2.1 Location

NOTE: Compressor must be installed in a well

ventilated area.

Corken compressors are designed and manufactured for

outdoor duty. For applications where the compressor will be

subjected to extreme conditions for extended periods such

as corrosive environments, arctic conditions, etc., consult

Corken. Check local safety regulations and building codes

to assure installation will meet local safety standards.

Corken compressors handling toxic or flammable gases such

as LPG/NH3should be located outdoors. A minimum of 18

inches (45 cm) clearance between the compressor and the

nearest wall is advised to make it accessible from all sides

and to provide unrestricted air flow for adequate cooling.

NOISE. Corken vertical compressors sizes model 91

through 891 should not exceed an 85 DBA noise level

when properly installed.

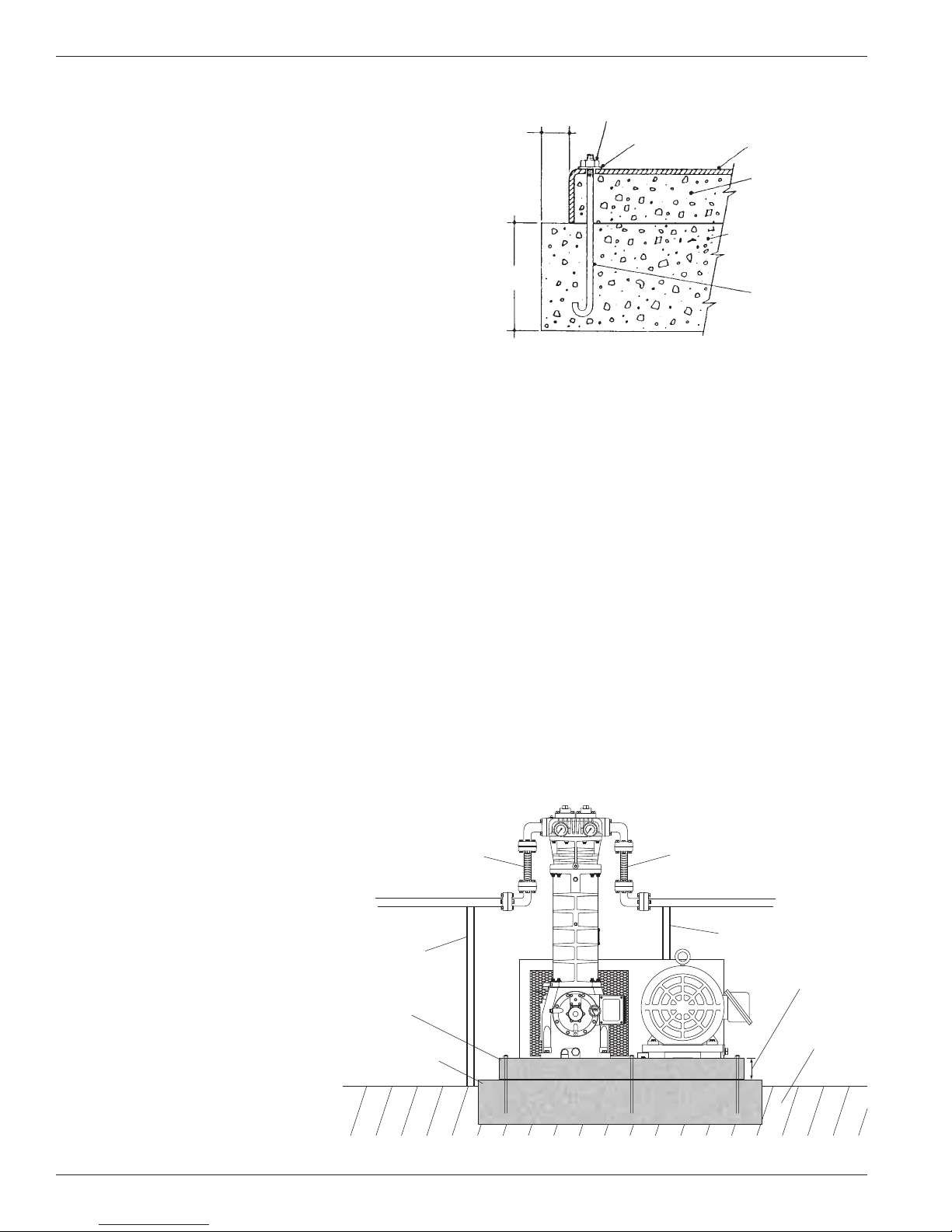

2.2 Foundation

Proper foundations are essential for a smooth running

compression system. Corken recommends the compressor

be attached to a concrete slab at least 8 in. thick with a 2

in. skirt around the circumference of the baseplate. The

baseplate should be securely anchored into the foundation

by 1/2 in. diameter “J” bolts 12 in. long. Four bolts should

be used for models 91, 291, and 491. Six bolts should

be used for model 691. The total mass of the foundation

should be approximately twice the weight of the compressor

system (compressor, baseplate, motor, etc.).

After leveling and bolting down baseplate, the volume

beneath the channel iron baseplate must be grouted

to prevent flexing of the top portion

of the baseplate and the “J” bolt that

extends beyond the foundation. The

grout also improves the dampening

capabilities of the foundation by

creating a solid interface between the

compressor and foundation.

On some of the longer baseplates, such

as with the 691–107, a 3 in. hole can be

cut in the baseplate for filling the middle

section of the baseplate with grout.

See ED410 (Compressor Foundation

Design).

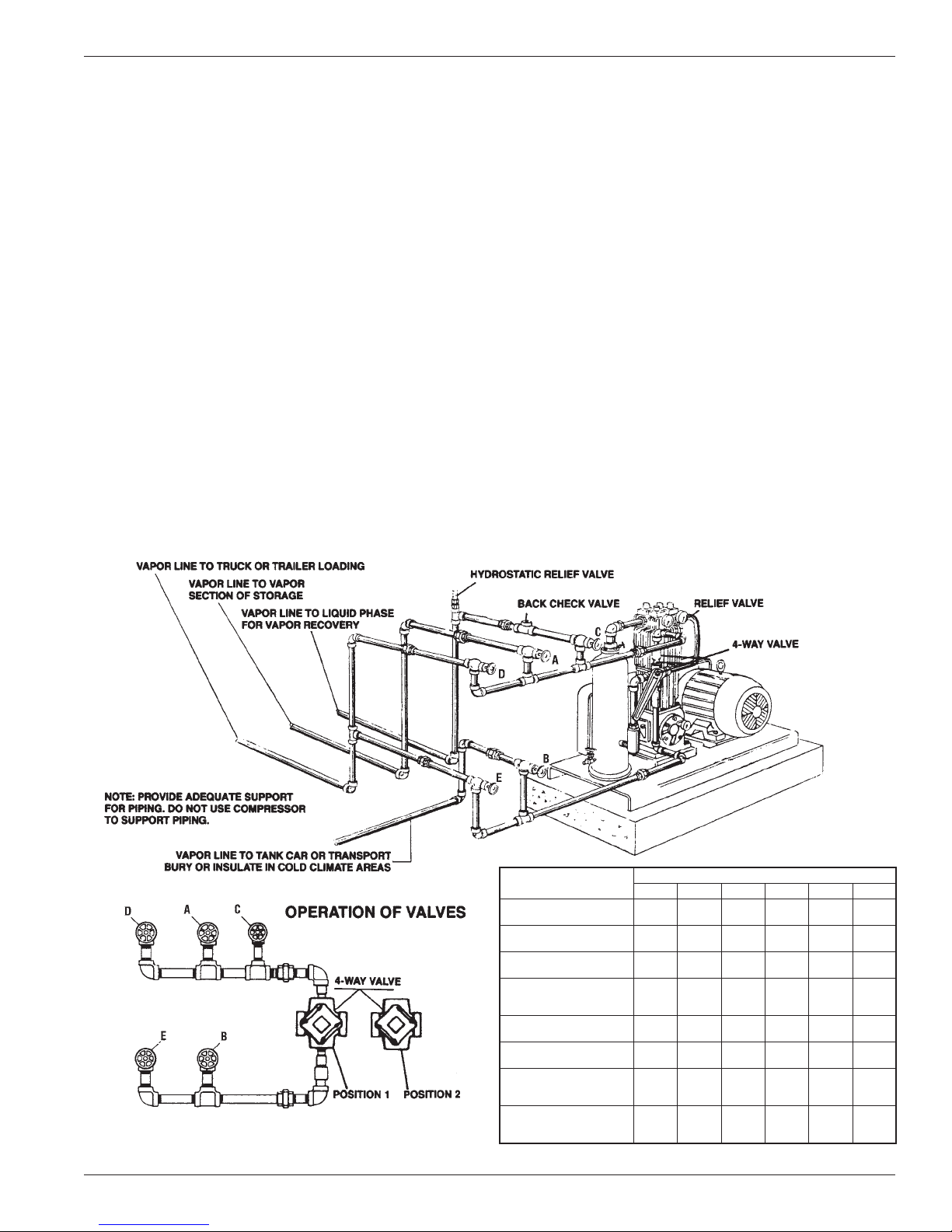

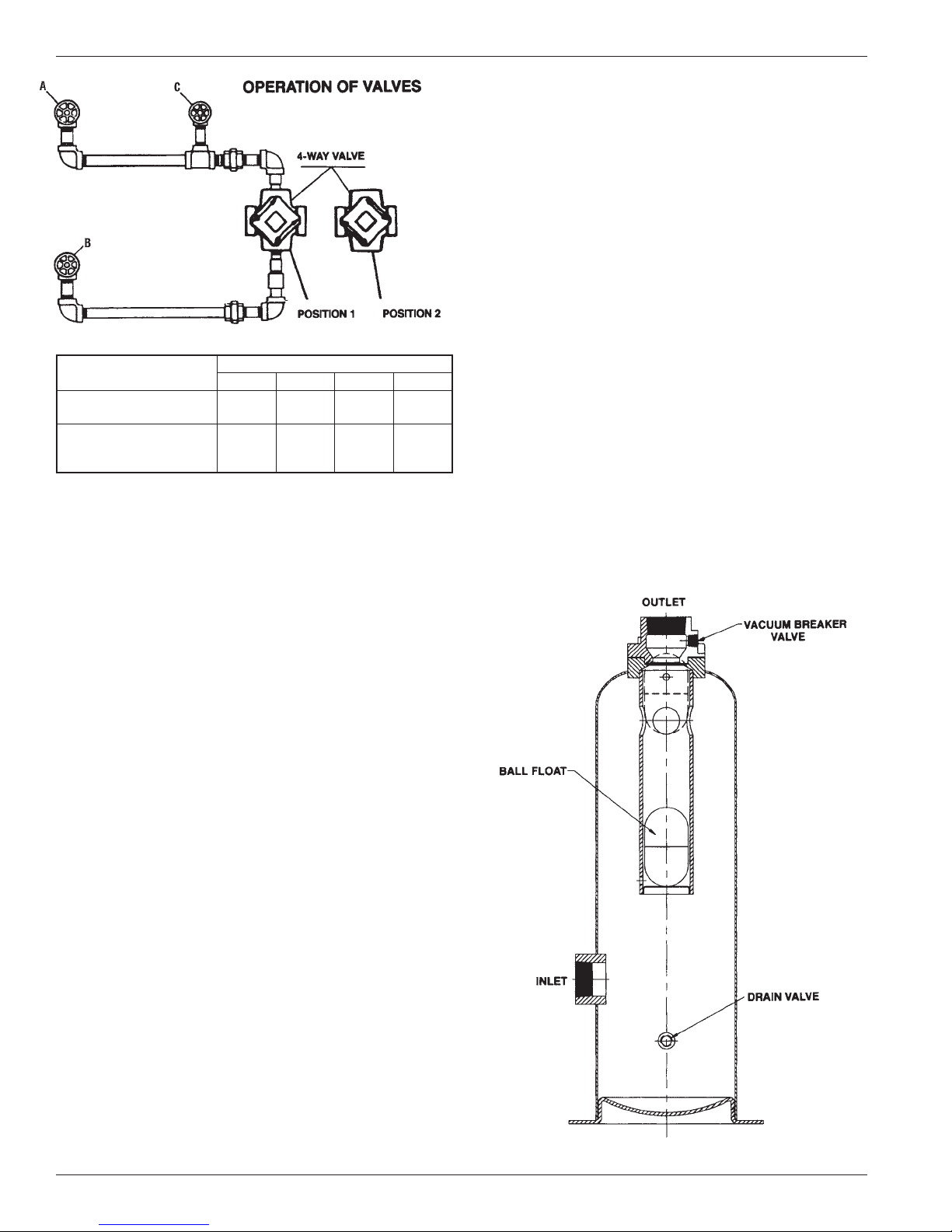

2.3 Piping

Proper piping design and installation

is as important as the foundation is to

smooth operation of the compressor. Improper piping

installation will result in undesirable transmission of

compressor vibration to the piping.

DO NOT SUPPORT PIPING WITH THE COMPRESSOR.

Unsupported piping is the most frequent cause of

vibration of the pipe. The best method to minimize

transmission of vibration from the compressor to the

piping is to use flexible connectors (see figure 2.3A).

Pipe must be adequately sized to prevent excessive pressure

drop between the suction source and the compressor as

well as between the compressor and the final discharge

point. In most cases, piping should be at least the same

diameter as the suction nozzle on the compressor. Typically,

LPG/NH3liquid transfer systems should be designed to

limit pressure drops to 20 psi (1.3 bar). Appendix D shows

recommended pipe sizes for each compressor for typical

LPG/NH3installations.

Figure 2.2A: Recommended Foundation Details

for Corken Compressors 91 - 691

2” MIN.

ALL SIDES

8” MIN.

HEX NUT

WASHER

COMPRESSOR

BASEPLATE

GROUT BENEATH

BASE

CONCRETE FOUNDATION

WITH REINFORCEMENTS

SHOULD BE USED ON ALL

MODELS

1/2” “J” BOLTS

12” LONG

NOTE:

LOCATE “J” BOLTS PER

COMPRESSOR OUTLINE

DIMENSION DRAWINGS.

Ground level

Concrete

foundation

Baseplate should be

a maximum of 4″ high

Grouted

baseplate

Pipe support

Pipe support

Flexible connections Flexible connections

Figure 2.3A: On –107 mountings, the flexible

connectors should be located near the four way valve.

Chapter 2—Installing Your Corken Compressor

8