General Notes on Crankcase Oil

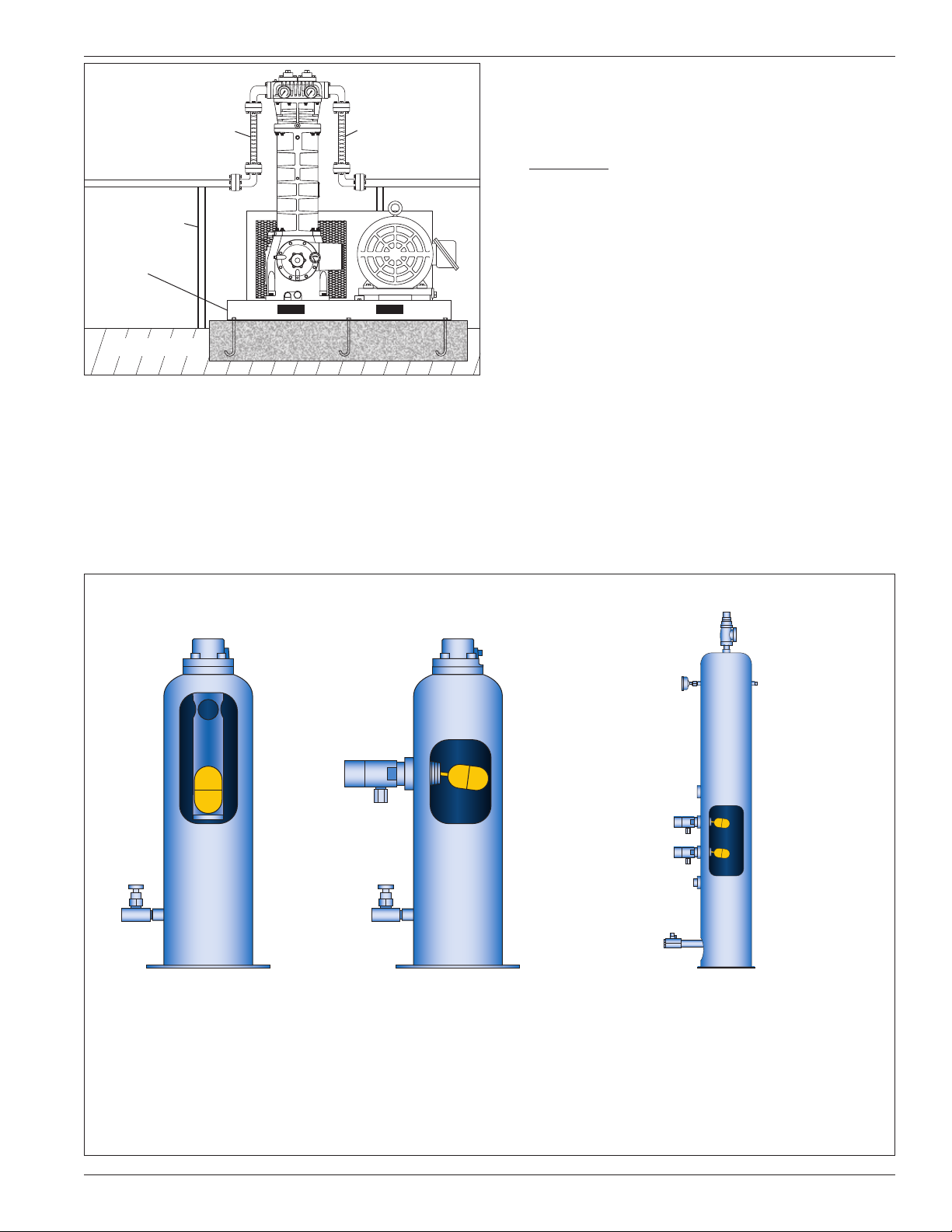

Corken gas compressors handle a wide variety of gases

in a multitude of operating conditions. They are used in

all areas of the world from hot dusty deserts, to humid

coastal areas, to cold arctic climates. Some compressors

may be lightly loaded and run only occasionally, while

others may be heavily loaded and operate 24/7. Thus, no

single crankcase oil or maintenance schedule is right for

every compressor. Availability of brands and grades of

oil can vary from one location to another. These factors

can make it challenging for a Corken compressor user to

select a suitable crankcase oil. This guide is intended to

aid in that regard.

It is safe to say that purchasing a quality crankcase oil,

and changing it regularly, is significantly less costly than

the repair bill and downtime associated with a lubrication

failure in any gas compressor. Considering the relatively

small volume of oil used in Corken compressors, and the

critical nature of the services where these compressors

are used, selecting the appropriate high quality oil is

the most economical choice. It will help ensure the

dependability and longevity of the compressor.

Corken recommends using industrial oils (rather than

engine oil or “motor oil”). Industrial oils have additives

selected and blended for specific purposes. Many are

designed specifically for the challenges inherent in

compressor crankcases. Industrial oils are available as

a conventional (mineral based) oil, a synthetic oil, or a

blend of the two.

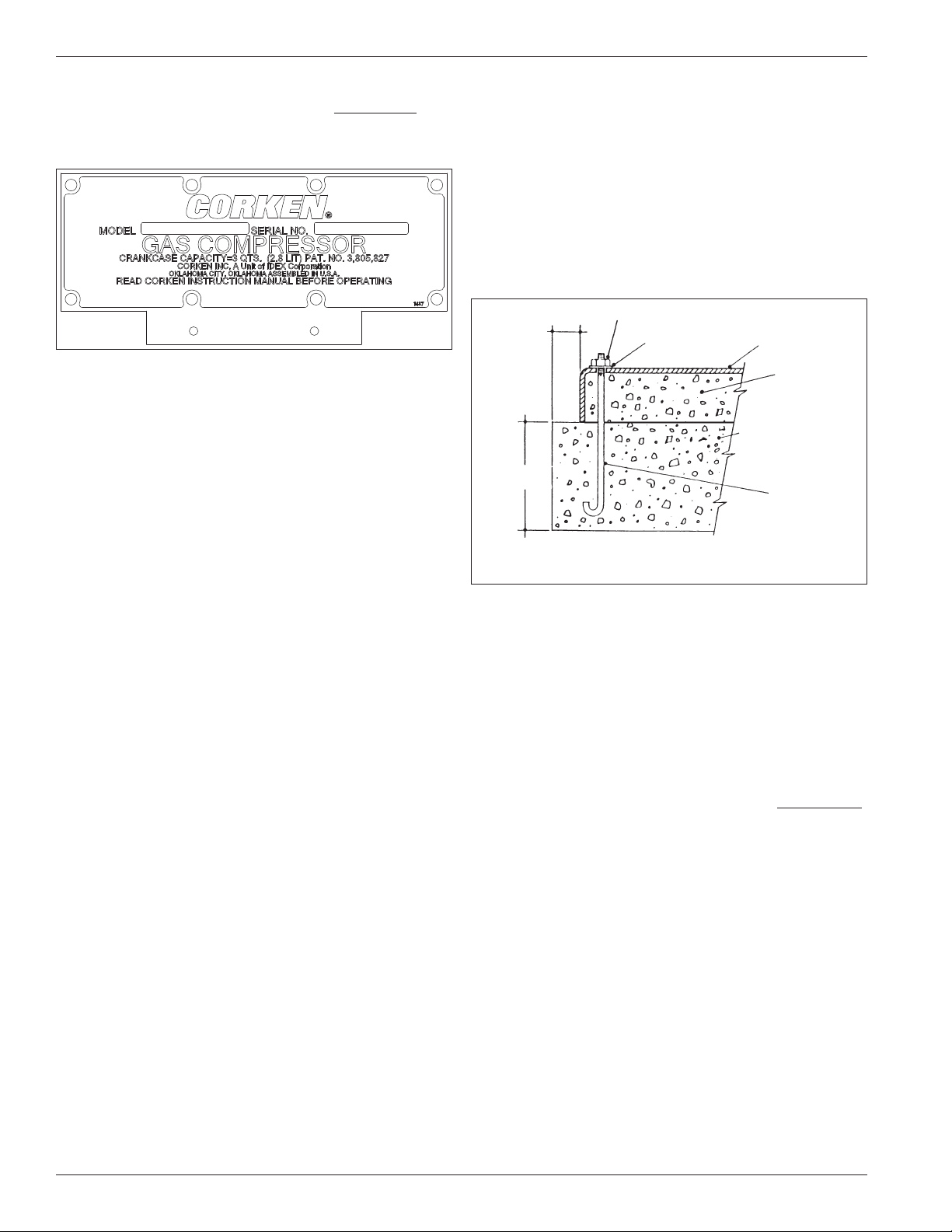

All new Corken compressors are tested at the factory

using a conventional mineral oil. This oil is drained

prior to shipment. An oil suitable for the anticipated

environmental and operating conditions must be selected

and added to the compressor prior to the initial startup.

2.6.1 Oils to Avoid

Selecting a crankcase oil based on low price or easy

availability is seldom the best decision. Following are oils

to avoid:

• Do not use any oil with a viscosity index below 95.

• Do not use any oil with a pour point less than 20°F

(11°C) lower than the anticipated minimum ambient

temperature (unless a crankcase oil heater is used).

• Do not use engine/motor oil.

See below for additional detail on each of these

parameters.

2.6.2 Critical Oil Characteristics

Viscosity

Viscosity is the most important physical property of

lubricating oil. Simply put, the viscosity of an oil is a

measure of its resistance to flow. In gas compressors,

oils with higher viscosity (like ISO 100) are thicker and

are used for higher ambient temperatures. Oils with lower

viscosity (like ISO 68) are thinner and are used at lower

ambient temperatures. If the oil’s viscosity is too high, the

oil may not circulate through the compressor adequately.

If the viscosity is too low, the lubricating film will be

unable to protect the components from wear.

Viscosity Index

Viscosity Index (VI) is a measure of how much the oil’s

viscosity changes as its temperature changes. A low

viscosity index is an indication that the viscosity changes

more as the temperature changes. Oils with low viscosity

index tend to become thin as the oil temperature

increases. This can cause lubrication failure as well as

unstable oil pressure. A high viscosity index reflects

a more stable viscosity, and is generally preferred for

Corken compressors. The minimum Viscosity Index

for oils used in Corken compressors is 95 (VI is a

unit-less number). This is particularly important when

operating at high or low temperature extremes, or at

a variety of ambient temperatures (seasonal changes).

Oils with a high viscosity index can be used at wider

ambient temperature range compared to oils with a lower

viscosity index.

It should be noted that a conventional oil (not synthetic)

with a high viscosity index may not necessarily be

suitable for continuous service at high temperature.

Such an oil will oxidize faster than a synthetic oil.

Synthetics have naturally high viscosity index, and are

therefore recommended for “heavy service” as described

below—including high temperature and continuous duty

applications. It many climates, the use of the correct

synthetic oil will eliminate the need to change oil viscosity

grades as the seasons change.

Pour Point

The pour point of an oil is the lowest temperature at

which the oil flows. At temperatures below the pour

point, the oil is essentially solid and can’t freely flow to

the compressor’s bearings and other wear surfaces, or

even to the compressor’s oil pump.

The oil’s pour point is particularly critical when starting a

compressor at low temperature conditions. An oil should

have a pour point at least 20°F (11°C) below the lowest

expected ambient temperature. For example, if the minimum

ambient temperature is expected to be 0°F (-18°C), the pour

point must be no higher than -20°F (-29°C).

Do not assume the pour point of an oil is low enough.

Consult the oil’s technical data sheet – generally available

on the oil manufacturer’s website. Many conventional oils

have a pour point around 0 to 15°F (-18 to -9°C) which is

too high to use at low ambient temperatures. Synthetic oils

generally have a lower pour point than conventional oils.

9