Modulated OP-CL 230 Vac Valve

This device is designed for use with a 2-pipe, 3-speed FCU with 230 Vac common open or

close valve.

In this case, the valve performs regulation in the ∆T vicinity of set point; the valve opens

and closes at the rate of its dened time, according to the graph below.

Periodically, the valve is forced to the fully open position to eliminate accumulated error.

Error annulation period is dened by Reset valve error interval parameter. The valve is

controlled using two relays (Stg 1 - open, Stg 2 - close).

The diagram of working compressor according to room temperature is shown in the graph

below.

T (˚

Sp-3∆T Sp+3∆TSp-2∆T Sp+2∆TSp-∆T Sp+∆TSpH SpC

100

Ymin

0

• SpH - Set point for heating

• SpC - Set point for cooling

• Y - Valve position (0% closed, 100% fully open)

• Ymin - Minimum position of valve when the set point is reached

• T - Room temperature

• ∆T - Step of temperature difference (∆T=N•0.5 °C, where N is a settable parameter)

• t - Time to valve reach full open or close position

NTC

1

Fan

1

CV

1

S

WS

WR

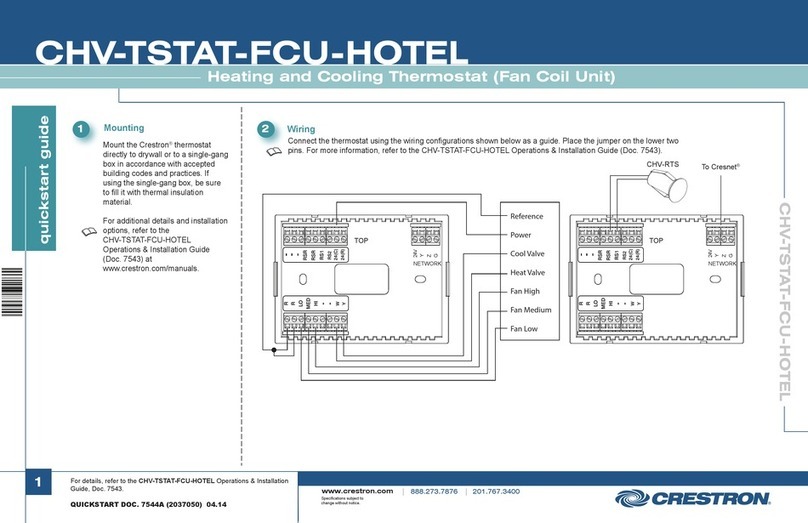

POWER SUPPLY:

230 Vac power input for

line, neutral, and earth

STAGE OUT:

230 Vac max power for open

and close control to the valve

FAN OUT:

230 Vac max fan power

in and fan control out

STATUS

NET

COM

DIN-TSTAT-FCU

TEMP SENSE

DIGITAL IN COM

VALVE OUTPOWER SUPPLY STAGE OUTFAN OUT

NET

L

L

L

L 1

FL

FM

FH

NC

L2

ST1

ST2

OP

24V

CL

24V

0-10

G

E

NC

N

N

N

CDI

DI3

CDI

TS1

G

TS2

G

DI0

CDI

DI1

CDI

DI2

Y

Z

G

EP

A

B

G

24

COM:

To the

room

controller

NET:

To the

control

system

TEMP SENSE:

From the

temperature

sensor

Spring-loaded 230 Vac Valve

This device is designed for use with a 2-pipe, 3-speed FCU with spring-loaded 230 Vac

valve.

In this case, the valve operates as an on and off valve. The valve value is calculated

according to room temperature, as shown in the graphs below. The valve is controlled using

one relay (Stg 1 - open).

The diagram of working compressor according to room temperature is shown in the graph

below.

t (time)

Sp

T* Ymin

0

0t (time)

100

valve %

t (time)

Sp

T* Ymin

0

0

100

valve %

• Sp - set point

• ∆T* Ymin - Temperature when the valve is open

NTC

1

Fan

1

CV

1

WS

WR

POWER SUPPLY:

230 Vac power input for

line, neutral, and earth

FAN OUT:

230 Vac max fan power

in and fan control out

STATUS

NET

COM

DIN-TSTAT-FCU

TEMP SENSE

DIGITAL IN COM

VALVE OUTPOWER SUPPLY STAGE OUTFAN OUT

NET

L

L

L

L 1

FL

FM

FH

NC

L2

ST1

ST2

OP

24V

CL

24V

0-10

G

E

NC

N

N

N

CDI

DI3

CDI

TS1

G

TS2

G

DI0

CDI

DI1

CDI

DI2

Y

Z

G

EP

A

B

G

24

STAGE OUT:

230 Vac max power for

open control to the valve

COM:

To the

room

NET:

To the

control

TEMP SENSE:

From the

temperature

1-2 Stage Direct-expansion System

This device is designed for use with a 3-speed, direct-expansion system with compressor

control - cooling only.

In this case, a compressor is controlled instead of a valve. The compressor state for stage

one and stage two is determined by the room temperature. The compressor is controlled

using two relays (Stg 1 – stage 1, Stg 2 – stage 2).

The diagram of working compressor according to room temperature is shown in the graph

below.

t

∆T

∆T/2

Sp

S1

S2

0

0

• Sp - set point

• ∆T - Step of temperature difference (∆T=N•0.5, where N is a settable parameter)

• S2 - Stage 2 on

• S1 - Stage 1 on

NTC

1

Fan

1

AS

AR

POWER SUPPLY:

230 Vac power input for

line, neutral, and earth

FAN OUT:

230 Vac max fan power

in and fan control out

STATUS

NET

COM

DIN-TSTAT-FCU

TEMP SENSE

DIGITAL IN COM

VALVE OUTPOWER SUPPLY STAGE OUTFAN OUT

NET

L

L

L

L 1

FL

FM

FH

NC

L2

ST1

ST2

OP

24V

CL

24V

0-10

G

E

NC

N

N

N

CDI

DI3

CDI

TS1

G

TS2

G

DI0

CDI

DI1

CDI

DI2

Y

Z

G

EP

A

B

G

24

STAGE OUT:

230 Vac max power for Stage 1 and

Stage 2 control to the compressor

COM:

To the

room

NET:

To the

control

TEMP SENSE:

From the

temperature

Fan Speed Control

For all congurations, the fan speed shifts to low, medium, and high based on room

temperature. When a room temperature reaches its set point, the fan either shuts down or

the fan turns on low.

If the fan speed is forced, the fan constantly runs at the selected speed.

High

Medium

Low

T (˚C)

Sp-3∆T Sp+3∆T

Sp-2∆T

• SpH - Set point for heating

• SpC - Set point for cooling

• T - Room temperature

• ∆T - Step of temperature difference (∆T=N•0.5 °C, N is settable parameter)

Water Temperature

The second TEMP SENSE input can be used for water temperature measurement.

Parameters can be set to determine the minimum temperature difference between the

ambient temperature of the room and the water temperature for the FCU to effectively

perform its function. When cooling is performed, the device ensures that the water in the

system is adequately cooler than the ambient temperature. When heating is performed,

the device ensures that the water in the system is adequately warmer than the ambient

temperature. If the water temperature is not adequate, the fan is turned off and the valve

is fully opens.

Digital Inputs

The device has four digital inputs that act as alarm inputs. Alarm inputs are used for

accepting contacts from a window or door sensor, condensation canister full sensor, PIR

sensor, etc.

If using the digital inputs, congure them using the settable parameters. When a digital

input is activated, it blocks the device outputs. For example, fan speed will be set to 0 and

valve will be shut.

There are three parameters available for each digital input:

• Enable - alarm is used or unused

• Polarity - alarm active state

• Delay - time from alarm activation to blocking the outputs

DIGITAL IN:

From the window

switch, door switch, or

occupancy sensor

POWER SUPPLY:

Power input for line,

neutral, and earth

STATUS

NET

COM

DIN-TSTAT-FCU

TEMP SENSE

DIGITAL IN COM

VALVE OUTPOWER SUPPLY STAGE OUTFAN OUT

NET

L

L

L

L 1

FL

FM

FH

NC

L2

ST1

ST2

OP

24V

CL

24V

0-10

G

E

NC

N

N

N

CDI

DI3

CDI

TS1

G

TS2

G

DI0

CDI

DI1

CDI

DI2

Y

Z

G

EP

A

B

G

24

COM:

To the

room

NET:

To the

control

Commission the System

The DIN-TSTAT-FCU is set up and commissioned using DIN-TSTAT-FCU Conguration

Tool. Refer to the DIN-TSTAT-FCU Setup and Commissioning Guide (Doc. 8207) at

www.crestron.com/manuals for more information.

As of the date of manufacture, the product has been tested and found to comply with specications for

CE marking.

The product warranty can be found at www.crestron.com/warranty.

The specic patents that cover Crestron products are listed at www.crestron.com/legal/patents.

Certain Crestron products contain open source software. For specic information, please visit

www.crestron.com/opensource.

Crestron and the Crestron logo are either trademarks or registered trademarks of Crestron Electronics,

Inc. in the United States and/or other countries. Other trademarks, registered trademarks, and trade

names may be used in this document to refer to either the entities claiming the marks and names or their

products. Crestron disclaims any proprietary interest in the marks and names of others. Crestron is not

responsible for errors in typography or photography.

This document was written by the Technical Publications department at Crestron.

©2017 Crestron Electronics, Inc.

Crestron Electronics, Inc. Installation Guide - DOC. 8203B

15 Volvo Drive Rockleigh, NJ 07647 (2048940)

Tel: 888.CRESTRON 08.17

Fax: 201.767.7576 Specications subject to

www.crestron.com change without notice.