INTRODUCTION

Congratulations! You are in possession of the most advanced and powerful

(yet simple to operate) multi-pressure diagnostic leak test machine available.

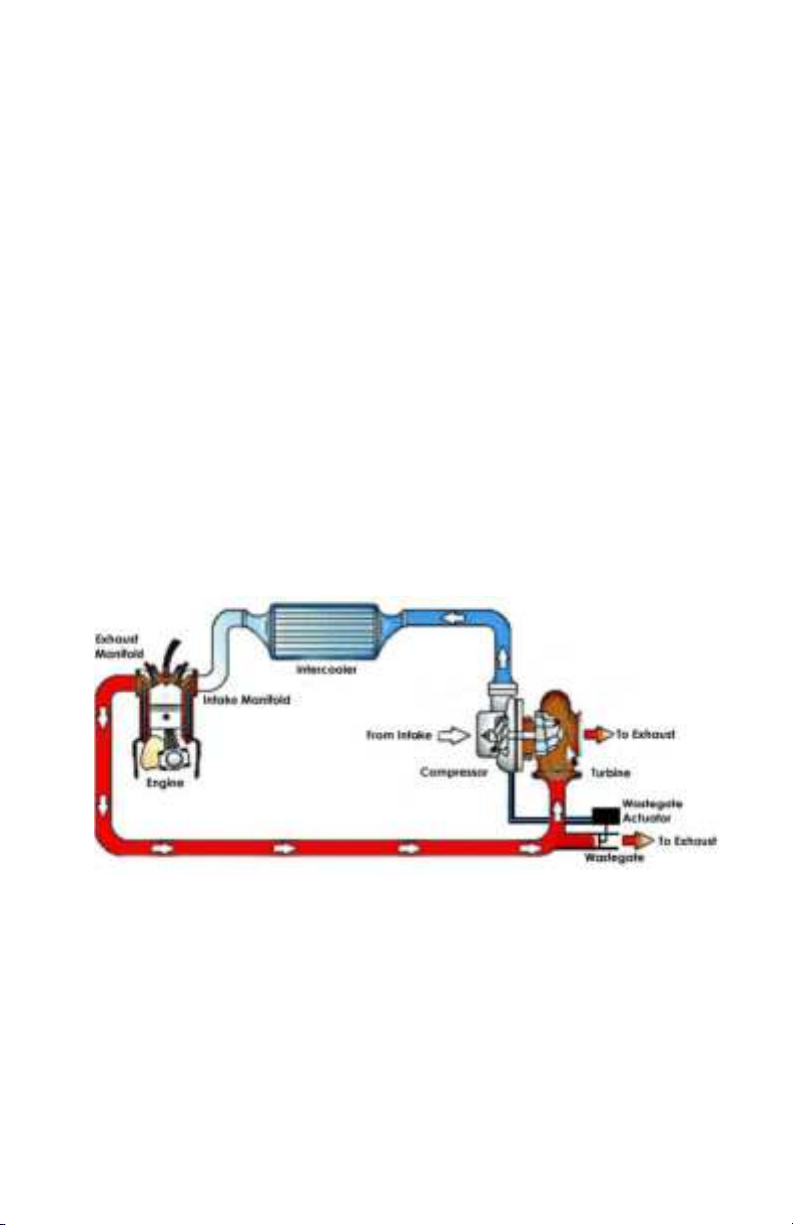

Our patented MotorVac® Cool Smoke® “no heat” technology creates a high

volume, smoke-like vapor eliminating the need for high temperature glow plugs

or resistance coils. The Cool Smoke® MP was specifically developed to OEM

specifications for diagnosing leaks in high pressure air systems such as turbo

chargers and charge air coolers. The Cool Smoke® MP can be used to not only

determine if there is a leak in a system and pinpoint its location, it can also

determine the actual size of the leak allowing the technician to decide whether

a repair is necessary.

The MotorVac® Cool Smoke® MP uses advanced dynamically controlled pneumatics

and microprocessor technology to determine the actual leak size throughout the

entire operational pressure range. The Cool Smoke® fluid will deposit ultraviolet

(UV) dye at the location of small leaks where it would be difficult to see smoke.

The MotorVac® Cool Smoke® MP comes with both a powerful UV light to easily

locate the UV dye deposits at leak points, as well as a powerful white light to

locate the smoke at visible leak points.

The MotorVac® Cool Smoke® Fluid is a unique solution that allows for highly visible

vapor (smoke) to carry UV dye to leak points. The UV dye will be deposited at small

leak locations where the smoke is forced out during a test. Your MotorVac Cool

Smoke MP can perform smoke or leak tests between 3-60 psi (0.2-4.1 bar) while in

MP mode and 0.5 psi (0.03 bar) while in EVAP mode. The MotorVac® Cool Smoke MP

comes prefilled with a charge of Cool Smoke® Fluid and is refillable by the end- user

when the smoke-producing solution is depleted. The smoke it produces, as well

as the UV dye, is non-toxic, solvent free and noncorrosive. The MotorVac® Cool

Smoke® MP needs no assembly and requires no maintenance.

Your MotorVac® Cool Smoke® automatically sets the critical pressure that must

be maintained during EVAP testing. You don’t need to set flow rates and you don’t

need to be concerned with ambient temperatures or barometric pressures. The

MotorVac Cool Smoke® is refillable by the end-user when the smoke-producing fluid

is depleted.

Please review this User Guide to become familiar with the Cool Smoke® MP and

all its features. Thank you for choosing the MotorVac® Cool Smoke® MP.

CPS Products Inc.