Coxo CX235 User manual

CONTRA ANGLE

Please read this operation Manual

carefully and file for future reference.

MODEL:CX235

Thanks for purchasing our dental Contra angle!

In order to fully exert the function of this equipment, safely and

effectively use this equipment, please read this instruction carefully

before using , and please keep this manual well for reference anytime.

Under regulations'request, we have been committed to the

optimization of our product, this may cause some parts of change, when

you find the product appears some difference from description in the

manual, please contact the dealers or our after-sales center for details .

Preface

1

•Protection of liquids-normal liquids – protected equipment

•Temperatures range: - 40°C--+135°C

•Relative humidity:10% to 80%,non-condensing

•Noise:≤70dB

Technical specifications

•Please read this operation manual carefully before use and file it for future

reference .

•This product is spcialized for stomatology treatment abnormal,don’t use it in

other ways.

•This product is only for doctors.

•Every time you use it,please check first.If find anything unnormal,stop using

immediately,and contact your supplier or our after-sales center for details.

•Before operating low speed handpiece,pull contra angle handpiece with

hand to make sure handpiece connect firmly and safely.

•Head can not running without insert bur,otherwise head or motor would be

damaged.

•Ensure working pressure before running,Air pressure for four bole air motor

is 0.3Mpa,for two hole air motor is 0.25Mpa.

•Don’t immerse handpiece in any chemical solvent or solution or by dry-heat

disinfection.Sterilization by autoclave at(135±2)°C&0.22MPa is sugguested.

2

Product Composition

(CX235-1C)

Push button

Optic fiber

(CX235-1B)

Push button

Fig.1

Optic fiber

(CX235-1E)

Push button

Generator inside

1:1

1:1

1:1

LED contra angle with generator

Optic fiber contra angle

LED bulb

Inner channel1:1

Φ2 .35

Φ2 .35 Φ 2.35

Inner channel1:1

3

(CX235-1G)

1:1

contra angle

Push

button

Use the attached wrench to remove the cap[Fig.2.2].

Use the bur to push out the cartidge.

Insert the new cartridge into handpiece head,being sure the small raised

part aligns the groove inside the front of the head,to insure proper fit.

Loosen the small screw on the curving part ,move the head cover and remove

the transmission gear[Fig.2.1].

Fig.2.2 Fig.2.4Fig.2.3

1:1

Cartridge Replacement

•Inner channel contra angle low speed handpiece ;

•Burs:for CA burs Φ2.35;

•Max.speed of contra angle:40000rpm

Inner channel1:1

4

Fig.2.1

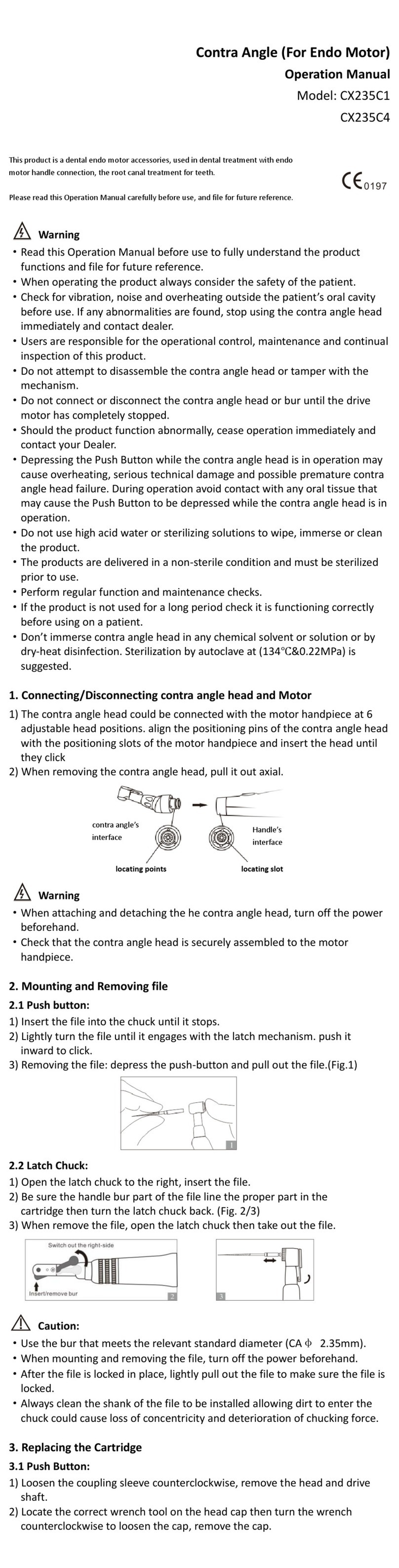

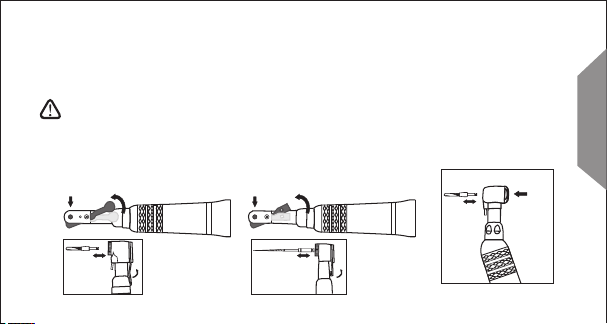

Contra angle and motor connections

1. Straightly insert the motor into the connection of contra angle, until you

hear a “cracking" sound can be.

2. Hold the bending machine and pull out the motor, it will be separated[fig.3.2].

3.Alignment the groove,contra angle can insert into the air motor[fig.3.3].

Fig.3.2

optic fiber

Optic Fiber Contra angle

Bur size:Ø2.35

Optic Fiber/LED Air motor

1:1 drive

Fig.3.4

Contra angle(CX235-1B)

Bur size:Ø2.35 Air motor(CX235-3B)

1:1 drive

Fig.3.3

(CX235-1C) (CX235-3C/CX235-3D)

Fig.3.1

Contra angle with generator

(CX235-1E) Bur size:Ø2.35 Air motor(CX235-3B)

1:1 drive

Inner channel1:1

5

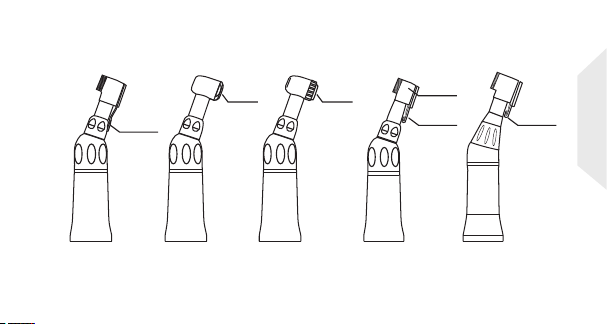

2.contra angle head technical parameters

Model Rotate head BUR

CX235CH-1 /2 max.40,000rpm for CA burs Φ2.35

CX235CH-3 /4 max.40,000rpm for CA burs Φ2.35

CX235CH-6 /7 max.40,000rpm for use files

CX235CH-13 max.30,000rpm forCA burs Φ2.35

360° reciprocating rotate head360° reciprocating rotate head

360° reciprocating rotate head

Fig.1.2

Fig.1.1 Fig.1.4

Fig.1.3

10.7mm

CX235CH-15/16 max.3,000rpm forCA burs Φ2.35

EXTERNAL CHANNEL

6

CX235CH-17 max.40,000rpm for CA burs Φ2.35

Fig.1.6

7

2.Special head movement technical parameters

Model Rotate head BUR

CX235CH-10 90° reciprocating for CA burs Φ2.35/prophylaxis brush

CX235CH-11 Up and down movement for CA burs Φ2.35/the crevices knife

CX235CH-12 60° reciprocating for use files

Fig.1.5

90° reciprocating rotate head

90°

Up and down mov ement

60° reciprocating rotate head

60°

Internal spray nozzle

Irrigation tube

wate r outlet wate r outlet

Inte rnal spra y nozzle

Irri gation tu be

Fig.1.8

Fig.1.7 Fig.1.9

CX235CH-9 360° reciprocating forCA burs Φ2.35/implant files

CX235CH-14 360° reciprocating forCA burs Φ2.35/implant files

EXTERNAL CHANNEL

Product Composition

4

Fig.2.4Fig.2.1

Push button

Latch plate

Fig.2.2 Fig.2.3

Push button

Latch plate

for FG burs Φ1.6.for CA burs Φ2.35 for CA burs Φ2.35 for CA burs Φ2.35

CX235C1-2 CX235C1-4 CX235C1-7 CX235C1-13

mini head

1:1 direct drive

1:1 direct drive

8

Fig.2.5

Latch plate

for CA burs Φ2.35

CX235-1F

4

Fig.2.6

Push button

Latch plate

Fig.2.7 Fig.2.8

Push button

Latch plate

for FG burs Φ1.6.for CA burs Φ2.35 for CA burs Φ2.35 for CA burs Φ2.35

Fig.2.8

CX235C2-1 CX235C2-3 CX235C2-6 CX235C2-13

mini head

•External contra angle low speed handpiece--1:1 Direct Drive

•Burs:for CA burs Φ2.35 ; for FG burs Φ1.6.

• CX235C1 Series; CX235C2 Series.

Φ2 .3 5

18°

Φ1 .6

18°

Fig.3.2

Φ1 9.6

Φ1 9.6

Fig.3.1

1:1 direct drive

9

Insert bur Switch out the rightside

1.Locking pin

Open the latch chuck,insert the bur,be sure the quadrate part of the bur

aline the proper part in the cartridge then turn the latch chuck back.

When remove the bur,open the latch chuck then take out the bur.

2.Push button

The fixed method of internal contra low speed handpiece is push button,

push the button to the end and then the bur can be get out of head.

press

Mounting of bur

Fig.3.3 Fig.3.4

Insert bur

NOTE:

1、Do not use a bending , cracking, deformation and unqualify bur. If using it,

may cause a it broken,or a flying off leading injured accident during operation

process.

2、make sure the bur lock tightly before operating.

1:1 direct drive

1 0

Product Composition

Fig.4.1 Fig.4.2 Fig.4.3

Prophylaxis

Push button

Latch plate

4:1 reduction 4:1 reduction

4:1 reduction

Fig.4.4 Fig.4.5 Fig.4.6

Latch plate Latch plate

CX235C3-13 CX235C3-10 CX235C3-11

up and down

movement

mini head

90° reciprocation

rotate

CX235C3-1 CX235C3-4 CX235C3-8

4:1 reduction

4:1 reduction

Ø5.27

1 1

Insert bur Switch out the rightside

1.Locking pin

Open the latch chuck,insert the bur,be sure the quadrate part of the bur

aline the proper part in the cartrdge then turn the latch chuck back.

When remove the bur,open the latch chuck then take out the bur.

2.Push button

The fixed method of internal contra low speed handpiece is push button,

push the button to the end and then the bur can be get out of head.

press

Mounting of bur

Fig.5.1 Fig.5.2

Insert bur

press

Insert bur

Fig.5.3 Fig.5.4

4:1 reduction

1 2

3.Prophylaxis

Mounting and Removing the Rubber Cup/Brush

Mounting

1)Insert the rubber cup/brush into a screw hole of the handpiece head.

2)Turn rubber cup/brush in a colckwise direction to fix the screw shank.

Removing

Perform a reverse procedure of Mounting. Turn the Rubber cup/brush

way of “Loosen”dirction.

rubber cup

/brush

Fig.6.1 Fig.6.2

4:1 reduction

1 3

Φ19 .6

18°

push button

hand use file 10:1reduction hand

Product Composition

10:1 Reduction

CX235C5-12

Mounting and Removing File

Insert the hand use files

press

NOTE:

1-Do not connect or disconnect the handpiece until

the drive motor has completely stopped.

2-After the file is locked in place, lightly pull

out the file to make sure the file

is locked. Fig.7.1

10:1 reduction

1 4

Fig.7

Product Composition

Fig.8.1 Fig.8.2

Push button

Latch plate

Fig.8.5 Fig.8.6 Fig.8.7

Latch plate

CX235C4-13 CX235C4-10 CX235C4-11

up and down

movement

mini head

90° reciprocation

rotate

External

spray nozzle

Latch

plate

Push

button

Push button

External

spray nozzle

16:1 Reduction

Fig.8.8

CX235C4-9 CX235C4-14

Fig.8.4

CX235C4-2 CX235C4-4

16:1 reduction

1 5

Insert bur Switch out the rightside

1.Locking pin

Open the latch chuck,insert the bur,be sure the quadrate part of the bur

aline the proper part in the cartrdge then turn the latch chuck back.

When remove the bur,open the latch chuck then take out the bur.

2.Push button

The fixed method of internal contra low speed handpiece is push button,

push the button to the end and then the bur can be get out of head.

press

Mounting of bur

Fig.9.1 Fig.9.2

Insert bur

press

Insert bur

Fig.9.3 Fig.9.4

push button

16:1 reduction

1 6

Fig.9.5

Product Composition

Fig.10.1 Fig.10.2

Latch plate

20:1

reduction 20:1 reduction

Latch plate

External

spray nozzle Push

button

20:1

reduction

MINI head

Fig.10.3

CX235C6-9 CX235C6-14 CX235C6-13

20:1 Reduction

20:1 reduction

1 7

Fig.10.4

20:1

reduction

External

spray nozzle

CX235C6-19

Insert bur Switch out the rightside

Locking pin

Open the latch chuck,insert the bur,be sure the quadrate part of the bur

aline the proper part in the cartrdge then turn the latch chuck back.

When remove the bur,open the latch chuck then take out the bur.

Mounting and Removing Bur

Insert bur Switch out the rightside

NOTE:

1-Do not connect or disconnect the handpiece until the drive motor has

completely stopped.

2-After the file is locked in place, lightly pull out the bur to make sure

the bur is locked.

Fig.11.2

Fig.11.1

push button

Fig.11.3

20:1 reduction

1 8

Mounting the”Y”type water tube

Three irrigation methods are available; External,

Internal or both External and Internal, depending

on tool and operation procedure.

External spray nozzle

irrigation Tube

(1) External Spray Nozzle

Connect the Irrigation Tube to the External

Spray Nozzle firmly. Fig.12.1

(2) Internal Spray Nozzle

Only a drill with internal irrigation is used.

1-Connect the Irrigation Tube to the Internal Spray Nozzle firmly.

2-Put the Internal Spray Nozzle into the slot on the head.

(3) External and Internal Irrigation together

Only a drill with internal irrigation is used.

1-Connect the ends of the Y-Connector to the External Spray Nozzle and

Internal Spray Nozzles refer as detailed in procedures (1) and (2).

2-Connect the Irrigation Tube to the Y-Connector firmly.

(locking pin)

1 9

Other manuals for CX235

2

This manual suits for next models

4

Table of contents

Other Coxo Dental Equipment manuals