Figure-1 Inventory

List of Contents

O. Flat Washer 1/4”-16 1.2mm ......................... 4

P. Hex Bolt 1/4”*5/8” .................................... 4

Q. Miter Gauge Holder ..................................... 1

R. Fence Holder ................................................ 1

S. Miter Gauge .................................................. 1

T. Scale (for the front rail) .................................. 1

U. Fence Assembly ............................................ 1

V. Front Rail ....................................................... 1

W. Rear Rail ....................................................... 1

X. Front Rail Brackets ....................................... 2

Y. Rear Rail Brackets ......................................... 2

Z. Front Rail Knobs ............................................ 2

AA. Rear Rail Knobs ......................................... 2

BB. Flat Washers 3/8” ....................................... 2

CC. Knobs 3/8”-16 ............................................ 2

DD. Hex Bolts 1/4”-20x1/2” ........................................ 2

EE. Lock Washer 1/4” ...................................... 2

F F. Flat Washers 1/4” ........................... ........... 2

GG. Table Insert................................................. 1

Figure-2 Inventory

Setup

Before setting up your machine you need to

read and understand this user manual

completely.

The unpainted surfaces of this band saw are

coated with a rust preventive waxy oil and you

will want to remove this

before you begin assembly. Use a

solvent cleaner that will not damage painted

surfaces. amount of cleaner/degreaser, then let it

soak for 5-10 minutes.

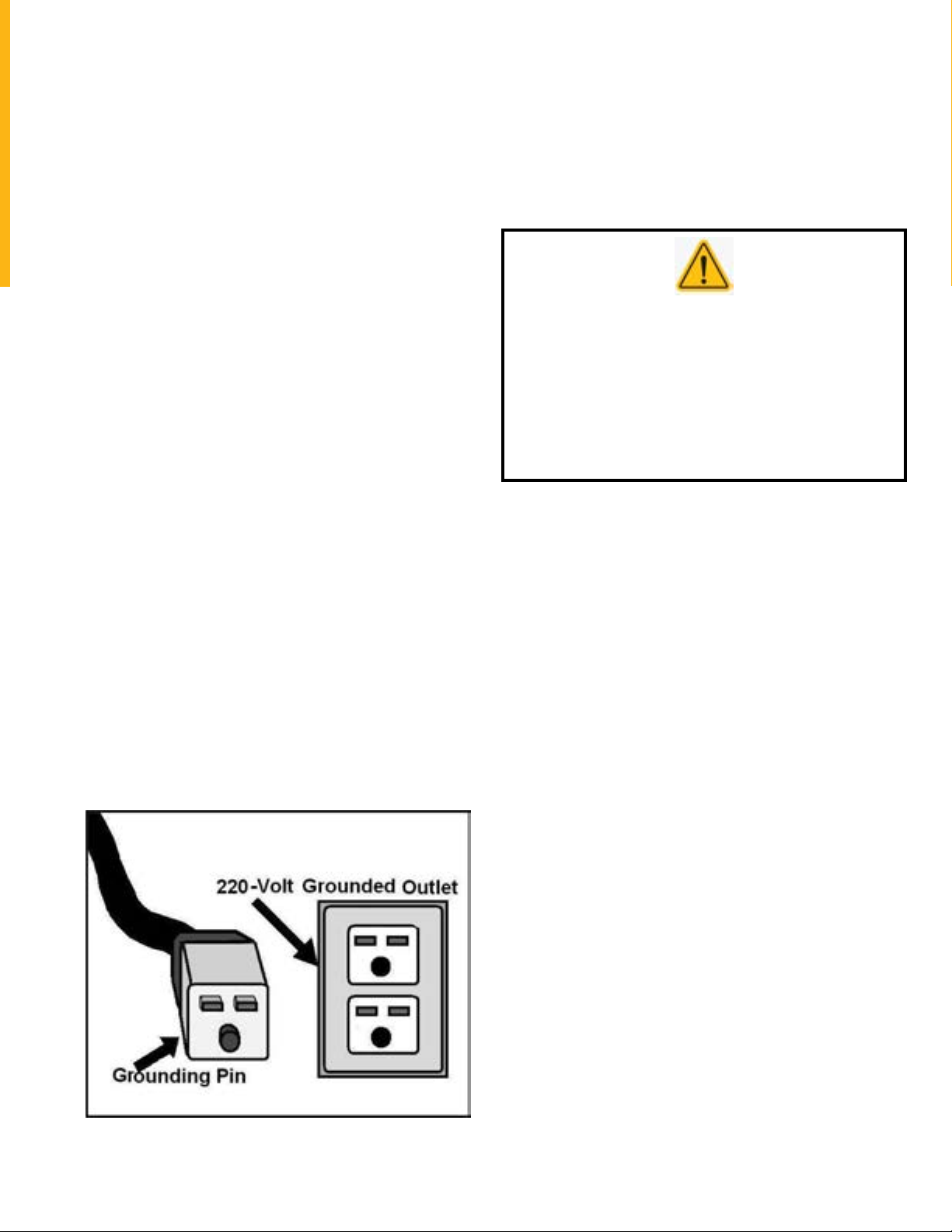

WARNING

CX108N is a heavy machine. Do not

over-exert yourself. Use a fork truck or

get the help of an assistant or a friend.

Unpacking

The machine is properly packaged in a carton

for safe transportation. When unpacking,

carefully inspect the crate and ensure that noth-

ing has been damaged during transit. Open the

crate and check that the machine is in good

condition.

The hardware (screws, washers etc) might be

shipped in a plastic bag.

After the machine has been un-packed, check

that all loose parts and

hardware are present.

List of Contents

A. Allen Keys 2, 3mm ................................... 2

B. Wrench ..................................................... 1

C. 1/4” Lock Washer .................................... 2

D. Flat Washer 5/16” .................................... 1

E. 1/4” Lock Washer .................................... 2

F. Flat Washer ............................................. 1

G. Knob Bolt 3/8-16 x 1 1/4 ........................ 1

H. Hex Bolt 5/16-18x1 .................................. 1

I. Angle Adjustment Plane ............................ 1

J. Hex Bolt 1/4-20x1/2 ................................. 2

K. Bushing .................................................... 1

L. Nylon Nut 5/16-18 ................................... 1

M. Adjustment Bar Bracket ......................... 1

N. Square Nut 5/16 ...................................... 4

HG

A

B

GG

E

K

J

C

L

MD

I

DD

CC

EE

BB

FF

F

O

P

N