Cramer LS 5000 XP User manual

Leaf and litter vacuum 671.02-49 10.2014

Original Operation Manual Englis

Operation Manual

Model

LS 5000 XP

Machine no.

Leaf and litter vacuum

Original Operation Manual

Englis -2

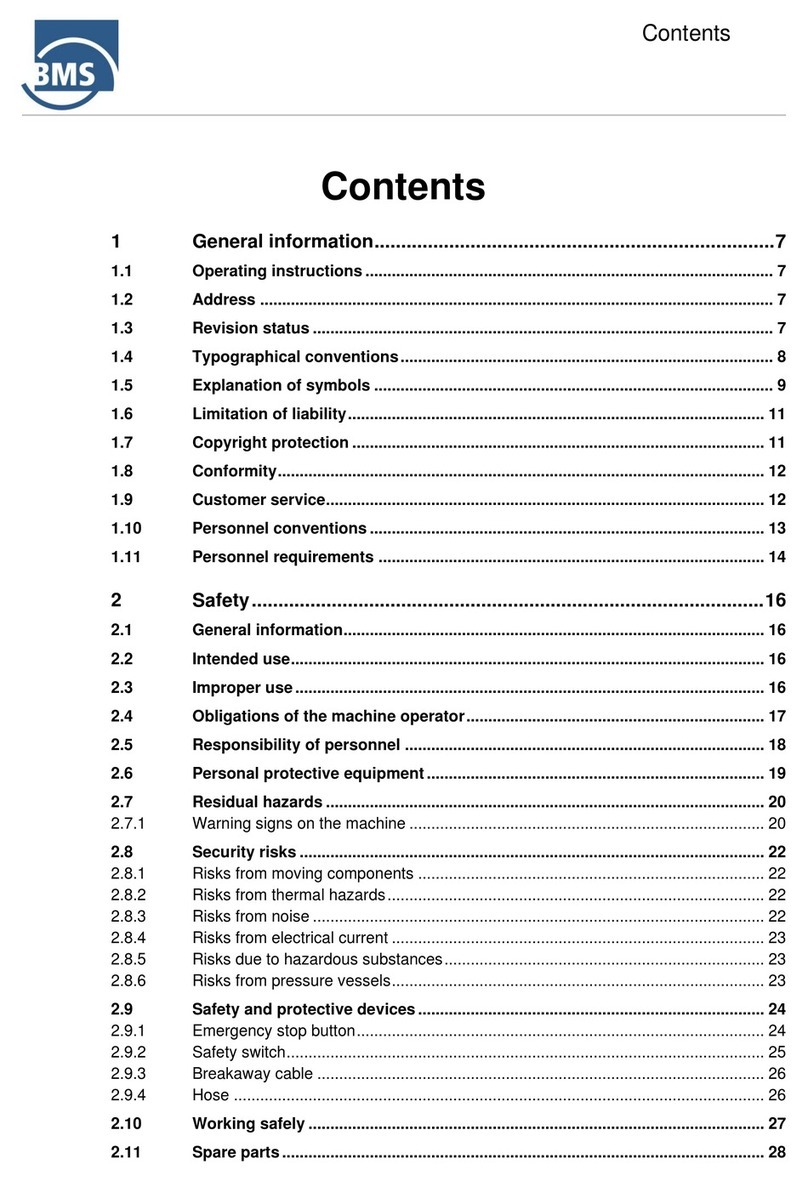

Contents

1 Important information...................................................................................................................................................3

1.1 General ............................................................................................................................................................3

1.2 Symbols ...........................................................................................................................................................3

1.3 Limitation of liability..........................................................................................................................................3

1.4 Copyright..........................................................................................................................................................3

1.5 Warranty...........................................................................................................................................................3

2 Safety..........................................................................................................................................................................4

2.1 Use in compliance with intended purpose........................................................................................................4

2.2 Possible misuse...............................................................................................................................................4

2.3 General sources of risks...................................................................................................................................4

2.3.1 Use and operation.................................................................................................................................4

2.3.2 Product-specific risks............................................................................................................................4

2.3.3 Risks from motor operation...................................................................................................................4

2.3.4 Risks for children, elderly persons and pets..........................................................................................4

2.4 Maintenance.....................................................................................................................................................4

2.5 Staff and operator qualification.........................................................................................................................4

2.6 Safety instructions............................................................................................................................................4

2.7 Required protection equipment for operation...................................................................................................4

2.8 Safety devices..................................................................................................................................................5

2.9 Behaviour in case of danger.............................................................................................................................5

2.10 Environmental protection..................................................................................................................................5

3 Technical data.............................................................................................................................................................5

4 Design and function.....................................................................................................................................................6

4.1 Brief description ...............................................................................................................................................6

4.2 Overview..........................................................................................................................................................6

4.3 Operating elements and functions....................................................................................................................6

4.4 Working position and areas of risk...................................................................................................................9

4.5 Accessories and spare parts............................................................................................................................9

5 Transport, storage.......................................................................................................................................................9

5.1 Information on transport...................................................................................................................................9

5.2 Storage (short-term).........................................................................................................................................9

5.3 Storage (long-term)..........................................................................................................................................9

6 Operation...................................................................................................................................................................10

6.1 Safety.............................................................................................................................................................10

6.2 Activities prior to use......................................................................................................................................10

6.3 Switching the machine on and off ..................................................................................................................10

6.4 Normal operation............................................................................................................................................10

6.5 Activities after use..........................................................................................................................................11

6.6 Emptying the collection bag ...........................................................................................................................11

7 Start up (first machine inspection).............................................................................................................................11

7.1 Safety.............................................................................................................................................................11

7.2 Start-up and functional test ............................................................................................................................11

8 Maintenance..............................................................................................................................................................12

8.1 Safety when performing maintenance work ...................................................................................................12

8.2 Maintenance plan...........................................................................................................................................12

8.3 Maintenance work..........................................................................................................................................13

8.3.1 Check safety precautions....................................................................................................................13

8.3.2 Check vacuum nozzle and fan rotor for damage.................................................................................13

8.4 Cleaning work ................................................................................................................................................13

8.4.1 Machine cleaning................................................................................................................................13

8.4.2 Cleaning the collection bag.................................................................................................................13

8.4.3 Cleaning the vacuum nozzle...............................................................................................................13

9 Troubleshooting.........................................................................................................................................................14

9.1 Safety.............................................................................................................................................................14

9.2 Service address .............................................................................................................................................14

9.3 First action for troubleshooting.......................................................................................................................14

10 Declaration of conformity...........................................................................................................................................14

11 Installation Manual.....................................................................................................................................................15

Leaf and litter vacuum

Original Operation Manual

Englis -3

1 Important information

We are pleased that you have selected a machine from Cramer GmbH

in Germany.

Please read this Operation Manual before you use the machine

for the first time and observe the notes and safety instructions.

Imprint

Cramer GmbH

Reimersstr. 36

D-26789 Leer

Phone: +49491/60950

Fax: +49491/6095200

District court of Aurich HRB 110877

VAT ID: DE 814 305 398

1.1 General

Information on this Manual

•Observing the instructions in this manual allows for the safe and

efficient handling of the machine.

•The operator must have read this manual carefully and

understood it before starting working with the machine.

•Compliance with the safety instructions contained is a prerequisite

for using the machine without any risk.

Keeping the Operation Manual

•The Operation Manual is an integral part of the machine and shall

be kept in its immediate vicinity.

•The operator must have access to this Manual at any time.

Traffic regulations

•Any applicable traffic regulations have to be complied with in

regard to manoeuvring and transporting the machine on public

roads.

Accident prevention regulations

•General safety and local accident prevention regulations must also

be observed.

•National occupational safety regulations shall be complied with.

Other applicable documents

Assembly, Declaration of conformity

1.2 Symbols

DANGER !

T is symbol cautions against an immediate

t reat resulting in serious injuries or deat if

not avoided.

WARNING !

T is symbol cautions against a potentially

dangerous source of risk w ic may result in

deat or serious injury if not avoided.

ATTENTION !

Indication of a potential risk w ic may result

in minor injuries if not avoided.

NOTE !

T is symbol indicates a potential risk source w ic may

result in damage to property or minor personal injuries.

1.3 Limitation of liability

Liability on part of the manufacturer is excluded in the following cases:

•Non-compliance with the Operation Manual

•Use not in compliance with intended purpose.

•Assignment of untrained staff.

•Use of unauthorised spare parts. Only original components may

be used.

•Unauthorised modifications of the machine.

1.4 Copyright

© Cramer GmbH

Copying of the Operation Manual is only permissible for internal

training purposes.

1.5 Warranty

The General Terms and Conditions of Business as issued by us in

every country shall be applicable. Failures within the statutory

warranty period will be remedied by us free of charge if they are

caused by a material or manufacturing defect in our responsibility.

Please contact your authorised dealer in case of a failure and submit

the proof of purchase.

Leaf and litter vacuum

Original Operation Manual

Englis -4

2 Safety

2.1 Use in compliance with intended purpose

The machine is suitable for use as a leaf and litter vacuum.

Any use exceeding this is considered not in compliance with the

intended purpose. The manufacturer shall not be liable for damage

resulting from use not in compliance with the intended purpose; the

risk for this shall be in the sole responsibility of the user.

Use in compliance with the intended purpose shall also include

compliance with the operation and maintenance provisions specified

by the manufacturer.

2.2 Possible misuse

•Do not vacuum any wires, cables or heavy stones. These could

damage the collection bag and cause injuries by flinging.

•Do not use your foot to push any objects beneath the vacuum

nozzle. This could cause injuries by flinging objects.

•Do not vacuum any materials which may block the fan.

2.3 General sources of risks

2.3.1 Use and operation

•Prior to starting the machine, the machine shall be checked for

proper condition and operational safety.

•The operator shall use the machine in compliance with its intended

purpose.

•Indoor machine operation is prohibited.

•The machine is only approved for floorings as indicated in the

Operation Manual.

•The machine may only be operated by staffs who have been

instructed in its use or have provided evidence of their operating

capability, and who have explicitly been instructed to operate the

machine.

•When starting the motor, no other persons may be in the vicinity of

the machine.

•Any protection equipment must be properly attached and in

functional order.

•Never leave the machine unattended.

•When leaving the machine, stop the motor and secure the machine

against unintended movement.

•The operator shall be responsible for accidents involving other

persons or their property.

2.3.2 Product-specific risks

•Do not vacuum any highly flammable materials or hot objects (e.g.

barbecue coal) - danger to life by burning.

2.3.3 Risks from motor operation

•Do not touch any parts of the motor during or after operation.

Significant risk of burning by hot surfaces.

•Stop the motor and let it cool down before working on the machine

as well as before performing maintenance, cleaning and repair

work.

2.3.4 Risks for children, elderly persons and pets

•The operator shall take account of surrounding conditions, e.g. the

effects of noise on persons and animals.

•The machine must never be left on a slope.

•Children, elderly persons and pets/livestock must not stay near the

machine.

•Children must not play with/on the machine.

2.4 Maintenance

•Servicing, maintenance and repair work as well as troubleshooting

shall only be carried out when the machine is switched off and the

motor is at a standstill. As required, the spark plug connectors shall

be disconnected.

•The machine must not be cleaned with spray water (risk of short

circuits or other damage).

•Safety checks pursuant to local regulations for non-stationary

commercially used machines shall be complied with.

•Always use appropriate tools when working on the machine.

•Only use the manufacturer's original spare parts.

2.5 Staff and operator qualification

•Persons with physical, sensory or mental handicaps or persons

with insufficient experience or knowledge must not operate the

machine unless a person in charge for their safety acts as

operation or instruction supervisor.

•People under the age of 16 must not operate the machine.

•The operator's responsiveness must not be affected, e.g. by drugs,

alcohol or medications.

•The operator shall have been instructed in the operation of the

machine.

•The operator shall be familiar with the Operation Manual.

2.6 Safety instructions

These warning labels on the machine warn you of possible dangers

and thus help you to avoid serious injuries and damage to property. If

labels have become detached or illegible, please contact your Cramer

dealer to have the labels replaced.

The operation manual and safety instructions must be

read and observed prior to starting the machine.

Risk by flinging parts with running motor. Keep a safety

distance of 3 m.

Risk of injury from rotating parts. Machine parts may only

be touched once they have come to a complete

standstill.

Always wear ear and face protection when working with

the machine.

2.7 Required protection equipment for operation

•Rugged footwear

•Close-fitting clothing

•Ear protection

•Safety gloves

•Face protection

The information on accident prevention regulations must also be

observed.

Leaf and litter vacuum

Original Operation Manual

Englis -5

2.8 Safety devices

•

Do not remove any covers during operation.

•

Immediately remedy any damage to safety devices.

2.9 Behaviour in case of danger

1. Stop work immediately

2. Stop the motor

3. Disconnect power supply if necessary

4. Remedy the risk situation

2.10 Environmental protection

•Oils, fuels, greases and filters shall be disposed of properly and

separately in accordance with legal regulations. Please do not

dispose of any wastes in the environment.

•Packaging materials are recyclable. Please make sure that they

are collected for reuse.

•Legacy devices contain valuable recyclable materials which should

be collected for reuse. These devices may be disposed of through

appropriate collection systems.

3 Technical data

LS 5000 XP model

Drive:

Petrol motor

Honda GX 160

4.8 HP/3.6 KW (net output)

Operating speed: 3000 rpm

Petrol consumption: 1.4 l/h

Speed: 0-4.8 km/h progressively

Weight: 118 kg

Dimensions (L x W x H): 185 x 86 x 111 cm

Collection bag volume: 180 litres

Working width: approx. 80 cm

Chassis 4 wheels

Sound pressure level:

Guaranteed acoustic power level:

86 dB(A)

99 dB

Hand / arm vibration: 3.6 m/s²

Application area: Conventional use in agriculture and forestry, park maintenance and landscape gardening

Connections / interfaces: Receiver point for collection bag

Front tyres:

Rear tyres:

Ø 180x80

Ø 330 (13x5.00-6)

Rear tyre pressure: 1.8 bar

Year of construction: Please refer to the machine's nameplate

Working ground: Plane surfaces on park areas, paving, tarmac, bitumen, concrete, lawns

Temperature, ºC See motor data from Honda

Responsibility limits for components: Motor (op. manual)

Leaf and litter vacuum

Original Operation Manual

Englis -6

4 Design and function

4.1 Brief description

The universal vacuum is used for collecting leaves and litter. The machine is driven by a petrol motor. The collection bag can be removed and is

suitable for leaves and coarse waste.

4.2 Overview

4.3 Operating elements and functions

Overview

1 = Height adjustment of vacuum nozzle

2 = Collection bag release

3 = Drive lever

4 = Throttle for suction power

Height adjustment of vacuum nozzle

The height of the vacuum nozzle can be adjusted using this lever in order to adapt the vacuum

power to the weight and nature of the material to be collected.

Bend the lever slightly outward, to release it, and then move the lever to the desired height setting.

Pushing the lever away from you will lower the vacuum nozzle

Pulling the lever toward you will raise the vacuum nozzle

1 Collection bag release (parallelogram)

2 Throttle for suction power

3 Handle, drive lever on right

4 Collection bag

5 Parking brake

6 Drive wheel

7 Vacuum nozzle

8 Fan

Leaf and litter vacuum

Original Operation Manual

Englis -7

Collection bag release

The adjustment lever is used to unlock or lock the collection bag when

removing or attaching it. The collection bag is attached to a support

frame which is always detached together with the bag when the bag is

removed.

Removing the collection bag

1. To be able to remove the collection bag, you must first pull the

throttle lever toward you (to the idle position).

2. The collection bag release can then be pulled toward you. The roller

frame is lowered/unlocks and the frame with the collection bag can

be removed.

3. Detach the collection bag from the support and empty it.

Note! The collection bag cannot be removed until the throttle lever

has been moved.

Attaching the collection bag

1. To attach the collection bag, the support frame with the collection

bag is placed on the machine support and is then pushed

completely onto the holding fixture.

2. First push the release bar back in order to raise the collection bag

again and lock it.

3. Then push the throttle lever away from you.

Switching on the motor

1 Choke lever

2 Fuel tap

3 Tank opening

4 Starter handle

5 Ignition switch ON/OFF

1 = Choke

2 = Fuel tap

Starting the motor:

1. Move the choke lever to the left (CLOSED)

The choke is always needed for a cold-start.

2. Open the fuel tap (ON).

3. Move the ignition switch to ON

4. Pull the starter handle until you feel resistance, then pull it out quickly

and forcefully. Guide the starter handle back gently.

5. Using the throttle lever on the control console, set the motor power to

FULL or STOP (idle).

6. Move the choke lever to the right (OPEN).

Switching off the motor:

1. Move the motor switch to OFF

2. Close the fuel tap (OFF)

(turn the lever to the left)

Collection bag

removal

Collection bag

attachment

Leaf and litter vacuum

Original Operation Manual

Englis -8

Drive

The drive handle for the machine is located on the right-hand side.

Turn the handle to the right and hold – the machine moves forward

Turn the handle to the left or release it – the machine comes to a standstill.

Throttle for suction power

The engine speed can be regulated between FULL and STOP. When collecting

material, the throttle must be set to FULL, otherwise the blower outlet will not be

fully open.

The engine speed can be changed by moving the throttle lever to the desired

position.

The following settings are possible:

1 = FULL (full throttle) - up

2 = STOP (idle) - down

Parking brake

The machine can be secured against unintended movement by applying the parking brake.

Apply brake:

•Press the brake lever down with your foot.

Release brake:

•Firmly push back the machine. The brake is released from the tyre tread.

Vacuum nozzle

To remove the vacuum nozzle for maintenance and repair work, use the wrench provided.

1. Unscrew the hexagon bolt using the wrench.

2. Pull the vacuum nozzle upwards and out of the retainer.

Airflow

The zip fasteners for regulating the air extraction volume, located on the sides of the collection

bag, can be opened if the airflow needs to be increased.

The zip fastener should be opened if the airflow needs to be increased in order to collect larger

objects such as tin cans.

Leaf and litter vacuum

Original Operation Manual

Englis -9

Tool supplied

The wrench illustrated is attached to a retainer on the steering bar.

4.4 Working position and areas of risk

Working position:

Next to the machine

Areas of risk:

•Catchment area of the machine's vacuum nozzle

•Discharge area of the blower outlet

4.5 Accessories and spare parts

Original parts

Only original spare parts and original accessories may be used.

5 Transport, storage

5.1 Information on transport

Transport without packaging

•Stop the machine

•Fix the machine by using lashing straps.

5.2 Storage (short-term)

The machine:

•must not be stored in the open air.

•Do not expose it to aggressive materials.

•Clean machine with a soft brush before storage.

5.3 Storage (long-term)

The following recommendations will help to ensure the long-standing

functionality of your Cramer machine:

1. Clean the machine - Important! The discharge area should also

be cleaned (see Maintenance, Cleaning)

2. Check machine for wear, repair paint damage.

3. Store the machine in a dry place.

Additional recommendations for machines with petrol motor:

1. Ensure that fuels are prepared for long-term storage (longer than

30 days), e.g. add fuel stabilizer

2. Renew motor oil

3. Treat spark plugs

Please refer to the attached motor operation manual for instructions

on how to care for the motor!

Leaf and litter vacuum

Original Operation Manual

Englis -10

6 Operation

Before starting the machine, please read the safety information on

pages 4 and 5 as well as the "Activities prior to use" section on page

10.

6.1 Safety

Unauthorised restart

•It is prohibited to start the machine while another person is

working on it.

Risks of non-applied protection devices

WARNING !

Danger of injuries due to missing protective

covers!

Lack of covers may cause injuries by flinging materials.

Do not open or remove any covers during operation.

Risks of insufficient order and cleanliness

•Clean the machine regularly.

•Check the machine for blocking objects.

Requirements at location of use

•Only leave the machine on plane surfaces and solid ground.

6.2 Activities prior to use

To ensure your safety and the maximum service life of the machine,

please check the following before switching on the machine:

•Observe the safety information in this manual at all times.

•Ignition switch set to OFF

•Check the vacuum nozzle for any foreign objects

•Check the machine for damage and repair as required

•Check the fuel level

•Check the motor oil level

•Check the condition of the safety devices. The machine must not

be started if safety devices are missing or defective.

WARNING !

Exhaust gases contain toxic carbon

monoxide!

The machine must never be started or used indoors or in enclosed

spaces where other persons may be present.

Only operate the machine outdoors.

6.3 Switching the machine on and off

Basic prerequisites for switching on the machine

- Adjust the height of the vacuum nozzle

- Attach the collection bag

- Check the machine's fuel level and refill as required.

Switching on

1. Set the choke lever to CLOSED

2. Open the fuel tap

3. Set the ignition switch to ON

4. Set the throttle to FULL

5. Pull the starter handle and guide it back gently

6. Move the choke to OPEN

Switching off

1. Set the throttle to STOP

2. Set the ignition switch to OFF

3. Close the fuel tap

Switching off in an emergency

1. Immediately switch the machine to OFF

2. Leave the machine.

Switching on again after an overload or EMERGENCY-OFF

1. Move the engine switch to OFF

2. Wait until the machine has come to a standstill

3. Remove any blockage

4. Start the motor

6.4 Normal operation

1. Basic setting:

•Park machine on an even surface

•Refill consumables

2. Push the collection bag into the machine support.

3. Switch on the machine

3.1 Set the choke lever to CLOSED (only when engine is cold)

3.2 Open the fuel tap

3.3 Move the ignition switch to ON

3.4 Pull the starter handle

3.5 Move the choke to OPEN as required

3.6 Set the power output using the throttle

If no functional failures occur until then, the machine is ready for

use.

4. Push the machine over the material to be collected

•Set throttle to FULL

•Use the turning handle for the drive to move the machine

forward and back

5. Empty the collection bag when the machine begins to move down

•To empty the collection bag, switch off the machine first or set

to Idle. See Section 6.6.

6. The vacuum nozzle can be lowered for heavy materials to be

collected.

•Move the height adjustment lever to the desired position.

7. Switch off the machine before leaving it

•Place the machine in a dry area

•End drive operation

•Move the ignition switch to OFF

•Close the fuel tap.

In the event of faulty operation, please contact your Cramer dealer.

Leaf and litter vacuum

Original Operation Manual

Englis -11

6.5 Activities after use

Please perform the following steps after using the machine:

1. Always empty the collection bag before storage.

2. The machine must be left in a clean and dry condition

3. Apply the parking brake and close the fuel tap.

6.6 Emptying the collection bag

The collection bag's filling limit is reached when the machine starts

to move down at the back and the vacuum nozzle rises up.

ATTENTION!

Risk of injury from the fan!

Working on the machine with the motor running can lead to

minor injuries.

Always switch off the motor when:

Carrying out any work on the collection bag

Carrying out any work on the vacuum nozzle and intake

canal

Empty the collection bag immediately when it is full. Do this as

follows:

1. Set the drive handle to Idle

2. Pull the throttle lever toward you

3. Pull the collection bag release toward you

4. Then detach the collection bag from the guide rail and empty it.

5. Insert the empty collection back into the guide rail and push it

into the holding fixture.

6. Push up the collection bag release

7. Use the throttle lever to set the motor power.

7 Start up (first machine inspection)

Assembly and start-up shall be performed by your authorised

Cramer dealer.

7.1 Safety

Before start-up, you must have read and understood the operation

manual and be familiar with the machine's functions.

7.2 Start-up and functional test

Before initial start-up, please check that all safety devices are

attached. Only then shall the following functional test be performed:

After an operating duration of approx. one hour, all fastening screws

of the blades as well as the fastening screw of the blade disc should

be re-tightened.

Functional test / starting the machine

1. Park machine safely on an even surface

2. Add fuel and check the oil level

3. Attach protective devices

4. Switch on the machine

If no functional failures occur until then, the machine is ready for use.

If functional failures do occur, please contact your Cramer dealer.

Leaf and litter vacuum

Original Operation Manual

Englis -12

8 Maintenance

8.1 Safety when performing maintenance work

Regular and correctly performed maintenance work is essential for

the safe, economical and fault-free operation of the machine.

The information in the following sections helps you to ensure the

correct maintenance of your machine. You can perform routine

maintenance work yourself using basic hand tools. More complex

maintenance work requiring special tools should be performed by

qualified staff, e.g. at your Cramer dealer or by a qualified mechanic.

Some of the most important safety precautions and dangers are

listed in the box on the right. However, it is not possible here to list

all potential dangers that could arise during maintenance work and

describe the associated precautions. You are solely responsible for

deciding which maintenance work you wish to perform yourself.

8.2 Maintenance plan

Maintenance Prior to each use Regularly Intervals in hours

25 50 100 200

Cleaning X (Item 8.4)

Check safety precautions X (Item 8.3.1)

Check all screws for tight fitting O

Check motor oil level B

Check air filter B

Clean or replace air filter (normal use) B

Clean or replace air filter (dusty conditions) B

Adjust tyre pressure O

Check machine for damage or corrosion on paint

coating and remedy as appropriate O

Check machine for fuel or oil leaks O

Replace fuel filter B

Check vacuum nozzle for damage X (Item 8.3.2)

Check rotor fan for damage X (Item 8.3.2)

Check and adjust Bowden cables F

Grease rotating points and joints O

Grease Bowden cables O

Check battery B

Replace spark plugs B

X = Described in this Operation Manual in the indicated section

O = Not described in the present Operation Manual, inform specialist dealer as required

B = Description is enclosed in attached motor operation instructions

F = Work may only be performed by a qualified expert in this field

DANGER !

Risk of injury by inappropriately performed

maintenance work!

Defective work may result in serious bodily injuries and damage to

property.

Make sure that you have sufficient working space.

Disconnect the power plug from the mains supply when

working on the machine.

Place components separately.

Remount all components.

Remount all safety covers.

Keep the risk area clear of persons.

Leaf and litter vacuum

Original Operation Manual

Englis -13

8.3 Maintenance work

ATTENTION!

Risk of injuries by combustion motors

Cleaning and repair work must never be carried out

during operation or when the machine runs idle, since

this may result in burns and cuts.

Stop machine and motor and let them cool down.

Disconnect the spark plug connector.

8.3.1 Check safety precautions

Safety precautions comprise:

- Discharge covers

- Vacuum nozzle

The machine must not be operated if the covers show any signs of

damage or are removed. They are to be replaced in case of damage

or loss. The machine must not be started without safety precautions.

8.3.2 Check vacuum nozzle and fan rotor for damage

1 Switch off the machine and leave it to cool down.

2 Use the wrench to unscrew the bolt on the vacuum nozzle (the

wrench is supplied with the machine)

3 Pull the vacuum nozzle upwards and out of the retainer

4 Remove any foreign objects from the vacuum nozzle

5 Check the fan rotor for foreign objects Remove all foreign

objects. If damaged, the rotor must be replaced.

6 Insert the vacuum nozzle into the retainer and secure using the

bolt.

8.4 Cleaning work

The machine should be cleaned regularly so that damage to the

paint coating or plastic components can be detected. Please

observe the notes listed for cleaning in order to avoid damage to the

electronics.

8.4.1 Machine cleaning

After every use, clean the outside of the machine and check it for

damage.

1. Park the machine on an even surface before cleaning it.

2. Clean the machine with a soft brush.

3. If necessary, then clean the machine with a damp cloth.

NOTE !

Machine damage!

Do not clean the machine with spray water.

8.4.2 Cleaning the collection bag

Remove the collection bag from the machine. When cleaning with

water, the collection bag must first be detached from the support

frame. Turn the collection bag inside out to wash it

The following cleaning methods may be used:

•Beat the dirt out of entire collection bag

•Clean in bath of water

•Clean under running water

•Clean at professional cleaners

Subsequently allow the collection bag to dry out completely.

Clean the zip with a soft brush and occasionally rub with talcum. Re-

attach the dry collection bag. See page 17 for attaching the

collection bag.

8.4.3 Cleaning the vacuum nozzle

The vacuum nozzle must always be dismantled for cleaning. Use the

tool (wrench) attached to the machine frame in order to dismantle

the vacuum nozzle.

1. Switch off the machine and leave it to cool down

2. Use the wrench to unscrew the bolt on the vacuum nozzle

3. Remove the vacuum nozzle from the retainer

4. Remove any foreign objects from the vacuum nozzle

Leaf and litter vacuum

Original Operation Manual

Englis -14

9 Troubleshooting

9.1 Safety

Procedure for failures and accidents

1. Initiate emergency stop (leave working position).

2. Stop the machine.

3. Determine the failure cause.

4. Remedy failure or contact specialist dealer.

9.2 Service address

Please contact your sales consultant in case of failures, problems or

otherwise. Please always indicate the machine serial no. in inquiries.

(Please refer to nameplate on the machine or on the Operation

Manual cover).

9.3 First action for troubleshooting

Failure / Error message Possible cause(s) Remedy

Motor will not start Motor switch set to »OFF« Set switch to »ON«

No motor power Petrol tank empty

Spark plug defective

Fuel tap blocked or water in petrol

Air filter contaminated

Refill fuel

Replace spark plug

Take machine to authorised dealer

Clean (rinse) air filter

Motor becomes excessively hot Carburettor adjusted incorrectly

Not enough motor oil Re-adjust carburettor

Refill motor oil

Machine has no suction power Collection bag too full

Filter surface of collection bag contaminated

Vacuum nozzle blocked

Empty collection bag

Clean filter surfaces (wash if necessary)

Clean vacuum nozzle

Wheel drive slips Gear coupling dragging Notify authorised dealer

10 Declaration of conformity

EU Declaration of conformity pursuant to machine directive 2006/42/EC Annex II 1-A

The authorised party with residence in the EU,

Cramer GmbH

Reimersstr. 36

26789 Leer

herewith declares, that the following product

Manufacturer:

Cramer GmbH

Reimersstr. 36

26789 Leer

Product designation:

Leaf and litter vacuum

Make:

Cramer GmbH

Serial number:

see cover nameplate

Type(s):

LS 5000 XP

complies with all relevant regulations of the above-stated Directive as well as all other applicable Directives - including their amendments applicable

at the date of this declaration.

The following harmonized standards were applied:

EN 953:1997+A1:2009

EN ISO 12100:2010

EN ISO 3744:2010

DIN EN ISO 5349-2

Name and address of person authorised to compile the technical documentation:

Andre Schwarzkopf

Cramer GmbH

Reimersstraße 36

26789 Leer

Site:

Leer

Date:

20/10/2014

A. Bruns A. Schwarzkopf

Managing Director CE Officer

Leaf and litter vacuum

Original Operation Manual

Englis -15

11 Installation Manual

Safety during assembly

Delivery, packaging, assembly

T e individual parts for t e screw connections are attac ed to

t e mounting parts.

ATTENTION!

Squeezing hazard during assembly

Parts of the body may be squeezed when components

are assembled.

Risk of ig dead weig t

•Remove mac ine parts separately from packaging.

Perform transport inspection

•C eck t e mac ine for completeness and potential damage on

delivery.

•T e front unit is supplied to t e specialist dealer in a partially

assembled condition.

•Assembly and start-up ave to be performed by a specialist dealer

and/or an expert in t is field.

Packaging

•Please dispose of packaging materials separately.

Assembly overview

Working steps Description Assembly parts

1. Unscrew t e struts and fold up t e control

console.

2. T e bolts wit t e was ers and nuts from

item 1 are required to secure t e control

console and side wall.

1Struts

2Control console

3Side wall

Leaf and litter vacuum

Original Operation Manual

Englis -16

3. Use t e bolts to fasten t e control console

to t e side wall.

4. For transport reasons, t e bar of t e eig t

adjustment lever as been divided into two

parts. T e bolts required for t ese parts are

located at t e bore oles of t e bar.

5. Remove t e bolts and nuts from t e bar.

6. Hold t e two ends of t e bar toget er so

t at t e bore oles are aligned. Place a

was er on eac of t e two bolts and secure

using t e was er and nut.

1Bolt connection from

item 1

4Heig t adjustment bar

7. T e blower outlet must be secured between

t e fan and t e control console.

8. Remove t e locking nut wit t e was er

from t e flange on t e control console.

9. T en remove t e bolt connections (bolt,

was ers and nut) on t e flange of t e fan

ousing.

10. Hold t e blower outlet against t e control

console and secure wit t e was er and

locking nut (illustration).

11. Secure t e blower outlet to t e fan ousing

using t e bolts as s own in t e illustration at

t e bottom.

5Blower outlet

6Flange wit rubber

seal

(M6x25)

7Flange wit rubber

seal

(Locking nut M6)

T e required bolts,

was ers and nuts are

attac ed to t e respective

flange. Please secure t e

bolts in t e same way.

Leaf and litter vacuum

Original Operation Manual

Englis -17

12. Guide t e flange of t e vacuum nozzle

between t e side brackets.

13. T en pus t e vacuum nozzle furt er down

into t e angle bracket.

Caution!

The nose of the flange must sit in the guide

slot of the angle bracket.

14. Secure t e vacuum nozzle wit t e pre-

assembled exagon bolt.

8Vacuum nozzle

9Hexagon bolt

10 Side bracket

11 Angle bracket

15. Secure t e collection bag to t e frame using

t e Velcro strips. T e side zip fasteners for

regulating t e airflow must be parallel to t e

w eels on t e frame.

16. T e collection bag and dust cover are

included in t e scope of delivery.

Attac t e collection bag using t e Velcro

fasteners as s own in t e picture. (P oto s ows

t e black wet waste bag)

12 Frame

13 Collection bag (w ite)

14 Dust cover (black)

17. T e dust cover is open at t e bottom and

can be attac ed to t e frame over t e

collection bag using t e Velcro fasteners.

18. Pull t e bottom of t e dust cover over t e

collection bag.

Note!

T e strap on t e bottom of t e dust cover must

be lengt ways in t e direction of travel.

Table of contents

Other Cramer Blower manuals

Cramer

Cramer 40B730 User manual

Cramer

Cramer KM 70 G Type 02 User manual

Cramer

Cramer 2400386 User manual

Cramer

Cramer KM 80 H User manual

Cramer

Cramer 2400186 User manual

Cramer

Cramer KM domus 82 V User manual

Cramer

Cramer 2400986 User manual

Cramer

Cramer KM domus 82 V User manual

Cramer

Cramer 2401086 User manual

Cramer

Cramer 82B1000 User manual

Popular Blower manuals by other brands

Canarm

Canarm 600 Series Operation instructions and parts manual

Ironton

Ironton 79032 instructions

Makita

Makita DUB185F001 instruction manual

Finn

Finn Bark Blower BB302 Operator Instructions And Parts Manual

Troy-Bilt

Troy-Bilt TB310QS Operator's manual

Giant-Vac

Giant-Vac Leaf Buster 16Z Assembly instructions