2

G 220 - RGM 12..-22.. C1 Eng. 09.95

We reserve the right to make changes without notice

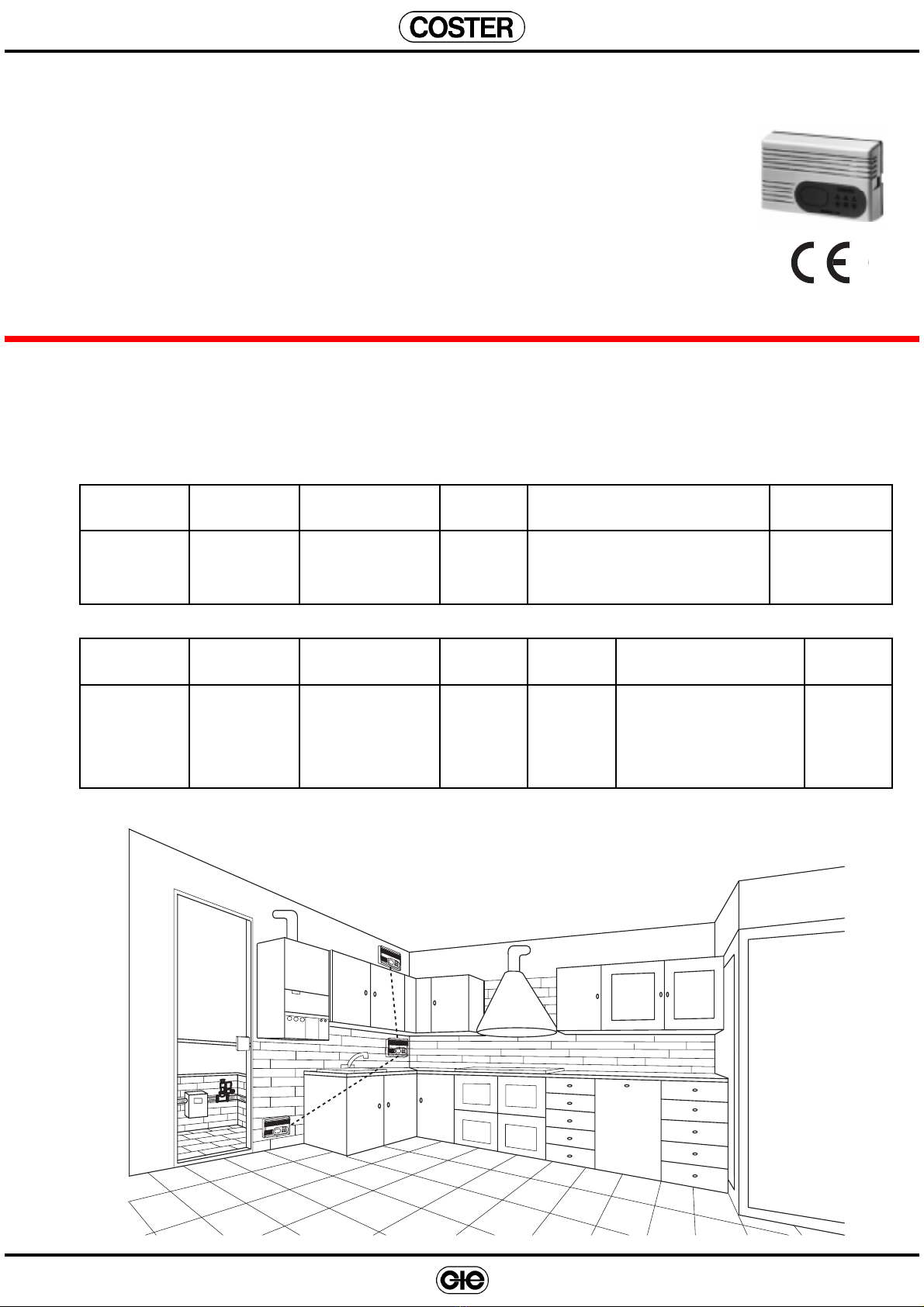

OPERATION

All the functions of the detector are processed by a CMOS

microprocessor.

When it is powered the detector does not signal alarms for a

period of two minutes so as to give time to the internal sensor,

and to any remote sensors used, to become stabilised. This

conditionis indicated bytheflashing of thegreen LED (fig.2.5).

Following this period the detector is ready to signal an alarm.

The internal sensor, and, if used, the remote sensors, monitor

the gas concentration level in the surrounding air and, in the

event that the pre-alarm concentration threshold is discerned

by one of the sensors, the detector causes the red alarm LED

(fig. 2.4) to flash; in the event that alarm threshold is exceeded,

the detector causes red LED to light and stay lit and, after 30

seconds, the detector also switches on audible alarm and

activates output relay.

The alarm threshold is equal to a concentration of 0.8% (8,000

ppm)ofmethane (naturalgas)in theairand 0.35%(3,500ppm)

ofpropane-LPG,whichcorrespondstoabout16%ofLEL(lower

explosivelimit). Theregulationsrequirethatthealarmthreshold

is below 25% of LEL.

LEL methane (natural gas) = 5 % (50,000 ppm);

LEL propane-LPG = 2.1 % (21,000 ppm).

Consequently,intheeventofagasleak,RGMdetectorsmakeit

possible to intervene in conditions of maximum safety.

DETECTION OF CARBON MONOXIDE

Byconnectingremote sensorSRC358orSRC352todetectorit

is possible to detect the presence of carbon monoxide. The

dangerof thisgas doesnot derivefrom itsflammability butfrom

itshightoxicityforhumansandthisdependsontheconcentration

level and time of exposure to the gas.

Concentration Time Effect

0.01 % (100 ppm) Irrelevant

0.03 % (300 ppm) 60 min. Lethargy

0.05 % (500 ppm) 90 min. Headache, nausea

0.06 % (600 ppm) 90 min. Loss of senses

0.07 % (700 ppm) 120 min. Coma, death

The alarm threshold is equal to a concentration of 0.05 % (500

ppm)of carbonmonoxide inthe airand thepre-alarm threshold

is 0.03 % (300 ppm).

WARNING LEDS

•GreenLED-Line(fig.2.5):Whendetectorispowered,thisLED

flashes for two minutes and then remains lit.

•Red LED - Alarm (fig. 2.4) : When gas concentration reaches

pre-alarm threshold this LED flashes and, when it reaches

alarm threshold, LED remains lit.

•Yellow LED - Sensor fault (fig. 2.3) : Lights up when one of the

sensors is faulty.

OUTPUT RELAY

The output relay can be used in two different ways :

•Normally not energised :

– Programmer (fig. 3.12) with switch 2 on On;

–Undernormalconditions(detectorpoweredandnotinalarm

state) the relay is not energised with contact 5-6 closed and

4-5 open;

– In alarm state, relay is energised with contact 5-6 open and

4-5 closed;

•Normally energised (BSI 7348 requirement);

– Programmer (fig. 3.12) with switch 2 on Off;

–Undernormalconditions(detectorpoweredandnotinalarm

state), relay is energised with contact 5-6 open and 4-5

closed;

–In alarm state,relay isnotenergised withcontact 5-6 closed

and 4-5 open.

LATCHING ALARM

Onceinalarmstate,if programmer(fig.3.12)hasswitch1onOn

(LatchingAlarm),thisstateremainsevenwhengasconcentration

returns below threshold level; to return to normal state it is

necessarytopressresetkey(fig.2.6)foratleastthreeseconds.

If switch 1 is on Off (without Latching Alarm), when gas

concentration returns below threshold level normal functioning

is automatically resumed.

COVER MODULE/OVERALL DIMENSIONS

fig. 2 36

▼

▼

▼

▼

80

21

130

▼

▼

3

45

6

COSTER

1 – Base module 4 – Alarm LED

2 – Cover module 5 – Line LED

3 – Sensor fault LED 6 – Reset button

CONSTRUCTION

The detector consist of two parts:

•Basemodule(fig.2.1andfig.3.1)inshockproofplasticmaterial,

suitable for wall mounting, which houses :

– Printed circuit (fig. 3.2), constructed according to Italian

Electrotechnical Committee (CEI) standards, on which are

located : terminal block for electrical connections (fig. 3.9),

programmer(fig.3.12),microprocessor(fig.3.13),resetbutton

(fig.3.14),alarmbuzzer(fig.3.11),sensingelement(fig.3.10),

transformer(fig.3.7)andairtightoutputrelaycontaininginert

gas (fig. 3.8).

– Cutout for passage of leads from rear (fig. 3.4).

–Mountingholes(fig.3.3)whichareastandarddistanceapart

andthereforesuitable for fixingto a flush-mountingpattress

if required.

– Hinge elements (fig. 3.5).

•Cover module (fig. 2.2), in shockproof plastic material, on the

faciaofwhich are the sensorfault, alarm and lineLEDs(fig. 2.

3.4.5).Thetwomodulesareattachedtoeachotherbyengaging

thecorresponding hinge elementsandby meansof securing

clip on base module (fig. 3.6) and catch on cover module.

BASE MODULE

fig. 3

1 – Base module 8 – Output relay

2 – Printed circuit 9 – Terminal block

3 – Mounting holes 10 – Sensing element

4 – Cutout for leads 11 – Alarm buzzer

5 – Hinge elements 12 – Programmatore

6 – Securing clip 13 – Microprocessore

7 – Transformer 14 – Reset button

▼

▼

83.5

6

3

9827

1

4

5

5

11

10

13

12

3

14