6

G 521 - RFG 361 C1 Eng. 25.11.08 MZ Rev. 02

We reserve the right to make changes without notice

COSTER

The pre-alarm and alarm levels of the sensor are determined by the processing of a microprocessor which

keeps account of the concentration of the gas in the air and of the exposure time. For this reason the “Sen-

sitivity” knob must not influence the sensor readout and must be set in “0” position.

The intervention modes of the detector are accordingly as follows:

– concentration < 0.005%(50 ppm): the safety of the persons is guaranteed for an indefinite length of time and

so the detector does not intervene,

– concentration 0.005...0.01%(50...100 ppm): within this concentration range, for 60 minutes the detector signals

a “Pre-alarm” situation and after this period switches to “Alarm”,

– concentration 0.01...0.03% (100...300 ppm): within this concentration range, for 10 minutes the detector signals

a situation of “Pre-alarm” and after this period switches to “Alarm.,

– concentration > 0.03% (300 ppm): the safety of the persons present in the space is not guaranteed. The de-

tector immediately switches to the “Alarm” condition.

The concentration values and the times taken into consideration by the detector are established allowing a large

safety margin to ensure there is no danger to the persons.

The action of the detector is of the “Dynamic” type: if the concentration passes from one level to another, the time

calculation increases or decreases as a consequence, thereby modifying the response of the detector. In particular,

if the concentration of carbon monoxide (CO) should return below 0.005% (50 ppm) for more than one minute, the

detector returns to the “Normal” condition, canceling all the times counted up to that moment and, if it has been

programmed “Without latching” will also exit from any “Alarm” condition.

9.4 Pre-alarm

If the pre-alarm threshold is exceeded, this is indicated by the intermittent lighting of the ALARM LED (4.4) on the

detector.

9.5 Alarm

When the signal exceeds the alarm threshold for more than 20 seconds (so as to have the certainty that it is not a

momentary situation or a false alarm), the detector:

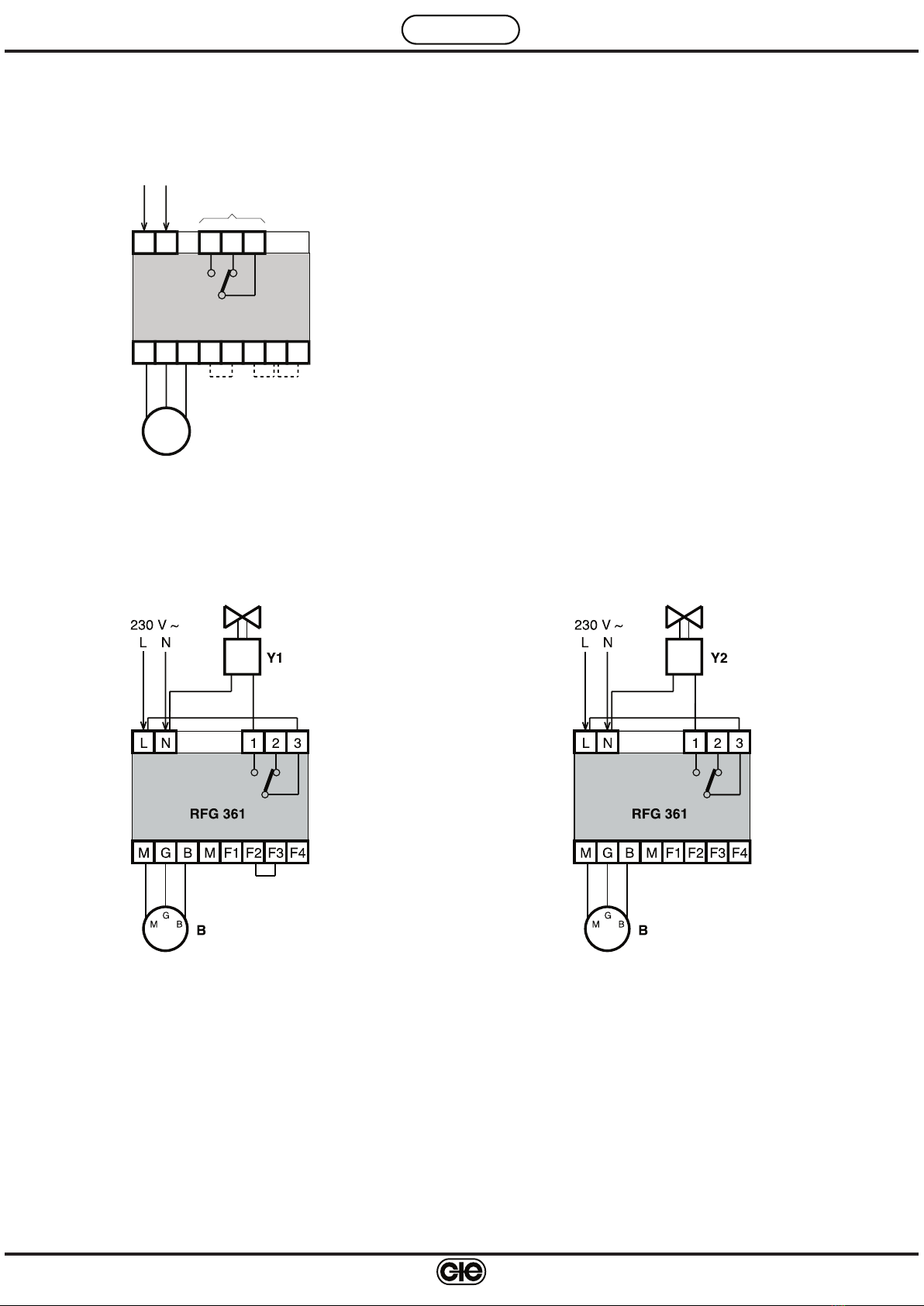

– activates the internal alarm (only if without jumper M-F1),

– on the facia the ALARM LED lights and stays lit (4.4).

Moreover, the alarm status causes the operational control relay to act as follows:

– if normally switched off (with jumper between F2-F3): the relay is energised (switch 1-3 closes, 2-3 opens),

– if normally switched on (without jumper between F2-F3): the relay is de-energised (switch 1-3 opens, 2-3

closes).

9.6 Latching and restoration

The detector can be programmed in two ways:

• Without latching (with jumper between F3-F4):

– alarm ceases when concentration of gas returns below threshold level,

– a slow flashing (0.2 seconds On and 1 second Off) from the ALARM (4.4) signal, indicates that the alarm

triggered,

– to switch off, press RESET button (4.5) .

• With latching (without jumper between F3-F4):

– the alarm continues even when the concentration of gas has returned below threshold level,

– to switch off, press, for at least 5 seconds, the RESET button (4.5).

9.7 Autodiagnosis

In the event of a fault or incorrect connection of the sensor, the FAULT LED (4.3) lights or the detector goes into

“Alarm”, obviously with the lighting of the ALARM LED (4.4):

Type of fault Warning

FAULT ALARM

– Sensor fault X

– Not connected to terminal G X

– Not connected to terminal B X

– Not connected to terminal M X

– Connection G and B inverted X

– Connection G and M inverted X

9.8 Life of sensors

The typical life span of gas detection sensors, from the moment of installation, is as follows:

– for semiconductor sensors for methane and propane (LPG): 10 years

– for electrochemical cell sensor for carbon monoxide (CO): 5 years.

After these periods the life cycle of the gas sensing element becomes exhausted and so the sensor must be re-

placed.

On the sensor cover a label shows the date when it should be replaced.