4 - 6

After Installation/Adjustment

Flush the toilet two to three times to confirm there is no

water leakage and that the lever mechanism is working

properly.

6) Connect the opposite end of the water supply hose to

the angle stop (See figure 5). A flexible supply hose is

recommended. Hand tighten only - do not use plumbers

putty or other sealants. Open the supply valve and flush

the toilet several times. Check all the connections for leaks

and periodically afterwards following the installation.

Figure 5

FLOAT

CUP

LOCK

RING

REFILL TUBE

FILL

VALVE

SHANK

WASHER

FLOAT

CUP

LOCK

RING

REFILL TUBE

FILL

VALVE

SHANK

WASHER

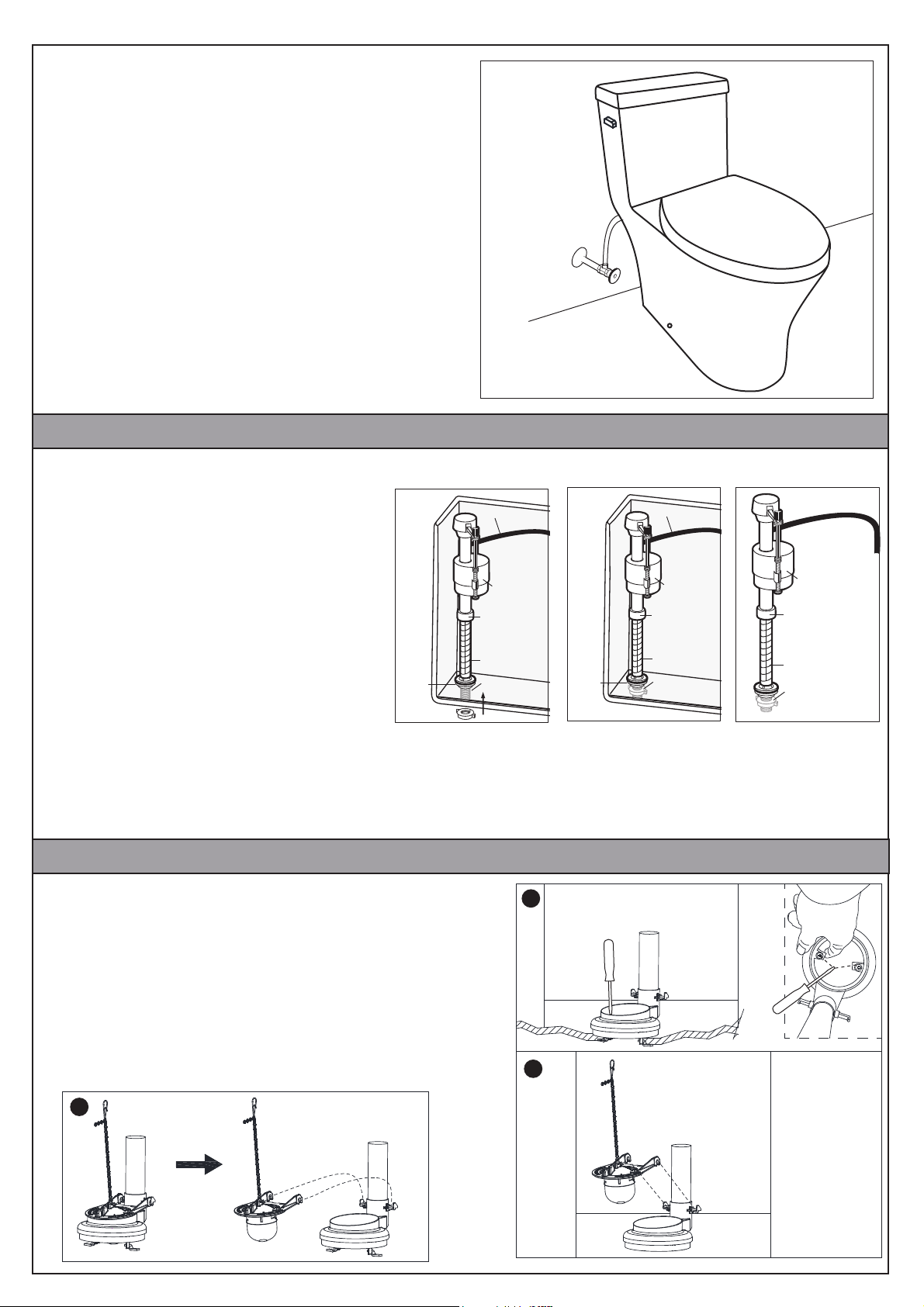

Fill Valve Installation Instruction

Replacement Installation

1) Shut off the water supply. Flush the toilet and

remove any remaining water from the tank.

Remove the old fill valve.

2) Install new fill valve by sliding the threaded

portion of the shaft through the hole in the

bottom of tank.

3) Thread mounting nut onto exposed shaft under

the tank/bowl and tighten nut.

WARNING! Do not over-tighten.

4) Connect the water supply.

FLOAT

CUP

LOCK

RING

FILL

VALVE

Water Level Adjustment

1) Loosen the lock ring (see figure 3)

Pull up the valve and set it to the desired water level, then turn it clockwise until the valve snaps into the locked position.

2) Turn on the water supply.

Figure 1 Figure 2 Figure 3

A

1) Turn off water supply and flush the toilet.

2) Remove the tank lid and place it upside down on a clean surface.

3) Note the orientation of the flush valve for reassembly.

4) Remove the flapper from flush valve by pulling up frame of

flapper one side at a time.

5) With a screw driver to loosen the two screws & metal plates

holding the valve, then remove the flush valve from the tank.

6) Install a new flush valve into the tank.

Flush the toilet several times using side lever to proper operation.

Check for leak

Replacement Installation

Flush Valve Installation Instruction

B

C