Cristofoli Ultrasonic cleaner User manual

Cristófoli Ultrasonic Cleaner

13485

D

E

S

G

A

E

M

S

E

T

T

Ã

S

O

I

S

Cristófoli, Brazilian company importer and manufacturer of health products

certified by ISO 9001 - Quality Management System, ISO 13485 - Medical

Devices - Quality Management System - Requirements for Regulatory Purposes,

ISO 14001 - Environmental Management and *BPF - Boas Práticas

de Fabricação - ANVISA.

CRISTÓFOLI’S MISSION

CRISTÓFOLI QUALITY AND ENVIRONMENTAL POLICY

*BPF - Boas Práticas de Fabricação: Brazilian standard similar to the GMP - Good Manufacturing Practices (FDA / US).

Develop innovative solutions to protect life and promote health.

Cristófoli Equipamentos de Biossegurança Ltda., established at Rodovia BR-158, nº 127, Jardim Curitiba in Campo

Mourão, Paraná, Brasil, manufactures biosafety equipment to assist the health field having as policy: “Develop innovative

solutions for the health field by using agile, robust and objective processes to better serve its clients. Fulfill the requirements

for regulatory purposes of the applicable standards, promote the continuous improvement of its quality and environmental

systems, prevent pollution, reduce its environmental impacts and continuous training of its employees, achieving this way, a

sustainable profitability and the maximization of the company’s value”. Rev. 2.

Manual Cuba de Ultrassom Cristófoli Ing. Rev.1-2015

CONTENTS

Legend of Symbols ......................................................................................................................................

Intended Use ...............................................................................................................................................

Operation Principle ......................................................................................................................................

Contents of the Box .....................................................................................................................................

Recommendations and Warnings ...............................................................................................................

Installation Instructions ..................................................................................................................................

Components Identification ..........................................................................................................................

Safety Devices .............................................................................................................................................

Degassing / Using the Beaker .......................................................................................................................

Heating ........................................................................................................................................................

How to Use the Cristófoli Ultrasonic Cleaner .................................................................................................

T ............................................................................................................................................echnical Data

How to Identify your Ultrasonic Cleaner ........................................................................................................

Preventive Maintenance ..............................................................................................................................

Troubleshooting ............................................................................................................................................

Quality Control .............................................................................................................................................

Authorized Technical Assistance ..................................................................................................................

Customer Service Department - CSD ..........................................................................................................

Guidance for Final Disposal of the Equipment ............................................................................................

Warranty Terms .............................................................................................................................................

03

04

04

04

04

05

06

07

07

07

08

10

11

11

12

13

13

13

13

14

2

CRISTÓFOLI

ULTRASONIC CLEANER

INSTRUCTION MANUAL

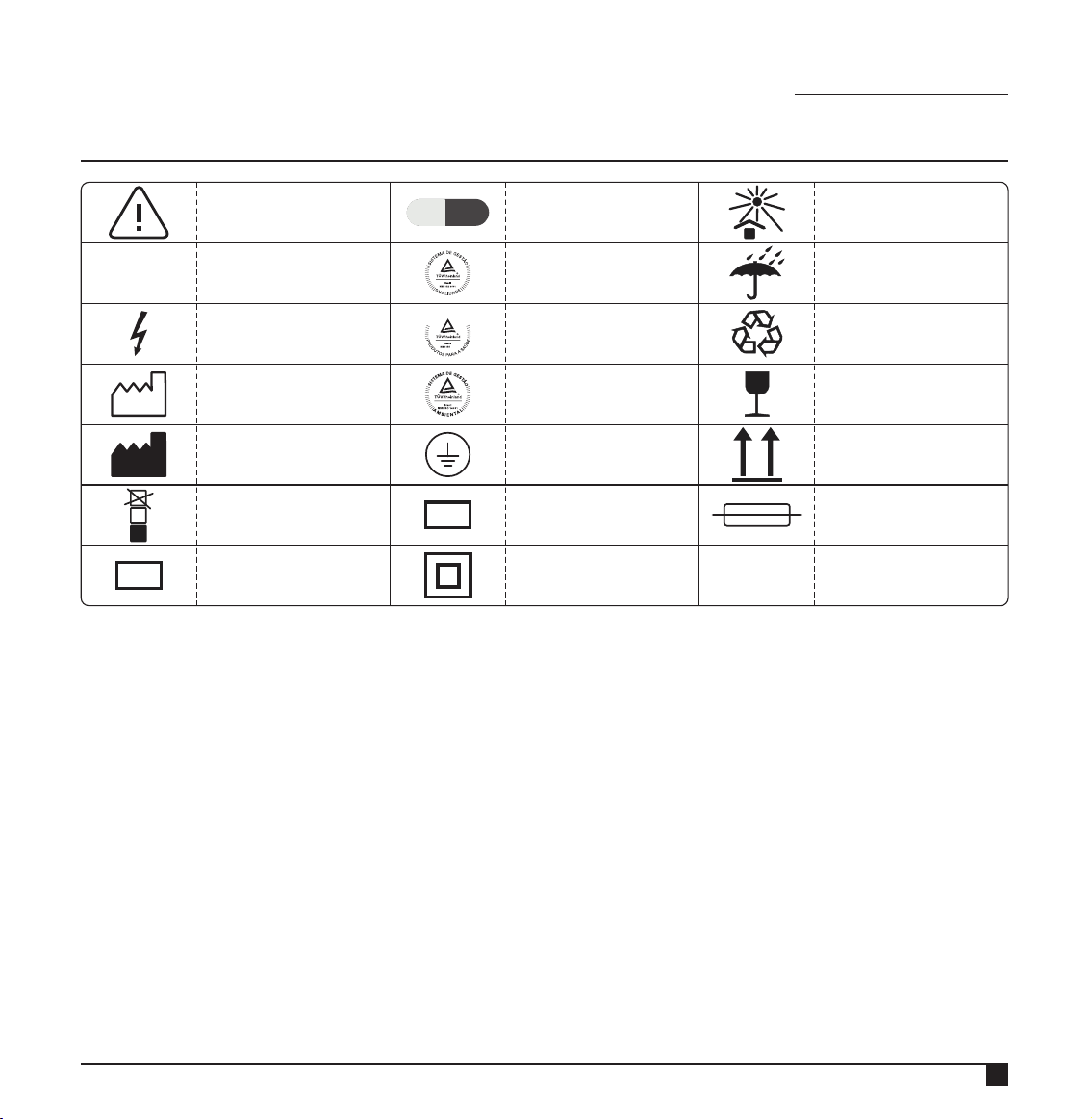

LEGEND OF SYMBOLS

~

This side up

Maximum

pile

Caution! Consult

accompanying

documents

Manufacturer

Alternate Current

Protection Grounding

Terminal

Fuse

Date of

manufacture

Good Manufacturing

Practices

5

P

BF

LOT

SN

Fragile - Handle

with care

Dangerous Electrical

Tension

Serial Number

Batch code

Keep away from

sunlight

Recyclable

Keep dry

ISO 13485

ISO 14001

ISO 9001

13485

D

E

S

G

A

E

M

S

E

T

T

Ã

S

O

I

S

Class II

Equipment

3

CRISTÓFOLI

ULTRASONIC CLEANER

INSTRUCTION MANUAL

4

This equipment was developed to clean dentistry, veterinary and laboratory instruments/articles as well as any other

material which is suitable for ultrasonic cleaning (cavitation).

INTENDED USE

OPERATION PRINCIPLE

CONTENTS OF THE BOX

Items included in the product box:

- 1 Cristófoli Ultrasonic Cleaner; 1 basket;-

- 1 power cable; - 1 instruction manual.

What is cavitation?

Cavitation is the formation and collapse of millions of tiny little bubbles or cavities inside a liquid produced by the

alternation of high and low pressure waves that are generated by the ultrasonic cleaner The bubbles appear in the .

water/solution and the effect of millions of implosions per second help the enzymatic detergent to break the molecules

of dirt and contaminants, resulting in an efficient cleaning.

RECOMMENDATIONS AND WARNINGS

MANUFACTURER

Shenzhen Codyson Electrical Co. Ltd.

2/F,B & 3/F,East A, Minlida Industrial Building, The 4th Block,

Honghualing Industrial Zone, Xili, Nanshan District,

Shenzhen - China

IMPORTER

Cristófoli Equipamentos de Biossegurança Ltda.

Rod. BR 158, nº127 - Campo Mourão - PR - Brasil.

CEP 87309-650

CNPJ 01.177.248/0001 - 95 - Inscr. Est. 90104860-65

Website: www.cristofoli.com - e-mail: [email protected]

Responsible Technician

Eder William Costa Camacho

CREA/PR – 87826/D

Read all the instructions in this manual before using your ultrasonic cleaner. Incorrect use may result in deficient cleaning,

damage to the equipment and/or accidents.

The equipment must be handled by qualified and well-informed personnel, regarding its features and functioning.

For your safety, when performing any kind of maintenance, remember to unplug the equipment and use PPE (Personal

Protective Equipment).

Never turn the equipment on without water in the vat, that will cause immediate burn out of the equipment and loss of

warranty.

Never put the instruments/articles or beaker directly into the stainless steel vat for cleaning without the plastic basket.

Never put paper, plastics, towels or any other kind of fabric under the cleaner, this may obstruct the side vents located on

the lower part of the equipment causing overheating and damage to the equipment.

Do not allow patients or especially children to get close to the equipment.

CRISTÓFOLI

ULTRASONIC CLEANER

INSTRUCTION MANUAL

CRISTÓFOLI

ULTRASONIC CLEANER

INSTRUCTION MANUAL

Before initiating the cleaning process, make sure the material to be cleaned may be submitted to ultrasonic

cleaning (cavitation).

Never put your hand or any other part of your body inside the cleaner when it is in use, this procedure may be harmful to

your health.

5

INSTALLATION INSTRUCTIONS

1

2

.The storage must be done in a place protected from the weather action (indoors) in normal temperature conditions

Install the at ultrasonic cleaner in an exclusive sterilization room, ventilated and clean, on a flat, leveled and firm surface,

a proper height for the operator to handle it Leave enough room next to the equipment for handling the instruments/articles..

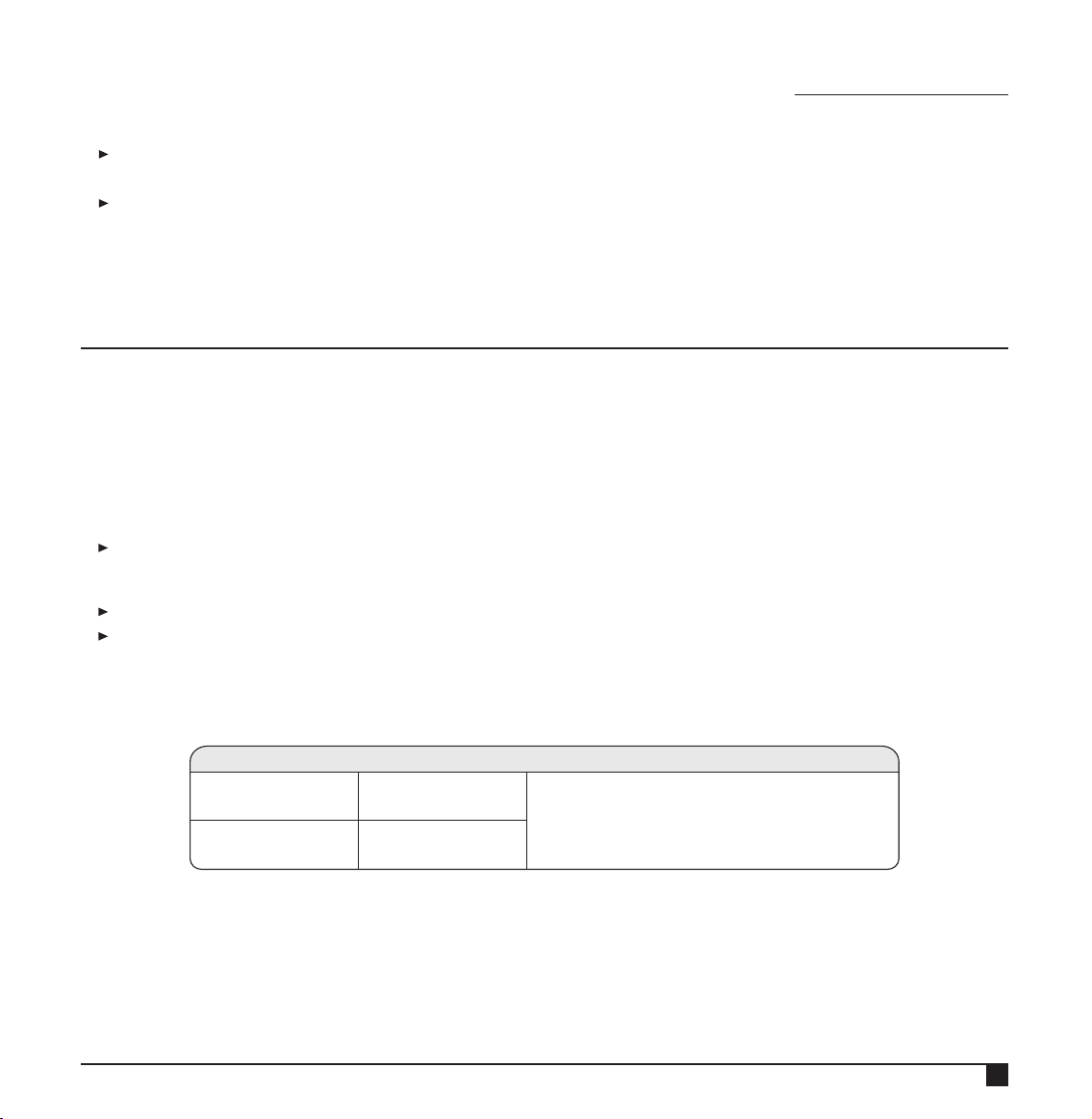

Table 1

3

The voltage of the ultrasonic cleaner is 127V or 220V, as informed on the identification label located on the bottom

of the equipment. (Fig. 1, pág. 6). Make sure the wiring where the equipment will be installed is in voltage

accordance with these values.

For the installation, use a three pin outlet with grounding pin (2P + T, 10A).

Never use extensions, adapters or voltage transformers.

ATTENTION Grounding is very important for the safety of the operator and the warranty of your equipment! . Install the

ultrasonic cleaner where it can be easily unplugged.

Electrical

See “Authorized Technical Assistance” (Page 13). In case the user chooses an unauthorized electrician or technician to

install the equipment, Cristófoli Biossegurança will not be responsible for any services performed in disagreement with the

instructions described in the product manual.

The electrical installation must follow the data from the table below.

MODEL AMPERAGE WIRING GAUGE (DIAMETER)

Cristófoli Ultrasonic

Cleaner (127 V)

1,5 A

Cristófoli Ultrasonic

Cleaner (220 V)

The wiring from the breaker to the electrical outlet

used to connect the equipment

must have a diameter of at least 2.5 mm.

0,8 A

CRISTÓFOLI

ULTRASONIC CLEANER

INSTRUCTION MANUAL

COMPONENTS IDENTIFICATION

Transparent Lid

Stainless Steel Vat

Panel & Control keys

Housing

Air Entrance

Air exhaust

Identification Label

(at the bottom)

Power cable

connector

Front View

Fig.1

Off key

On key

Mode Key

(Adjustment of operation times)

Green LED - indicates that the

equipment is plugged in or in operation

Right red LED - indicates that

the overheating protection is on

Left red LED - indicates

the heating function is on

Heating key

Fig.3 LIG DES MD AQ

Fig.2

Power cable

Fig.4

Basket

(it can also be used in the Cristófoli Plastic Vat

for soaking the instruments)

Beaker

(glass accessory, item sold separately)

Fig.5

6

CRISTÓFOLI

ULTRASONIC CLEANER

INSTRUCTION MANUAL

7

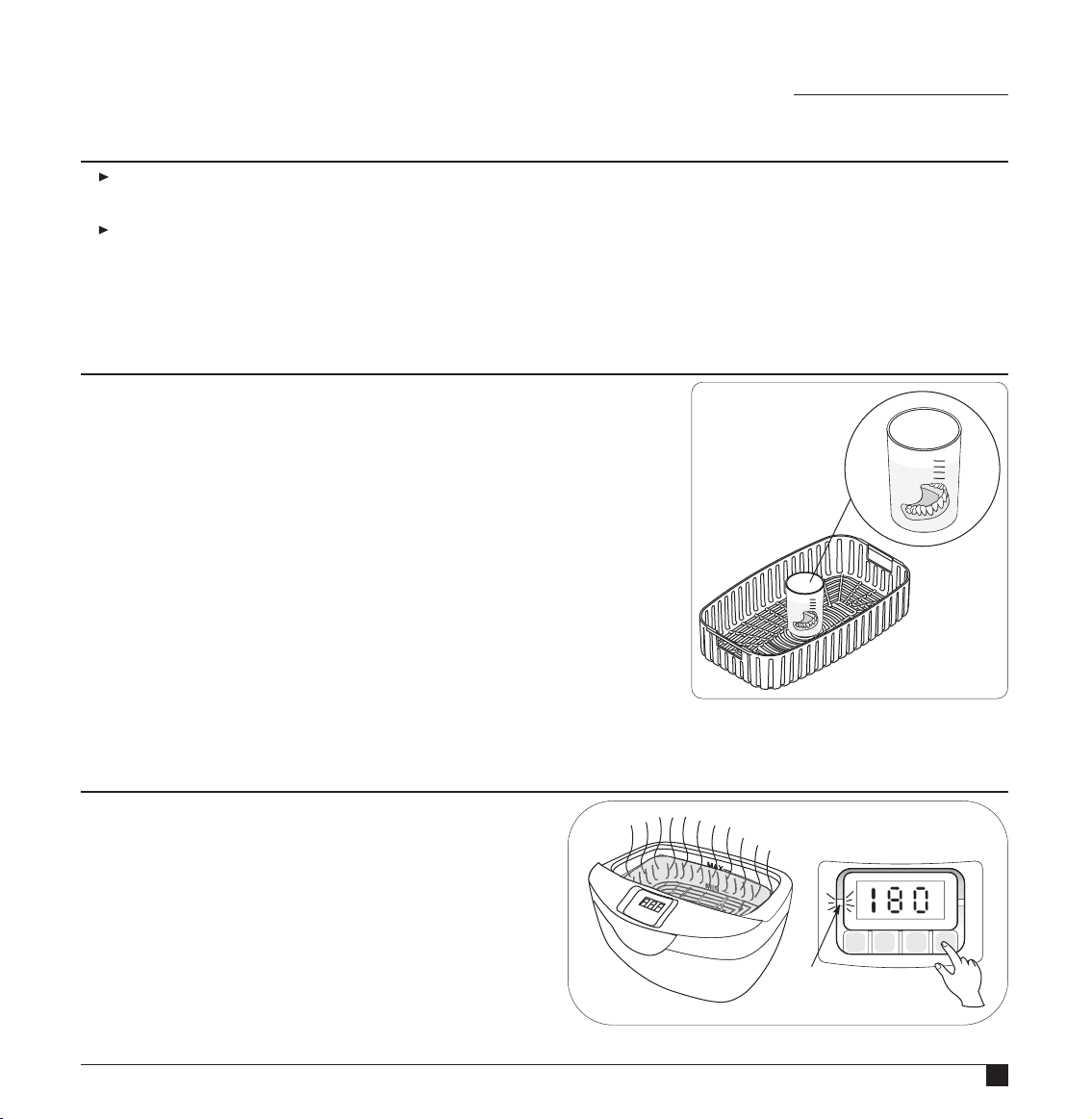

DEGASSING / USING THE BEAKER

The water degassing has the purpose of removing the gases dissolved in the

water that impair the cavitation process and must be repeated every time the

water/solution is changed. The procedure consists in leaving the equipment on

for 8 minutes (480s cycle) without any instruments /articles in the vat.

When using the beaker (accessory that must be purchased separately used

to clean very small items (burs, files, etc.) that would certainly go through the

basket orifices falling on the bottom of the vat, remember that the water inside

the beaker must also be degassed Use always a heat resistant glass beaker .

specific for this purpose. Put the water in the stainless steel vat, the basket, the

beaker on top of the basket and water inside the beaker, seal it with some PVC

film (the same used for food wrapping) and proceed the degassing.

Always use the lid when the equipment is operating with the basket, when

using the beaker, remove it, unless the beaker being used has a compatible

size for the basket depth and allow the use of the lid.

The Cristófoli Ultrasonic Cleaner may also be used to clean dental prosthesis

like dentures, bridges or orthodontic devices like braces, etc., as shown by the

drawing (Fig. 6). Fig.6

Fig.7

FUSE - Internal safety device built into the electronic board which . See cuts the power from the equipment

“Troubleshooting” (Page 12).

OVERHEATING PROTECTION SENSOR It protects the cleaner against overheating. If the lig (On) key is pressed, the -

display shows the remaining time and there’s no cavitation (production of ultrasonic waves), that means that the

equipment needs to cool down for about 15 minutes. After that, press lig again and the equipment will resume

operation.

1

SAFETY DEVICES

2

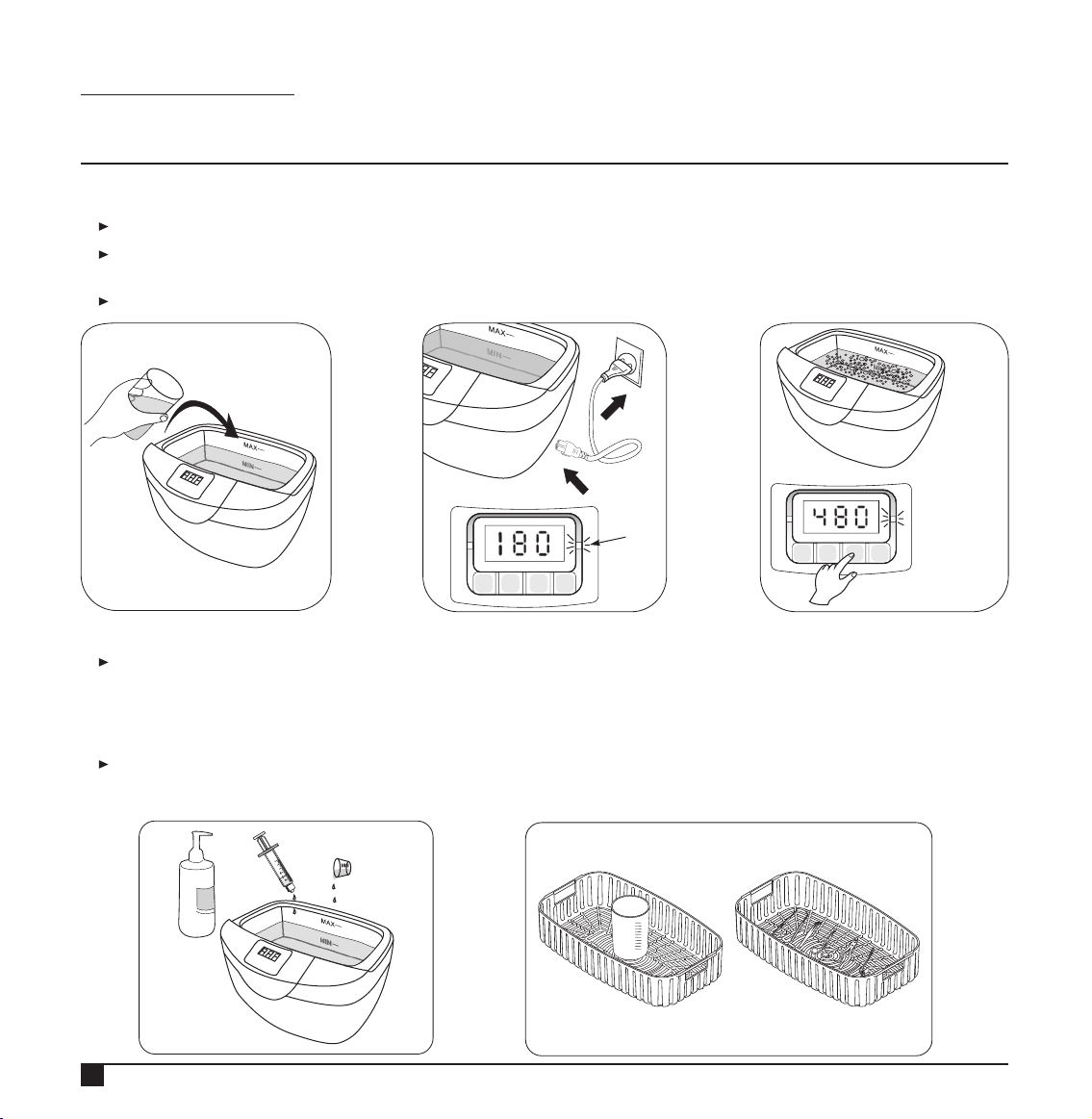

For a deeper cleaning, with the presence of fat, optionally,

the water heating function can be used. Just press the AQ key to

start the water heating (Fig. 7) that will take approximately 40

minutes to achieve the ideal temperature for cleaning, which

is 65 ºC.

Once the right temperature is reached, heating will turn off

automatically The red LED on the left side of the display will be .

on when the heating is in use If it’s needed to reduce the .

heating time, water already warm may be used by the

operator. Do not use water too hot (above 65ºC), this will hinder

the cleaning of the instruments/articles.

HEATING

Red

LED

AQ

DESLIG MD

CRISTÓFOLI

ULTRASONIC CLEANER

INSTRUCTION MANUAL

HOW TO USE THE CRISTÓFOLI ULTRASONIC CLEANER

1

2

4

3

5

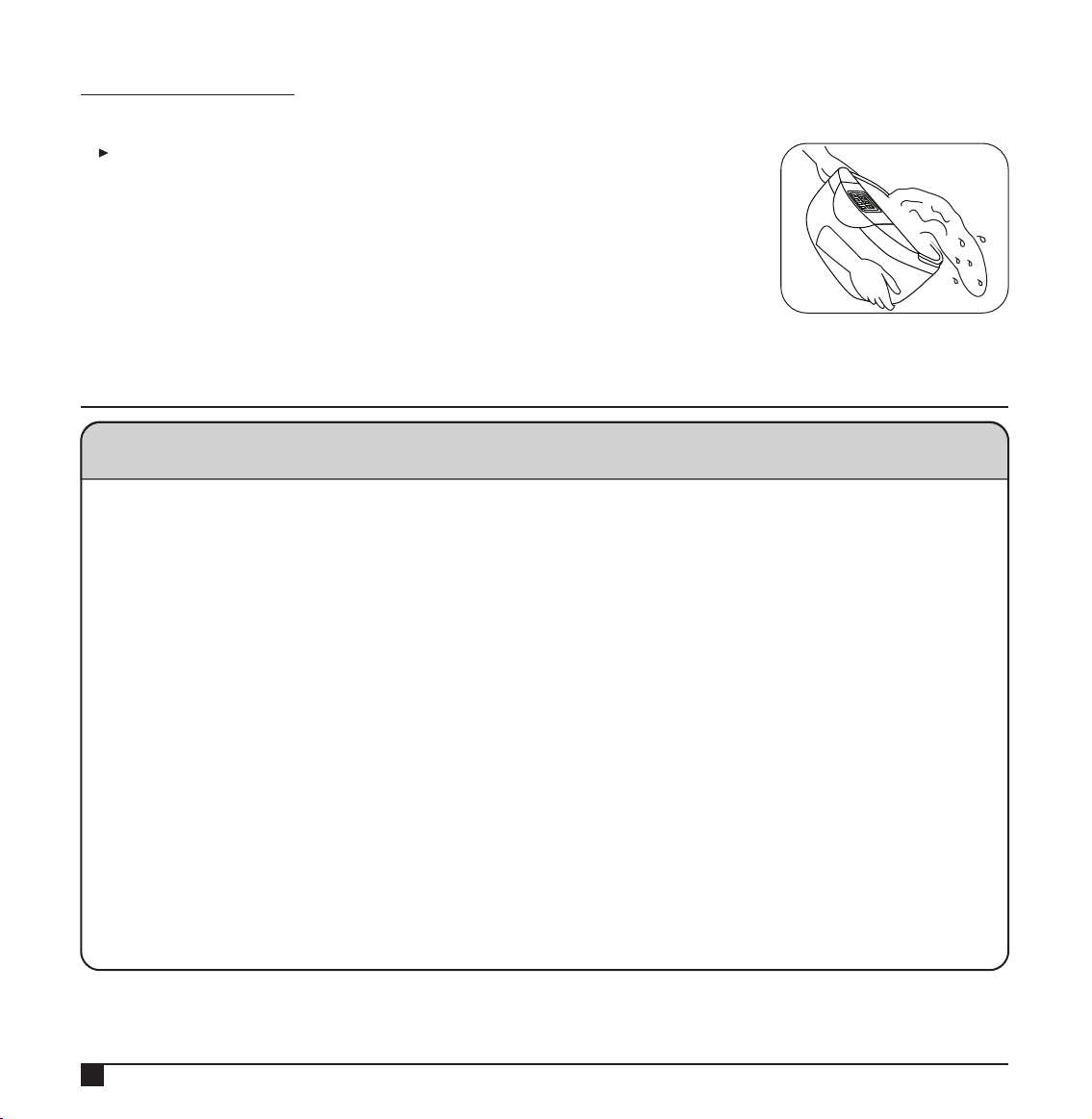

Pour preferably filtered water up to the maximum level of 2,1 liters indicated on the vat MAX (Fig. 8).

Insert the power cable in the cleaner connector and the other end to the wall outlet The green LED indicates that (Fig. 9).

the equipment is plugged in The display will show the standard cycle of 180s (3 minutes). .

Proceed the water degassing according to the instructions on the topic ” (Page 7).“Desgassing / Using the Beaker

LIG DES MD AQ

Green

LED

LIG DES MD AQ

j

k

Add the right amount of enzymatic detergent in the vat or beaker, diluting it according to the recommendations

specified by its manufacturer. We suggest, for your convenience that you use a small medicine measuring cup or

syringe without the needle to measure the volume of detergent, make sure to reserve this syringe for this purpose only in

case the detergent doesn’t have its own measurer (Fig. 11). Do not use anti-crust solutions/productos, they have a highly

acid concentration, that may damage the vat, its sealing and the instruments.

Put the instruments/articles in the basket or beaker, see the topic “Degassing / Using the Beaker” (Page 7). Do not put

instruments/articles in the basket at the same time you are using the beaker. The instruments must be totally immersed

but not overlapped (Fig. 12).

For a better visualization, the drawings below do not show the lid. Remember to always use the lid when the equipment is

in operation.

Fig.8

Fig.11

Fig.9 Fig.10

Fig.12

8

CRISTÓFOLI

ULTRASONIC CLEANER

INSTRUCTION MANUAL

DES DES DES DES DES

MD MD MD MD MD

AQ AQ AQ AQ AQ

LIG LIG LIG LIG LIG

3 min. 4 min. 30 s. 6 min. 30s. 8 min. 1 min. 30 s.

Fig.13

Select the time desired on the panel using the MD key. The time selection begins with the standard cycle of 180s (3 min.).

Each touch on the MD key, the display will show one of the 5 preset cleaning times (Fig.13).

Press the lig key to start cleaning (Fig. 14), at this moment the operator will hear the typical sound of the cavitation

process. key (Fig. 15) To pause the cycle press the des to resume cleaning, press lig again.

6

7

Fig.14 Fig.15

DES

LIG MD AQ

LIG DES MD AQ

At the end of the cycle the display will show 000 and the cavitation process will stop automatically. Unplug the

equipment and open the lid. .(Fig. 16)

Remove the beaker or the basket with the instruments/articles from the vat as soon as the cleaning finishes and perform

a visual inspection, if there’s still any residue left, remove it with a proper brush.

8

9

Fig.16

j

kl

9

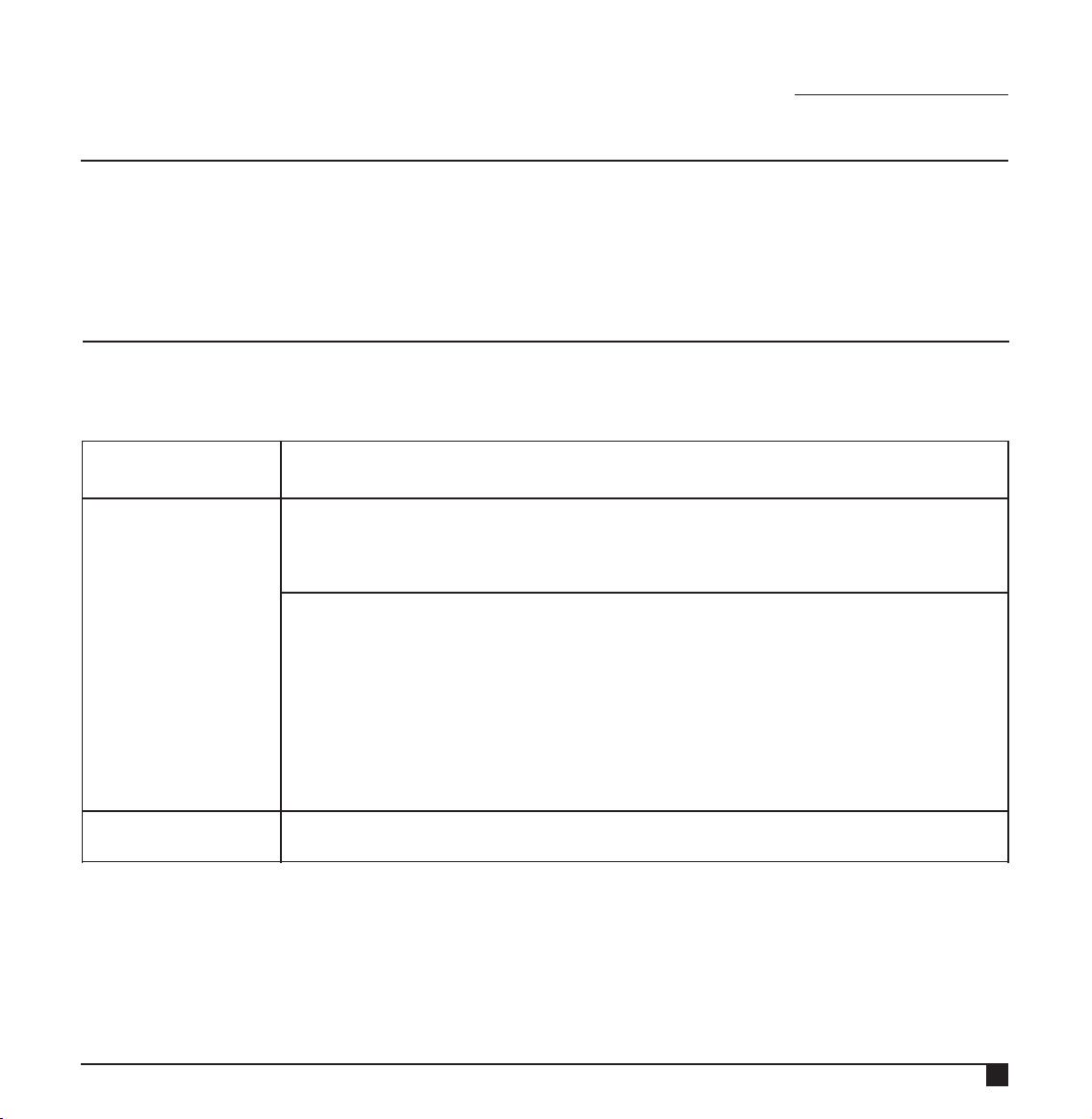

Finally, pour the contaminated solution into an appropriate sink, used exclusively for this

purpose proceeding like this: carefully tip the equipment over one of its back corners to

avoid getting the control panel wet (Fig. 17) and dispose the solution into the sink. For a

new cycle, wait 15 minutes and then follow the use instructions again.

10

Fig.17

TECHNICAL DATA

Table 2

Total Capacity ...............................................................................

Useful Capacity .............................................................................

Net weight .....................................................................................

Gross weight ..................................................................................

External dimensions (W x H x D) ....................................................

Internal dimensions (W x L x D) .....................................................

Voltage .........................................................................................

Frequency .....................................................................................

Power ............................................................................................

......................................................................................................

Ultrasonic frequency ......................................................................

Timer .............................................................................................

Power consumption .......................................................................

......................................................................................................

Proper working ambient temperature .............................................

Certifications .................................................................................

2,5 liters

2,1 liters

2,5 kg. (with components)

3 kg. (in the box)

28,5 x 18,5 x 22,5 cm

28,8 x 14,8 x 8 cm

127 or 220 V

50/60 Hz

160 Watts (127 V model)

170 Watts (220 V model)

42 kHz

Digital: 5 preset time cycles (180s - 280s - 380s - 480s - 90s)

16 Watts/hour (127 V model)

17 Watts/hour (220 V model)

15 to 40 ºC

This equipment is imported by Cristófoli Biossegurança, company

which Quality Management System is certified and in accordance

with the ISO 9001:2008, ISO 13485:2003, BPF- Boas Práticas de

Fabricação - ANVISA, (Brazilian standard similar to GMP-FDA/US) and

ISO 14001:2004 - Environmental Management standards.

TECHNICAL DATA CRISTÓFOLI ULTRASONIC CLEANER

10

CRISTÓFOLI

ULTRASONIC CLEANER

INSTRUCTION MANUAL

The identification label is affixed on the bottom of the equipment (Fig. 1, page 6).

ATTENTION - Removing the identification label and/or any other stickers from the product will cause automatic loss of

warranty.

HOW TO IDENTIFY YOUR ULTRASONIC CLEANER

Some procedures are necessary for the best functioning and durability of your equipment. The preventive

manintenance corresponds to the fulfilment of all procedures listed below.

Make sure the equipment is unplugged before performing any kind of maintenance.

PREVENTIVE MAINTENANCE

PERIODICITY

MAINTENANCE

DAILY

External cleaning:

Unplug the equipment. Clean it with a soft cloth moistened in water and neutral biodegradable

detergent, next, use another soft cloth moistened with alcohol 70% or peracetic acid at 1%.

Clean the lid the same way. Wipe it with smooth movements in only one way.

Vat cleaning:

Clean the stainless steel vat and change the cleaning solution after each cycle to maintain the

cleaning efficiency. The contaminated solution must be disposed according to the instructions

of the topic “How to Use the Cristófoli Ultrasonic Cleaner”, instruction 10 (Page 10).

After disposing the water/solution, remove the excess of residues that may have accumulated

at the bottom of the vat with a soft sponge, cloth or even paper towels, then clean it with a soft

sponge with water and neutral detergent, rinse it with running water (be careful not to get the

control panel wet, avoiding this way that some water get into the equipment through any of its

many orifices), dry the vat with a soft cloth or paper towel and finish by disinfecting it with alcohol

70% three times according to the technique recommended for its use (BRASIL 1994).

ANNUAL

We recommend performing a general preventive maintenance of the equipment with a

Cristófoli authorized technician. See “Authorized Technical Assistance” (Page 13).

Table 3

11

CRISTÓFOLI

ULTRASONIC CLEANER

INSTRUCTION MANUAL

12

CRISTÓFOLI

ULTRASONIC CLEANER

INSTRUCTION MANUAL

For any replacement of parts, contact your local retailer or an authorized Cristófoli representative. It’s strongly not

recommended the replacement of any parts by non-qualified people.

We have listed below the most frequent problems and possible solutions the operator can try in his/her own office.

TROUBLESHOOTING

If the problem persists after the verification of all the items listed, contact your local retailer

or an authorized Cristófoli representative.

•·The equipment may be 220V and be connected to

a 127V power outlet ----------------------------------------------

•·Damaged circuit board --------------------------------------

•·See that the necessary arrangements for the electrical wiring

are made as shown on item “Installation Instructions” (Page 5).

• See “Authorized Technical Assistance” (Page 13).

•·Plug the power cable on both ends, the power connector of the

cleaner and the wall outlet (Fig. 9, page 8).

• See “Authorized Technical Assistance” (Page 13).

•·Check if there’s a power outage in your building.

•·The equipment is not plugged in ----------------------------

•· --------------------------------------------------Burned out fuse

•·No power --------------------------------------------------

THE ULTRASONIC CLEANER DOES NOT TURN ON

LOW CAVITATION OR NO CAVITATION AT ALL

• See “Authorized Technical Assistance” (Page 13).

•· ----------------------The heating element has burned out

POSSIBLE CAUSES

SOLUTIONS

POSSIBLE CAUSES SOLUTIONS

POSSIBLE CAUSES SOLUTIONS

THE ULTRASONIC CLEANER TURNS ON BUT THE HEATING DOES NOT WORK

•·The transducer burned out because of the lack of

water in the vat or incorrect voltage installation -----------

• See “Authorized Technical Assistance” (Page 13).

CRISTÓFOLI

ULTRASONIC CLEANER

INSTRUCTION MANUAL

13

CUSTOMER SERVICE DEPARTMENT - CSD

In case you have doubts, complaints or suggestions, contact Cristófoli through the Customer Service Department -

CSD by the e-mail: [email protected].

AUTHORIZED TECHNICAL ASSISTANCE

If there’s any problem with your equipment, first, take a look at the topic “Troubleshooting” (Page 12), in case the problem

persists, get in touch with your local retailer or an authorized Cristófoli representative to schedule an evaluation or repair of

your equipment.

Before making contact, please have in hands the model of your equipment, voltage, serial number and the date of

manufacture found on the identification label located on the bottom of the equipment (Fig. 1, page 6) and a description of

the problem.

The environment is something that belongs to everyone, therefore, it is up to each one of us to make the decisions

that will help in its preservation and reduction of the damages resulting from human activities.

All products have a useful life span, but it is not possible to determine how long, as it varies according to the

intensity and how the equipment is used or handled.

Cristófoli Equipamentos de Biossegurança Ltda., makes clear its concern, already demonstrated by the

implementation of the Environmental Management System, according to standard NBR ISO 14001:2004, strongly

recommends users of their products to seek the best destination when disposing your equipment or its components,

taking into account the materials recycling legislation effective in your country.

We advise you to take your equipment to specialized recycling companies that, due to the continuous and fast

paced development of new recycling technologies and materials reuse, provide the best way of disposing the

equipment. Cristófoli contributes this way to reduce the consumption of non-renewable raw materials.

On behalf of all users, we thank you for your comprehension and cooperation.

GUIDANCE FOR FINAL DISPOSAL OF THE EQUIPMENT

QUALITY CONTROL

The Cristófoli Ultrasonic Cleaners are tested on a batch basis according to the internal parameters of tests and

manufacturing approved by the Cristófoli Quality Control Department.

CRISTÓFOLI

ULTRASONIC CLEANER

INSTRUCTION MANUAL

14

WARRANTY TERMS

CRISTÓFOLI EQUIPAMENTOS DE BIOSSEGURANÇA LTDA., warranties the Cristófoli Ultrasonic Cleaners for 01 (one) year

against any manufacturing defect from the date of the purchase receipt (provided it contains the serial and lot numbers of

the equipment), of which 03 (three) months refer to the legal warranty (established by section II, art. 26, CDC, Brasil) and nine

(09) months to the contractual warranty (arranged in art. 50, CDC, Brasil). Visit our website www.cristofoli.com and register

your product online.

Traveling costs (based on the distance traveled in km) and the stay of the authorized technician for installation, repair or

maintenance before or after the warranty period will be responsibility of the buyer/owner as well as the freight charges for

shipping the equipment to the authorized technical assistance office for repairs or if necessary, to the factory itself.

The warranty will be voided in cases of:

• Problems arising from natural causes (such as floods, landslide, building collapse, lightning, etc.);

• Damage caused by accidents, such as: dents, drops, short circuits, fire, etc.;

• Sinister (theft or robbery);

• Improper use / installation of the equipment and/or plugging it into an incorrect voltage outlet;

• Problems due to failure of the power supply and/or building wiring;

• Removal and/or tempering of the serial number shown in the identification label of the product;

• Signs of tampering and/or blotted out data on the purchase or service receipt of the equipment;

• Signs of external violation of the product or broken factory seal;

• Lack of preventive maintenance of the equipment or neglect regarding any item presented on the topic “Preventive

Maintenance” of this instruction manual;

• Use of non-original parts or parts not acquired at the Cristófoli Authorized Service Network;

• Repairs performed by technicians who are not part of the Cristófoli Authorized Service Network;

• Noncompliance with any measure or caution recommended in the instruction manual of the product.

The internal fuse, the basket and the power cable are not covered by the warranty. The warranty will also not cover

damages caused to instruments / articles with low resistance to ultrasound cleaning or their natural wearing.

ATTENTION! In order to validate the contractual warranty of the product it is necessary to send a copy of the purchase

receipt to the following e-mail address: [email protected].

Table of contents