Coxo CX235 User manual

CONTRA ANGLE

Please read this operation Manual

carefully and file for future reference.

MODEL:CX235

1:5

Thanks for purchasing our dental Contra angle!

In order to fully exert the function of this equipment, safely and

effectively use this equipment, please read this instruction carefully

before using , and please keep this manual well for reference anytime.

Under regulations'request, we have been committed to the

optimization of our product, this may cause some parts of change, when

you find the product appears some difference from description in the

manual, please contact the dealers or our after-sales center for details .

Preface

1

•Protection of liquids-normal liquids – protected equipment

•Temperatures range:-40°C--+135°C

•Relative humidity:10% to 80%,non-condensing

•Noise:≤70dB

Technical specifications

•Please read this operation manual carefully before use and file it for future

reference .

•This product is spcialized for stomatology treatment abnormal,don’t use it in

other ways.

•This product is only for doctors.

•Every time you use it,please check first.If find anything unnormal,stop using

immediately,and contact your supplier or our after-sales center for details.

•Before operating low speed handpiece,pull contra angle handpiece with

hand to make sure handpiece connect firmly and safely.

•Head can not running without insert bur,otherwise head or motor would be

damaged.

•Ensure working pressure before running,Air pressure for four bole air motor

is 0.3Mpa,for two hole air motor is 0.25Mpa.

•Don’t immerse handpiece in any chemical solvent or solution or by dry-heat

disinfection.Sterilization by autoclave at(135±2)°C&0.22MPa is sugguested.

2

Inner channel1:5

Product Composition

Inner channel contra angle speed increase 1:5

(CX235C7-1)

Push button

Optic fiber

Optic fiber

1:5

Φ1 .6

(CX235C7-2)

Push button

1:5

Φ1 .6

Optic fiber Inner channel push button contra angle Inner channel push button contra angle

Inner channel1:5

Fig.1.1

Cartridge Replacement

Technical parameters:

•Inner channel contra angle low speed handpiece ;

•Burs applicable:for CA burs Φ1.6;

•Max.speed of contra angle:200,000rpm

•Speed: speed up to 5times

•Chuck speed:push button

•Spray:4 way spray

Fig.1.2

1

2

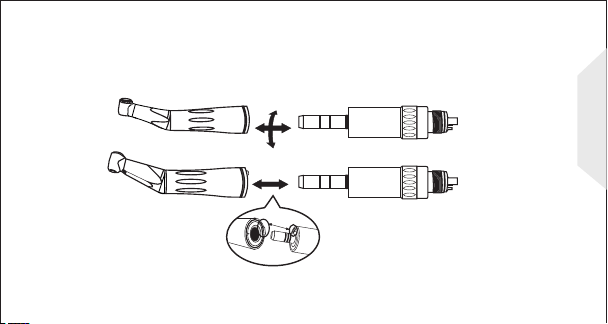

1. Use a screwdriver to make the screw out from the tail of the contra angle and

pull out small head from outside, as shown in figure 1-1.

Inner channel1:5

Fig.1.1

Cartridge Replacement

Technical parameters:

•Inner channel contra angle low speed handpiece ;

•Burs applicable:for CA burs Φ1.6;

•Max.speed of contra angle:200,000rpm

•Speed: speed up to 5times

•Chuck speed:push button

•Spray:4 way spray

Fig.1.2

1

2

1. Use a screwdriver to make the screw out from the tail of the contra angle and

pull out small head from outside, as shown in figure 1-1.

Inner channel1:5

1

2

Fig.1.3 Fig.1.4

Prot ectiv e Cover

Prot ectiv e Cover Cart ri dge

Fig.1.5

2. Use the unloading tool to open the rear cover, and make shaft out

from small head .as shown in figure 1-3.

3.Take the cartridge and cartridge set out ,replace the new cartridge. as

shown in figure 1-4.

4. After Replacing the new cartridge ,use the loading tool to tighten the back cover

and shaft ,You must aim for insert of the fuselage, as shown in figure 1-4, tighten

screw of the tail part

Inner channel1:5

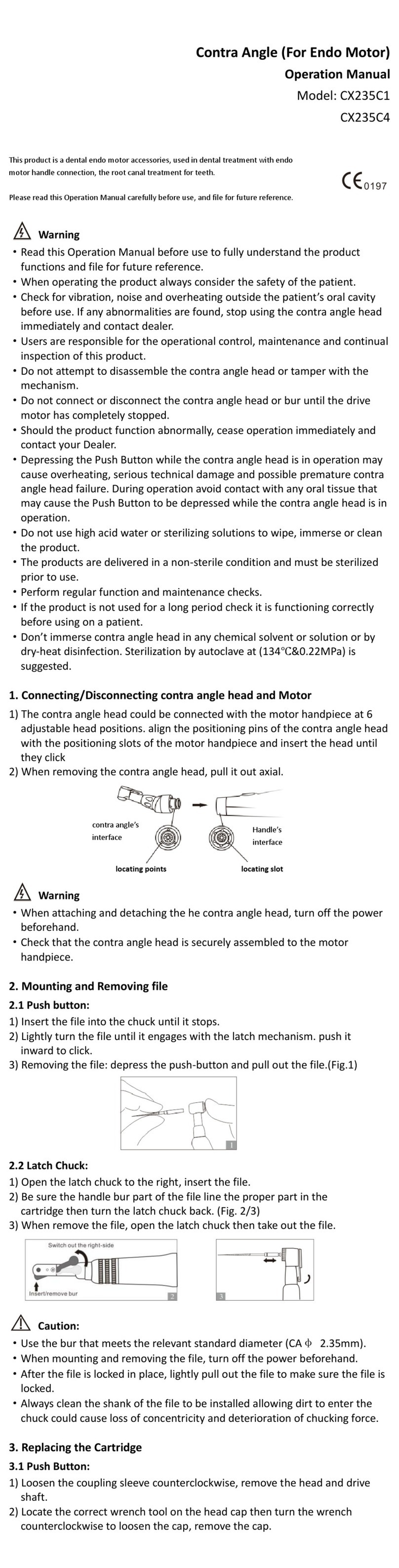

Contra angle and motor connections

1. Straightly insert the motor into the connection of contra angle, until you

hear a “cracking" sound can be.

2. Hold the bending machine and pull out the motor, it will be separated[fig.3.2].

3.Alignment the groove,contra angle can insert into the air motor[fig.3.3].

Fig.3.2

optic fiber

Optic Fiber Contra angle

Bur size:Ø2.35

Optic Fiber/LED

Inner channel Air motor

Fig.3.4

Fig.3.3

(CX235C7-1)

Fig.3.1

Contra angle with generator

(CX235-1E) Bur size:Ø2.35 Inner channel Air motor

1:5

Electric motor

Electric motor

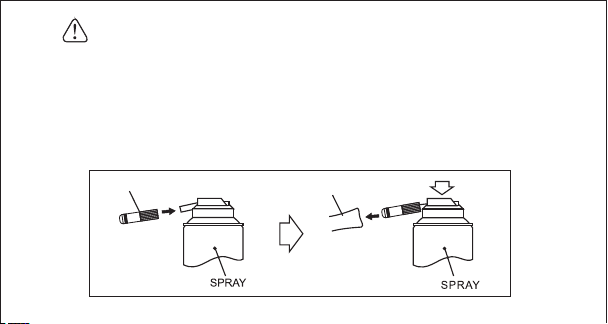

*Dismount contra handpiece from motor.

*Install E spray nozzle on the lubricant.

*Insert E spray nozzle on the back of contra handpiece to spray2-3 seconds

till the lubricant through out of head,Stop until clean lubrication comes out.

*Keep contra handpiece standing for a while,and then connect with the

motor after the lubricant inside come out.

After daily use,spray lubricant for 1 to 2 seconds by inserting lubricant

nozzle all the way into drive air tube.

If work heavily,lubrication should be implemented at noon and

afternoon’s after using everyday.

Lubricate the head,gear and inside.[Fig.16]

When lubricate the head,please open

the latch chuck.

Fig.16.3

contra hand

E spray nozzle

Fig.18

Caution

Be sure to hold the handpiece firmly to prevent the handpiece

from slipping out by the spray pressure when lubricating.

Supply lubricant until it comes out of the handpiece nose

(for approx 2 seconds)

Keep the SPRAY can upright

Clean-head system

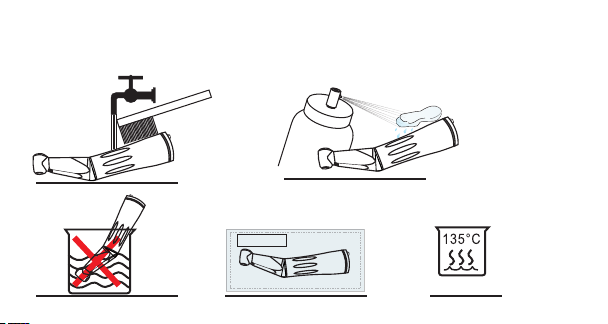

1-Scrub dirt and debris from the handpiece.

2-Stop the handpiece and wipe it dry.If the dirt could not remove from the hole,

remove the cartridge and clean by brush.

Fig.17

Use only clean water to maintain the clean head system.

Cleaning -bulb

Wipe clean the Cellular optical bulb entry point with an alcohol-immersed

cotton swab.Remove all debris and oil.

Notice!

Sterilization and cleaning

-Steam autoclave is recommended.

-Sterilization requirement after using as noted below.

-Autoclave Procedure:

-Scrub dirt and debris from the handpiece,and wipe clean with alcoholic

cotton.Do not use a wire brush(Fig.18.4)

-Lubricate with SPRAY or Lubricant oil.

-Lubrication.

-Insert into an autoclave pouch.Seal the pouch.

-Autoclavable up to a max.135°C(EX.)Autoclave for 20 min. at 121°C or

15 min.at 132°C(Fig.18.2/18.3).

NOTE:After treatment or before autoclave,please do the lubrication.

STERILE

275°F

NOTE:After treatment or before autoclave,please do the lubrication.

Fig.18.4 Fig.18.5

Fig.18.7

Fig.18.6 Fig.18.8

2 9

1:5

1:5

1:5

1:5

Trouble Shooting

Trouble Possible cause Solution

Our service center can offer technical assistance to you.

Body of straight head or

contra angle rotates during

motor running

O-ring on the nose of motor

wears Change o-ring

Handpiece fail to rotate Clean and lubricate,

move it by hand

Contra angle chucking with

bur but lacth plate fail to be

fixed in the proper position.

dirt get into the handpiece

COXO grants the user a 12 months guarantee for its complete product

range,except ball bearing(3 months guarantee) from the date of invoice issued,

Maintenance over the term of guarantee will be at the customer's charge.

COXO will not be responsible for damage or injury resulting from:

----excessive use

----improper manipulation of the product,or modification to product

carried out by persons not authorizes by COXO.

----fail to follow the instruction to install,operate and maintenance

the handpiece.

----damage of chemical,electrical or electrolysis due to improper

autoclaving and storing.

----improper working pressure.

The technical specifications and dimension in these instruction are given only as a guide.

They may not be subject of any claim.

Warranty

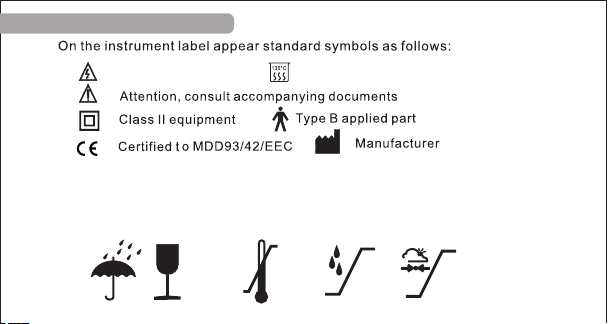

STANDARD SRMBOLS

Important notice! Autoclave

Standard Symbols

Transportation and deposited condition

Environmental temperature range:- 40°C--+50°C;Relative humidiy≤80%;

The scope of air pressure: 50 0hPa—1060hPa.

+70°C/158°F 80% 106

max.

+40°C/40°F

10%

min. kPa

50

Address:21 Wufeng Si Road,Foshan,Guangdong,China

Foshan COXO medical instrument Co.,Ltd

Wellkang Ltd.

Address:SuiteB,29 Harely Street,London W1G9QR,United Kingdom

Foshan COXO medical instrument Co.,Ltd

TEL:+ 86 757 86174018,86121615

FAX:+86 757 86125200

E-mail:coxotec@163.com

Http://www.coxotec.com

Rev.D revision Date:2015-6-30

Other manuals for CX235

2

This manual suits for next models

2

Table of contents

Other Coxo Dental Equipment manuals