Crystal GauGeCaLXP User manual

Service Instruction Sheet

Introduction

These instructions are intended for use with comparator rebuild kit (PN 3143). Rebuild kit 3143 con-

tains all of the parts and tools required to rebuild the GaugeCalXP™pressure comparator. Rebuilds

should be performed only by qualied personnel.

Service Instructions

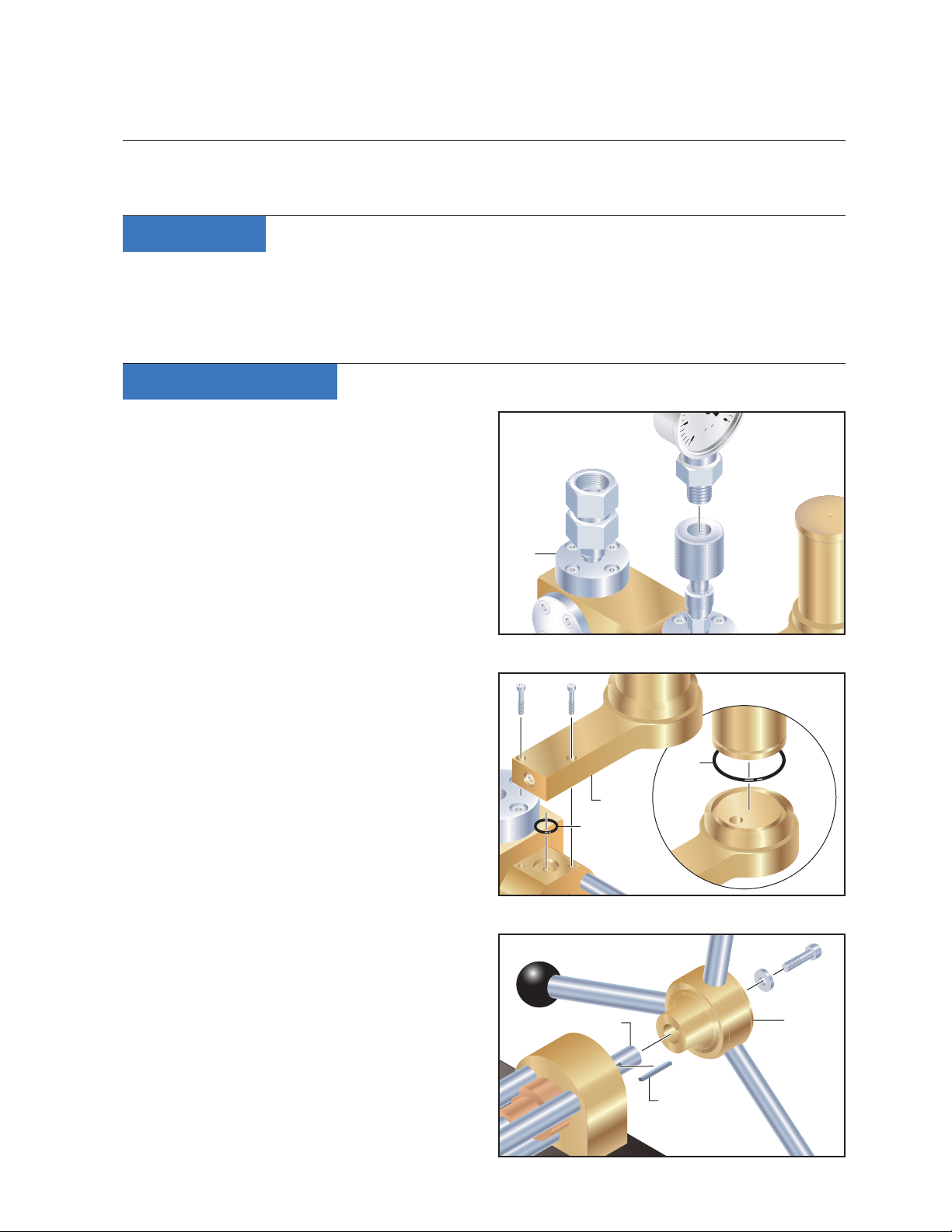

1Remove all gauges from the GaugeCalXP

pressure comparator (gure 1).

2Tip the comparator on its end to completely

drain the water, oil, or isopropyl alcohol from

the system. Always dispose of uids in a

responsible manner.

3Use a 3mm Allen key to remove the two (2)

cap screws securing the Reservoir to the

Main Seal Block, then lift to remove the Res-

ervoir and Reservoir o-ring (PN 2018)

(gure 2).

4Remove the press-t Reservoir Vessel,

and replace the lower seal o-ring (PN 3303

or PN 3376) (gure 2).

*Note:The GaugeCalXP is assembled with

a Reservoir o-ring in one of two sizes. Com-

pare your o-ring to the illustrated parts list

on page 6, to determine the appropriate

replacement size for your unit.

5Use a 5mm Allen key to remove the Handle

Assembly cap screw and washer, then pull to

slide the Handle Assembly from the Piston

Assembly (gure 3). Be sure to also remove

the Key from the Piston Assembly Leadscrew

(gure 3).

PRESSURE COMPARATOR

10000PSI–700bar

Gau

G

eCa

LXP

XP™

Figure 1

Figure 2

Figure 3

C R Y S T A L

engineering corporation

PSI

50

0300

Gauge

Base

Reservoir

O-ring(PN 2018)

O-ring

(PN 3303)

(PN 3376)

or *

Handle

Key

Leadscrew

Page 2 •GaugeCalXP Service Instruction Sheet

C R Y S T A L

engineering corporation

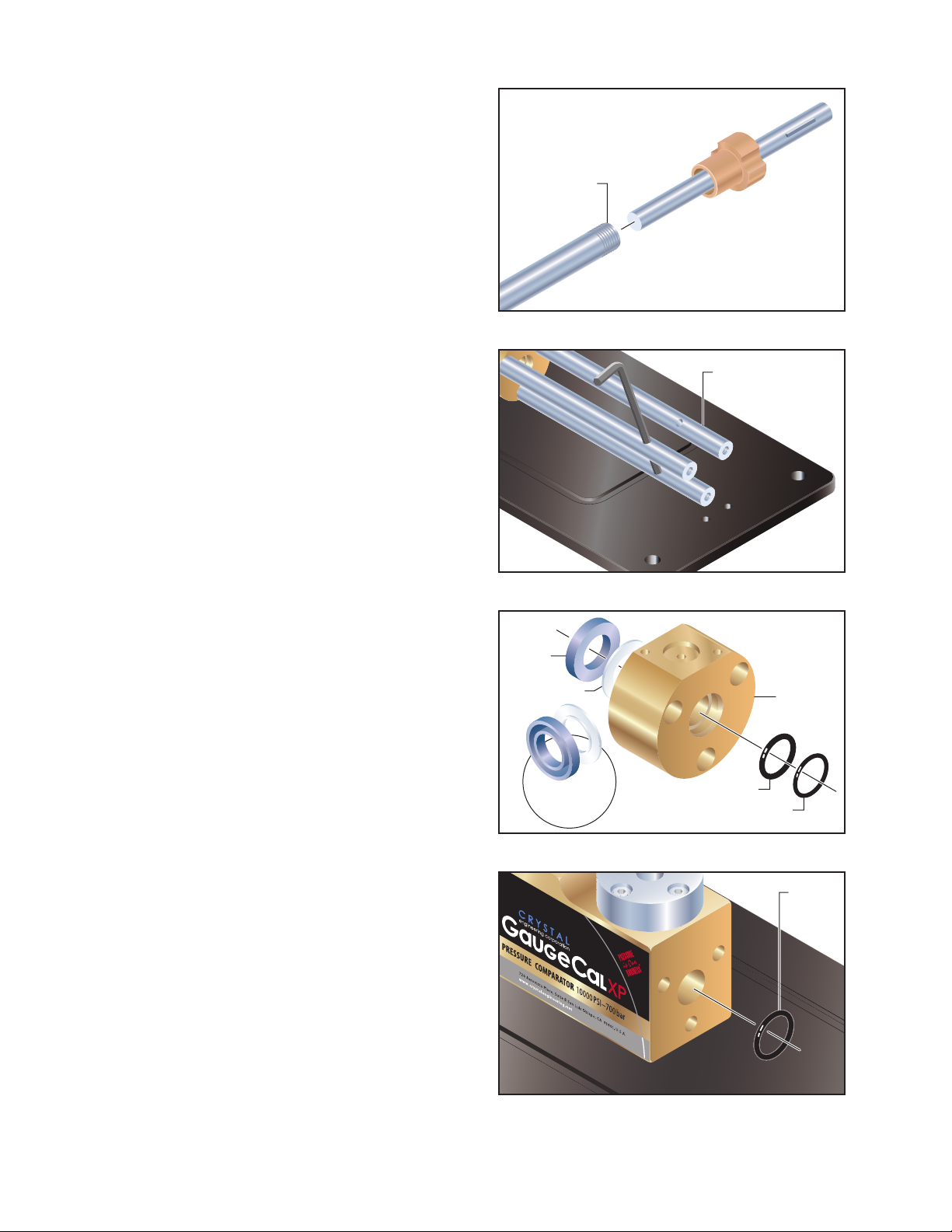

6Turn the comparator over to gain access to

the underside of the Baseplate.

Be aware that water or other test uid may

still be present in the system, and may drain

out as the comparator is turned over.

7Use a 4mm Allen key to remove the two (2)

cap screws holding the Bearing Block to the

Baseplate (gure 4).

8Turn the comparator back over, and then use

a 5mm Allen key to remove the three (3) cap

screws from the front of the Bearing Block

(gure 5).

9Carefully pull to slide the Bearing Block and

Piston Assembly from the Manifold Block

and Baseplate, taking care to avoid making

contact with the three guide rods (gure 6).

10 Pull to slide the Piston Assembly from the

rear of the Bearing Block, and then remove

the Bearing Ring and Bearing Washer from

the front of the Leadscrew (gure 7).

11 Unscrew the Piston Shaft from the Piston

Assembly for cleaning, and then apply a

light coat of grease before reassembling

(gure 8).

Note: The Piston Shaft has a left-hand

thread, so you will turn it clockwise to

remove it, and then counter-clockwise to

replace it.

Figure 4

Figure 5

Figure 6

Figure 7

Bearing Block

Baseplate

Piston

Assembly

Guide

Rod

Bearing

Washer

Bearing

Ring

Leadscrew

GaugeCalXP Service Instruction Sheet •Page 3

C R Y S T A L

engineering corporation

12 To remove the three (3) stainless steel Guide

Rods, insert the 4mm Allen key into the hole

in the side of each rod, and then pull to the

left (counter-clockwise) to loosen and un-

screw each one (gure 9).

When the nal Guide Rod has been re-

moved, the Main Seal Block will fall away

from the Manifold Block.

13 From the front of the Main Seal Block,

remove the o-ring (PN 3131) and the back-

up ring (PN 3151) (gure 10).

14 From the rear of the Main Seal Block, remove

the Rod Seal (PN 3152) and Rod Seal Backup

(PN 3434) (gure 10).

Note: When rebuilding the Main Seal Block

assembly, Dow Corning®111, or a similar sili-

cone-based lubricant, must be applied to the

grooved surface of the Rod Seal (PN 3152).

When the Rod Seal is installed, its at sur-

face should face toward the Main Seal Block,

while its grooved surface faces out to mate

with the Manifold Block (gure 10).

15 From the front of the Manifold Block,

remove the Main Seal Block o-ring (PN 3418)

(gure 11).

Note: When re-attaching the Main Seal

Block and Guide Rods to the Manifold Block,

you may nd it easier to rst remove the

Manifold Block from the Baseplate.

From the underside of the Baseplate, use a

4mm Allen key to remove the four (4) cap

screws holding the Manifold Block in place.

Use the three (3) Guide Rods to attach the

Main Seal Block to the Manifold Block, then

re-attach the Manifold Block to the Base-

plate before attaching the Piston Assembly

and Bearing Block.

Figure 8

Figure 9

Figure 10

Figure 11

Piston

Shaft

Guide Rod

Rod Seal and

Backup shown

rotated 90°

Rod Seal

(PN 3152)

Rod Seal Backup

(PN 3434)Main Seal

Block

O-ring (PN 3131)

Backup ring

(PN 3151)

O-ring

(PN 3418)

Page 4 •GaugeCalXP Service Instruction Sheet

C R Y S T A L

engineering corporation

16 Use a 5mm Allen key to remove the four (4)

cap screws holding the rear Gauge Base to

the top of the Manifold Block. Then, lift the

Gauge Base and its o-ring (PN 3130) from

the Manifold Block and separate the Gauge

Adapter and its o-ring (PN 2018) from the

Gauge Base (gure 12). Remove the forward

Gauge Base by following the same procedure.

If the comparator is tted with an optional

Fine Adjust Kit, continue to step 18. If not,

you may skip ahead to step 24.

Note: A comparator without the Fine Adjust

option is instead tted with an Accessory

Cap, plus an o-ring that should be replaced.

The screws for the plate will require a 4mm

Allen key to remove. Screws included with

older Fine Adjust Kits will require a 5mm key,

while those included with recent, redesigned

kits will require a 4mm key.

18 Use either a 4- or 5mm Allen key to remove

the four (4) cap screws holding the Fine Ad-

just to the side of the Manifold Block, then

pull the Fine Adjust and its o-ring (PN 2018

or PN 3130) away from the Manifold Block

(gure 13).

19 Use a 3mm Allen key to loosen the set screw

inside the Fine Adjust knob, then slide the

knob o of the piston (gure 14).

20 Use a 15mm box wrench to remove the Fine

Adjust bushing from the body, then slide the

bushing and its o-ring (PN 2018) o of the

piston (gure 15).

21 With the front of the Fine Adjust body facing

toward you, turn the piston clockwise until

the piston threads are clear of the hole in the

back of the Fine Adjust body (gure 16).

22 From the back of the Fine Adjust body, slide

out the piston (gure 17).

Figure 12

Figure 13

Figure 14

Figure 15

Rear

Gauge

Base

Gauge

Adapter

O-ring

(PN 3130)

O-ring

(PN 2018)

O-ring

(PN 2018 or

PN 3130)

Fine Adjust

Fine Adjust

Knob

Fine Adjust

Bushing *

O-ring

(PN 2018)

*Whenreassembling, apply

Dow Corning 111 or a similar

silicone-based lubricant .

GaugeCalXP Service Instruction Sheet •Page 5

C R Y S T A L

engineering corporation

23 From the front of the Fine Adjust body,

remove the o-ring (PN 3129) and the backup

ring (PN 3150) (gure 18).

Note: The o-ring and backup ring may be

rmly seated in the Fine Adjust body. If so,

they can be extracted with a pair of tweezers

or other appropriate tool.

24 Use a 4mm Allen key to remove the four (4)

screws holding the Accessory Cap to the side

of the Manifold Block, then pull the cap and

its o-ring (PN 2018) away from the Manifold

Block (gure 19).

25 If the comparator is not tted with an

optional Fine Adjust, remove the second

Accessory Cap located on the other side of

the Manifold Block. Follow the procedure

outlined in step 24.

26 Clean all of the parts. Crystal recommends

you use an ultrasonic bath and an appropri-

ate cleaning solution.

In addition, we recommend that you use a

round brush to clean the piston hole in the

Manifold Block.

27 Reassemble the GaugeCalXP pressure com-

parator and optional Fine Adjust by follow-

ing the preceding steps in reverse order.

Replace all o-rings, backup rings, and main

seal with those supplied in the rebuild kit.

Refer to the illustrated parts list on page 6.

Dow Corning®111, or similar silicone-based

lubricants, are recommended for use on new

o-rings to ensure proper sealing.

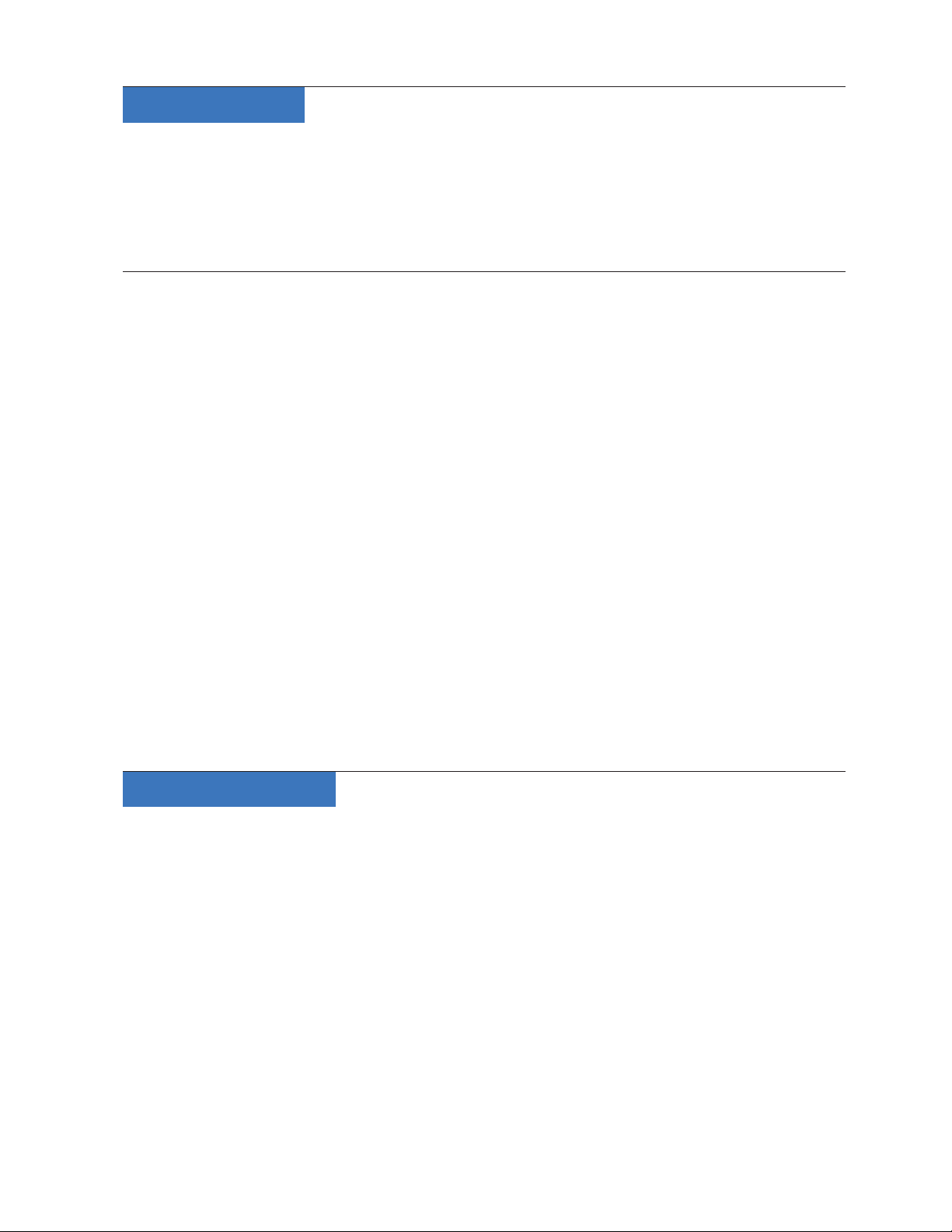

When installing the gauge

bases, accessory caps, and ne

adjust; tighten the screws in the

order shown at right: rst to a

snug t, and then fully-torqued

to 85 in-lbs / 9.6 N-m.

List

Figure 16

Figure 17

Figure 18

Figure 19

1

32

4

Fine Adjust Piston

Fine Adjust Piston

Backup ring

(PN 3150)

O-ring

(PN 3129)

O-ring

(PN 2018)

Accessory

Cap

Page 6 •GaugeCalXP Service Instruction Sheet

C R Y S T A L

engineering corporation

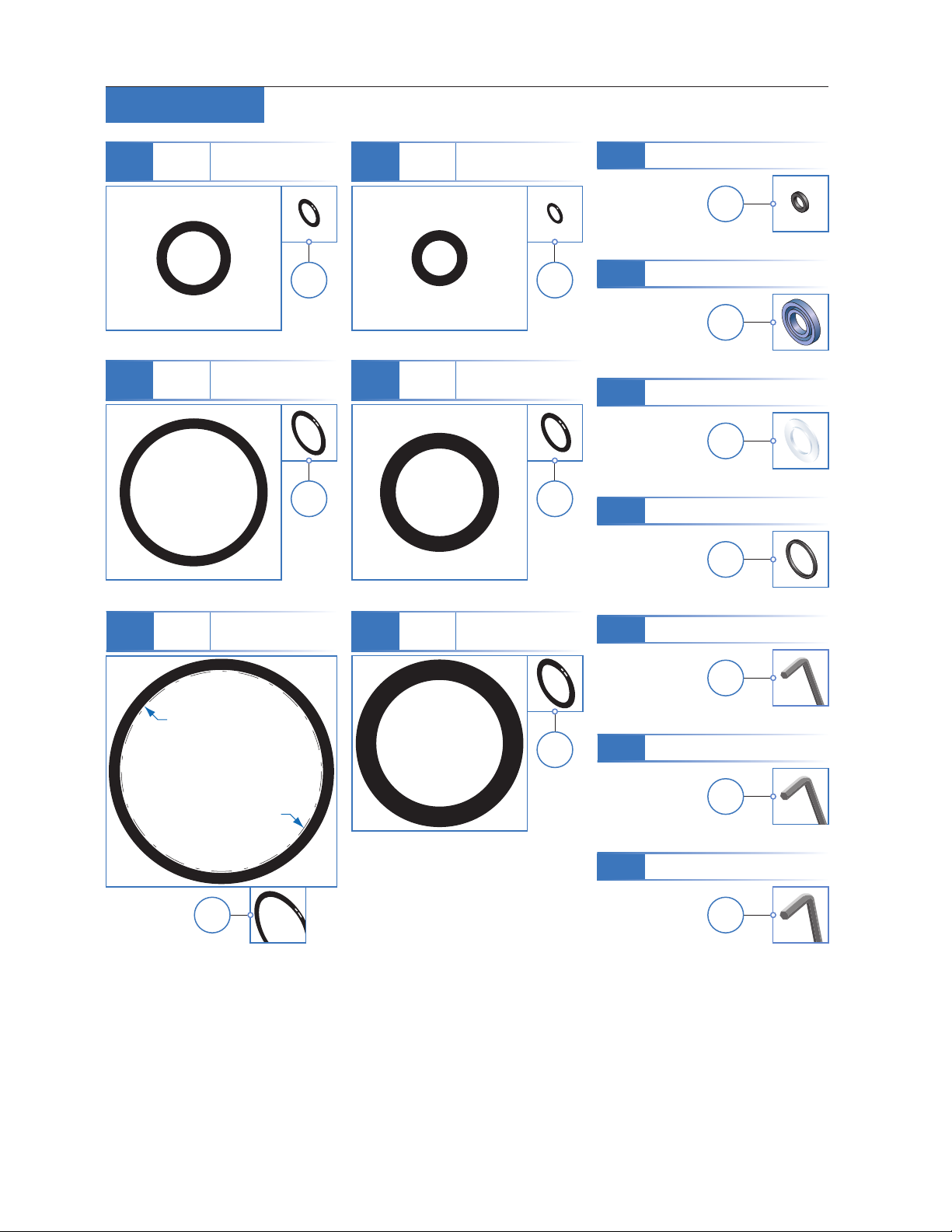

3143 Parts List

3130 O-ring 21.94mm x 1.78mm

0.864in x 0.070in

QTY

3

3150 Backup ring

3131 O-ring 1 5.1mm x 2.7mm

0.594in x 0.106in

QTY

1

3303

3376

O-ring See the dimensions

for each o-ringbelow.

O-ring 3303

34.65mm x 1.78mm

1.364in x 0.070in

QTY

1

3152 Rod Seal

QTY

1

3178 Allen key, 5mm

QTY

1

3177 Allen key, 4mm

QTY

1

3434 Rod Seal Backup

QTY

1

3176 Allen key, 3mm

QTY

1

QTY

1ea

O-ring 3376

35mm x 2.5mm

1.378in x 0.098in

2018 O-ring 9.25mm x 1.78mm

0.364in x 0.070in

QTY

6

3129 O-ring 6.07mm x 1.78mm

0.239in x 0.070in

QTY

1

3418 O-ring 21.82mm x 3.53mm

0.859in x 0.139in

QTY

1

3151 Backup ring

QTY

1

Notes:

The full-size o-ring diagrams may not

reproduce to scale when printed from

the pdf download.

All o-ring dimensions provide rst the

inside diameter, then the thickness.

GaugeCalXP Service Instruction Sheet •Page 7

C R Y S T A L

engineering corporation

How to Contact Us:

Phone (805) 595-5477

Toll-Free (800) 444-1850

Fax (805) 595-5466

Email service@crystalengineering.net

Web www.crystalengineering.net

Send your comments to: feedback@crystalengineering.net

Routine Flushing

If a complete rebuild is not required, ushing the GaugeCalXP can serve as a quick and simple way

to remove small amounts of dirt or sediment from the system. Flushing can also be used to ensure

that any air is removed from the system prior to performing a calibration test. Flushing the unit

should never serve as a substitute for a rebuild; and remember that any service beyond a routine

ush should always be performed by a qualied technician.

Flushing Instructions

1Remove all gauges from the GaugeCalXP pressure comparator.

2To completely open the reservoir, wind the handle counter-clockwise until you feel it stop.

3Securely grip the front of the Baseplate (near the bearing block) and lift to tip the GaugeCalXP

on its end. Any hydraulic uid in the system will run out through the rear Gauge Base port.

4Set the unit back down, at on the Baseplate, and begin to pour isopropyl alcohol, warm soapy

water, or clean hydraulic oil into the reservoir. Continue to ll the unit until the uid begins to

run out of the Gauge Base ports. Always dispose of uids in a responsible manner.

5Once again, tip the GaugeCalXP on its end until all of the uid in the system has drained out.

6Set the unit back down, then wind the handle clockwise at least 10 turns, then ll the reservoir

with test uid to within 6mm (1/4") from the top.

7Follow the operator instructions supplied with your GaugeCalXP to ll the system and begin

calibration testing.

CAUTION: Solvents can damage o-rings and should never be used when ushing or otherwise

cleaning the GaugeCalXP.

CRYSTAL

engineering corporation

© 2006 Crystal Engineering Corporation

708 Fiero Lane, Suite 9, San Luis Obispo, California 93401-8701

PN: 3175—Rev D

Table of contents

Other Crystal Test Equipment manuals

Popular Test Equipment manuals by other brands

Martindale Electric

Martindale Electric PD440S instruction manual

MULTI MEASURING INSTRUMENTS

MULTI MEASURING INSTRUMENTS ALCL-40 instruction manual

Atel Electronics

Atel Electronics DADI DA280 user guide

VOLTCRAFT

VOLTCRAFT VC-BT100 operating instructions

Klein Tools

Klein Tools NCVT-2P instructions

Varytec

Varytec Blitz Bar 240 user manual