6

1 To debind a document which has been bound press the

‘Debind’ button to set the binding system in the debind

mode.

2

bind the document. The left side of the document should rest

Locating Pin.The Locating Pin is on the left hand side of the

to slide the document to the right while resting against the

3

Counter’ will display and count down the number of seconds

the machine takes to debind.The bar will rise one it is

complete.

4

away from the document. If you do not perform this step

the strip faster this time.

Another method for debinding is the Debinder Tool, which is

packaged free with all systems. Additional Debinder Tools and

1

should be at your right with the formed studs heads up.

2 Holding the document in place with the left hand and using

the Debinder with the right hand, insert the blade between

3 With the Debinder snug against the right side of the

document and continuing to pull toward you, swing the

handle of the Debinder to the right, away from the document.

4

the next stud, swing to shear, pull to the next stud and so on.

For rapid debinding, the Debinder can be pulled toward the

sheared. Extreme caution should be used when using this

method.

5

6 Replace the Debinder blade when it becomes dull.

Debinding a document which has already been bound can

Feature on the equipment or the Debind Tool.

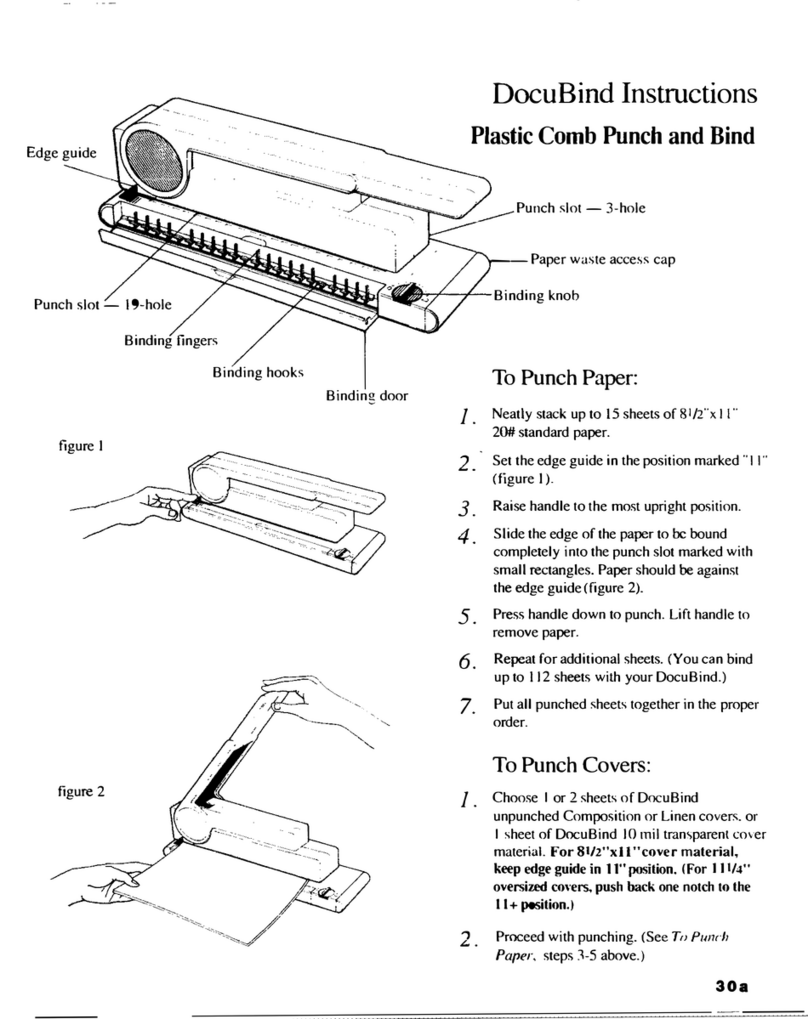

Punching

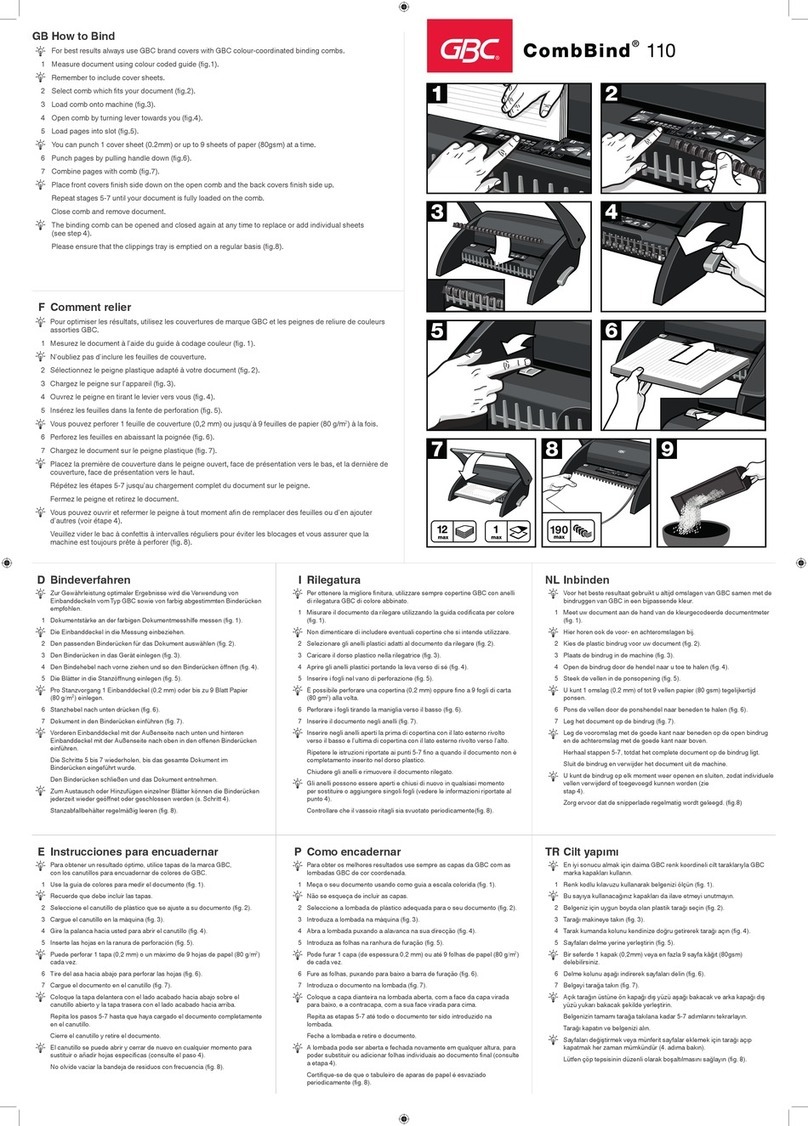

1 Selecting the ‘Auto Punch’ button allows you to punch in

the automatic mode by sliding the paper against the Punch

allows you to punch by pressing the footpedal. If you choose

not to punch in the ‘Auto Punch’ mode switch back to the

‘Manual Punch’ mode by pressing the ‘Auto Punch’ button.

Then place the paper fully in the punch throat and press the

‘punch’ button.

2

2bond paper

should be punched at one time (fewer sheets if the paper

3 Remember to lay each punched segment of your documents

document on another surface can cause binding problems

Locating Pin).

1 Adjust the Punch Edge Guide by loosening the thumb screw

on top of the Guide and sliding Guide along the scale to the

correct paper size. Retighten the screw to lock the Guide

into position.

2

strip in the Strip Recess area. Lay a sheet of correctly aligned

punched paper on the strip, matching up the holes and the

strip so that the strip is not showing at the top or bottom of the

paper. Adjust the Guide if necessary by loosening the thumb

screw on top of the Guide and sliding the Guide to the edge of

the paper. Retighten the screw to lock the Guide into position.

6

5

2

Binding

If you are just turning on the machine you will need to wait for

the machine to warm up. Do not attempt to bind until the yellow

1

textured side down in the Strip Recess located in the front

The Locating Pin is on

the left hand side of the Strip Recess area in front of the

2

3 Now determine the correct size of the pin strip. Use the scale

or 75mm). The pins should extend all the way through the

document but not more than 1” (25mm) beyond. Insert the

4

5

toward you and lowering it on the top of the document.

The binding cycle will begin and the bar will raise once it is

the document rather than ‘drop’ it.

43

1