WARNING! Ensure that you have read, understood and apply the chapter 1 safety instructions before using the cleaning

tank.

4.1. Check that the washer power switch is in the off position, and that the unit is unplugged from the mains power supply.

4.2. Check that the lid will close under its own weight by opening fully and releasing. Free up if necessary.

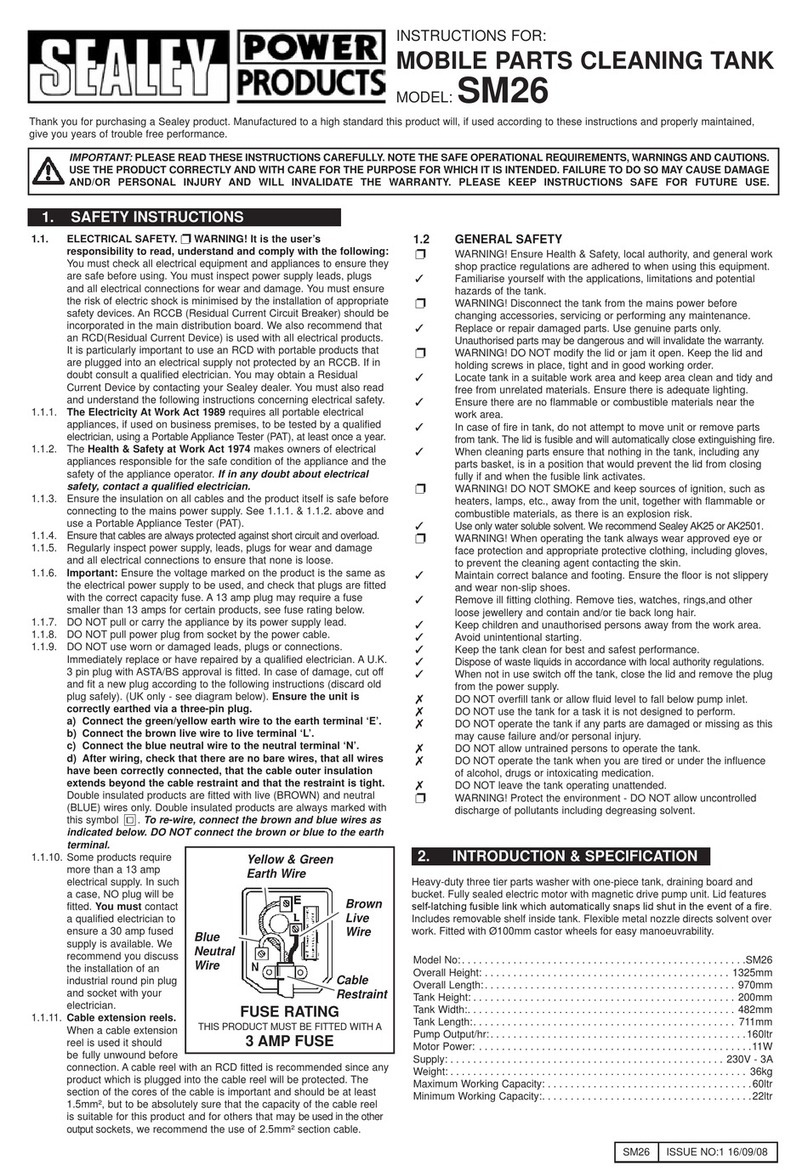

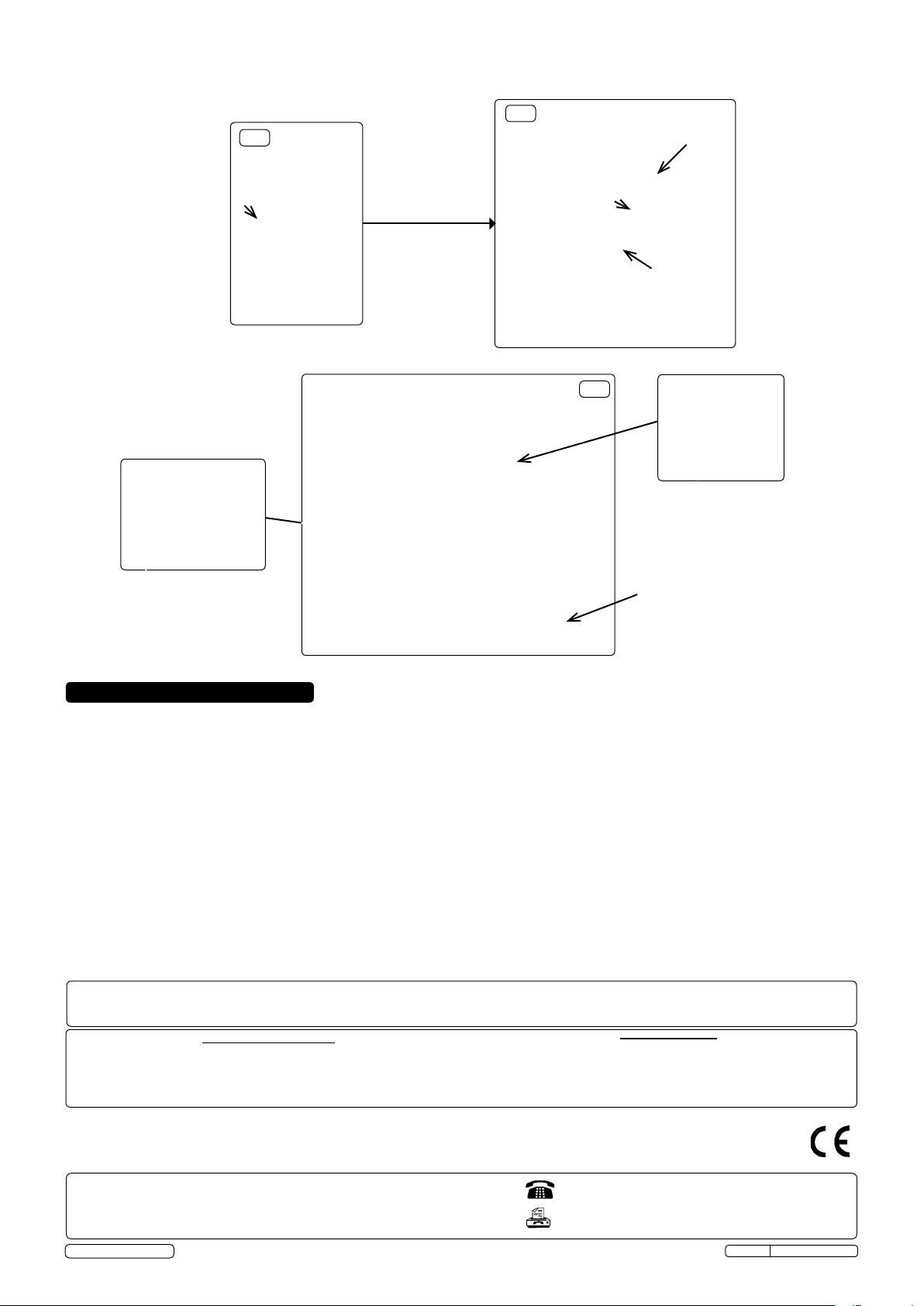

4.3. Open the lid fully and ensure the "over centre" link engages (fig.1 and fig.2). Fill the tank to appropriate capacity; between a minimum

of 7ltrs and a maximum of 15ltrs with a Sealey solvent or a general purpose degreaser. Contact your local Sealey dealer for supply.

DO NOT use any other type of solvent. CAUTION! Ensure that you follow any instructions provided with the solvent.

4.4. If fitted, remove the internal tray to ensure the pump is immersed correctly in the solvent. Replace the internal tray.

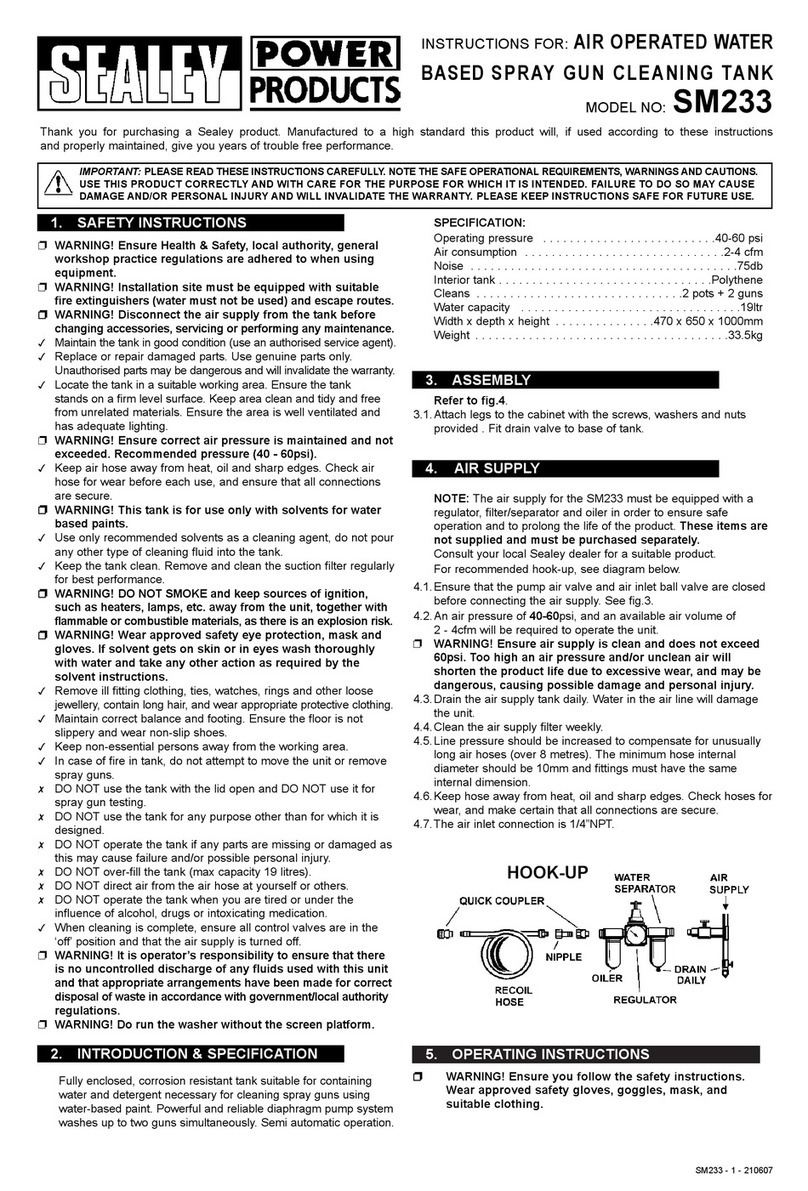

4.5. Plug the unit into the mains power supply and switch the unit on (fig.3). Check that the solvent flows freely through the flexible spout.

4.6. Place parts to be cleaned onto the internal cleaning tray. Ensure any splash back stays inside the tank. For ground-in dirt etc, leave

the parts to soak in the bottom of the tank. Brush parts with the cleaning brush if required. Turn off the pump and leave the parts to

drain on the shelf.

4.7. When complete, turn the washer off and unplug from the mains power supply.

WARNING! DO NOT allow uncontrolled discharge of fluids, thus polluting the environment. Dispose of waste liquids according to local

authority regulations.

4.8. Keep the cleaning tank clean. Remove and clean the filter regularly (fig.4) for the best and safest performance.

IMPORTANT! This cleaning tank has an anti-fire device built into it (fig.1 and fig.2). In the event of a fire and subsequent increase in

temperature locally, the low melting point solder in the fusible links turns from solid to liquid allowing the lid to close under gravity.

DO NOT prop the lid open with anything other than the fitted fused linkage. Use your finger (fig.2) to ensure full engagement. Once

actuated, the fire detection device cannot be re-used and must be replaced. When cleaning parts ensure that nothing in the tank,

including the parts basket and the flexible spout, is in a position that would prevent the lid from closing fully, if and when the fusible

link activates.

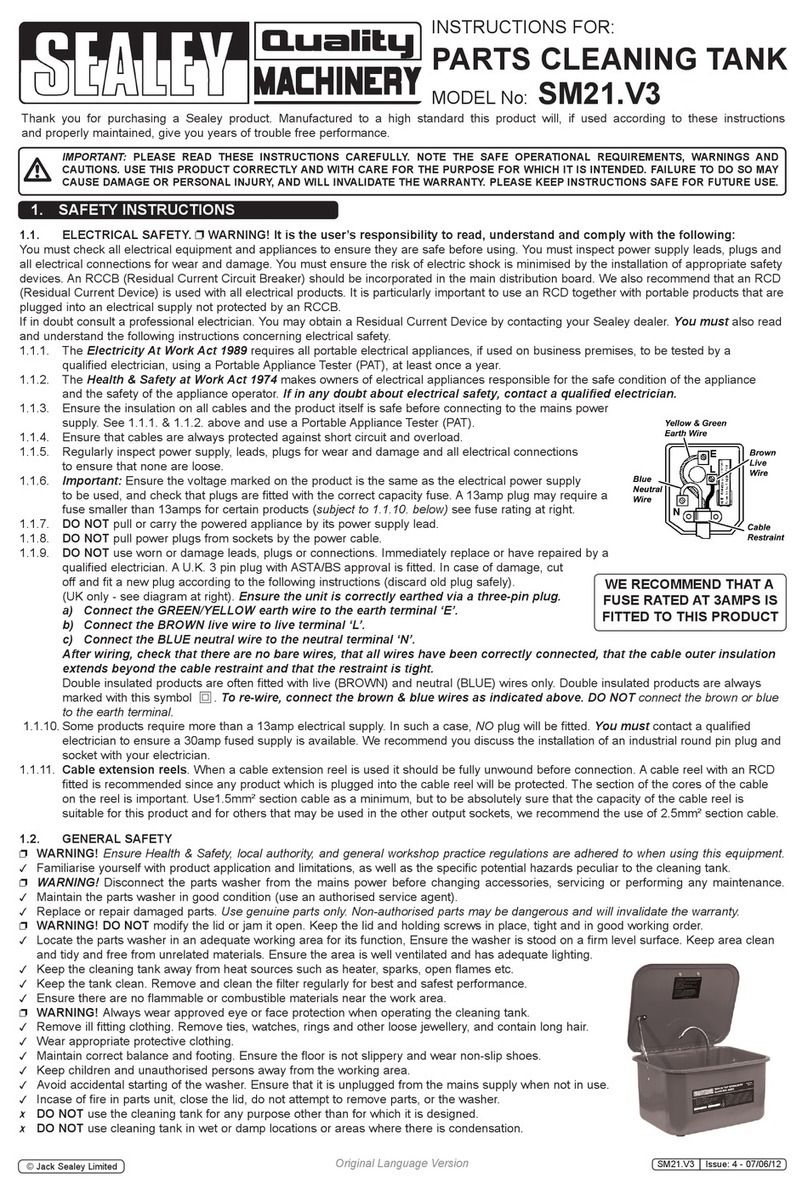

One-piece tank with triple baked finish and fully sealed magnetic drive pump unit with replaceable impeller. Smaller capacity tank is suitable

for bench-top mounting. Lid features self-latching fusible link which enables the lid to shut automatically in the event of a fire. Recirculated fluid

is filtered before entering the pump and is directed over the workpiece with a flexible metal delivery nozzle. Removable shelf included.

Model No: ............................SM21.V4

Power Supply: ............................230V

Motor Power: ............................. 26W

Tank Height/Width/Length: ..........210/290/395mm

Overall Height: ..........................225mm

Minimum Working Capacity:................... 7ltr

Maximum Working Capacity: ................. 15ltr

Pump Output/Hr: ...........................90ltr

Weight: .................................6.88kg

2. INTRODUCTION

3. SPECIFICATION

4. OPERATION

1.2. GENERAL SAFETY

WARNING! Ensure Health & Safety, local authority, and general workshop practice regulations are adhered to when using this equipment.

Familiarise yourself with product application and limitations, as well as the specific potential hazards peculiar to the cleaning tank.

WARNING! Disconnect the cleaning tank from the mains power before changing accessories, servicing or performing any maintenance.

Maintain the cleaning tank in good condition (use an authorised service agent).

Replace or repair damaged parts. Use genuine parts only. Non-authorised parts may be dangerous and will invalidate the warranty.

WARNING! DO NOT modify the lid or prop it open. Keep the lid and holding screws in place, tight and in good working order.

Locate the cleaning tank in an adequate working area for its function. Ensure the cleaning tank is stood on a firm level surface. Keep

area clean and tidy and free from unrelated materials. Ensure the area is well ventilated and has adequate lighting.

Keep the cleaning tank away from heat sources such as heater, sparks, open flames etc.

Keep the tank clean. Remove and clean the filter regularly for best and safest performance.

Ensure there are no flammable or combustible materials near the work area.

WARNING! Always wear approved eye or face protection when operating the cleaning tank.

Remove ill fitting clothing. Remove ties, watches, rings and other loose jewellery, and contain long hair.

Wear appropriate protective clothing.

Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

Keep children and unauthorised persons away from the working area.

Avoid accidental starting of the cleaning tank. Ensure that it is unplugged from the mains supply when not in use.

Incase of fire in parts unit, close the lid, do not attempt to remove parts, or the cleaning tank.

DO NOT use the cleaning tank for any purpose other than for which it is designed.

DO NOT use cleaning tank in wet or damp locations or areas where there is condensation.

DO NOT use the cleaning tank where there are flammable liquids, solids or gases.

DO NOT allow untrained persons to operate the cleaning tank.

DO NOT over fill the cleaning tank with solvent. Full capacity should be just below the parts tray.

DO NOT operate the cleaning tank if any parts are missing or damaged as this may cause failure or possible personal injury.

DO NOT modify or jam the cleaning tank lid open. Retain the lid open by use of the attached elbow strut only.

DO NOT use any solvent with a flash point below 105°F. Use only Sealey solvent, contact your local Sealey dealer for details.

DO NOT leave the cleaning tank operating unattended.

DO NOT operate the cleaning tank when you are tired, under the influence of alcohol, drugs or intoxicating medication.

The tank is not suitable for paint thinners, gun wash or air drying.

When not in use switch the cleaning tank off, remove plug from the power supply.

Dispose of waste liquids in accordance with local authority regulations.

WARNING! DO NOT allow uncontrolled discharge of fluids thus polluting the environment.

Original Language Version SM21.V4 Issue: 1 - 20/05/14

© Jack Sealey Limited