CPC 485 User manual

026-1701 Rev 0 01-05-98

CPC Peripherals

Installation and

Operation

Computer Process Controls, Inc.

1640 Airport Road Suite #104

Kennesaw, GA 31044

Phone (770) 425-2724

Fax (770) 425-9319

ALL RIGHTS RESERVED

The information contained in this manual has been carefully checked and is believed

to be accurate. However, Computer Process Controls, Inc. assumes no responsibility

for any inaccuracies that may be contained herein. In no event will Computer Process

Controls, Inc. be liable for any direct, indirect, special, incidental, or consequential

damages resulting from any defect or omission in this manual, even if advised of the

possibility of such damages. In the interest of continued product development, Com-

puter Process Controls, Inc. reserves the right to make improvements to this manual,

and the products described herein, at any time without notice or obligation.

Peripherals Manual Table of Contents • i

Table of Contents

INTRODUCTION............................................................................................................................................................. 1

485 ALARM PANEL........................................................................................................................................................ 3

OVERVIEW........................................................................................................................................................................... 3

Features .......................................................................................................................................................................... 3

INSTALLATION ..................................................................................................................................................................... 3

Mounting......................................................................................................................................................................... 3

Power Wiring.................................................................................................................................................................. 4

Power Jumpers................................................................................................................................................................ 4

Network Wiring............................................................................................................................................................... 4

Network Terminating Resistance Jumpers...................................................................................................................... 4

Device ID Numbering ..................................................................................................................................................... 4

Baud Rate........................................................................................................................................................................ 5

Printer Setup................................................................................................................................................................... 5

Audible Annunciation...................................................................................................................................................... 5

Setting the Clock ............................................................................................................................................................. 6

OPERATION.......................................................................................................................................................................... 7

Modes of Operation ........................................................................................................................................................ 7

Acknowledging and Resetting Alarms............................................................................................................................. 7

Displaying Alarms........................................................................................................................................................... 7

Network Loss................................................................................................................................................................... 7

Clearing Alarms.............................................................................................................................................................. 7

RS232 BUS AMPLIFIER (P/N 812-1800) ...................................................................................................................... 9

OVERVIEW........................................................................................................................................................................... 9

Features .......................................................................................................................................................................... 9

INSTALLATION ..................................................................................................................................................................... 9

Power .............................................................................................................................................................................. 9

Location .......................................................................................................................................................................... 9

Mounting......................................................................................................................................................................... 9

System Connections....................................................................................................................................................... 10

SYSTEM DESCRIPTION ....................................................................................................................................................... 11

Indicator Lights............................................................................................................................................................. 11

System Override Buttons............................................................................................................................................... 12

MODEM (P/N 370-9600)................................................................................................................................................ 13

OVERVIEW......................................................................................................................................................................... 13

HARDWARE SETUP ............................................................................................................................................................ 13

SOFTWARE SETUP.............................................................................................................................................................. 13

CHECKIT REFRIGERATION SYSTEM MONITOR (P/N 508-2000).................................................................... 15

OVERVIEW......................................................................................................................................................................... 15

Features ........................................................................................................................................................................ 15

INSTALLATION ................................................................................................................................................................... 15

Location ........................................................................................................................................................................ 15

Orientation................................................................................................................................................................... 15

SET-UP ............................................................................................................................................................................... 16

Board and Point Settings .............................................................................................................................................. 16

Set Points and Time Delays .......................................................................................................................................... 16

ii • Table of Contents 026-1701 Rev 0 01-05-98

Other Environmental Management Systems................................................................................................................. 17

DEW CELL DEW POINT PROBE (P/N 203-1902).................................................................................................... 19

OVERVIEW ......................................................................................................................................................................... 19

MOUNTING......................................................................................................................................................................... 19

WIRING .............................................................................................................................................................................. 19

SOFTWARE SETUP.............................................................................................................................................................. 20

Input Board and Point Configuration........................................................................................................................... 20

Sensor Control Setup..................................................................................................................................................... 20

LIGHT LEVEL SENSOR (P/N 206-0002).................................................................................................................... 21

OVERVIEW ......................................................................................................................................................................... 21

MOUNTING......................................................................................................................................................................... 21

WIRING .............................................................................................................................................................................. 21

SOFTWARE SETUP.............................................................................................................................................................. 22

Input Board and Point Configuration........................................................................................................................... 22

Sensor Setup.................................................................................................................................................................. 22

INDOOR RELATIVE HUMIDITY SENSOR (P/N 203-5750)................................................................................... 23

OVERVIEW ......................................................................................................................................................................... 23

INSTALLATION ................................................................................................................................................................... 23

Mounting the Indoor RH Sensor ................................................................................................................................... 23

WIRING .............................................................................................................................................................................. 23

SOFTWARE SETUP.............................................................................................................................................................. 24

Input Board and Point Configuration........................................................................................................................... 24

Sensor Control Setup..................................................................................................................................................... 24

OUTDOOR RELATIVE HUMIDITY SENSOR (P/N 203-5760)............................................................................... 25

OVERVIEW ......................................................................................................................................................................... 25

INSTALLATION ................................................................................................................................................................... 25

WIRING .............................................................................................................................................................................. 25

SOFTWARE SETUP.............................................................................................................................................................. 26

Input Board and Point Configuration........................................................................................................................... 26

Sensor Control Setup..................................................................................................................................................... 26

REFRIGERANT TRANSDUCER (P/N 809-1550)...................................................................................................... 27

OVERVIEW ......................................................................................................................................................................... 27

Features......................................................................................................................................................................... 27

INSTALLATION ................................................................................................................................................................... 27

Power ............................................................................................................................................................................ 27

Location......................................................................................................................................................................... 28

Mounting ....................................................................................................................................................................... 28

System Connections....................................................................................................................................................... 28

SYSTEM DESCRIPTION ....................................................................................................................................................... 31

Programming the RMCC .............................................................................................................................................. 31

ECLIPSE PRESSURE TRANSDUCERS..................................................................................................................... 33

OVERVIEW ......................................................................................................................................................................... 33

DESCRIPTION...................................................................................................................................................................... 33

MOUNTING......................................................................................................................................................................... 34

INSTALLATION ................................................................................................................................................................... 34

SOFTWARE REQUIREMENTS FOR ECLIPSE‚ PRESSURE TRANSDUCERS .............................................................................. 35

STANDARD PRESSURE TRANSDUCERS................................................................................................................ 37

Peripherals Manual Table of Contents • iii

OVERVIEW ......................................................................................................................................................................... 37

DESCRIPTION ..................................................................................................................................................................... 37

Installation.................................................................................................................................................................... 38

SOFTWARE REQUIREMENTS............................................................................................................................................... 38

TEMPERATURE SENSORS ........................................................................................................................................ 39

OVERVIEW......................................................................................................................................................................... 39

MOUNTING AND LOCATION............................................................................................................................................... 39

Inside Temp Sensor....................................................................................................................................................... 39

Outside (Ambient) Temperature Sensor........................................................................................................................ 40

Temperature Probe for Duct and Walk-In Box............................................................................................................. 40

Insertion and Immersion Probes................................................................................................................................... 40

Pipe Mount Sensors ...................................................................................................................................................... 41

OTHER SENSORS................................................................................................................................................................ 41

WIRING.............................................................................................................................................................................. 41

REFRIGERANT LIQUID LEVEL SENSOR (P/N 207-0100) ................................................................................... 43

OVERVIEW......................................................................................................................................................................... 43

INSTALLATION ................................................................................................................................................................... 43

SOFTWARE SETUP.............................................................................................................................................................. 43

REFRIGERANT LEVEL TRANSDUCER PROBE (P/N 207-1000)......................................................................... 45

OVERVIEW......................................................................................................................................................................... 45

INSTALLATION ................................................................................................................................................................... 45

SOFTWARE SETUP.............................................................................................................................................................. 45

TRANSFORMERS......................................................................................................................................................... 47

OVERVIEW......................................................................................................................................................................... 47

MATCHING TRANSFORMERS TO BOARDS .......................................................................................................................... 48

Power Requirements..................................................................................................................................................... 48

FUSING SPECIFICATIONS.................................................................................................................................................... 48

TRANSFORMER WIRING DIAGRAMS .................................................................................................................................. 48

Wiring the 16AI, 8RO, 4AO, or 8DO............................................................................................................................ 49

Wiring the 8IO Board ................................................................................................................................................... 49

SAIL SWITCHES........................................................................................................................................................... 53

OVERVIEW......................................................................................................................................................................... 53

SPECIFICATIONS................................................................................................................................................................. 53

MOUNTING & WIRING THE S437A & S637A................................................................................................................... 53

S437A ............................................................................................................................................................................ 54

S637A ............................................................................................................................................................................ 54

Peripherals Manual Introduction • 1

Introduction

This manual describes how to wire and configure various peripheral devices that are commonly used with CPC control

networks. Each section gives a brief overview of the device and provides device specifications. Sections also include in-

formation on installing (mounting and wiring) and configuring the device within the proper CPC controller (RMCC, BCU,

BEC).

Peripherals Manual 485 Alarm Panel • 3

485 Alarm Panel

For 120/240 VAC–P/N 811-4850

For 24 VAC–P/N 811-4855

Overview

One of the most important requirements ofany network

environment is its ability to notify personnel of system fail-

uresorpossibleproblems.REFLECScontrolsare designed

with sophisticated logging, graphing, notification, and

alarming features that put system data at the fingertips of

the service technician or store manager. However, no net-

work is complete without the basic ability to provide an-

nunciated alarms in the event of serious system problems.

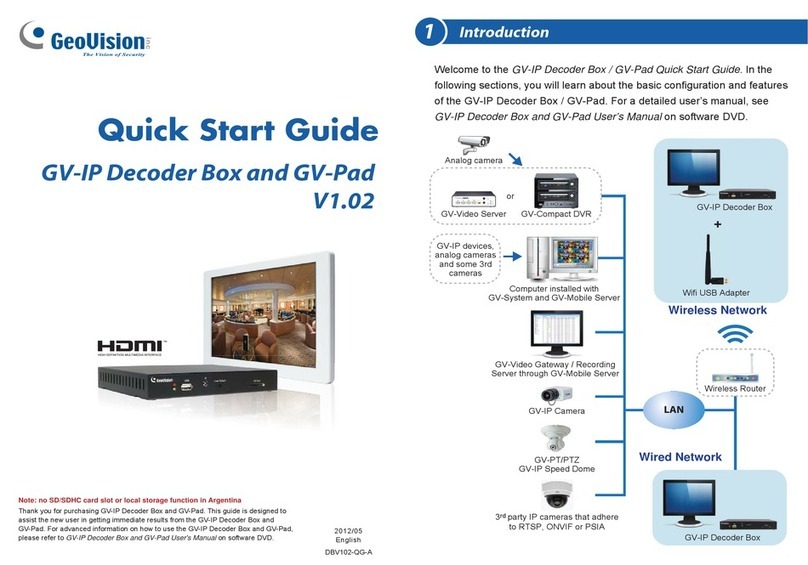

CPC uses the 485 Alarm Panel (Figure 1) to accom-

plish this task. The 485 Alarm Panel is linked to all RE-

FLECS Controllers through the RS485 COM B Host

Network. Although the alarm panel has many features that

make it a powerful notification tool, the primary and most

important function of the alarm panel is to receive signals

from the REFLECS and deliver an alarm annunciation.

The REFLECS constantly compares real time system

conditions against user-defined alarm set points. When a

systemreadingfallingoutsideofthesesetpointsisdetected

by the REFLECS, a signal is sent to the alarm panel, which

in turn emits an alarm signal and displays the alarm infor-

mation on the notification screen.

Features

•Alarmreset

• Date and time adjustment

• Storage of twenty separate alarms

• Audible annunciation can be set to either pulsed

or continuous mode

• Interfaces with existing facility alarm system

• 25-pin parallel printer interface port.

Installation

Mounting

The 485 Alarm Panel is supplied with four mounting

holes in the rear panel of the enclosure. These holes are ac-

Figure 1 - 485 Alarm Panel

LEGEND

Date/Time Button

Alarm Reset Button

Screen Scroll Buttons LED Power Indicator

LCD Alarm Screen

LED Alarm Indicator

1

2

3

4

5

6

1

2

3

4

5

4 • 485 Alarm Panel 026-1701 Rev 0 01-05-98

cessible without removal of any boards inside the enclo-

sure. Figure 2 shows the enclosure dimensions and weight.

Power Wiring

Connect the 485 Alarm Panel to the power supply at the

threeterminalslabelledPOWERIN.Connectthe ground to

terminal G, the neutral to terminal N, and the hot wire to

terminal H.

Power Jumpers

If 120VAC power is being used, set jumpers JU1 and

JU2 to the DOWN position as shown in Figure 4 on page

6. If 208VAC power is being used, set jumpers JU1 and

JU2 in the UP position.

If you ordered the 24VAC alarm panel, jumpers JU1

and JU2 will be hard-wired to the correct position. No ad-

justment will be necessary.

Network Wiring

The 485 Alarm Panel connects to one or more RE-

FLECS units via the RS485 Host Network (COM B). Us-

ing a Belden #8641 or equivalent cable, connect the three

terminals labelled RS485 Network on the 485 Alarm Panel

to the three COM B terminals on the REFLECS Power In-

terface Board (PIB), as shown in Figure 3.

1. Using the RED wire, connect the positive ter-

minal (+) on the alarm panel to the positive

(+) terminal on COM B.

2. Using theBLACKwire,connect the negative

terminal (-) on the alarm panel to the negative

(-) terminal on COM B.

3. Connect the cable shield wire from the com-

mon terminal (0V) on the alarm panel to the

common (0V) terminal on COM B.

Network Terminating Resistance Jump-

ers

If the 485 Alarm Panel is connected to only one RE-

FLECS via its RS485 Network terminals, place jumpers

JU3, JU4, and JU5 in the UP position.

Otherwise, if the panel is connected in between two

REFLECS units (i.e. NOT at the end of the RS485 Host

Network), place jumpers JU3, JU4, and JU5 in the DOWN

position.

Device ID Numbering

The 485 Alarm Panel must be given a COM B network

device number. Refer to your REFLECS Installation and

Operation Manual for more details on COM B device num-

bering.

Rockers 1 through 5 on switch SW2 on the 485 Alarm

Panel board are used to set the 485 Alarm Panel’s device

number. To set the device ID, set the switches as shown in

Table 1.

Figure 2 - 485 Alarm Panel Mounting Dimensions

Figure 3 - COM B Wiring - REFLECS to 485 Alarm Panel

Peripherals Manual 485 Alarm Panel • 5

Baud Rate

Rockers 6 and7 on switch SW2on the 485Alarm Panel

determines the baud rate at which alarm messages will be

received acrossthe COM B network. The 485 AlarmPanel

can only communicate at 4800 baud; therefore, both

switches 6 and 7 must be set to the DOWN position as

shown in Figure 4.

Printer Setup

The 25-pin female socket located at the bottom of the

485 Alarm Panel (labelled DB25S) may be used to connect

a printer. Connecting a printer will allow the 485 Alarm

Panel to dump alarms to the printer in ASCII format.

To connect a printer:

1. Connecttheprinter’scommunicationcableto

DB25S.

2. Locate the Mode switch on the 485 Alarm

Panel board (labelled SW3). Switch rocker

#1 on SW3 to the UP (ON) position as shown

in Figure 4.

Audible Annunciation

The 485 Alarm Panel comes equipped with a buzzer

that can be configured tosound when analarm is present on

the controller. To enable this buzzer, locate the Mode

switch on the 485 Alarm Panel board (labelled SW3).

Switch rocker #2 on SW3 to the DOWN position as shown

in Figure 4.

ID ROCKER POSITION

12345

1 UPDNDNDNDN

2 DNUPDNDNDN

3 UPUPDNDNDN

4 DNDNUPDNDN

5 UPDNUPDNDN

6 DNUPUPDNDN

7 UPUPUPDNDN

8 DNDNDNUPDN

9 UPDNDNUPDN

10 DN UP DN UP DN

11 UP UP DN UP DN

12 DN DN UP UP DN

13 UP DN UP UP DN

14 DN UP UP UP DN

15 UP UP UP UP DN

16 DN DN DN DN UP

Table 1 - 485 Alarm Panel Dip Switch Settings

6 • 485 Alarm Panel 026-1701 Rev 0 01-05-98

Setting the Clock

To set the 485 Alarm Panel’s on-board clock:

1. Be sure that the display shows NO

ALARMS. If the display shows ALARMS,

the unacknowledged alarms will have to be

cleared before the clock can be set (see “Ac-

knowledging and ResettingAlarms,” page 7).

2. Pressand holddown the Time/Date buttonon

the front panel. Do not release the Time/Date

button until the clock is properly set.

3. Pressand releasethe Resetbutton onthe front

panel.

4. Use the arrow buttons to select the month.

5. Quickly press and release the Reset button.

The indicator onthe second line moves to the

DATE position.

6. Repeat steps 4 and 5 to set the day, hour,

minute, and AM/PM indicator.

7. When finished, quickly press and release the

RESET button.

Figure 4 - 485 Alarm Panel Board

) )

32:(5

-8 -8 -8

32:(5

$0392/7

25

$*&25

$*25

66

$/$50

$0392/7

25$*&

25$*25$

-803(5)259

:,7+'523&25'

-8 -8

56

1(7:25.

32:(5,1

*1+

$/$50

/, /2

32:(5

21

2)) 5(6,67$1&(

7(50,1$725

-803(56/2&$7(83

(1'326,7,21

21

2))

21

2))

6:

6:

1(7:25.

02'(

&2175$67

2)',63/$<

'%6)(0$/(

35,17(562&.(7

9

7232:(5 72&20%

2

2

3

3

4

4

5

5

6

7

8

1

1

Peripherals Manual 485 Alarm Panel • 7

8. Release the Time/Date button.

Operation

Modes of Operation

There are two basic modes of operation for the alarm

unit.

No Unacknowledged Alarms

When there are no unacknowledged alarms, the display

will show the date/time and the message NO ALARMS.

During this mode of operation, users may view the previ-

ous 20 alarm messages in the 485 Panel’s log by using the

UP and DOWN arrow keys (see “Displaying Alarms” for

information about viewing alarms).

Unacknowledged Alarms

When there are unacknowledged alarms, the display

will show the date/time and the message ALARMS. Press-

ing the arrow keys will display the unacknowledged

alarms. From this screen, you may also reset the unac-

knowledged alarms (see “Acknowledging and Resetting

Alarms” below for more).

Acknowledging and Resetting Alarms

When the unit receives an alarm message, the display

will show the word ALARMS, and the alarm LED will il-

luminate. The buzzer will sound if the 485 Alarm Panel is

set up to do so (see “Audible Annunciation,” page 5).

Pressing the Reset button once will silence the audible

alarm. At this time, users may view the new alarms by us-

ing the arrow keys (see “Displaying Alarms” for more spe-

cific instructions).

Once the conditions that caused the alarms have been

corrected, pressing the Reset button a second time will ac-

knowledge and reset all new alarms. The alarm messages

are saved in the 485 Alarm Panel’s memory as “old”

alarms. If an alarm reoccurs after it has been reset, the an-

nunciator will sound again.

Displaying Alarms

A single alarm message consists of four lines (two

screens) of information. The first two lines give informa-

tion about the time, date, and unit number for the alarm,

and the last two lines give a description of the alarm.

Since the 485 Alarm Panel display can only display two

lines at a time, users must use the arrow keys to view all

four lines of an alarm message.

Alarm messages may be thought of as a list on a sheet

of paper. The display is simply a window moving up or

down the page viewing the first two or the second two lines

of each alarm. Press the UP and DOWN arrow keys to

scroll through this list and view the alarms.

Pressing both arrow keys simultaneously will bring the

display back to the screen that says ALARMS or NO

ALARMS. From this screen, users may begin viewing

alarms again starting with Alarm #1.

Network Loss

If the 485 Alarm Panel loses communications, it will

turn on both the LED and audible alarms and display NET-

WORK DOWN on the display.This may be acknowledged

by pressing the Reset button. This error suggests a wiring

or switch setting problem.

If this error occurs, follow the checklist below:

• Check for loose cable connections at both the

RS485 NETWORK terminals on the 485 Alarm

Panel and the REFLECS COM B terminal(s).

• Ensure that the network cable is properly wired

(see “Network Wiring,” page 4).

• Check that the Device ID number chosen for the

485 Alarm Panel is not being used by another

unit on the network. Refer to “Device ID Num-

bering,” page 4.

• Check that the 485 Alarm Panel’s baud rate is set

to 4800 baud. Rockers 6 and 7 on switch SW2

should be in the DOWN (OFF) position. All

REFLECS units on the network must also have

their baud rates set to 4800 (refer to the unit’s

I&O Manual for more).

If the problem still exists after the above checklist has

been followed, contact CPC support.

Clearing Alarms

To clear all alarms from the 485 Alarm Panel’s memo-

ry, remove power from the panel by turning the power

switchOFForby unpluggingthepower cord,andpowerup

the unit while holding down all four buttons on the front

panel. All alarms will be cleared.

If the unit goes into CLOCK SET mode when powered

up,press theRESET button until NO ALARMS appears on

the display.

Peripherals Manual RS232 Bus Amplifier (P/N 812-1800) • 9

RS232 Bus Amplifier (P/N 812-1800)

Overview

The RS232 Bus Amplifier (P/N 812-1800), shown in

Figure 5, is used to connect CPC products together as an

integrated communications system. Communication prob-

lems sometimes associated with large computer systems—

such as limited cable lengths, data rate limitations, and ter-

minal and modem communication interference—are elim-

inated through the use of the RS232 Bus Amplifier

Features

• Allows the use of long cable runs

• Works with high data rates (9600 baud) Allows

for remote modem set-up

• Eliminates modem interference while using the

local terminal

• Eliminates terminal interference when accessing

the site from a remote computer

• Improves local terminal data retrieval from CPC

products

• Eliminates the use of custom cables for modems

and local terminals

Installation

Power

Power is supplied to the RS232 Bus Amplifier through

a standard power cord, allowing the amplifier to use the

same wall outlet as the modem and local terminal. The

RS232 Bus amplifier may be powered by 120 volts or 208

to 250 volts. An internal jumper selects which voltage

range will be used. AC power may be either 50hz or 60hz.

Location

Although there are no specific location requirements

for installation of the RS232 Bus Amplifier, it is recom-

mended that the amplifier be located close to the bussed

CPC controllers to prevent data loss over long cable

lengths. It is also recommendedthat the bus amplifier be lo-

cated adjacent to the modem and, if present, the local com-

puter terminal to provide easy access to all components

necessary for refrigeration system monitoring.

Mounting

To mount the RS232 Bus Amplifier, an installation en-

velopeeightinches wide,nineinches high,andthreeinches

deep is required.

1. Remove the four front panel screws.

2. Remove the front panel (with circuit board at-

tached)

3. Mount the empty amplifier body with the

plain edge down using four #8 (4mm) or #10

(5 mm) screws.

4. Remount the front panel.

.

Figure 5 - RS232 Bus Amplifier

10 • RS232 Bus Amplifier (P/N 812-1800) 026-1701 Rev 0 01-05-98

System Connections

The RS232 Bus Amplifier can be connected to the ex-

isting refrigeration system in a variety of ways depending

upon the relative proximity of the compressor racks, other

CPC controllers, and the local computer terminal to each

other.

Table 2 provides a brief description of the RS232 Bus

Amplifier ports, connecting components, and the cable

type required for system connection:

Single-Amplifier Layout

In general, the RS232 Bus Amplifier will be installed in

close proximity to the CPC controllers, modem, and local

computer terminal. Figure 6 shows this layout.

If the CPC controllers, modem, and local computer ter-

minal are located adjacent to one another, connect the

RS232 Bus Amplifier to the system as follows:

1. Connect the modem to the REMOTE MO-

DEM PORT usinga standard 9-pin to 25-pin

cable.

2. Connect the computer terminal to the TER-

MINAL PORT using a standard 9-pin to 25-

pin cable.

3. Connect the bussed CPC controllers to the

SYSTEM SHORT BUS PORT using a

Belden #8771 (three conductor shielded

22AWG) cable.

4. Connect any stand-alone CPC controller

(such as a BEC) to the SYSTEM LONG

LINE 1 OUT PORT using a Belden #8771

(three conductor shielded 22AWG) cable.

Two-Amplifier Layout

In some cases, location of the modem and local termi-

nal will not allow location of the bus amplifier to both the

modem and local terminal and the CPC controllers. Since

data loss is possible when multiple CPC controllers trans-

mit data over long cable lengths, it may be necessary to

connect the CPC controllers to a remote amplifier adjacent

Port Description Cable Type

Terminal Local Computer Ter-

minal Standard 9-25 pin

Modem

(Remote) Modem

Satellite Standard 9-25 pin

Determined by satel-

lite system

Long

Line In

(Remote)

Laptop Computer

RemoteBusAmplifier

to Main Bus Amplifier

DB9 REFLECS Lap-

top Cable (P/N 535-

1190)

Belden #8771 (Three

Conductor Shielded

22AWG)

Long

Line 1

Out

Stand-alone CPC Con-

troller

Main Bus Amplifier to

Remote Bus Amplifier

Belden #8771 (Three

Conductor Shielded

22AWG)

Long

Line 2

Out

Stand-alone CPC Con-

troller

Main Bus Amplifier to

Remote Bus Amplifier

Belden #8771 (Three

Conductor Shielded

22AWG)

ShortBus

(System) Multiple Bussed CPC

controllers Belden #8771 (Three

Conductor Shielded

22AWG)

Table 2 - RS232 Bus Amplifier Port and Cable Description

Figure 6 - Typical Single-Amplifier Layout

Peripherals Manual RS232 Bus Amplifier (P/N 812-1800) • 11

to the controllers, and then connect the remote amplifier to

a main amplifier connected to the modem and local termi-

nal. This two-amplifier installation is shown in Figure 7.

If the CPC controllers, modem, and local computer ter-

minal are not located adjacent to one another, install a re-

mote and main RS232 Bus Amplifier as follows:

1. Install the main RS232 Bus Amplifier adja-

cent to the modem and local computer termi-

nal as described in steps 1 and 2 above.

2. Install the remote RS232 Bus Amplifier adja-

cent to the bussed CPC controllers as de-

scribed in steps 3 and 4 above.

3. Connect the main bus amplifier to the remote

bus amplifier using a Belden #8771 (three

conductor shielded 22AWG) connected to

the SYSTEM LONG LINE 1 OUT PORT on

the main bus amplifier, and the REMOTE

LONG LINE IN PORT on the remote bus

amplifier.

System Description

Once connected to the system and a power source, the

RS232 bus amplifier will automatically perform the func-

tions necessary to improve system performance and com-

munication. However, there are a number of status lights

that will provide useful information concerning amplifier

operation and aid in troubleshooting if necessary. A brief

description of these indicators is provided below:

Indicator Lights

Power

A single green light to the left of the power switch illu-

minates when power is being supplied to the RS232 Bus

Amplifier.

System Data To Lights

The red SYSTEM DATA TO light, shown in Figure 4,

flashes when data arebeing transmitted to a CPC controller

or additional bus amplifier. If no data arebeing transmitted,

the green light remains illuminated. These lights are asso-

ciated with the RX output of each SYSTEM PORT.

System Data From Lights

TheredSYSTEMDATAFROMlight,showninFigure

4, flashes when data are being received from a CPC con-

troller or additional Bus amplifier. If no data are being re-

ceived, the green light remains illuminated. These lights

are associated with the TX input of each SYSTEM PORT.

System Data Terminal Ready (DTR) Lights

The red SYSTEM DTR light, shown in Figure 4, illu-

minates when DTR is on. The green light illuminates when

the DTR OFF command is received from any CPC control-

ler or other bus amplifier. These lights are associated with

the DTR input of each SYSTEM PORT.

Remote Data From Lights

The red REMOTE DATA FROM light, shown in Fig-

ure 4, flashes when data are being received from the MO-

DEM PORT or the LONG LINE IN PORT. If no data are

being received from the modem, the green light remains il-

luminated. These lights are associated with the RX input of

the REMOTE LONG LINE IN PORT and REMOTE MO-

DEM PORT.

Remote Data To Lights

The red REMOTE DATATO light, shown inFigure8,

flashes when data are being transmitted to the REMOTE

MODEM PORT or REMOTE LONG LINE IN PORT. If

no data are being transmitted to the modem, the green light

remains illuminated. These lights are associated with the

TX output of the REMOTE LONG LINE IN PORT and

REMOTE MODEM PORT.

Figure 7 - Typical Two-Amplifier Layout

12 • RS232 Bus Amplifier (P/N 812-1800) 026-1701 Rev 0 01-05-98

System Override Buttons

Terminal Keyboard Button

The TERMINAL KEYBOARD button, shown in Fig-

ure 5, allows the user to regain use of the local terminal

when the modem is on-line. If the accompanying yellow

light is illuminated--indicating that the terminal has been

locked out by the modem-- pressing the TERMINAL

KEYBOARD button will allow use of the local terminal

keyboard while the modem is on-line. If the modem is off-

line, pressing the TERMINAL KEYBOARD button will

have no effect on the system.

Terminal to Modem Button

The TERMINAL TO MODEM button, shown in Fig-

ure 9, allows the user to disconnect the modem and local

terminal from the CPC controllers. By pressing the TER-

MINAL TO MODEM button, the user can either program

the modem or communicate with another computer termi-

nal. The accompanying yellow light will remain illuminat-

ed until the button is pressed again--reconnecting the

terminal and modem to the system, or if the terminal key-

board is not used for twenty (20) seconds. When the termi-

nal and modem are connected to the system, the

accompanying green light remains illuminated.

Figure 8 - System Indicator Lights

Figure 9 - System Override Buttons

Other manuals for 485

1

Table of contents

Other CPC Security System manuals

Popular Security System manuals by other brands

Spot Hug

Spot Hug GPS SECURITY SYSTEM user manual

Bosch

Bosch ISC-FPB1-W60QS Installation and operation guide

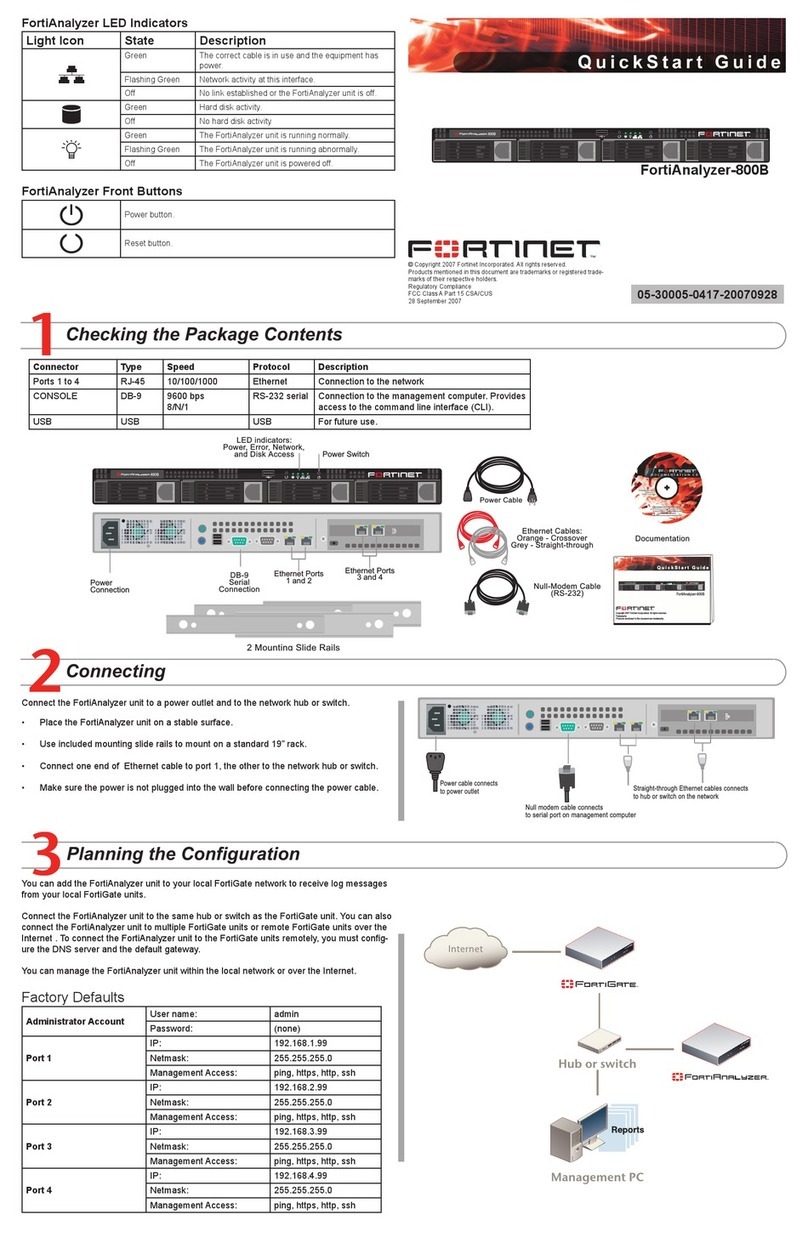

Fortinet

Fortinet FortiAnalyzer-800B quick start guide

Night Watcher

Night Watcher NW700 user guide

Whelen Engineering Company

Whelen Engineering Company 295HFSA5 installation guide

EDM

EDM Solution 8 installation manual