1. GENERAL INFORMATION

1.1.

Warranty

Your machine is guaranteed for 12 months from the date of delivery and includes

replacement of those parts that may, in the opinion of our Technical Department, be affected by

construction defects.

The parts not made by the manufacturer, elements working in the soil and failures caused

by incompetence or neglect, as well as consumables are excluded from the warranty.

The engine, instead, is covered by the engine manufacturer's warranty, according to the

conditions and terms envisaged by it.

The warranty is immediately voided if the machine is employed for uses or purposes other

than those recommended by the manufacturer, for damage caused by the application of

accessories that are not authorised or for repairs carried out with unsuitable spare parts.

When the machine is shipped, it is accompanied by a Warranty Certificate that details the

rules that regulate the performance of warranty service. We highly recommend that you read the

warranty form to be fully aware of the rights and possible liabilities. Complete the formtogether

with your dealer ensuring it is filled in correctly as the date, text content and other formalities

required (dispatch under the relevant conditions, etc.) represent the legal basis of the right to the

warranty on the vehicle. Purpose of the Manual

This manual has been prepared by the manufacturer and is an integral part of the machine.

It was drawn up in the Italian language, the original language of the manufacturer, and in

accordance with section 1.7.4 of Directive 2006/42/EC.

The information it contains is intended for the skilled operator with specific competence in

the field of use. The manual defines the purpose for which the machine was designed and built.

In order to avoid incorrect manoeuvres with the risk of accidents, it is important to read this

manual, in particular upon initial use, in order to become familiar with the main controls and

functions.

Constant observance of theinformation ensures the safety of persons, economy of operation

and a longer duration of operation of the machine.

To give more prominence to the passages of text that must not be ignored, these are

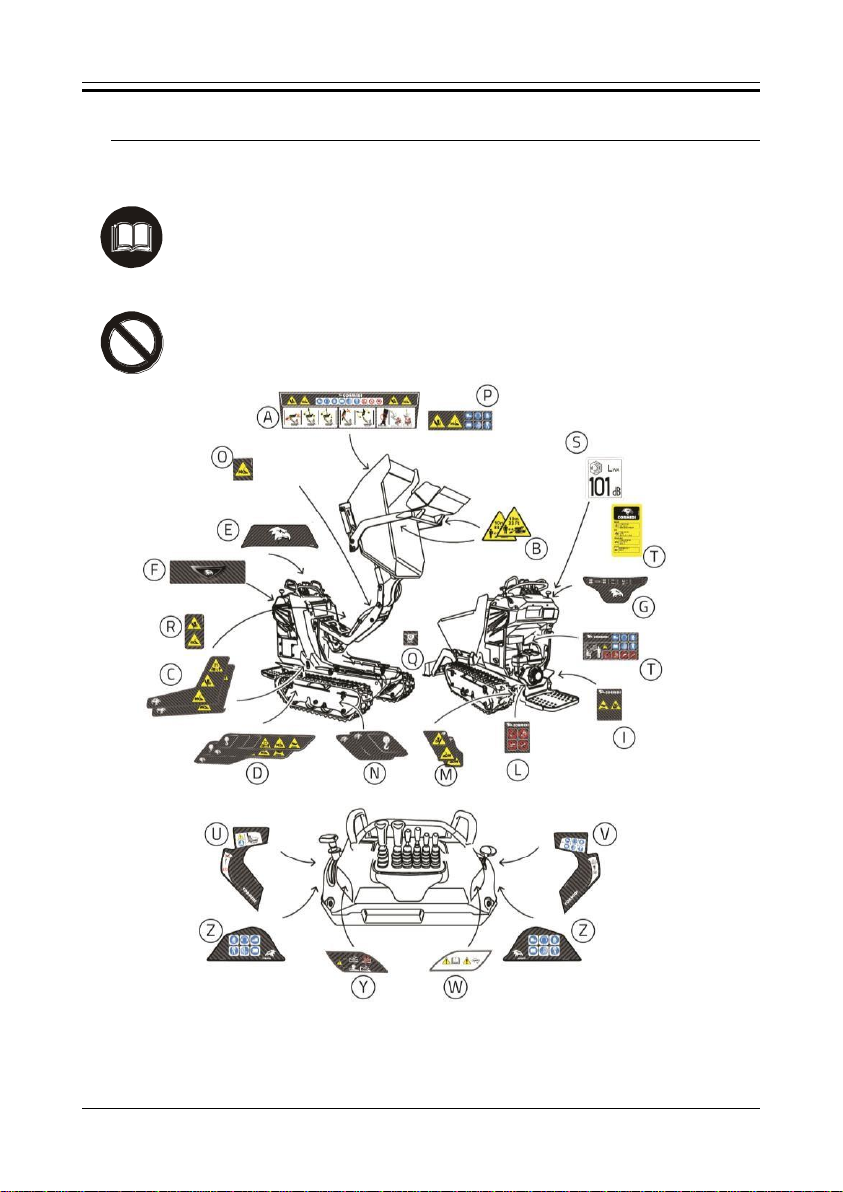

highlighted in bold and are preceded by the symbols illustrated and defined below.