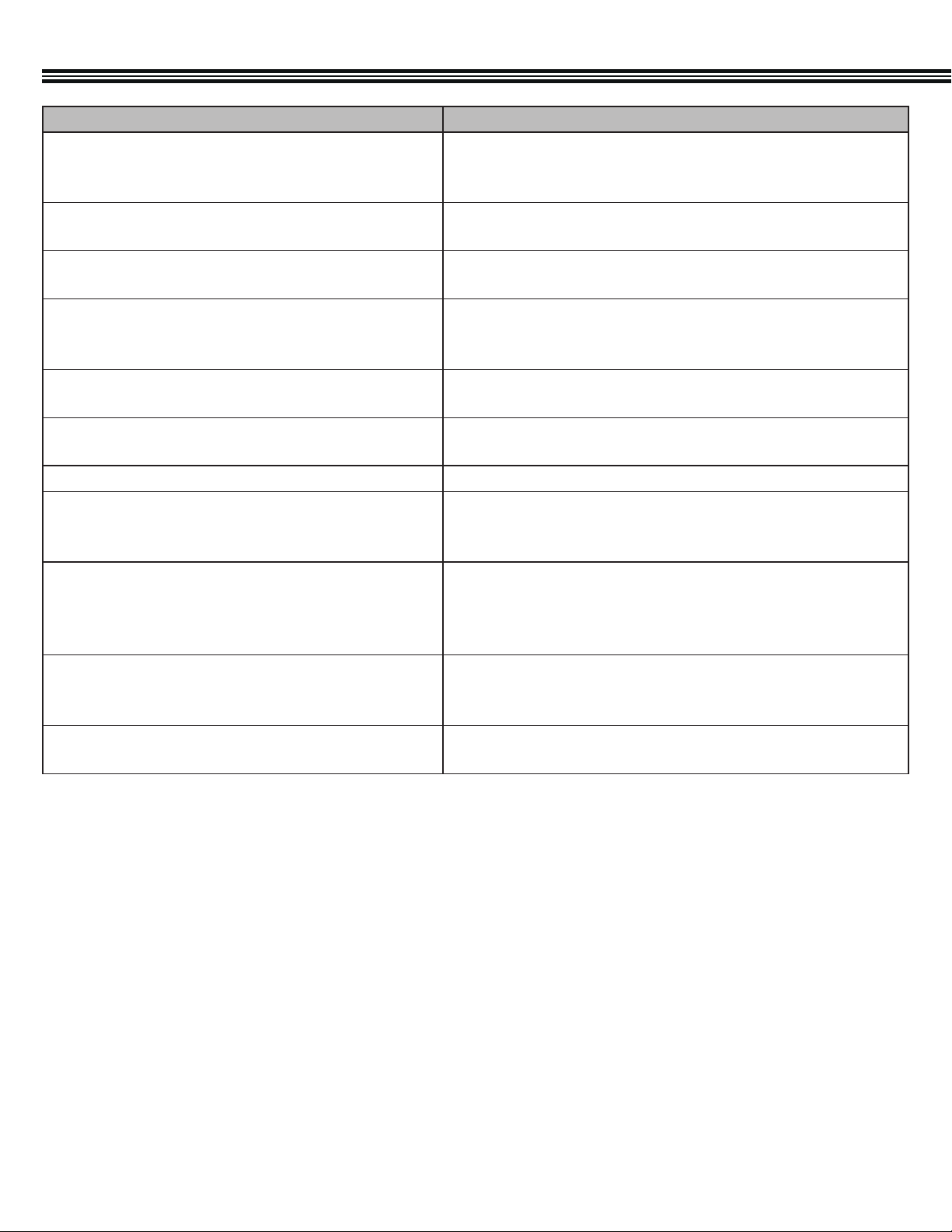

CONTENTS

General Safety Instructions...........................................4

Product Registration......................................................5

Agency Approvals, Standards, Patents ........................5

Overview ........................................................................5

Key Features / Benefits .................................................6

Optional Accessories ....................................................6

Specifications ................................................................7

MX1234 Machine........................................................ 7

Vacuum Pump ............................................................ 7

Refrigerant Scale........................................................ 7

30 Lb Recovery Tank ...................................................8

50 Lb Recovery Tank (Optional) ...................................8

Refrigerant Cylinder Heater Blanket (Optional) ...........8

Machine Layout ............................................................ 9

Quick Start Guide.........................................................11

Overview (Primary Touch Screen Keys)..................... 12

Home ....................................................................... 12

Touch Keys & Information Icons ............................... 12

Print Key, Help Menu ............................................... 13

Machine Upkeep ...................................................... 14

Setup Functions........................................................ 14

Maintenance Menu................................................... 14

Hybrid Vehicle Key ................................................... 15

Setup ...........................................................................16

Set Language ........................................................... 16

Set Units of Measure ............................................... 16

Set Tank & Refrigerant Weights ............................... 17

Job Tracker .............................................................. 18

Wireless Device Setup.............................................. 19

Set Date Or Time....................................................... 20

Online Registration/Warranty .................................. 21

Shop Information.......................................................22

Select SAE Or Global Standards ............................... 23

Operation .....................................................................24

Refrigerant Recovery ............................................... 24

A/C System Evacuation ............................................ 26

Refrigerant Charging ............................................... 27

Full Cycle ................................................................. 29

Refrigerant Tank Refill ............................................. 30

Maintenance ...............................................................32

Filter/Dryer Change ................................................. 32

Vacuum Pump Oil Change (Frequency) .................... 34

Oil Change Procedure ...............................................34

Pro-Set® Premium Vacuum Pump Oil ......................34

Refrigerant Charging Scale ..................................... 35

Pressure Transducer ................................................ 36

Tare Pressure Transducer .........................................36

Calibrate Pressure Transducer ..................................37

Air Purge .................................................................. 38

Diagnostics of Valves, Controls, Scale ..................... 39

Software Upgrade..................................................... 40

Touch Screen Display Calibration ............................. 40

Car System Health Mode ............................................ 42

Corded Temperature Probe (Included Accessory)........ 43

A/C Database For North American Vehicles .............. 44

Flush Refrigerant Hoses .............................................45

Job Tracker .................................................................45

APPENDIX

Touchscreen Icon Library............................................46

MX Error Codes............................................................48

Replace Parts ..............................................................48

Warranty ......................................................................49

A/C Database End-User License Agreement ..............50

CPS Company Locations .............................................51