Creator CRT-531 Series Owner's manual

SPECIFICATION Model No. CRT-531

Date 2010-2-1

Card Dispenser Ver. 3.0

Page 2/13

CONTENTS

1. OVERVIEW……………………………………………………………………. 3

2. ENERAL SPECIFICATIONS…………………………………………………. 3

3. FUNCTION………………………………………………………………….. .3

4. RS232 COMMUNICATION PROTOCOL………………………………… 4

5. ADJUST THE THICKNESS OF CARD DISPENSIN ………………… .10

6. MAINTENANCE AND CAUTIONS……………………………………… 11

6. 1 MAINTENANCE………………………………………………… 11

6. 2 CAUTIONS FOR USE SAFETY ……………………………. ….11

6. 3 CAUTIONS FOR PRO RAMME………………………………11

7. WARRANTY………………………………………………………………... 12

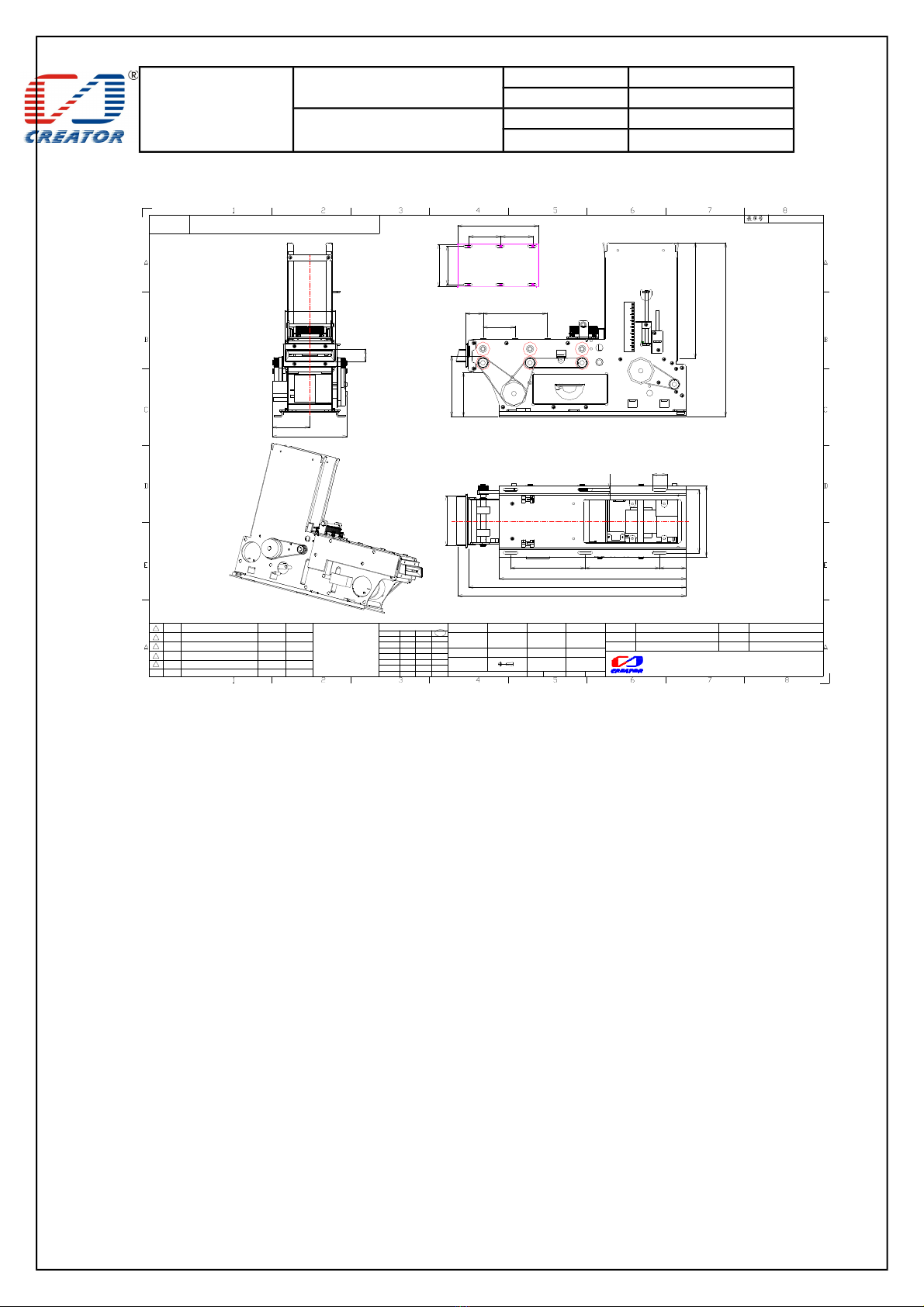

8. STRUCTURE AND DIMENSION DRAWIN …………………………. ..12

SPECIFICATION Model No. CRT-531

Date 2010-2-1

Card Dispenser Ver. 3.0

Page 3/13

1. OVERVIEW

CRT-531 ser es are card d spens ng module equ pment w th RS232 and TTL nterface to

d spense all k nds of cards. Card can be captured when the user doesn’t take the card or there

s any error dur ng operat on.

CRT- 531-( ) -

NOTE:CRT-531 Series fittings:

Extra long stacker: CRT-500-TCZ

ong stacker: CRT-500-CKZ

Short stacker: CRT-500-DKZ

Iron-block: CRT-500-MKK(for transformatived card)

2. ENERAL SPECIFICATIONS

1) Power supply : DC 24 V ± 10%

2) Current consumpt on : Stat c current 0.1A

Peak current dur ng operat on 1.5A

(700mA n normal cond t on)

3) Card feed ng-out speed : 0.1m/s OR 0.3m/s approx.

4) Commun cat on : RS-232C

5) Card standard : S ze : 55×86 mm

Th ckness: 0.20~1.2mm

(ex-work sett ng: 0.8mm)

6) We ght : 2.5 Kg Approx.

7) D mens ons : Refer to the enclosed mechan cal draw ng

8) Card stack ng capab l ty : 185pcs n case of 0.76 mm card

(can be set to 1000pcs max)

Stacker add ng f tt ng: Short: 60PCS;

Cl ent Code

001:CRT standard Ver 1.0

(Only d spense card)

002:CRT standard Ver 2.0

(d spense card&capture card to

the error card b n)

003:CRT standard Ver 3.0

(d spense card&capture card to

the error card b n and card read/wr te

pos t on)

XXX :Client shorten form

Commun cat on

R: RS232(standard)

W:Custom zed

Card capture

B: w th card capture b n

R: w th card capture channel

Bezel

N:No bezel

J:”J” bezel

Speed of d spens ng

card

H: 0.3M/S

L: 0.1M/S

Baffle at the bezel pos t on

N: No

S: S ngle d rect on (Only d spense card

from stacker)

D:B -d rect on (reserved)

SPECIFICATION Model No. CRT-531

Date 2010-2-1

Card Dispenser Ver. 3.0

Page 4/13

Long: 170PCS

Extra Long:285PCS

9) Card pre-empty detect on : 20~80pcs±2pcs

10) Env ronmental cond t ons :

Operat on: 0~50℃ 0~90% RH ( W thout Condens ng)

Storage:-10~75℃ 0~90% RH ( W thout Condens ng)

3. FUNCTIONS

1) Detect on funct on

To detect the card empty, card pre-empty or be ng full of error card b n

2) Doubled card d spens ng prevent on funct on

Mechan cal des gn, one motor forward, the other motor backward operat on, to

fundamentally prevent 2 cards d spens ng at the same t me

3) It can capture unl m ted cards f you choose the funct on of “card capture channel”

4) Easy card th ckness adjust ng dev ce

Patent technology, easy to adjust card th ckness by revolv ng graduat on of knob.

5) Eyew nkers prevent on funct on

Reflected opt cal sens ng locat on card s not effected by dust or other eyew nkers.

Profess onal des gned shutter to guard aga nst eyew nkers,eyew nkers cannot be nserted

from the d spenser ex t. Sav ng the ma nta n cost

6) Sensor c rcu t ntegrat on and photoelectr c ty to ensure the mach ne’s stab l ty and ma nta n

after sale

7) Pre-d spense funct on accelerate the speed of d spens ng, to keep d spense cont nuously

8) Download on l ne: support ISP download on l ne

9). Opt on for the speed of d spens ng card.

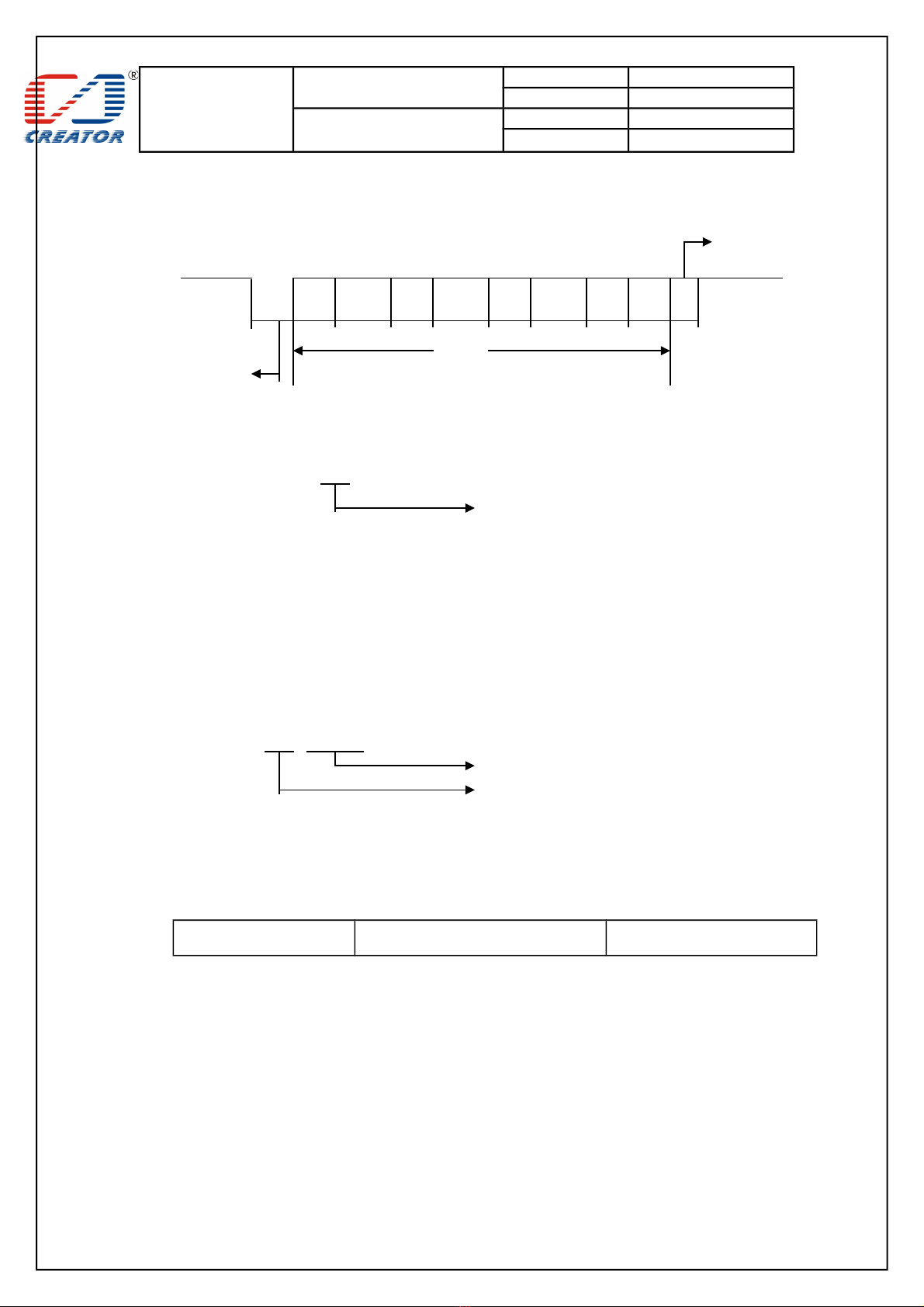

4. RS232 COMMUNICATION

4.1 RS232 Communication protocol

Baud rate (BPS) : Can be set by the host (Default: 9600 bps)

Commun cat on type : Asynchronous commun cat on

Transm t type : Half duplex

B t deta ls

Start b t : 1 b t

SPECIFICATION Model No. CRT-531

Date 2010-2-1

Card Dispenser Ver. 3.0

Page 5/13

Data b t : 8 b ts

Par ty b t : None

Stop b t : 1 b t

“1”

D0 D1 D2 D3 D4 D5 D6 D7

“0”

Data b t

Start b t

4.2 Command structure

4.2.1 Send command

〈STX〉 O O X 〈ETX〉 〈BCC〉

Command

〈STX〉 :02H, frame start

〈ETX〉 :03H, frame stop

〈BCC〉 :〈STX〉 0 ⊕ 0 ⊕〈ETX〉,block par ty

‘O’ : ASCLL of one b t

‘X’ : ASCLL of one b t, parameter of extend ng command(Poss ble to be

w thout the bas c command)

4.2.2 RF Status checking return

<STX> S F ○ ○ ○ <ETX><BCC>

Flag Code

Command (Send Flag)

<STX> : 0 2 (HEX) , Frame start

<ETX> : 0 3 (HEX) , Frame end

<BCC>: <STX> ⊕ ‘S’ ⊕ ‘F’ ⊕ 0 ⊕ 0 ⊕ 0 ⊕ <ETX>, Block Check Code

Definition of Flag Code

HEX BIN STATUS

SPECIFICATION Model No. CRT-531

Date 2010-2-1

Card Dispenser Ver. 3.0

Page 6/13

800

400

200

100

080

040

020

010

008

004

002

001

1 0 0 0 0 0 0 0 0 0 0 0

0 1 0 0 0 0 0 0 0 0 0 0

0 0 1 0 0 0 0 0 0 0 0 0

0 0 0 1 0 0 0 0 0 0 0 0

0 0 0 0 1 0 0 0 0 0 0 0

0 0 0 0 0 1 0 0 0 0 0 0

0 0 0 0 0 0 1 0 0 0 0 0

0 0 0 0 0 0 0 1 0 0 0 0

0 0 0 0 0 0 0 0 1 0 0 0

0 0 0 0 0 0 0 0 0 1 0 0

0 0 0 0 0 0 0 0 0 0 1 0

0 0 0 0 0 0 0 0 0 0 0 1

Dispensing card

Capturing card

Card Dispense error

Card Capture error

No Capture card

Overlapping cards

Jamming Card

Card pre-empty Status

Card empty Status

Disp-Sensor Status

Capt-Sensor 2 Status

Capt-Sensor 1 Status

4.2.3 AP status checking return

<STX> S F ○○○○ <ETX><BCC>

Flag Code

Command (Send Flag)

<STX> : 0 2 (HEX) , Frame start

<ETX> : 0 3 (HEX) , Frame end

<BCC>: <STX> ⊕ ‘S’ ⊕ ‘F’ ⊕ 0 ⊕ 0 ⊕ 0 ⊕ 0 ⊕ <ETX>, Block Check

Code

Definition of Flag Code

HEX BIN STATUS

SPECIFICATION Model No. CRT-531

Date 2010-2-1

Card Dispenser Ver. 3.0

Page 7/13

8000

4000

2000

1000

0800

0400

0200

0100

0080

0040

0020

0010

0008

0004

0002

0001

0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1

(Reserve)

(Reserve)

Failure alarm (sensor

invalid)

Error card bin is full

Card Is Dispensing

Card Is Capturing

Card Dispense error

Card Capture error

No capture

Card overlapped

Card jam

Card pre-empty

Card empty-Sensor Status

Disp-Sensor Status

Capt-Sensor 2 Status

Capt-Sensor 1 Status

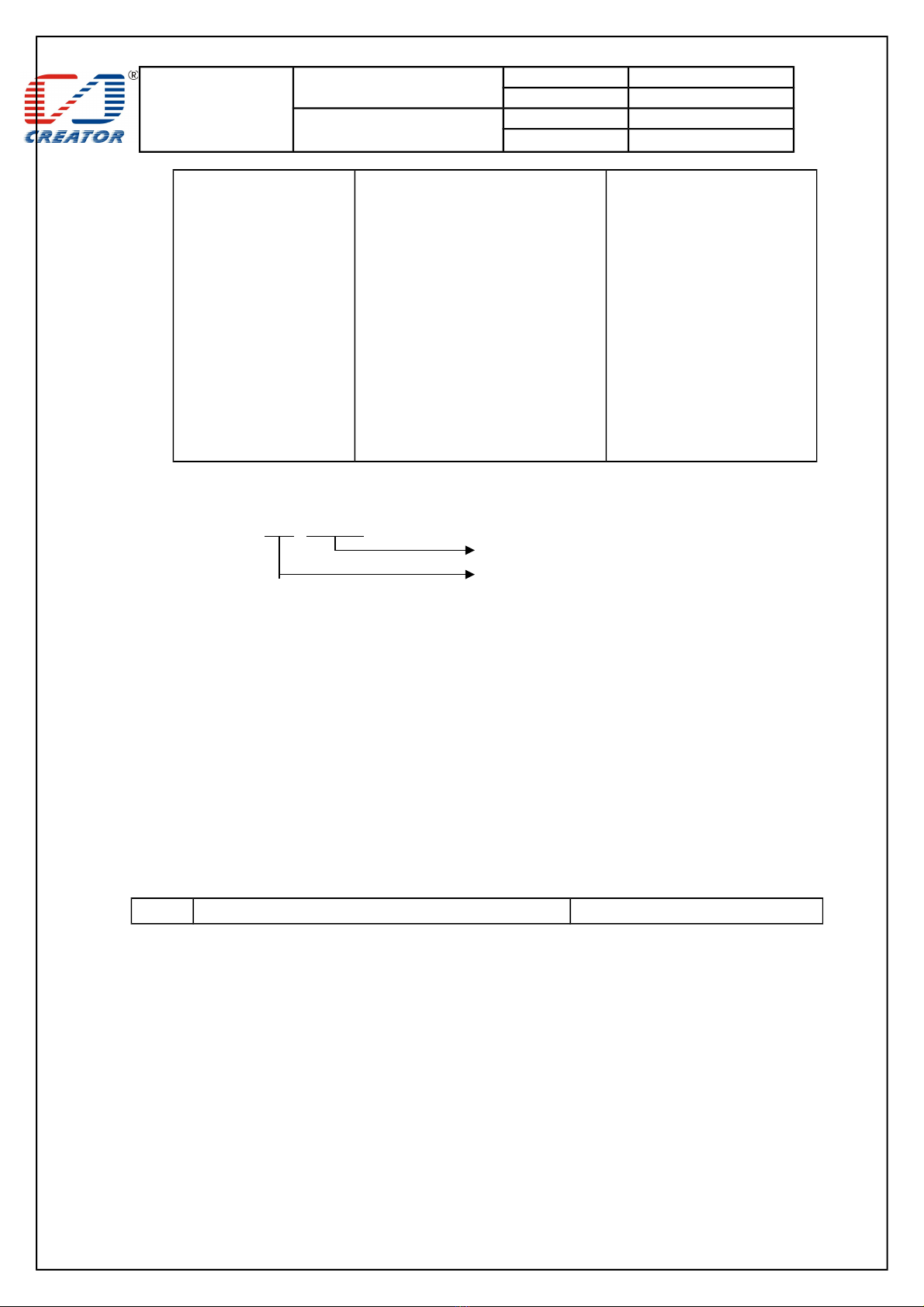

4.3 Basic command code(Compatible with KDE-1500)

Command(ASCL

L)

Content Return message

DC D spense card to ex t < 06H>

CP Card capture < 06H>

RF Status check ng Ref: RF status check ng return

AP H gh-class status check ng Ref: AP status check ng return

RS Reset < 06H>

SPECIFICATION Model No. CRT-531

Date 2010-2-1

Card Dispenser Ver. 3.0

Page 8/13

4.4 Extend CRT Command

Command +

Parameter

Return Comment

“FC”+ Position <06H> Card stop on the spec f ed pos t on ,

,1,2,3,4,5,6} parameter:

0x30,0x34,0x33,0x32,0x31,0x36,0x37}

“CS”+ Position <06H> Set up Baud rate.(0-5,

indicate 1200BPS-38400BPS)

“IN”+ Parameter <06H> Setting of card inserted from

dispenser mouth:

Parameter

=0x30 Prohibit cards in

=0x31 Allow cards into error card bin

=0x32 Allow cards into card

read/write position (I.e. card stop

location 2)

“SI” SI +Parameter(similar

to RF command returned)

Check the setting status of card

inserted from the dispenser mouth

Note : ( 1) “4”s the pos t on for card pre-d spense, program w ll execute “pre-d spense”

automat cally(Except press “Reset” keystoke on the d spenser by hand); Execute “FC+4”, no any

react on for th s command, and th s w ll cause unpred ctable damage, so please don’t use th s

command n a hurry.

(2)The operat on of check ng status for “SI” nsert ng card from d spenser mouth s s m lar to

“RF” and “AP”. The parameter of command returned w th 1byte s same as the “IN”parameter.

(3) “IN” s a operat on command for EEPRON. The sett ng status w ll not be affected even f

t s power on or reset, that means the last sett ng s st ll val d when power on. And It s defaulted

that the card s captured to the error card b n when ex-work.

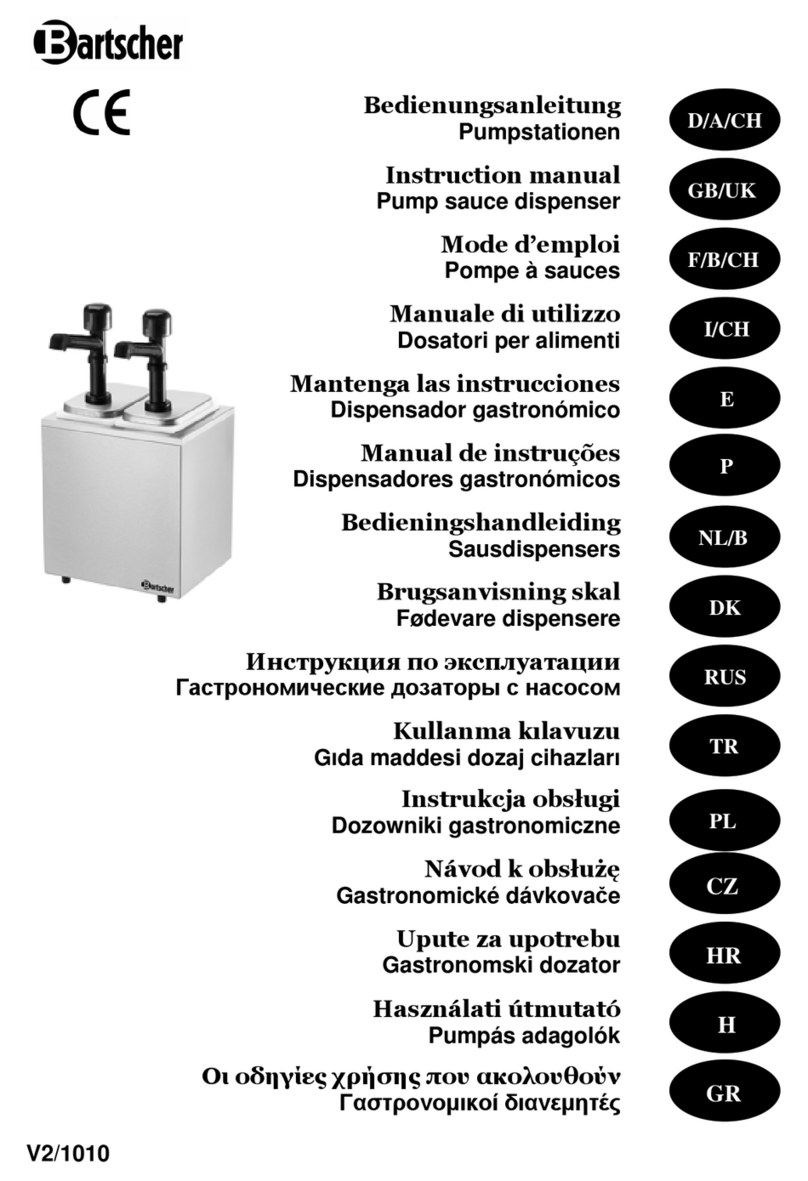

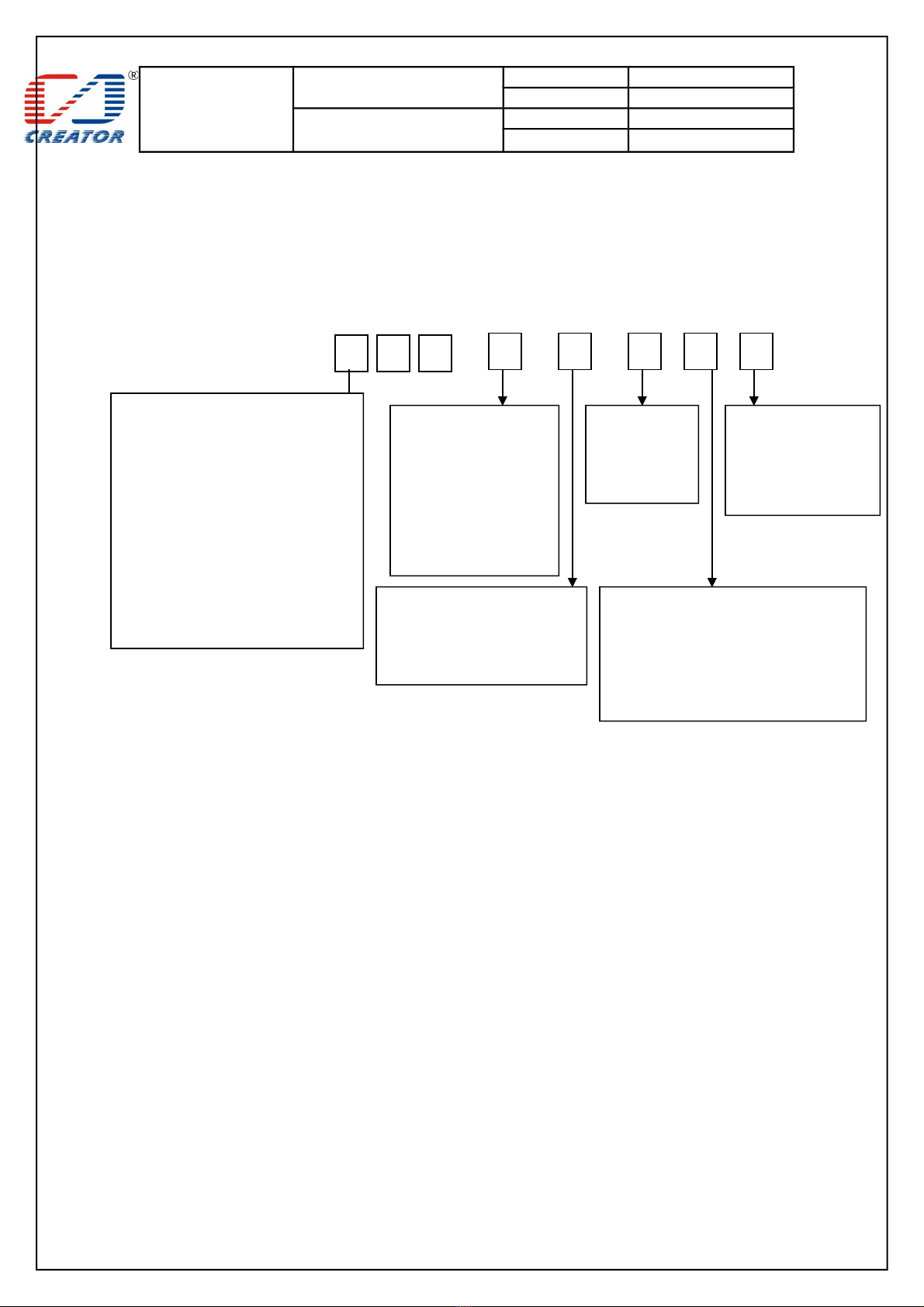

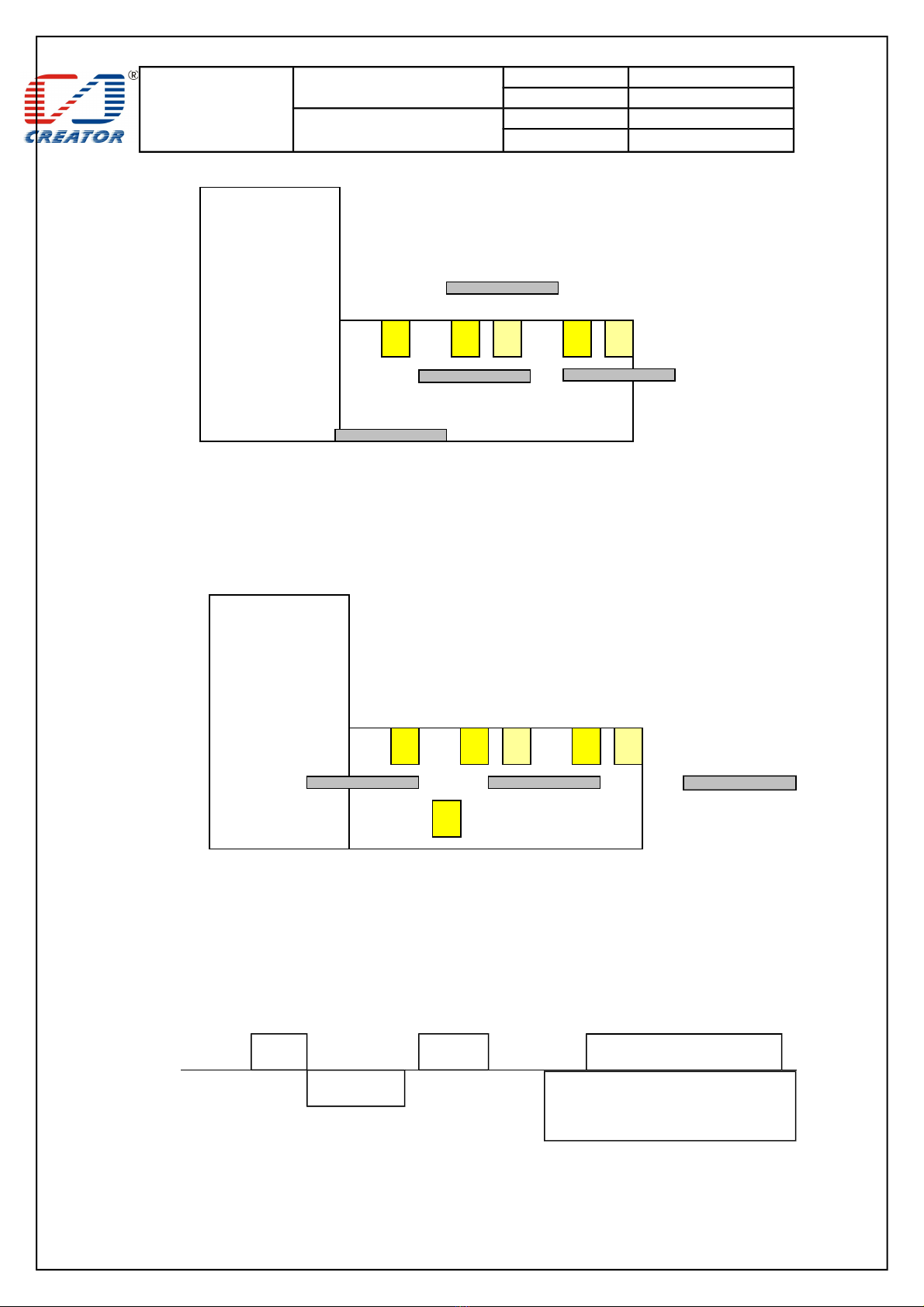

4.5 Specification of photoelectricity sensor and card stop location

4.3.1 Definition of graph

Card Stop Locat on

photoelectr c ty sensor photoelectr c ty sensor preserved

4.5.2 Sketch map of card stop location and photoelectricity sensor

n n

SPECIFICATION Model No. CRT-531

Date 2010-2-1

Card Dispenser Ver. 3.0

Page 9/13

4.6 Communication sample:

4.6.1 Card dispensing

Ma n controller :〈STX〉 DC 〈ETX〉〈BCC〉

Card d spenser : Send ACK,respons ble for card d spens ng and

mod f cat on of status of reg ster

Ma n controller

Card d spenser

there nto: 〈ACK〉:06H

〈NAK〉:15H

〈ENQ〉:05H

DC

ACK/NA

K

ENQ Enqu ry constantly

Card d spens ng and mod f cat on

of status reg ster

3 2 1

1112323212

6 4

No.3 card stop

leave Sensor 3

No.6 Card stop

Sensor 1

3 2 1

5

6 4

6

No.4 card stop,

Pre-dispense

card, sensor 3.

No.2 card stop

Card reading,

leave sensor

2.

No.1 card stop,

Dispense card to exit.

1112323212

No.0 card stop

Outside of dispenser.

No.5 card stop,

Sensor2

SPECIFICATION Model No. CRT-531

Date 2010-2-1

Card Dispenser Ver. 3.0

Page 10/13

Procedure as follow::

Ma n controller :〈STX〉DC〈ETX〉〈BCC〉

Card d spenser : Send ACK/NAK

4.6.2 Card capture(the procedure is similar to card dispensing)

Ma n controller :〈STX〉 CP 〈ETX〉〈BCC〉

Card d spens ng :Send ACK,respons ble for card d spens ng and mod f cat on of

status of reg ster

Controller “CP” ENQ

D spenser ACK/NAK

4.6.3 Status require

Ma n controller :〈STX〉 RF 〈ETX〉〈BCC〉

Card d spenser :Send ACK, rece ve ENQ, then send〈STX〉 SF OOO〈ETX〉

Ma n controller “RF”ENQ

Card d spenser ACK/NAK

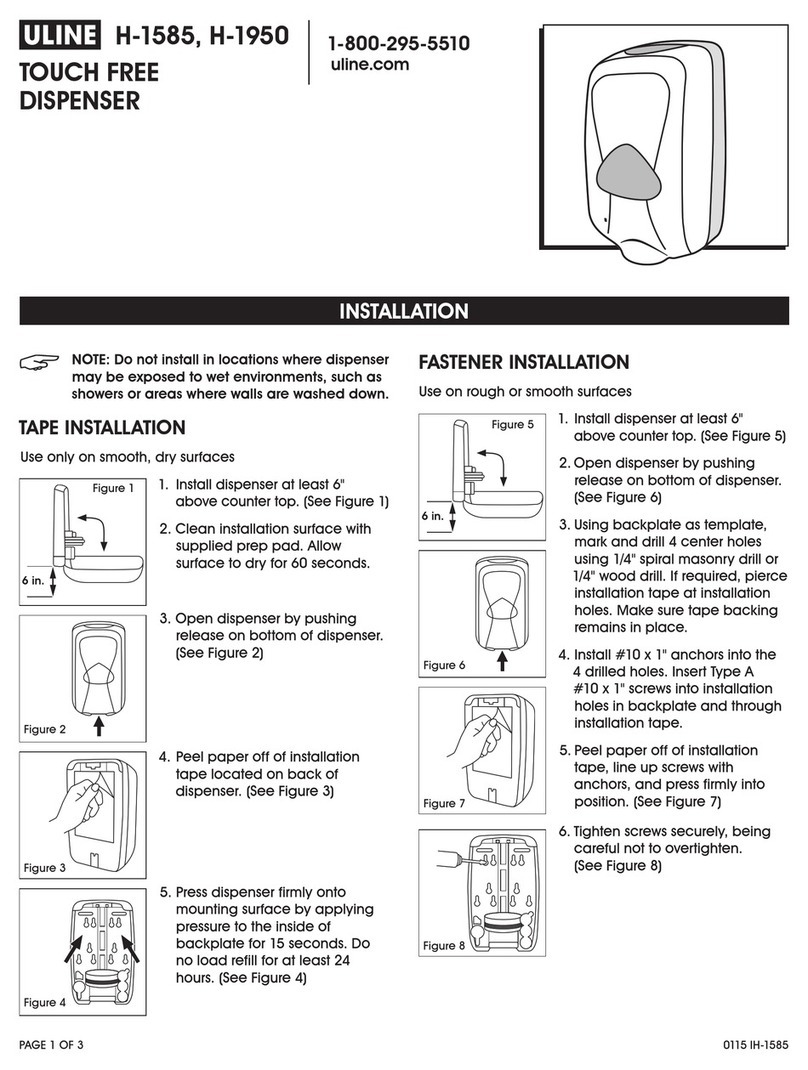

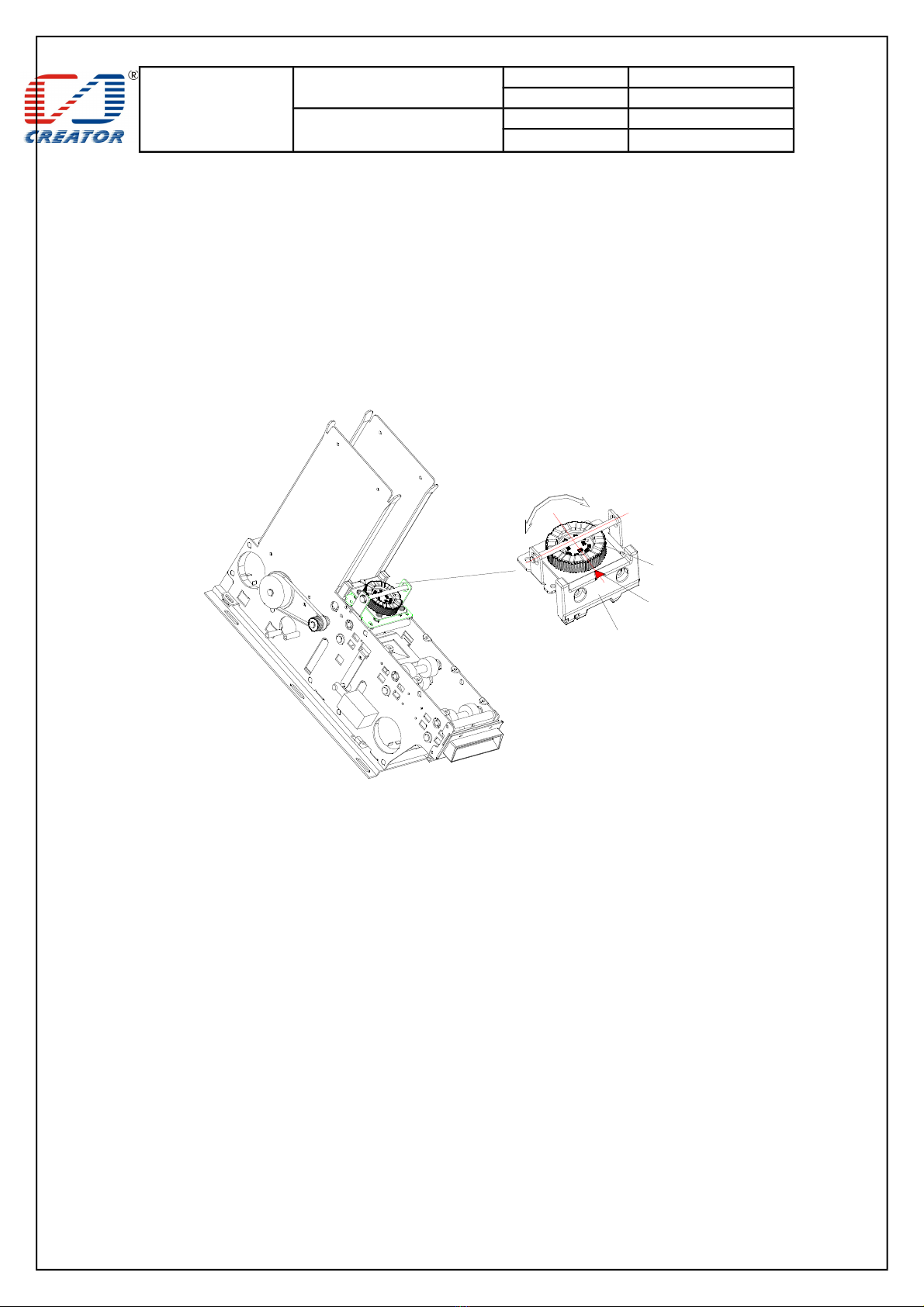

5. ADJUST THE THICKNESS OF CARD DISPENSIN

CRT-531 makes t more accurate and conven ent to d spense cards n d fferent th ckness v a

rotat ng the turn-knob to d fferent gear pos t on so as to adjust the gap between the upper and

lower transm t ng wheels, wh ch can el m nate the nconven ent and naccurate gap adjustment

defects. W th th s feature, CRT-531 s qu te su table for the unattended vend ng dev ces to

d spense var ous cards of d st nct th ckness.

Ma n controller : ENQ

Ma n controller :

Send‘RF’ constantly

unt l card d spens ng

completely

Card d spenser :Card

d spens ng and mod f cat on

of status reg ster

Enqu ry constantly

Card d spens ng and

mod f cat on of status reg ster

Card d spenser sends

code to host

SPECIFICATION Model No. CRT-531

Date 2010-2-1

Card Dispenser Ver. 3.0

Page 11/13

There are several steps to adjust the th ckness of cards:

1. Conf rm the th ckness of cards ( Ra sed type character are not nvolved n)

2. Push the turn-knob and turn around to the graducat on po nted by the red arrow.

See ng p ctures below.

3. Make sure the adjustment on the r ght pos t on by nsert cards from stacker. (Insert ng

one card from stacker w ll be smooth and two cards s multaneously from beh nd can

be mposs ble)

挡门

调节钮

标记

Adjustment Button

Mark

baffle

6. MAINTENANCE AND CAUTIONS

6.1 Maintenance

After us ng for some t me or d spens ng amount of cards, the d spenser w ll be ser ous

wear ng because of every part s runn ng, so we need to do some ma ntenance to the

mach ne. The steps as follows:

1)Check the parts of the d spenser. If they become flex ble or abnormal, re nforce them.

2)Check the straps of dr ve wheels. If they become flex ble, regulate the pos t on of the

elast c ty wheel.

3) Use clean ng card or soft cloth w th alcohol to clean the d spenser wheel n the

bottom of the hopper and the dr ve wheel.

SPECIFICATION Model No. CRT-531

Date 2010-2-1

Card Dispenser Ver. 3.0

Page 12/13

4)Use soft cloth w th alcohol to clean the d rty cards and replace the d stort on cards

5) Check the graduat on of knob to see whether they are correspond ng.

6.2 Cautions for safe use

1) Ensure the power connected w th card d spenser s off wh le repa r ng the whole

mach ne.

2) Not ce the cathode and anode of the mach ne power wh le power on for the f rst t me.

3) Not ce the Spec f cat on of JUMP when us ng for the f rst t me, because mproper

JUMP w ll cause work off or unpred ctable status.

4) If you do not use nsulat on power, external power must not be connected to nsulat on

power, otherw se, PCB w ll be broken.

5) Proh b t to nset or pull out the receptacle of the port. Otherw se, the c rcu t of the

controller may be spo led.

6) Ensure the d spenser out of smear. The smear w ll affect the capab l ty of the d spenser.

7) On the back of d spenser s de board, there s a red soft manual “Reset ” keystoke. When

error or abnormal s tuat on occurs on spot, then eng neer can press th s keystoke for reset.

It s not used n general s tuat on.

8) Red soft “RESET” keystoke funct on s looked as card coord nat ng and card return to

pre-d spense or capture pos t on when error occurs. Once use “RESET”, Pre-d spense

w ll be nval d, unt l use “DC” and “FC”.

9) “RESET” has overt me protect on funct on, when the keystoke s pressed for a long

t me, then motor w ll stop automat cally to protect tself.

6.3 Caution for program

1)“4” s pre-d spense pos t on, FC command w ll not has the funct on of th s pos t on.

2)In order to mprove the commun cat on speed of the program, cond t on nspect on

w ll just be execute one t me when “RESET”; User can “Reset” to check f the

cond t on s correct. (Reset by three ways: press “RESET” on PCB of d spenser

bottom, press red soft “RESET” on back of d spenser s de board, or by power on/off)

3) Under RS232 mode ,send ng enqu ry command w ll cause program enter

commun cat on nterrupt on process ng, wh ch w ll affect card d spens ng and other

execut on, the t me alternat on for next enqu ry command should be over 200ms.

7.WARRANTY

1) One year guarantee free of charge. Count ng from the day that users rece ve the goods.

2) User sends the goods to us for repa r ng.

3) Prov de after-sale serv ce after exceed ng guarantee per od. We w ll take some mater al

fee f need to replace f tt ngs. And we w ll take some upkeep n the follows s tuat ons

although t s n guarantee per od:

a) Damage and trouble caused art f c ally;

b) Damage and trouble caused by non-profess onal operat on;

c) Damage and trouble caused by nstab l ty of user’s power supply;

d) Damage and trouble caused by force majeure, such as earthquake, natural weather etc.

SPECIFICATION Model No. CRT-531

Date 2010-2-1

Card Dispenser Ver. 3.0

Page 13/13

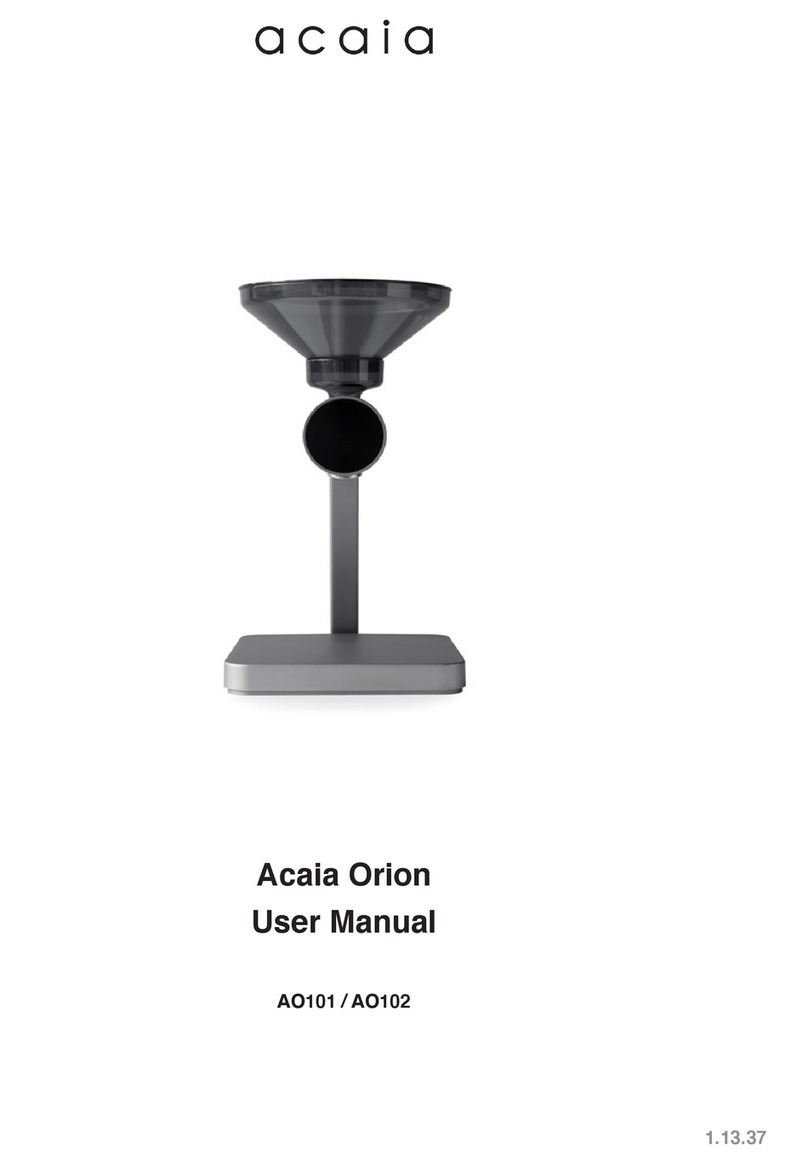

8.STRUCTURE AND DIMENSION DRAWIN

41.5

50

RF PCB

105

55

295.82

281.82

96.596.5

242

34.1

92

82

19

4

64.6

225.5

83

57

78.5

22.9

41.5

150

64.6

16

97

47.95

深 圳 市 创 自 技 术 有 限 公 司

CREATOR (CHINA) TECH CO., LTD

校 对 审 核

设 计

共 页 , 第 页 单 位 mm

图样标记 数 量

日 期

零件代码

工 艺

产品名称

版 本

>

120~250

A.0

>

50~120

比 例

零件名称 0755-26710345

0755-26710105

材 料

传 真

电 话

QR - 066/A.1

>

18~50

>

3~6 ±0.05

标 记 更改文件 号

处 数 日 期

字签

2

3

1

4

5

>

6~18 ±0.07

±0.10

±0.15

±0.21

±0.15

±0.18

±0.25

±0.30

±0.40

±0.35

±0.52

±0.62

±0.74

±1.00

≤

3±0.02 ±0.10 ±0 .25

>

250~500

±0.25 ±0.50 ±2.00

范围 1 级 2 级 3 级

一般公差

无特殊说明尺寸公差执行方法:

1.一般孔径、轴的尺寸按1级公

差带执行

2.一股线性公 差、圆角、倒角

按2级公差带执行

3.装配尺寸 、角度尺寸公差按

3级公差带执行

文件编号

11:1

CRT-531 系列

CRT-531 系列

RF-PCB 安装位置

Standard volume(0.76mm):180PCS

装载标准卡(0.76mm):180PCS

41.5

10

20

30

40

50

60

70

Table of contents

Other Creator Dispenser manuals

Popular Dispenser manuals by other brands

Sureshot Dispensing Systems

Sureshot Dispensing Systems AC-VP1 Operation manual

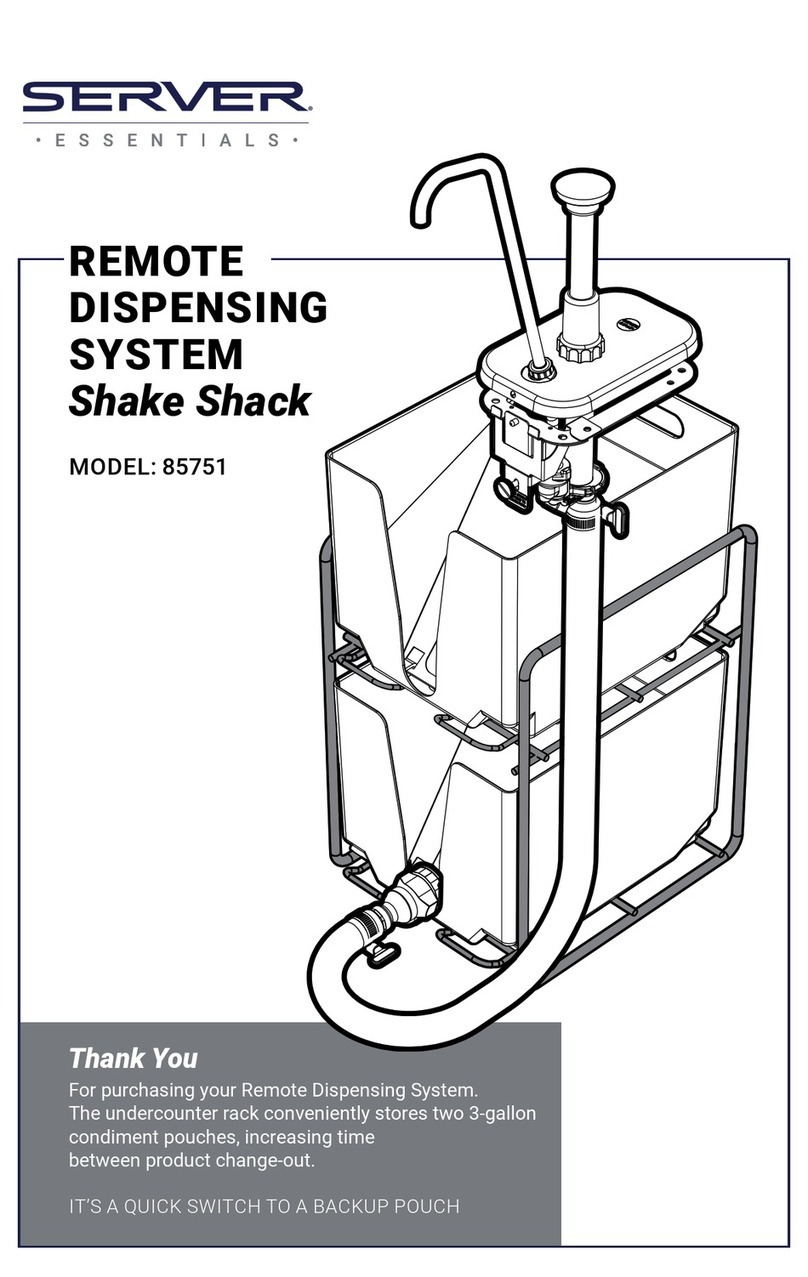

Server

Server Shake Shack 85751 manual

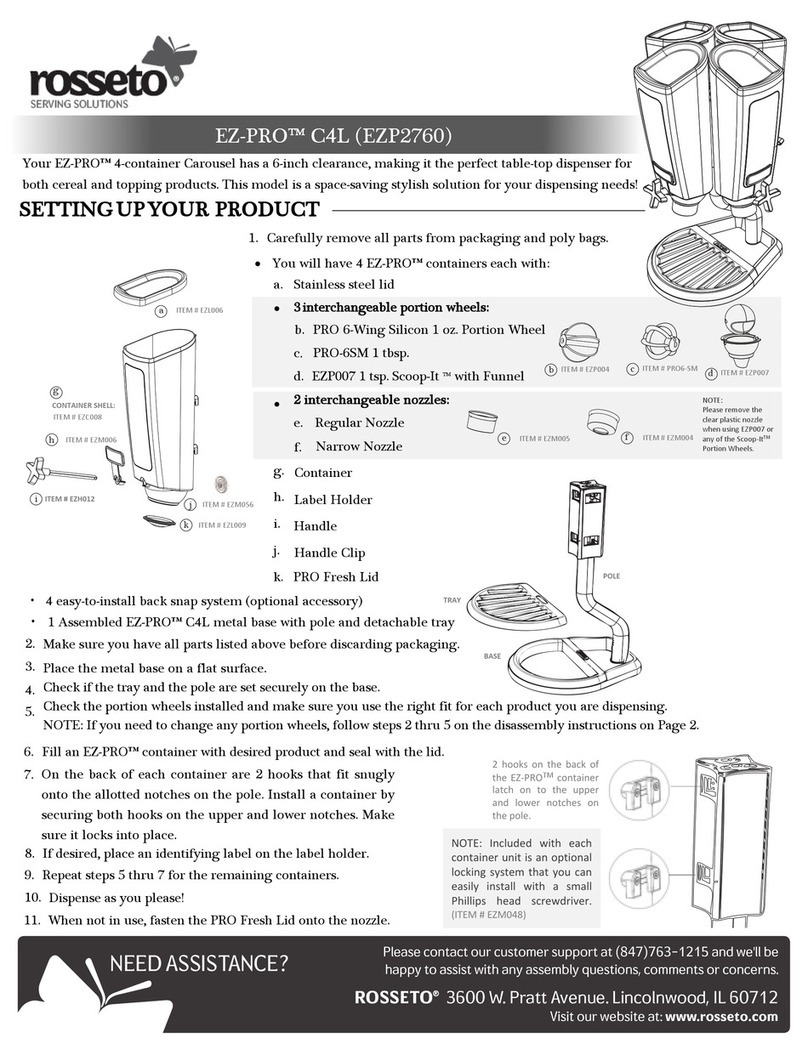

rosseto

rosseto EZ-PRO C4L quick start guide

Georgia Pacific

Georgia Pacific PRO enMotion 59466A reference guide

Vollrath

Vollrath Stoelting O111-I2F Operator's manual

Cornelius

Cornelius Nueva Tower Installation and service manual