7

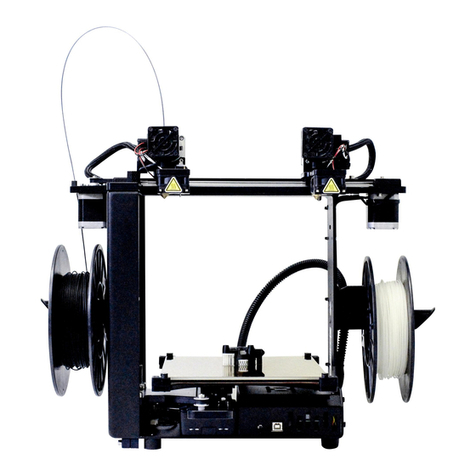

Printing - Dual Extruder

Both Pronterface and Simplify3D work with Dual Extruder units with

only minor changes.

In S3D, to control the second extruder, you need only select "Tool 1"

from the "Active Toolhead" drop-down menu in the Machine Control

Panel; this will send any extruder control commands (Extrude,

Retract or Set Temperature) to Tool 1, instead of the default Tool 0.

Switching back to "Tool 0" as the Active Toolhead will allow you to

control Tool 0 again.

In Pronterface, you first need to change the machine settings - click

on the Settings menu, and then the Options item. In the "Edit

settings" window that opens, you can change your machine

preferences - we are most concerned with "Extruders count" at the

bottom, which you will need to change from "1" to "2". Once

changed, click "OK" to save the settings and close the window, and

then close and open Pronterface to refresh everything.

Once that change has been made, you will have a "Tool: " item next

to the Extruder controls, which will let you toggle between Tool 0

and Tool 1. All Extruder related commands (Set Temperature,

Extrude and Retract) will apply to the selected Tool.

To preheat both nozzles for printing, you would first ensure that Tool

0 is select, and then Set your target temperature; then, select Tool 1,

and Set that target temperature as well.

Once both extruders are up to temperature, you can select either

and click Extrude to extrude filament; before attempting a print,

ensure that both Tool 0 and Tool 1 have extruded filament.

Select Tool 0, and then select "MGkey.g" from the SD card to being

printing. In S3D, that is done by clicking "Print from SD Card" and

selecting "MGkey.g" from the list that pops up; in Pronterface, the

same list can be accessed by clicking on "SD", and then "SD Print".

1

2

3

4

5

6