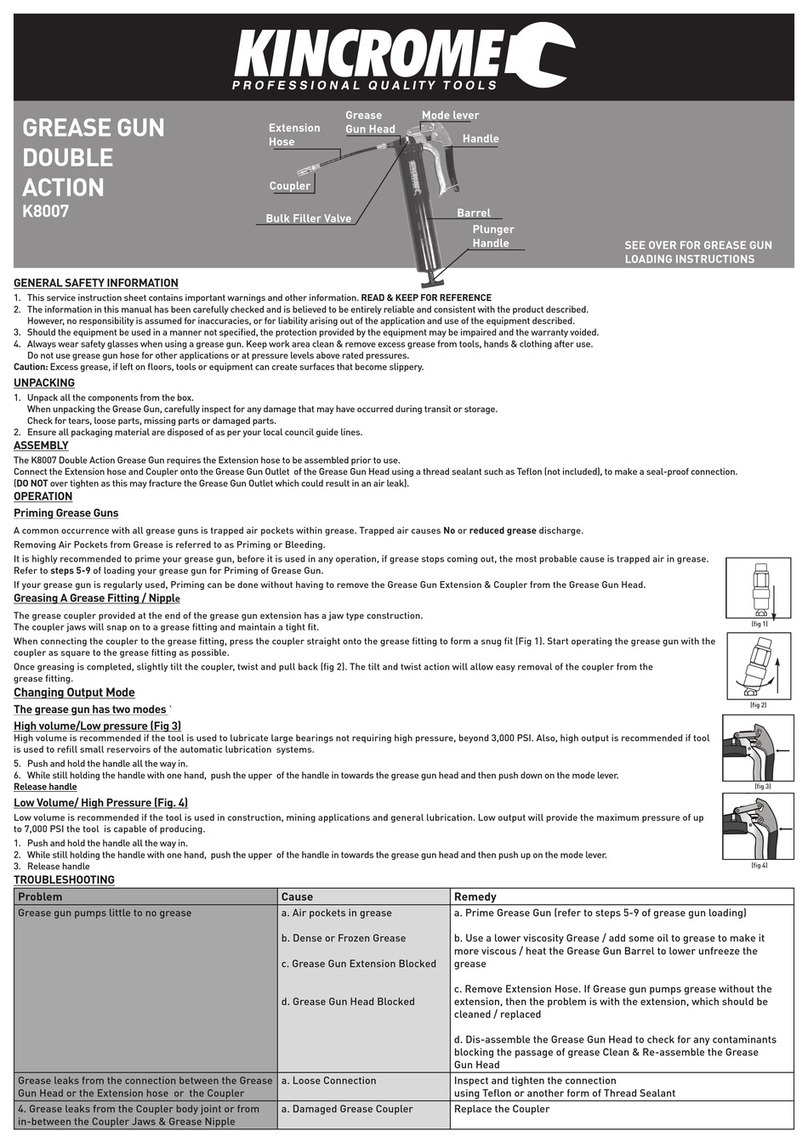

Changing Nose Pieces & Matching Mandrel

1. Select the Nose Piece (9,10,11,12) & Mandrel (1,2,3,4) you require for the job at hand. The Mandrel (1,2,3,4) & Nose Piece (9,10,11,12) must match the thread size of the riv-nut being used for

your application.

2. To change the Mandrel (1,2,3,4) that is already fitted to the EZI RIV-Nut Drill Attachment, use the supplied Wrench (13), to remove the attached Nose Piece (9,10,11,12) using the closed end of

the Wrench (13), by rotating anti-clockwise.

Note: If the Nose Piece (9,10,11,12) is locked into the Nose Housing (5), you may need to use an adjustable wrench (not supplied) on the Nose Housing (5) allowing the tightened Nose Piece

(9,10,11,12) to be removed.

3. Once loose, remove the Nose Piece (9,10,11,12) that is fitted to the tool.

4. Remove the Nose Housing (5) from the tool by rotating anti-clockwise with an adjustable wrench (not supplied).

Caution: There is a pressure spring under the Nose Housing (5) that could eject the Nose Housing (5) when removing from the Body Housing (7). Take caution when removing the Nose Housing (5)

to avoid any loss of the spring or Nose Piece (9,10,11,12).

5. Remove the spring located under the Nose Housing (5) and set aside.

6. Using your fingers, grab the Mandrel (1,2,3,4) body and pull outwards to allow full access to the Mandrels parallel spanner release surface.

7. Remove the Mandrel (1,2,3,4) that is already fitted to the EZI RIV-Nut Drill Attachment, using the open end of the Wrench (13), by rotating anti-clockwise.

8. Select the Mandrel (1,2,3,4) you require to suit the riv-nut thread size being used.

9. Insert the desired Mandrel (1,2,3,4) into the threaded area of the metal housing and tighten using the open end of the Wrench (13), then tighten by rotating clockwise.

10. Re-install the spring previously removed, over the Mandrel (1,2,3,4), noting that the widest/flanged end of the spring should be inserted within the threaded housing end of the tool.

11. Re-install the Nose Housing (5) onto the Body Housing (7) by threading the Nose Piece (9,10,11,12) onto the plastic Body Housing (7), and then tighten by rotating clockwise with an adjustable

wrench (not supplied).

12. Select the correct size Nose Piece (9,10,11,12) you require to suit the riv-nut being used, (which are stored in the Wrench (13) handle), and remove by rotating the Nose Piece (9,10,11,12) anti-

clockwise from the Wrench (13).

13. Insert the desired Nose Piece (9,10,11,12) into the threaded area of the Nose Housing (5) and tighten using the Wrench (13) by rotating clockwise.

14. The KP45003 EZI RIV-Nut Drill Attachment is now ready to use!

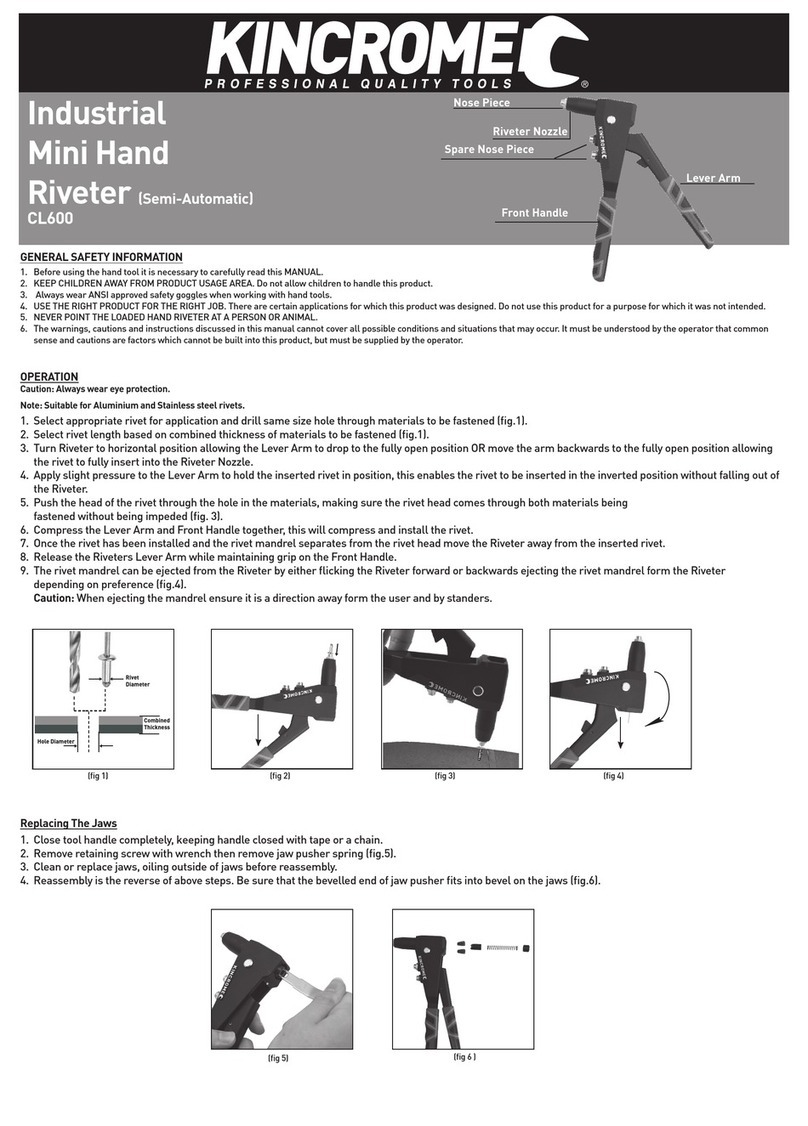

Operation

1. The KP45003 EZI RIV-Nut Drill attachment, is fully assembled, however requires to be fitted to your drill.

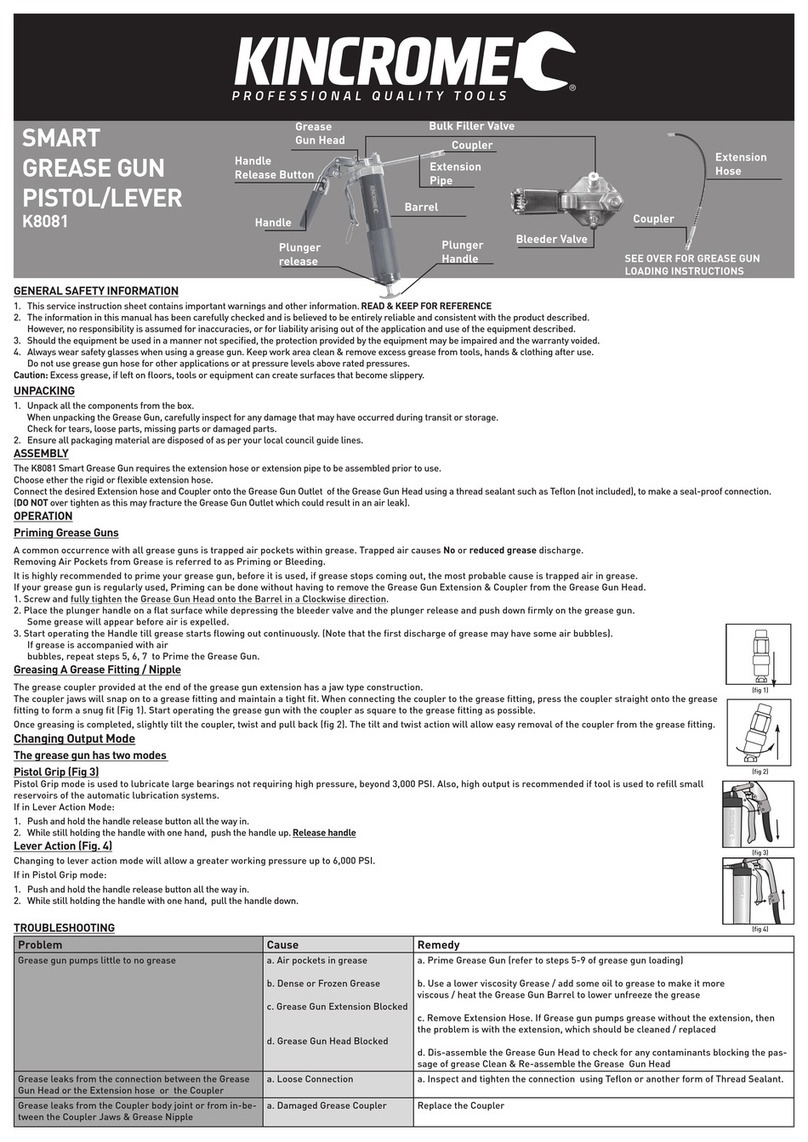

2. Align and insert the 6.35mm (1/4”) Hex Shank (6) of the EZI RIV-Nut Drill attachment, into the Chuck of your drill and tighten the drill chuck (Fig 1).

3. While holding the drill attachment Body Housing (7), put the drill in reverse and pull the drill trigger until you hear a clicking sound (Fig 2).

4. Ensure you have the correct Nose Piece (9,10,11,12) & Mandrel (1,2,3,4) installed to suit the riv-nuts being used for the job at hand. I.e. M4 riv-nut requires an M4 Mandrel (2) as marked on the

mandrel flange nut.

5. While holding the drill attachment Body Housing (7), put the drill in reverse and pull the drill trigger until you hear a clicking sound (Fig 2).

6. Screw the desired riv-nut onto the Mandrel (1,2,3,4) (Fig 3).

7. With the desired riv-nut fastened onto the Mandrel (1,2,3,4), align and insert the riv-nut into your pre-drilled material.

Caution: Ensure the correct drill speed is selected to ensure the speed is a Max of 1000 RPM.

8. While holding the drill attachment Body Housing (7) in one hand, select the forward direction of the drill & pull the drill trigger to clench the riv-nut to the material (Fig 4).

9. Select reverse on the drill and pull the drill trigger first & then manually rotate the drill attachment body anti-clockwise to reverse the mandrel out of the installed riv-nut. (Fig 5).

Repair

1. Have your EZI RIV-Nut Drill Attachment serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety, reliability and performance of the

EZI RIV-Nut Drill Attachment is maintained.

Maintenance

1. Clean and lubricate the jaws periodically, at least every 1,000 Rivets. Lubricate the riveter jaws as needed with a lubricant such as INOX or TF2 lubricating spray (not supplied).

Office Contact Details

Phone: 1300 657 528

Fax: 1300 556 005

Email: enquiries@kincrome.com.au

Website: www.kincrome.com.au

Warranty given by Kincrome Tools & Equipment Pty Ltd of 3 Lakeview Drive, Caribbean Park, Scoresby, Victoria, Australia (Tel +61 3 9730

7100) If this product has materials or workmanship defects (other than defects caused by abnormal or non warranted use) you can, at your

cost, send the product to place of purchase, an authorised Kincrome service agent or one of Kincromes addresses for repair or replacement.

Your rights under this warranty are in addition to any other rights you have under the Australian, United Kingdom & Ireland Consumer Law or

other applicable laws. Our goods come with guarantees that cannot be excluded under the Australian, United Kingdom & Ireland Consumer

Law. You are entitled to a replacement or refund for a major failure and compensation for any other reasonably foreseeable loss or damage.

You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a

major failure. For further details please visit www.kincrome.com.au or call us. Due to minor changes in design or manufacture, the product

you purchase may sometimes differ from the one shown on the packaging.

SCAN FOR

INSTRUCTIONAL

VIDEO

PART NO. DESCRIPTION PART NO. DESCRIPTION

KP45003-2 KP45003 Nose Housing KP45003-16 KP45003 M3 Mandrel

KP45003-4 KP45003 M5 Mandrel KP45003-17 KP45003 M4 Mandrel

KP45003-5 KP45003 Spring KP45003-18 KP45003 M3 Nose Piece

KP45003-6 KP45003 M5 Nose Piece KP45003-19 KP45003 M4 Nose Piece

KP45003-11 KP45003 Internal E-Clip KP45001-20 KP45003 M6 Nose Piece

KP45003-15 KP45003 Rear Circlip KP45001-21 KP45003 M6 Mandrel

MONTH

WARRANTY

Spare Parts

(Fig 1) (Fig 2)

(Fig 4) (Fig 5) (Fig 6)

* For a full list of available spare parts for this item, visit the Kincrome website

www.kincrome.com.au or alternatively Contact t Kincrome Customer Service.

* Kincrome reserve the right to change spare parts at any time without notice.