Creativity ELF PRO User manual

ShenZhen Creativity Technology Co.,Ltd

ELF PRO

3D Printer

User Manual

The User Manual is for the ELF PRO 3D printer.

Detailed instructions for using are available on the TF card.

Do not place the Printer near flammables, explosives or heat sources. It is best to place it in a well-

ventilated, low-dust environment.

Do not expose the Printer to violent vibration or any unstable environment.

This will cause poor print quality.

The filaments recommended by the manufacturer are preferred as to avoid clogging in the hot end

and/or Printer damage.

Do not use any other power cable than the one supplied. Use a grounded three-prong power outlet.

Do not touch the nozzle or hot bed during printing. Keep hands away from machine while in use to

avoid burns or personal injury.

Do not wear gloves or loose clothing when operating the Printer. These loose articles can become

caught in moving parts and cause personal injury or Printer damage.

Clean off filament from the nozzle tip with the provided pliers before the nozzle cools. Do not touch

the nozzle directly. This can cause personal injury.

Clean the Printer frequently. With the machine powered off, clean the printer body with a dry cloth to

remove dust, adhered printing materials and foreign objects on guide rails.

Use glass cleaner or isopropyl Alcohol to clean the print surface before every print for consistent

results.

Children under 12 years of age should not use the Printer without supervision.

Attention

Safet y Instructions-------------------------- ------------------- 1

Technical Speciflcation-----------------------------------------------------------------------2

Packing List----------------------------------------------------------------------------------3

Product Overview---------------------------------------------------------------------------------4

Installation---------------------------------------------------------------------------------------5

Install Frame---------------------------------------------------------------------------------6

Wire Connection--------------------------------------------------------------------------7

Warm Reminder------------------------------------------------------------------------------------8

Leveling------------------------------------------------------------------------------------9

Printing Test-----------------------------------------------------------------------------10

Test Print------------------------------------------------------------------------11

Cura Installation---------------------------------------------------------------------------12

Introduction to slicing software---------------------------------------------------13

Manipulate 3D modle in cura--------------------------------------------------------14

Cura Settings------------------------------------------------------------15

Start Srinting------------------------------------------------------------------16

FAQ---------------------------------------------------------------17

When printer is working, please beware of the high temperature of hot

bed, extruderhead,and other hot parts, Pleasedon't touch any hot part

during printing in case of scald.Pleasenote hot parts need time to cool

down after working.

Pleasenote hot parts need time to cool down after working.

The printer has 220V AC/110V AC voltage and other high voltage power

connector, Pleasedon't touch conductive part in case of electric shock

The power of some key parts of the printer(such as hot bed, extruder

head) is stronger,Duringinstallation and usage, please ensure all

terminals connected tightly to avoid anysparking may be caused by

loose wiring.To ensure safety, printer should be mannedduring

working.

The printer belongs to mechanical equipment. When it is working,

please don't touchmoving parts in case of mechanical wounding.

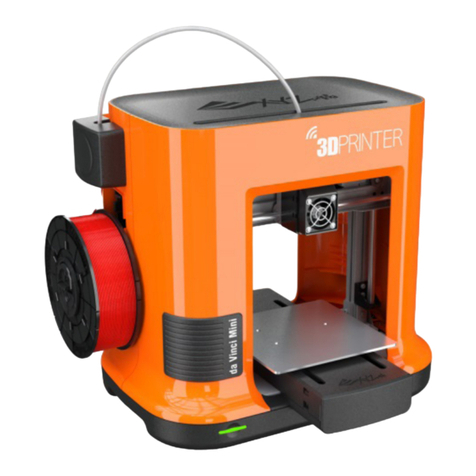

Printing Size(mm) 300*300*360 Molding Tech FDM

Slice Software

CURA /Simplify3D/

Repetier-Host ect Power Supply AC :110-120 V /

200-240V

DC:24V 15A

Nozzle Number 1Total Power MW-LRS-350W

Machine Size(mm) 460*480*560 Language

EN/RU/ES/FR/KR/ZH

-

CN

Machine Weight 16Kg

Printing Method

TF Card/Online Printing

Package Weight 23Kg Display 3.5 inch color touch

screen

Slice Thickness 0.1-0.4mm Bed Temp ≤ 110℃

Precision 0.1mm Nozzle Temp ≤ 260℃

Supported file

formats STL/G-Code Operating

System Windows/Lunix/Mac

Nozzle Diameter 0.4mm.Support

0.2/0.3/0.6/0.8mm Printing

Speed

≤180mm/s,

Normal 30-60mm/s

Working

Environment 10-30℃

humidity

20-50% After sales

service

One year warranty and free

consultation for life.Free software

upgrade,technical support

M3*5 screw 8PCS M4*16 screw 30PCS M5*25 screw 8PCS

ELF PRO Supplies holder limit switch+Material

break detection Coupling

Data cable TF Card+Card reader Shovel+VGA Support Plier

Filament 200g T-screw fixings Tool kit Power Cord

Extrusion Kit

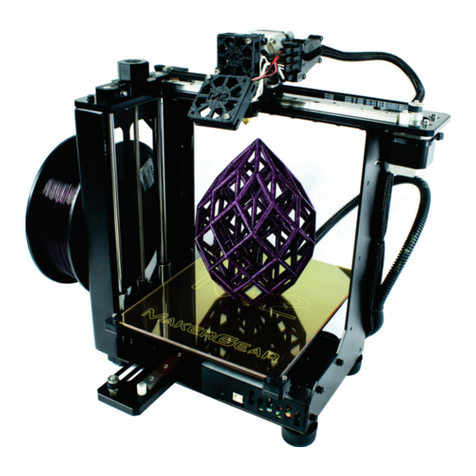

Frame

Display screen

Print platform

Z motor+Coupling

Power switch

Material break

detection

Nozzle

Base

Z limit switch

VGA cable

T-screw

Switch button

Fig.2

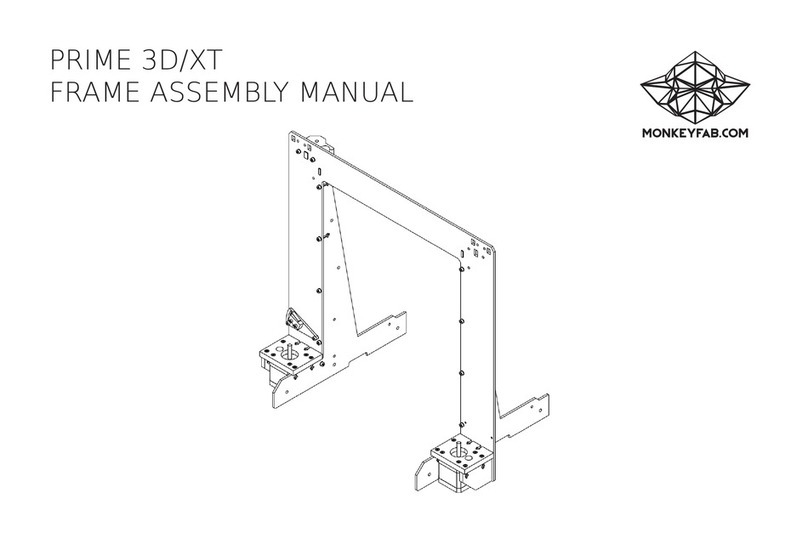

1.lnstall frame

1 Fig.1, Fix

the Z-axis hotbed

tray on the linear

guide with M3*5

cup head screws.

2 Fig.2, Insert 4

pieces of 2040

profiles and the

components in step

1 into the

corresponding

holes of the base.

M3*5-4PCS

Fig.1

M4*16

20PCS

3 Fig.3, Fix two

2020 profiles on

the Z-axis profile

with M5*25 cup

head screws

(6PCS)

4 Fig.4, Rotate

the T-screw into the

brass nut (note: be

sure to compress the

spring) and connect it

to the motor through

the coupling

M5*25

6PCS

Fig.3

Fig.4

T8*8 Screw

2PCS

D8-d5 Coupling

2PCS

5 Fig.5, Fix the

hotbed plate on the Z-

axis tray with M4*30

flat head screws, blue

die springs and black

hand-torque nuts (note:

the hand-torque nuts

can be tightened a

little) M4*30-P

4PCS

Fig.5

6 Fig.6, Put the

top cover assembly

on the profile frame

and fix it with M4*16

screws (the top cover

assembly needs to

be kept flat) Fig.6

M4*16

8PCS M3*5-4PCS

7 Fig.7, install

the Z-axis limit

switch and the Z-

axis T-screw fixing

piece in the

position shown in

the figure Fig.7

Y-axis motor & Z-axis

limit wiring diagram X-axis motor & Y-axis

limit & Z-axis limit wiring

diagram

Wiring diagram of

hotbed aviation

connector VGA wiring diagram

Dear customers:

1. In order to ensure the quality of products, we will carry out printing test for each

printer in the factory. If you find that the nozzle has slight traces of use, this is left

by the printing test. We try to clean it up as much as possible, but please don't mind.

2. The factory test voltage is 220V. When installing, please select 110V or 220V

according to your local power supply to ensure the printer can work normally.

Please find the following power supply identification, and use a screwdriver or

tweezers to move the regulator on the power supply.

1. Auto Home All Disable xy

If you want the

printer to shut

down

automatically

after printing,

Automatic

shutdown

2. Test with A4 paper, adjust the nuts under the platform up and down, to make the nozzle just presses the

A4 paper, and ensure that the four corners are the same distance. Repeat steps 1-2 times if necessary

There might be 3 kinds of results

for the first layer of the test prints.

A:Nozzle too close,lack of

extrusion,the nozzle rub against

the platform.Slowly tighten the

corresponding nuts underneath by

half circle or level again.

B:Proper nozzle height,good

extrusion and adhesion

C:Nozzle too high,Large

gap,filaments are not even adhere

to the platform.Slowly loosen the

corresponding nuts underneath the

platform by half circle or level again.

(1).ELF PRO 3D printer

reads Gcode file and prints. It

is necessary to convert

3Dfiles (such as stl file) into

Gcode files for machine to

recognize. Software that

convert 3D files into Gcode

files is called slicing software.

Cura_15.04.6 is used for

example here.Location of

cura: SD card---

>"Files_Engish_ELF PRO"---

>"cura"--->"Windows".

Double click"cura_15.04.6" ,

and follow the procedures as

shown in Fig.8:

Fig.8

(2)Next, before start Cura for

the first time, there will be more

settingsabout the language and

machine types, as show in

Fig.9.

Fig.9

Upon finish, open Cura for the first time, there might be a default robotmodel appears,

customers may click File --->"Clear platform todelete it.

Load 3D model into Cura

(1) Clear the platform by clicking“File”--->“Clear platform”

(2) Load 3D files onto the platform by“File”--->“Load model file...”.Files with extension

such as "STL","OBJ","DAE"and"AMF" can be loaded.Model in grey means it is outside

of the printable area and needs to bemoved or scaled to fit in.

Manipulate 3D model in Cura

(1)Zoom in/out: scroll the mouse wheel

(2) Change viewing angle: right click the model, hold on and move themouse

(3) Position change: left click on the model, hold on and drag the modelto move.

(4)Rotate: single left click on the model and several icons will appear atthe bottom left

of the window (Fig. 21).Click the rotate button, 3 circles will surround the model.Rotate

the model by moving the circle lines.

➢Lay flat: it is very important to ensure the flat portion of the model iswell attached to

the platform. So, please use Lay Flat option everytimeafter rotating the model, as it

will minimize the adhesion issues during printing.(Fig. 10)

➢Reset: click it to return the model to the original orientation.

(5) Scale: to uniformly scale the

modelalong X/Y/Z

dimensions.Todisable uniform

scaling, click the lock in the

lower section of the scaling

window. (Fig. 11)

Fig.10

Fig.11

Fig.12

(6) View mode (Fig. 12): to view the model in different ways and helpsto spotting

issues before print starts. Such as Layers mode: to viewthe toolpath of the print

head to check if there are skipped layers or gaps.

Scroll at

layers mode

Manipulate 3D model in Cura

(1)Machine settings

Refer to Fig. 13, click "Machine"--->"Machine settings" to input thosesuggested parameters

into the corresponding column.

Fig.13

Table of contents

Other Creativity 3D Printer manuals