1. General

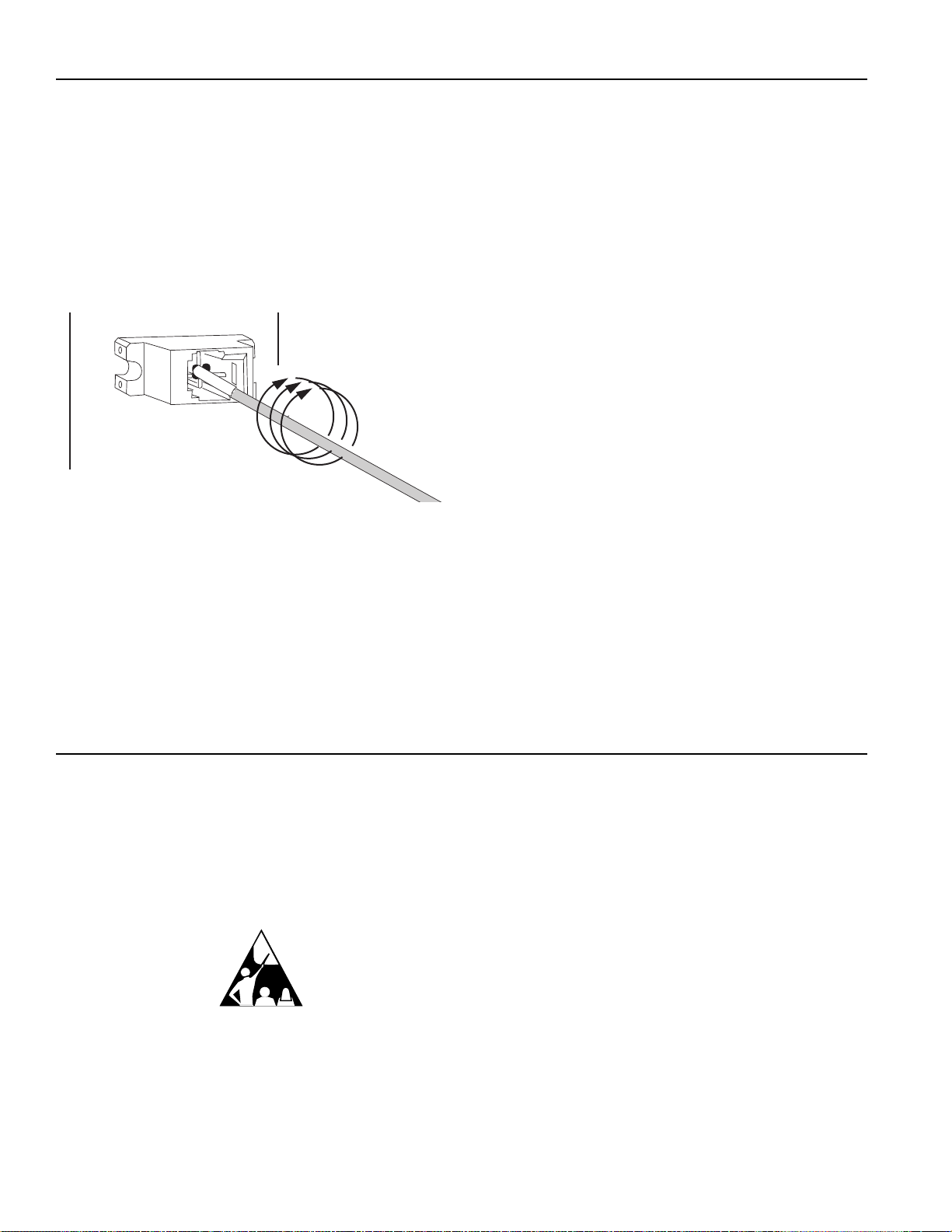

1.1 It is highly recommended that every connector is

cleaned before each mating. This procedure describes how

to use a Corning Cable Systems TKT-PNP Cleaning Kit

Figure 1) to clean connectors and connector adapters

found in Plug & Play systems trunks and modules.

1.2 The TKT-PNP connector cleaning kit provides

tools and materials needed for cleanings during connector-

ization, system installations, and reconfigurations.

Individual components are available from Corning Cable

Systems to replenish depleted kits.

1.3 This issue includes updated corporate information.

2. Precautions

2.1 General Precautions

2.2 Laser Handling Precautions

2.3 Chemical Precautions

2.3 Cable Handling Precautions

3. Tools and Materials

3.1 The following tools and materials are included in

the TKT-PNP kit:

• Universal connector cleaning cassette

p/n 2104359-01)

• MTP®Cleaning Tool p/n 2104466-01)

• Alcohol -soaked wipes p/n 1508001-01)

• 3-in. long foam-tipped swabs p/n 2104067-10)

• 1.25 mm ferrule cleaning sticks p/n 2104023-10)

• 2.5 mm ferrule cleaning sticks p/n 2104065-02)

Corning Cable Systems

SRP-006-093

Issue 3 April 2008

Page 1 of

Corning Cable Systems TKT-PNP Cleaning Kit

for Plug & Play™ Systems

Safety Glasses

WARNING:Corning Cable Systems strongly recom-

mends that you wear safety glasses to protect your eyes from

accidental injury when using alcohol-soaked wipes.

WARNING: Laser light can damage your eyes.

Laser light is invisible. Viewing it directly does not cause

pain. The iris of the eye will not close involuntarily as when

viewing a bright light. Conse uently, serious damage to the

retina of the eye is possible. Never look into the end of a fiber

or at a connector in a microscope which may have a laser

coupled to it. Should accidental eye exposure to laser light be

suspected, arrange for an eye examination immediately.

SRP-006-093 (311 89)

Isopropyl Alcohol

WARNING: Flammable. Flash point 59° F. Can

cause irritation to eyes on contact. In case of eye contact, flush

eyes with water for at least 15 minutes. Inhaling fumes may

induce mild narcosis. In case of ingestion, consult a physician.

Use with ade uate ventilation.

CAUTION: Fiber optic cable is sensitive to excessive

pulling, bending and crushing forces. Consult the cable specifi-

cation sheet for the cable you are installing. Do not bend cable

more sharply than the minimum recommended bend radius.

Do not apply more pulling force to the cable than specified. Do

not crush the cable or allow it to kink. Doing so may cause

damage that can alter the transmission characteristics of the

cable- the cable may have to be replaced.