COVERBIND 101 DFS User manual

COVERBIND 101 DFS

Operator’s Manual

Document Finishing System

Part No. 2K542 B

April 2008

2

Safety instructions ...............................................

Installation ...........................................................

Description ..........................................................

How to use the Coverbind 101 DFS ....................

User settings .......................................................

5.1 - How to select the language ..........................

5.2 - How to select the speed of binding .............

Troubleshooting ...................................................

Clearing and emptying .........................................

How to make the most of your binding machine ...

Specifications .....................................................

Index and addresses ...........................................

Contents

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

3

5

6

7

9

9

10

11

12

13

14

16

3

1. Safety Instructions

Please read these safety notes carefully before using this product.

The equipment and recommended supplies have been designed and tested to meet strict safety

requirements. These include safety agency approval, and compliance to established environmental

standards. Please read the following instructions carefully before operating the equipment and refer

to them as needed to ensure the continued safe operation of your equipment.

Store the manual in the holder at the rear of the binding machine.

In order to guarantee perfect binding of your documents, only Coverbind original covers can be used

with this machine.

Safety Instructions

Always follow the safety instructions below when using the machine.

Symbols: Warnings:

The “Important Symbol” means that if

you do not follow these instructions, the

paper feed can go wrong, the covers

can be damaged, or the result can be

unsatisfactory in some other way.

This WARNING alerts users to areas of the

equipment where there is the possibility of

personal injury.

The “Prohibited symbol” denotes actions

that you are not allowed to do.

The “Mandatory symbol” denotes actions

that you must do.

This WARNING alerts users to areas of

the equipment where there are heated

surfaces, which should not be touched.

Prohibited. Do not dismantle.

Mandatory. Disconnect the mains cable.

The machine must be connected to a power supply

that complies with the specifications in section 9 of

this manual.

The mains cable must not be damaged,

destroyed, or modified in any way. Do not

put heavy objects on the mains cable.

Do not remove any covers or screws on the

machine, other than those described in this

manual. There is high voltage in some parts

inside the machine. Contact with these

parts can cause a severe electric shock. If

the machine needs adjusting or repairing,

ask your service representative for help.

If the machine appears to be damaged,

stops functioning, starts smoking, or smells

peculiar, immediately disconnect the mains

cable from the wall socket. Do not continue

to use the machine in this condition.

Contact your service representative.

Do not put any metal objects or objects

containing liquids (e.g. vases, flower pots,

coffee mugs, etc.) on the machine. If the

liquid contents are spilt into the machine,

there will be a risk of fire and electric

shock.

Examples:

4

Electrical Supply

This equipment shall be operated from the type of electrical supply indicated on the equipment‘s data plate

label. If you are not sure that your electrical supply meets the requirements, please consult your local power

company for advice.

WARNING

This product must be connected to a protective earth circuit.

This equipment is supplied with a plug that has a protective earth connection. This plug will fit only into an

earthed electrical outlet. This is a safety feature. To avoid risk of electric shock, contact your electrician to

replace the electrical outlet if you are unable to insert the plug into it. Never use an earthed adapter plug to

connect the product to an electrical outlet that lacks an earth connection terminal.

Use an outlet that contains surge surpression or ground fault protection. For added protection during a lightning

storm, or when the binder is left unattended and unused for long periods of time, unplug it from the wall

socket.

Product Recycling and Disposal

European Union

Disposal Information

Application of this symbol on your equipment is conrmation that you must dispose of

this equipment in compliance with agreed national Procedures.

In accordance with European legislation end of life electrical and electronic equipment

subject to disposal must be managed within agreed procedures.

Prior to disposal please contact your local dealer or Coverbind representative for end

of life take back information.

Other Countries

Please contact your local waste authorities and request disposal information.

5

2. Installation

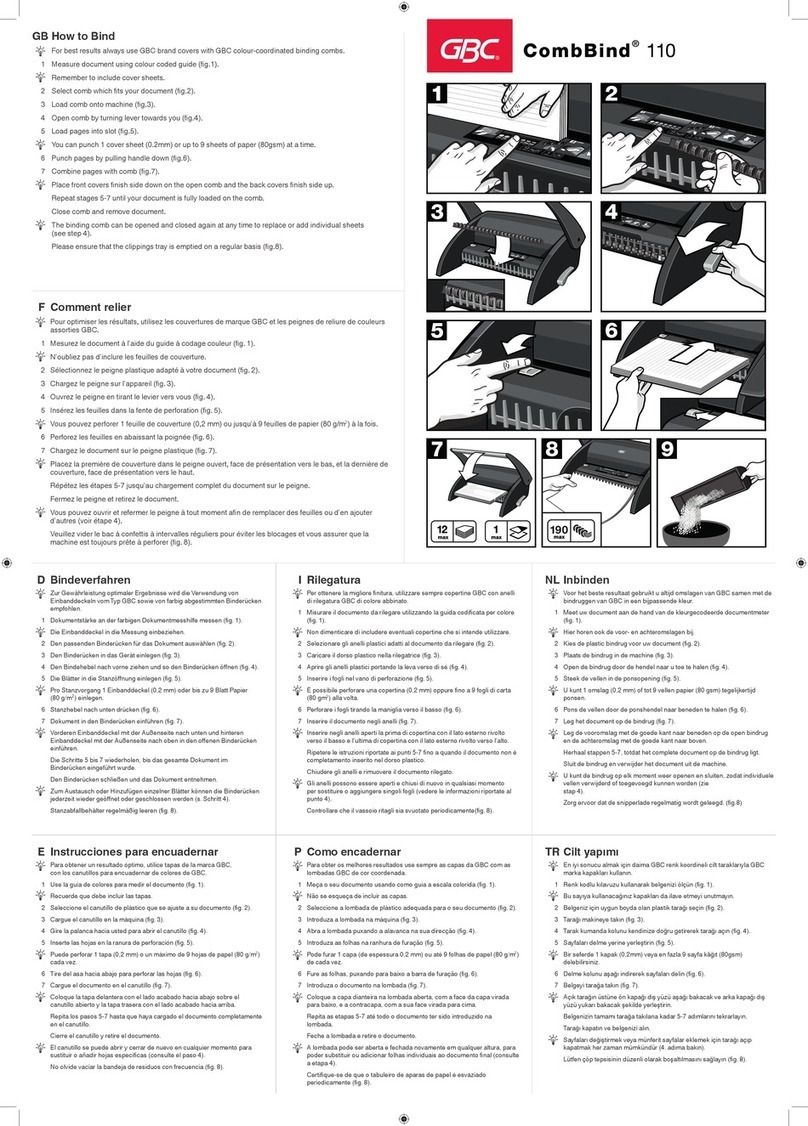

Besides the binding machine, the packaging should contain the following:

• Quick Guide

• Operator’s Manual on CD (also for download

on www.coverbind.com)

• Mains cable

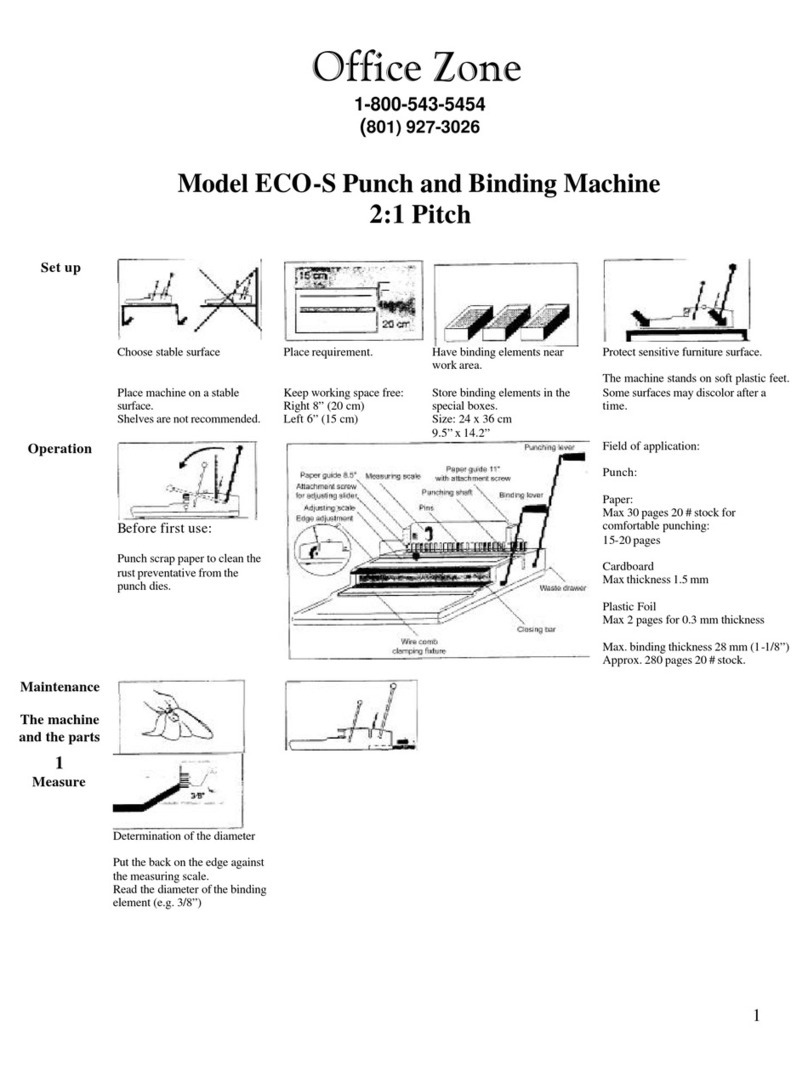

Preparations

1. Check that the items listed above are all

included.

2. Remove the Coverbind 101 DFS from the

packaging materials as described in the

instructions printed on the outside of the box.

3. Place the machine on a stable surface

with sufcient free area as work space.

Recommended surface height is ~ 20 inches.

This height will ensure the most comfortable

working position when loading documents.

Remove transport protection.

4. Plug the mains cable rst into the machine and

then into the wall outlet.

5. Press the control on the machine marked with

the symbol

6. Check that the Coverbind 101 DFS starts and

that the following message is shown on the

display:

MEASURE DOCUMENT

SEE PICTURE 1

To change language, see section 5.1.

7. After you have read the Operator’s Manual and

understand how to use the product, place the

Manual and Quick Guide in the holder at the

rear of the machine.

Your Coverbind 101 DFS is now ready for use.

Do not place the binder in an enclosure such as a cabinet without proper ventilation.

Do not stack the binder on top of or below, other electronic devices.

Do not overload wall outlets or extension cords, as this can result in a risk of re or electrical shock.

101DFS

art.no 2K514

v1.2008

Operator Manuals

& Quick Guides

MutiplesLanguages:

%&6t%/,t'*/

'3"t(#3t/-%

/03t135t48&

Holder for Operator’s Manual

and Quick Guide

6

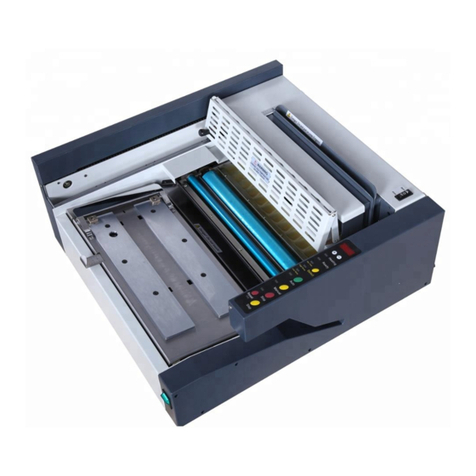

3. Description

Cover Selector

The cover selector comprises a slot into which you

insert the set of papers to be bound, short side first.

A sensor measures the thickness of the set and the

recommended type of cover is then shown on the

display.

Display

The display shows what is happening in the machine.

A number of user functions can be selected using the

two control-buttons on the panel. (See also section 5

“User settings”.)

Input bay

Insert the set of papers into the selected cover. This is

now called a document (cover with a set of papers).

Now load the document into the input bay with the

spine downwards as shown on the label.

Terminology

In this manual and in the Quick Guide, the Coverbind

cover is referred to as cover and the set of papers

is referred to as the set. When the set is put into the

cover, this is referred to as a document.

When a number of documents are piled on each other,

this is referred to as a batch.

The machine consists of ve main parts: Cover selector, Display, Input

bay, Binding unit, and Output tray.

Cover

Set

Batch

Document

Spine

width

If the binding machine stops for some reason, the

jam clearance door in the input bay can be pushed

aside and the document removed. (See also section 7

“Clearing and emptying”.)

Binding unit

The document is first jogged and then transported into

a heating zone where the glue in the cover melts. Then

the document passes through a cooling zone, and the

glue binds the pages together in the cover.

Output tray

The output tray moves outwards as the finished

documents are fed into it. An audible signal is heard

when the output bay is nearly full. A message is also

shown on the display which alerts the user to remove

the document from the output tray.

Output tray

Input bay

Jam clearance door

Heating zone

Binding unit

Cooling

zone

Display

Cover selector

7

4. How to use the Coverbind 101DFS

Following are the most important parts of the machine that you should be familiar with. The four (4)

steps to complete a binding, are also shown on the labels located on the top of the machine.

Input bay

Cover selector

Display

Control buttons

Indicator lights

Output tray

Jam clearance door

1. Start the machine by pressing on .

The display asks you to measure the thickness of

the set.

MEASURE DOCUMENT

SEE PICTURE 1

2. Measure the thickness of the set of papers to be

bound, by inserting the short side of the set into

the cover selector.

3. The recommended cover size (spine width) is

shown on the display.

USE COVER 1/16"

SEE PICTURE 2

8

4. Load the set of the papers in the selected cover.

5. Documents (cover and set) can always be loaded

into the machine for binding when the indicator light

is green. Documents can be loaded one by one or

in batches.

The machine conrms that a document has

been loaded by switching the indicator light

from green to red. As soon as the indicator

light is green again, the next document

or batch can be loaded. The machine

automatically switches to the energy saving

mode after 90 minutes.

When a batch of documents is loaded into the machine, the number of

documents in the batch should be limited as shown below.

Exceeding these numbers may compromise the strength of the bind, or cause

the machine to stop.

Max. Max. Max. Max. Max.

4 x 1/16” 3 x 1/8” 2 x 1/4” 1 x 3/8” 1 x 1/2”

6. Remove the bound documents from the output tray.

They are ready to be used. Note that full binding

strength is achieved only when the documents have

cooled down to room temperature.

By default setting, the normal processing time

is approx. 3 minutes for the rst document. The

continuous binding capacity is up to 30 documents

per minute

NOTE! Depending on the type of paper used,

the speed of binding can be increased by +33%

(see section 5.2 “How to select the speed of

binding”).

9

The user can change two parameters in User Settings.

5.1 How to select the language

The default language setting for your Coverbind 101 DFS is English. Other languages can be selected as

follows:

Note that the English language is always used in the “User Settings” mode.

1.

Start the machine by pressing on .

Press and hold down the RESTART and control for at least

2 seconds. The temporary functions of these two controls are

now shown on the lower line of the display.

2.

Press the control below Enter (i.e. the control) once.

3.

Press the control below More (i.e. the control) repeatedly

until the desired language is shown on the display.

4.

Press the control below Select (i.e. the RESTART control) twice.

5.

When satised with the settings, press the control below

Back (i.e. the RESTART control) once.

6.

MEASURE DOCUMENT

SEE PICTURE 1

The desired language has now been selected.

5. User settings

MEASURE DOCUMENT

SEE PICTURE 1

RESTART

> 2 s

CUSTOM SETTINGS

BACK ENTER

RESTART

1 x

ENGLISH

SELECT MORE

RESTART

> 1 x

ENGLISH

SELECT MORE

RESTART

2 x

SPEED NORMAL

SELECT MORE

RESTART

CUSTOM SETTINGS

BACK ENTER

RESTART

1 x

MEASURE DOCUMENT

SEE PICTURE 1

10

5.2 How to select the speed of binding

The default speed setting for your Coverbind 101 DFS is NORMAL

HIGH speed setting should ONLY be used to bind standard non-coated office copy/print paper.

NORMAL speed CAN be used to bind the above mentioned paper types, but MUST be used for coated and

other special paper types to achieve optimum binding strength. Special types may be heavy compressed, extra-

smooth or thicker than usual paper

Select the speed of binding as follows:

Note that the English language is always used in the “User Settings” mode.

1.

Start the machine by pressing on .

Press and hold down the RESTART and controls for

at least 2 seconds. The temporary functions of these two

controls are now shown on the lower line of the display.

2.

Press the control below Enter (i.e. the control) once.

3.

Press the control below Select (i.e. the RESTART control) once.

4.

Press the control below More (i.e. the control) once, to

display the alternative speed of binding.

5.

Press the control below Select (i.e. the RESTART control) once,

to select the displayed speed of binding.

For details on productivity/capacity please see section 9

“Specications”.

6.

When satised with the settings, press the control below

Back (i.e. the RESTART control) once.

7.

MEASURE DOCUMENT

SEE PICTURE 1

The desired speed of binding has now been selected. When/

if HIGH speed has been selected a symbol ( H ) will appear

in lower right corner of the display.

MEASURE DOCUMENT

SEE PICTURE 1

RESTART

> 2 s

CUSTOM SETTINGS

BACK ENTER

RESTART

1 x

ENGLISH

SELECT MORE

RESTART

1 x

SPEED NORMAL

SELECT MORE

RESTART

1 x

SPEED HIGH

SELECT MORE

RESTART

1 x

CUSTOM SETTINGS

BACK ENTER

RESTART

1 x

MEASURE DOCUMENT

SEE PICTURE 1

H

11

6. Troubleshooting

Use these instructions to solve the most common operating problems with your Coverbind

101 DFS binding machine:

NOTE! In order to guarantee perfect binding of your documents, correct speed of binding (see section 5.2) must be

selected and only Coverbind original covers must be used. Other types of covers or incorrect usage of the machine

can cause poor binding results or the machine may stop working, in which case an authorised service may be

required.

Symptom: Cause: Action:

The machine will not start.

No text on display.

No power supply.

Machine switched off.

Check the mains

connection. Press

RESTART or .

Red indicator light blinks.

Buzzer alarm.

Document not in

contact with oor of

input bay.

Too many documents

in the batch or

document too thick.

Remove document by pulling back the jam

clearance door.

Check the thickness

and quantity.

Press

RESTART.

Load the

document again.

Red indicator light illuminates

more than 3 sec.

Buzzer alarm.

Too many documents

in the same batch.

Remove the documents by pulling back the

jam clearance door.

Load documents

again with fewer

documents

in each batch.

Red indicator light illuminates

more than 3 sec.

Buzzer alarm (twice).

Output tray nearly full.

Remove documents

from the output tray

before loading more

documents in the

machine.

Red indicator light illuminates.

Buzzer alarm.

Machine stops.

Output tray full. Remove documents from output tray. The

machine then automatically continues

binding the documents that are already

loaded.

Machine stops.

Other error codes, e.g.:

Contact an authorised Coverbind partner.

See also section 7 “Clearing and Emptying”

about how to remove unbound documents

from the machine.

INPUT JAM

REMOVE DOC

RESTART

DO NOT INSERT

REMOVE DOC

ALMOST FULL

EMPTY TRAY

OUTPUT TRAY FULL

EMPTY TRAY

BINDER FAULT

CALL SERVICE

RESTART

12

7. Clearing and emptying

If there is a mains power failure or if the binding machine stops functioning for some other reason, documents

in input bay area and other unbound documents can be removed as described below. If there are unnished

documents in the machine when the power supply is restored, the machine will automatically move them forward

to the output tray. They can then be re-loaded and bound.

If the binding machine breaks down, any documents should be cleared and removed from the machine before

it is sent for service.

Clearing

If the display shows or remove all documents

from the input bay.

To facilitate removal of the documents, the machine is equipped with a jam clearance door.

Pull back the jam clearance door with one hand (1). Firmly grip the document(s) in the input bay

with the other hand (2) and lift them out of the machine (3).

The binding machine should then automatically

return to the normal position. However,

if it does not, press the RESTART control.

Emptying

The binding machine only needs to be emptied manually in exceptional cases (e.g. if the machine

breaks down or if there is an extended power failure).

Disconnect the mains cable before emptying the machine.

Wait for a while until the heating zone in the machine has

cooled down.

Stand in front of the machine and hold both hands in the

output tray, as shown in the gure below. Turn the outermost

drivers on both sides outward using your thumbs so that the

document is manually fed one step forward. This operation

may require some force. The drivers are designed to withstand

such force. Repeat the procedure to transport the remaining

documents forward until the binding machine is empty.

Driver

Jam clearance

door

INPUT JAM

REMOVE DOC

DO NOT INSERT

REMOVE DOC

13

8. How to make the most of your binding machine

Avoid loose pages!

Tip: Always use the cover selector to ensure you have the correct spine width and thus avoid

loose pages.

If there are too many pages in a cover, the strip of glue will be insufcient for all the pages.

Do not pull out pages!

Tip: Allow the document to cool down. When the document is removed from the machine, it

has cooled sufciently to handled and read, but do not test the strength of the binding

immediately. A document with only a few pages reaches full strength after a few minutes.

But a thicker document will require longer time to cool down and attain maximum strength,

especially if the set of papers comes directly from a copying machine or printer.

Check that the paper you are using is suitable for binding!

Tip: When using coated, heavy compressed, extra-smooth or thicker than usual paper, we

recommend that you rst make a test binding to check that the strength of the bind is good

enough. The strength of some special types of paper is very similar to ordinary copy paper

whereas other types have characteristics that may reduce the strength of the binding. Using

special paper for one or two pages in a document will usually not cause any problems.

Even jogging!

Tip: Always use the collating function on your copier/printer. On many copier/printers the sheets

can be collated into sets and delivered in a special output tray. For binding, it is always positive

to select the collating function. Normally the copier/printer jogs every sheet it collates. If the

standard output tray of the copier/printer is used, static electricity in each sheet of paper

may make it very difcult for the binding machine to jog the paper set properly. Such paper

set could result in poor binding strength.

Glue

14

9. Specications

General The Coverbind 101 DFS is a semi-automatic high-speed thermal binding machine that

only accept usage of Coverbind DFS document covers.

Output capacity Up to 30 documents can be bound per minute depending on the spine width and

the speed setting. The number of documents that can be loaded in the machine

simultaneously is shown in the table below and depends on the spine width. The

corresponding output speed is stated at the bottom line of the table as covers per

minute.

Spine width

Load qty

Speed HIGH

Speed NORMAL

1/16”

max 4 pcs.

30/min

22/min

1/8”

max 3 pcs.

22/min

16/min

1/4”

max 2 pcs.

15/min

11/min

3/8”

max 1 pcs.

7/min

5/min

1/2”

max 1 pcs.

7/min

5/min

Paper size Letter size, 8.5x11”

Spine width and

capacity

The table below shows approximately how many sheets of 20lbs paper the covers can

hold for each spine thickness.

1/16”

1-15

1/8”

16-30

1/4”

31-60

3/8”

61-90

1/2”

91-120

Jogging The sheets of paper in the set are automatically jogged on three sides during the

binding process.

Output tray capacity 8 – 50 documents depending on the spine width.

Binding temperature 330°F±10°F

Warm-up time 2-3 minutes depending on the ambient temperature and local variations in the power

supply voltage.

Energy-saver mode 90 minutes after last document is bound.

Voltage 115 VAC +/- 10%

Power consumption stand-by

binding

power saver

heating up

137 W

140 W

7 W

630 W

mean value

mean value

Environment Temperature 50 - 95°F, humidity 15 - 90% RH.

Dimensions Length

Width

Input height

Total height

18,5”

20”

13”

14”

Weight 62 lbs

15

10. Index

A

Addresses 15

B

Batch 6

Binding temperature 14

Binding unit 6

Buzzer 11

C

Clearing 12

Compartment 5

Copying paper 13

Cover 6

Cover selector 6

D

Description 6

Dimensions 14

Display 6

Documents 6

Driver 12

E

Emptying 12

Example 3

I

Index 15

Input bay 6

Installation 5

J

Jam clearance door 6

Jogging 14

L

Language 9

Lights 11

Loose pages 13

O

Operator’s Manual 5

Other error codes 11

Output tray 6

P

Paper size 14

Power consumption 14

Power failure 12

Processing time 8

Paper Quality 10,13

Q

Quick Guide 5

R

Restart 9

S

Safety Instructions 3

Set of paper 6

Sorting function 13

Specications 14

Speed of binding 10

Spine width 6

Symbols 3

T

Terminology 6

Test binding 13

Thermal binding machine 14

Tips 13

Troubleshooting 11

U

Unbound documents 12

User settings 9

V

Voltage 14

W

Warm-up time 14

Warnings 3

16

FCC Declaration

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful interference to radio

or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

– Consult the dealer or an experienced radio/TV technician for help.

Warning

This Class “B” digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe “B” est conforme à la norme NMB-003 du Canada.

17

COVERBIND CORPORATION

3200 Corporate Drive

Wilmington, NC 28405

Phone: (910) 799-4116

Tollfree: (800) 366-6060

Fax: (910) 799-3935

www.coverbind.com

Table of contents