Craft Brew Water 500 User manual

Craft Brew Water

For questions and support call

CRAFT BREW WATER

500 User Manual

Craft Brew Water

For questions and support call

The Craft Brew 500 Reverse Osmosis water system is ideal for small commercial applications

requiring a consistent supply of high-quality water in a simple and compact package. Designed to

be a modular system using mostly common nonproprietary components which allows for cost

effective maintenance and the highest degree of reliability. The 500 can produce up to 500 gallons

of high-quality reverse osmosis water per day. Available with float switch control or stacked with

pressure tank.

Filtration Process

Mechanical Filtration- The USA made sediment prefilter reduces dirt, silt, rust and other sediment

in the water. It’s 5 µm nominal rating helps to give a maximum life to the carbon filtration step.

Activated Carbon w/Polyphosphate- Carbon reduces chlorine and the Polyphosphate reduces

scaling of the membranes.

Reverse Osmosis Membranes- The 500 GPD reverse osmosis membrane is designed to reduce the

dissolved mineral content of the water. In the Reverse Osmosis process, dissolved minerals are

separated from the incoming water to produce the product water (permeate). The excess

minerals are rinsed to the drain. The reverse osmosis membranes have a typical rejection of >

90%. The water is then stored in either an atmospheric tank or a pressurized storage tank for

future use.

Post Filtration- The most common post filter is a carbon block and it is designed to give the water

and enhance polished taste.

Ultraviolet Sanitization- The water passes through an ultraviolet chamber which reduces the

potential of bacteria, viruses and other microorganisms from contaminating the high quality

water.

Dual Digital TDS Meter- The Craft Brew 500 comes installed with a Dual Digital TDS Meter. This

allows you to monitor incoming feedwater and permeate product water.

Blending Valve- The Blending Valve allows you to brew with straight reverse osmosis water or

you can blend minerals back into your product water.

Craft Brew Water

For questions and support call

Installation

The Craft Brew 500 is designed for an easy installation. It can be wall hung or it can be installed on

the floor. The system has three John Guest push in connections and a float assembly for a

atmospheric tank.

1. Feedwater is connected to the first bulkhead on the right side labeled INLET. Use the red

3/8 tubing and the 3/8 ball valve included with the system. Connect one end to the unit

the other end to your feed water.

2. Install the float assembly into your atmospheric tank. The float has a 3/8 John guest

tubing fitting on the end.

3. The middle bulkhead labeled TANK, use the yellow 3/8 tubing and connect one end to the

middle bulkhead of the unit and the other to the float assembly.

4. The last bulkhead to be connected labeled DRAIN use the black 3/8 tubing and run that to

a sink or floor drain. Included is a saddle clamp to run to sink.

If wall hanging, the wall holes are set to the 16 inch center for easy hanging.

Included in the manual are a couple of drawings for installation.

Startup

After all connections have been made and unit is secure open your feed valve and flood the filters

with water. The system is now ready to be plugged in. The system is pressure switched controlled

and will start filling your tank immediately. Look inside the tank to make sure the tank is filling

properly. Lift float up and wait for unit to shut down. This should take one to two minutes. Make

sure your blending valve is off. After the system is running press the power button on the TDS

meter. You should see digital numbers representing TDS of the water, press the number two

button on the meter to see your product water quality. Make sure your blending valve is off.

TDS Meter and Blending Valve

The blending valve is designed to allow feedwater after the carbon filtration into your product

water. All product water blended or not will run through the ultraviolet. With your TDS meter on

and the number two button selected slowly open the blending valve. You will see the number rise

on the TDS meter. This gives the Brewer control over the quality of water they require for

brewing. You have the option to brew with straight RO or blended.

Craft Brew Water

For questions and support call

Pre-Filtration Maintenance

1. Pre-filter’s (Sediment and Carbon) should be change approximately every three months.

More often in high demand use. Sediment filter removes dirt, sand, and other debris

down to a 5 µm range. Regardless of how many gallons or a how the filter looks, regular

replacement is important in order to keep the system sanitary. The high-capacity carbon

block with polyphosphate core reduces chlorine and other chemicals and adds a scale

inhibitor to the water in order to extend the life and performance of the reverse osmosis

membrane. The carbon block has an estimated capacity of 20,000 gallons or three

months, whichever comes first.

2. To order filters click on the link:

https://www.craftbrewwater.com/products/20-x-2-5-3-pack-filter-set

3. To change the filters unplug the power and turn off the water supply to the system.

Depressurize the filters, do this with the water shut off. Plug in the unit for three seconds.

Use the supplied filter wrench and remove the filter housings from the unit. Remove and

dispose of the use pre-filter’s. Use proper sanitary procedures for replacing the new

filters. Do not touch the filters at any time. It is recommended that the filter housings be

sanitized with 50 ppm chlorine solution during the filter change out procedure and that

the O-ring be removed and cleaned and lubricated with an appropriate silicone O-ring

lubricant. Install the new filters and use the wrench to gently tighten the filter housings.

DO NOT OVERTIGHTEN the filter housings and do not use a petroleum-based lubricant on

the O-rings or lip seal.

Reverse Osmosis Membrane Maintenance

The reverse osmosis membrane should be changed no less than annually. If the water quality or

production rate falls below acceptable tolerances, the membrane should be replaced. It is

recommended that the membrane housing be sanitized with 50 ppm chlorine solution during the

filter change procedure and that the O-ring to be removed cleaned and lubricated with the

appropriate silicone O-ring lubricant. Lubricate the membrane O-ring and lip seal with silicone O-

ring lubricant. Install the new membranes and gently tighten the filter housing caps. DO NOT

OVERTIGHTEN the filter housing and do not use a petroleum-based lubricant on the O-rings or lip

seal.

To order a new membrane click on this link.

https://www.craftbrewwater.com/products/20-x-2-5-3-pack-filter-set-uv-bulb-and-membrane

Ultraviolet Maintenance

The Bulb on the ultraviolet should be changed annually to ensure proper sanitization.

Craft Brew Water

For questions and support call

Daily Maintenance:

The system should be left powered on at all times and the system must be installed in a location

that is not subject to water damage. Regular maintenance will lessen the potential for system and

component failures.

1. Check the system for leaks, unusual noises, excessive heat, or any other anomalies

2. Check the water quality daily

Weekly Maintenance:

Carefully and closely inspect the entire system. Confirm that there are no drips or leaks on any of

the system tubing connections.

Three Months Maintenance:

Replace the pre-filters and post filter

https://www.craftbrewwater.com/products/20-x-2-5-3-pack-filter-set

Annual Maintenance:

1. Replace the UV lamp and clean the quartz sleeve

2. Replace the membranes

3. Carefully remove TDS meter probes and soak for two minutes and 10% HCl solution. Rinse

and reinstall

https://www.craftbrewwater.com/products/20-x-2-5-3-pack-filter-set-uv-bulb-and-membrane

DRAWINGS

Craft Brew Water

For questions and support call

This is a typical installation

This is a drawing that includes running a line into your coldbox.

Table of contents

Popular Water Filtration System manuals by other brands

SpectraPure

SpectraPure CR-RODI-90-10 Installation and operating manual

Evince

Evince INSIGHT EV-IN-BW-948-1.0 owner's manual

Grizzly

Grizzly T33150 owner's manual

AQUAPHOR

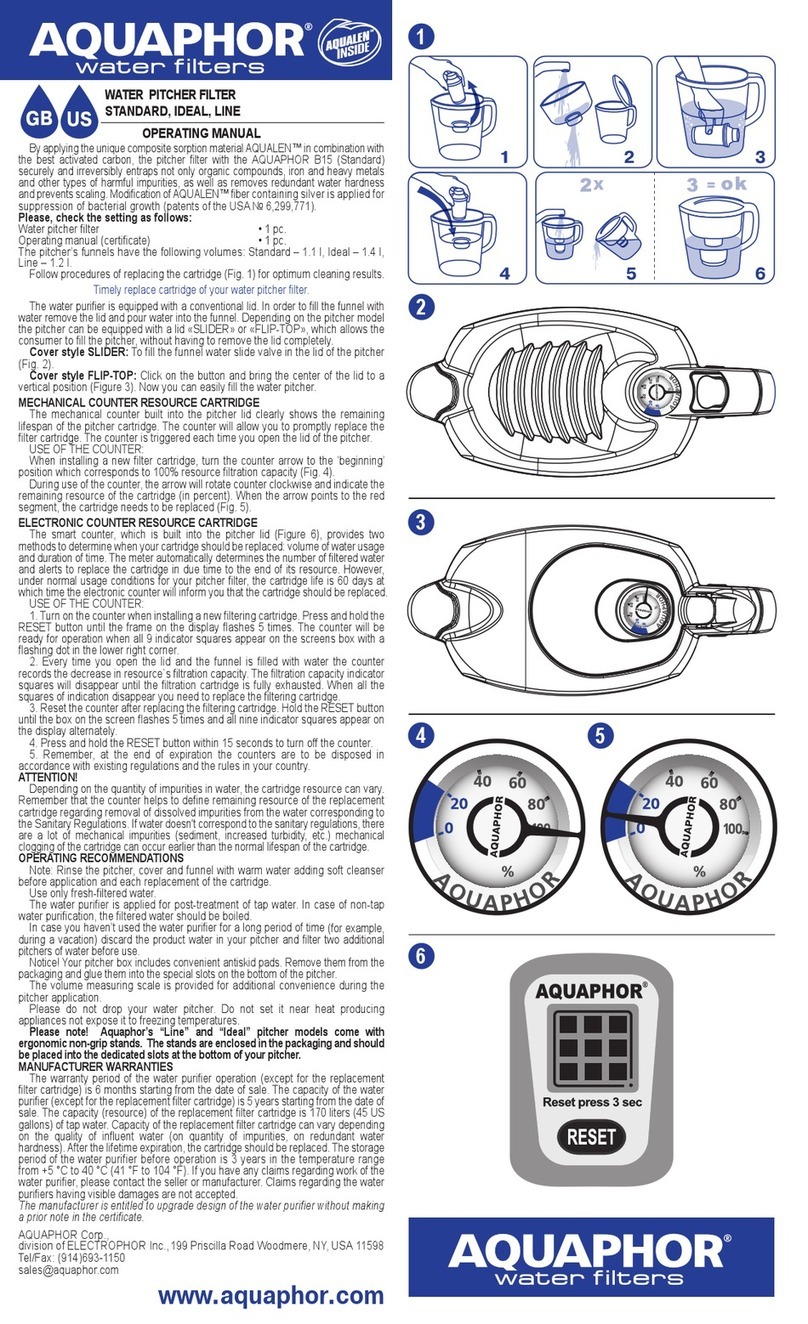

AQUAPHOR B15 Standard operating manual

BLUE COLLECTION

BLUE COLLECTION KIVI quick start guide

HEISSNER

HEISSNER TZ605 Instructions for use