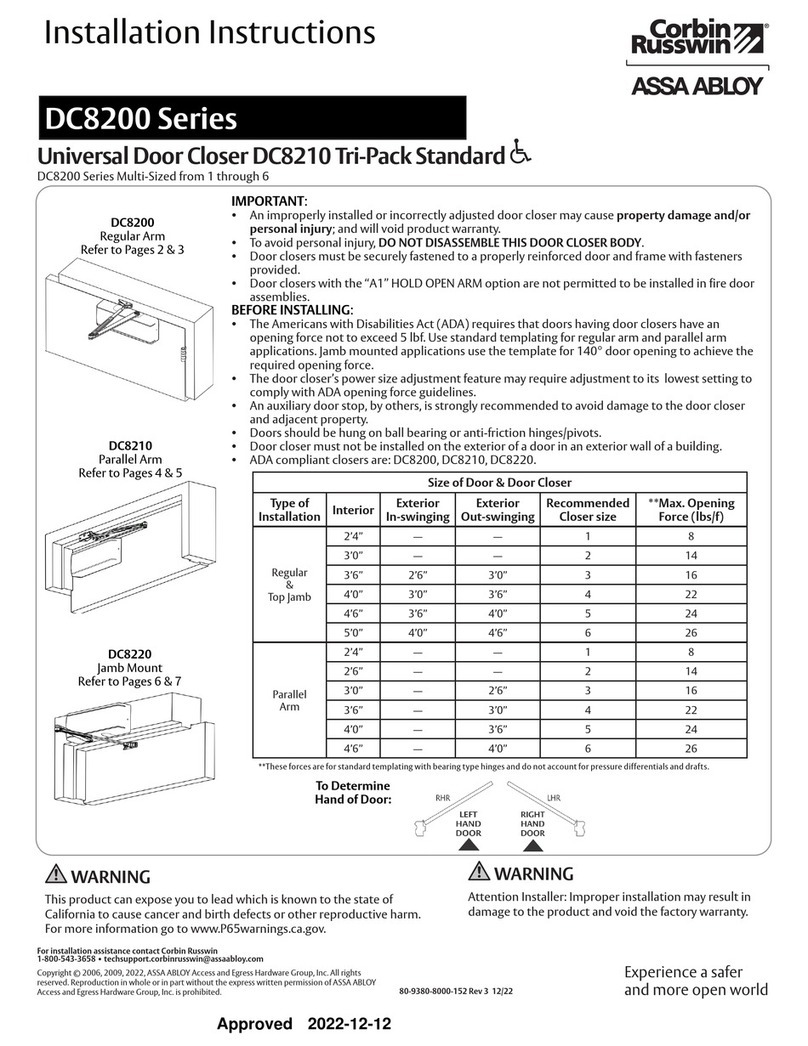

8. ASSEMBLE THE WHEEL ONTO THE

BENT ARM

• Place a spanner around the axle to hold

it stationary and fix the arm

screw tightly.

9. SECURE THE BENT ARM ONTO THE

STRAIGHT ARM

• Loosely do up the arm screws in two

of the four holes provided, as far apart

as possible.

• Adjust the overall length of the arm

assembly so that it stays horizontal

when the door is closed, without

hitting the timber reveal.

• Tighten the screws fully.

Note: Important - Attempt to do this only

once as the tightened screws will damage

the surface finish.

10. ADJUST SPEED

• Use a flat head screwdriver to adjust

the speeds.

• Use a 5mm hexagonal allen key to

adjust the power.

• Check the operation of the door and

readjust as necessary.

Note:

Backcheck Adjustment: Increases or

decreases cushioning when opening the door

Delayed Action: Increases or decreases hold

open time

Closing Speed: Adjusts the speed at which the

door closes

Latching Speed: Adjusts the speed at the end

of the closing operation

7. FIX TRACK

• Fix the bottom of the track in position

using 2 x track fixing screws.

1. BEFORE BEGINNING, MAKE SURE THAT THE SLIDING DOOR IS CLEAN AND FREE SLIDING. Clean dust and debris from the track. See reverse for the sliding door troubleshooting guide.

6. MOUNT THE WHEEL ONTO

THE TRACK

• Slide the wheel, axle and wheel cover

up into the track from the bottom.

Note: Ensure axle is pointing out away

from glass.

11. FINISHING

• Slide closer cover into position.

• Press cap over exposed square

spindle.

These surfaces flush