Electromechanical Push Bars

Installation (Continued)

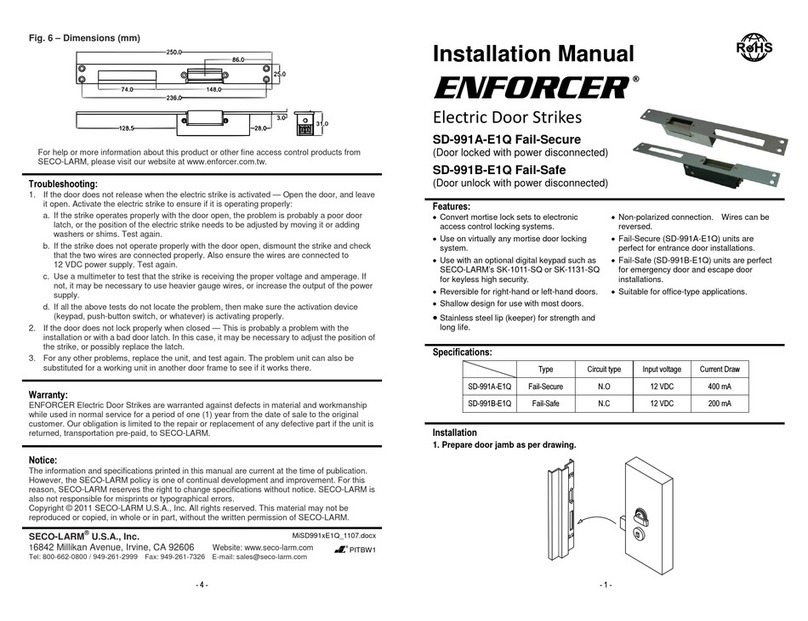

8. Install the strike assembly as shown in Fig. 5 on pg. 3. Ensure a

3

/

16

" (4 5 mm) gap between the strike assembly and end cap

(see Fig. 7). Use included spacers as needed.

9. Ensure the push bar and strike are operating smoothly and the

locking spindle teeth fully engage the strike before tightening the

two main strike assembly screws. Drill and install the middle

screw as the final step (see Fig. 5 on pg. 3).

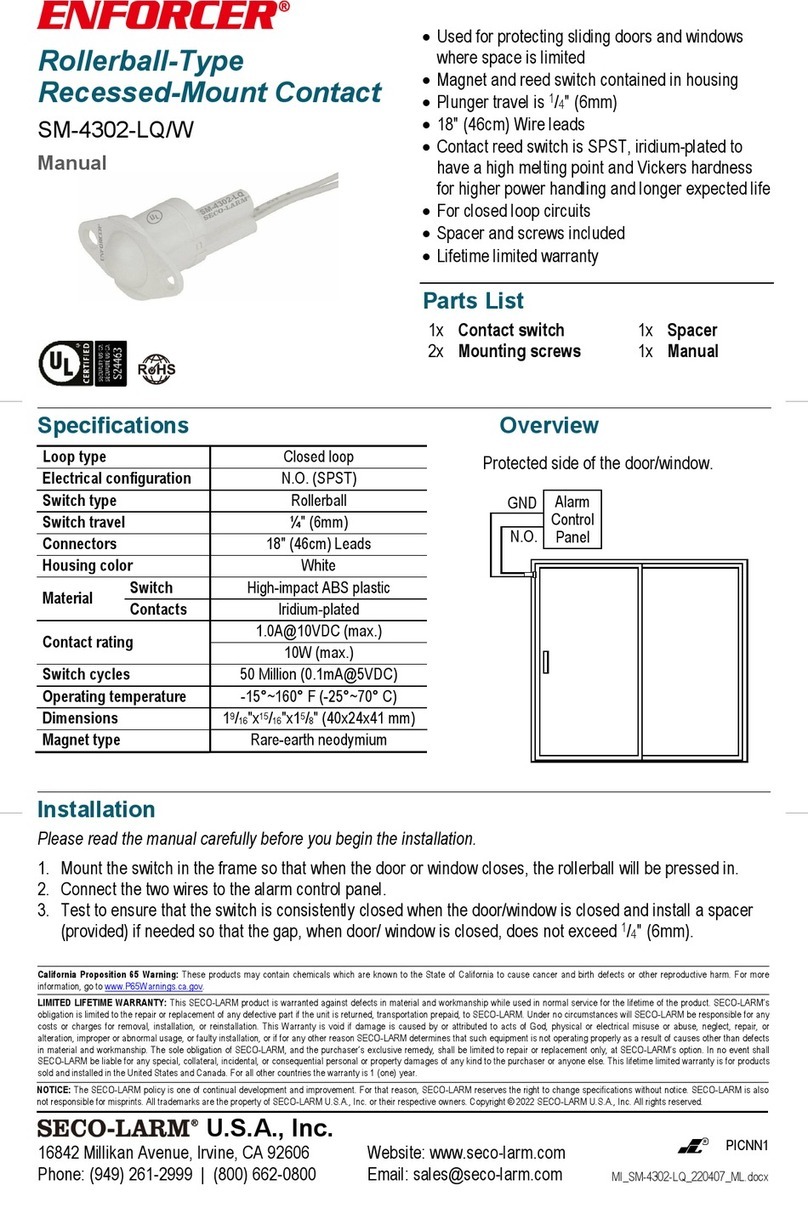

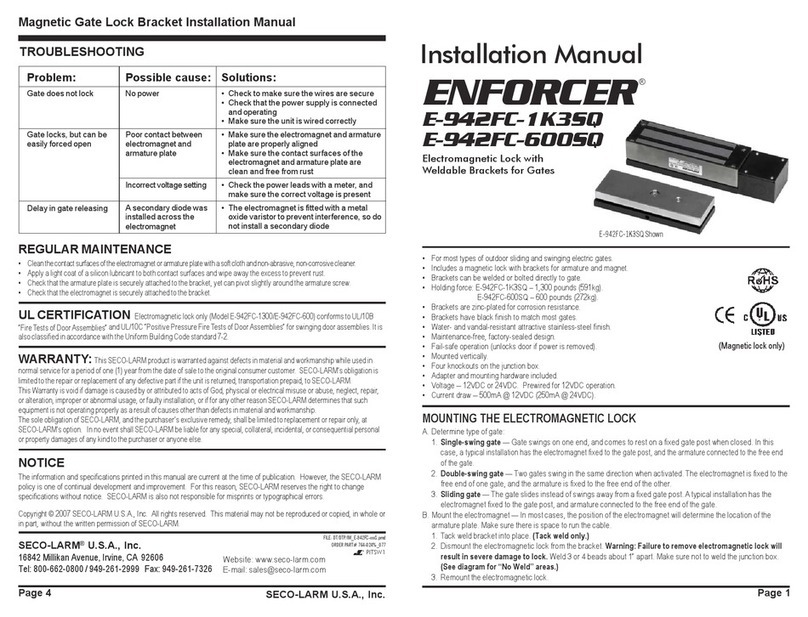

Wiring Diagram

When connecting solenoid-actuated models to an access control system or a control device, note

that the latch retraction duration is controlled by the connected N.O. switch.

Troubleshooting

Bar does not unlock when

triggered (models with solenoid)

•Check the input voltage (12 24 VAC/VDC)

•Check that the trigger switch is operating properly

Buzzing sound when activated

(models with solenoid)

•This may sometimes result when using AC voltage. Change to DC

if it persists

Device does not unlock •Check back pressure on latch and adjust

Power Supply

12/24

VAC/VDC

Lock status

indicator

Relay rating

5A@125VAC

N.O.

COM

–

+

Access

Control

Keypad /

Proximity

Reader

Connect lock status output according to status indicator directions

SD-961x-36GSQ Series Solenoid-Actuated Push Bars

Connection to Access Control Device

SD-961x-36GQ Series Manual Push Bars

Connection to Lock Status Indicator

SECO-LARM ®U.S.A., Inc.

16842 Millikan Avenue, Irvine, CA 92606

Phone: (949) 261-2999 | (800) 662-0800 Email: sales@seco-larm.com

PITGW1

MI_SD-961x-36GxQ_211125.docx

WARRANTY:

This SECO-LARM product is warranted against defects in material and workmanship while used in normal service for one (1)

year from the date of sale

to the original customer. SECO-LARM’s obligation is limited to the repair or replacement of any defective part if the unit is returned, transportation

SECO-LARM. This Warranty is void if damage is caused by or attributed to acts of God, physical or elec

trical misuse or abuse, neglect, repair or alteration, improper

or abnormal usage, or faulty installation, or if for any other reason SECO-

LARM determines that such equipment is not operating properly as a result of causes other

than defects in material and workmanship. The sole obligation of SECO-

LARM and the purchaser’s exclusive remedy, shall be limited to the replacement or repair

only, at SECO-LARM’s option. In no event shall SECO-LARM be liable for any special, collateral, incidental, or consequential

personal or property damage of any kind

to the purchaser or anyone else.

NOTICE: The SECO-LARM policy is one of continual development and improvement. For that reason, SECO-

LARM reserves the right to change specifications without

notice. SECO-LARM is also not responsible for misprints. All trademarks are the property of SECO-LARM U.S.A., Inc. or their respective owners. Copyright © 2022

SECO-LARM U.S.A., Inc. All rights reserved.

California Proposition 65 Warning:

These products may contain chemicals which are known to the State of California to cause cancer and birth defects or other

reproductive harm. For more information, go to www.P65Warnings.ca.gov.

IMPORTANT: Users and installers of this product are responsible for ensuring that the installation and configuration of this product complies with all natio

and local laws and codes. SECO-LARM will not be held responsible for the use of this product in violation of any current laws or codes.

IMPORTANT: The height at which the push bar is mounted may be subject to local regulations. It is the responsibility of the installer and/or end-

ensure the push bar meets all local regulations regarding the use of push bars for access security, including height, suitability for doors accessed by disabled persons,

and suitability for fire doors (the push bar is not fire-rated).

WARNING: The push bar is not weatherproof. Do not mount on exterior surface or where exposed to rain.

Fig. 7

3/16