INSTALLATION & OPERATION MANUAL 10132 REV 2 (08/22) PAGE 9 OF24

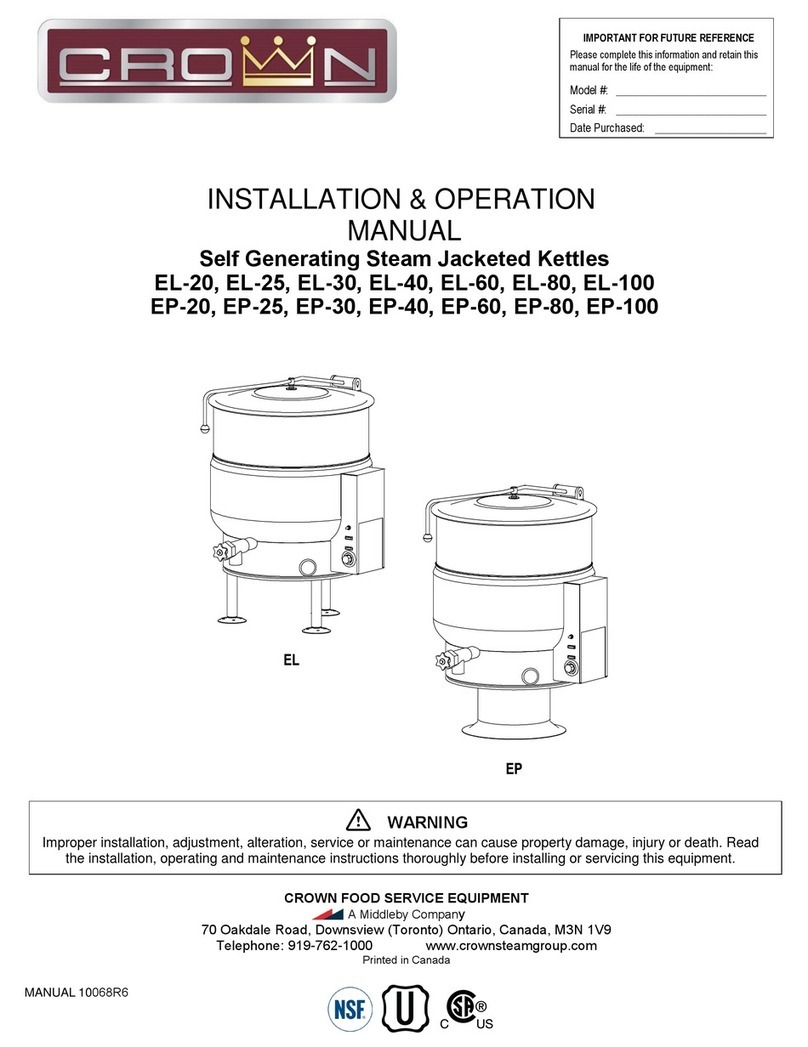

Self-Generating Steam Jacketed Counter Tilting Kettles

1. Ensure there is adequate vacuum in the kettle jacket before operating.

2. Ensure that the appliance and controls are not damaged and that it can be safely operated.

3. Ensure the work area of the operator is not slippery and is clear of debris so as to provide a safe workplace.

4. Ensure the appliance is clean before each use.

5. Check that the LOW WATER control is operational. Tilting the kettle more than 5 or 10 degrees should cause the

LOW WATER signal light to come on.

1. Perform a “try lever test” on the safety relief valve.

WARNING

The safety relief valve may discharge large amounts of steam and/or hot water. Keep away from the discharge

tube at all times. Warn others in the area so they will not be startled by the sound.

Under normal operating conditions a “try lever test” must be performed every two months. Under severe service

conditions, or if corrosion and/or deposits are noticed within the valve body, testing must be performed more often. A “try

lever test” must also be performed at the end of any non-service period.

free of sediment and debris. Then release lever and permit the valve to snap shut.

If lift lever does not activate, or there is no evidence of discharge, discontinue use of equipment immediately and contact a

1. Lubricate the bronze trunnion bearings.

2. Check the worm gearbox for evidence of oil leaks. It is permanently lubricated with synthetic oil (Shell TIVELA OIL

SC320 or equivalent) and should not require maintenance.

3. Check that the tilt mechanism has not become loose or has excessive backlash.

CAUTION

Under normal operating conditions a “try lever test” should be performed every two months. Under severe service

conditions, or if corrosion and/or deposits are noticed within the valve body, testing must be performed more often.

A “try lever test” should also be performed at the end of any non-service period.

CAUTION

to avoid any bodily contact.

CAUTION

High sound levels may be experienced during “try lever” test. Wear proper safety equipment and exercise extreme

care! Test at, or near, half of the operating pressure by holding the test lever fully open for at least two seconds to