CSH ID.LATCH-MOTOR.02 Specification sheet

INSTRUCTION MANUAL

for Installing

LINEAR MOTOR KIT

FOR INVISIDOOR

ID.LATCH-MOTOR.02

Products Included:

Installation Tools Needed:

• Step Ladder

• Power Drill

• #1 & #2 Philips Driver bit and #2 square

drive bit

• Wire Clips

• Tape Measure

• Pencil

• 7/6 4” Drill Bit

• Pliers

• Stud Finder

• Shim or Door Wedge

• Small Level

• Mortise Tool or Small Chisel

• Hammer

2

Instruction Manual for InvisiDoor Motorized Latch

Kit

• Linear Motor

• Motor Control Module

• (2) Key Fobs

• (2) Key Fob Mounting Magnets

• Pivot Bracket

• Wall Bracket w/ Pin

• Clevis Pin

• Spacer

• (2) Soft Washers

• Magnetic Door Catch w/ Plate

• (4) #8x¾” Pivot Bracket Screws

• (4) #8x1¾” Module Case Screws

• (2) #8x2½” Wall Bracket Screws

• (7) #4x⅝” Screws

Motor Control

Module

Linear Motor

Kit Includes:

3

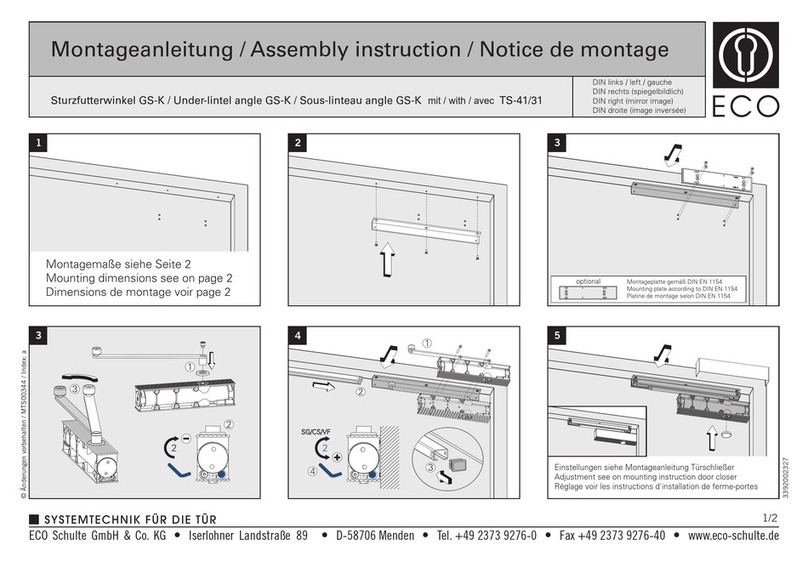

Installation Instructions:

1. Outswing InvisiDoor Application requires Linear Motor to be extended prior to installation. For Outswing

installation, extend motor for next steps. Make sure the Linear Motor is flat and free from obstacles for it to extend

out. Locate the Key Fob. Connect the Blue/White Clip to Power Lead Clip on Linear Motor. Plug the Driver Power

Cord into available outlet and press the Down Button once on the Key Fob to extend the linear motor out to its

full extension. Make sure to turn speed control knob on Enclosure to fastest speed. Unplug Power Plug from outlet

and unclip Linear Motor wire lead. Below are images of each InvisiDoor Inswing and Outswing after completing

installation and below that are images of the intended open swing angle for each application. These angles will vary

depending on wall thicknesses. Instructions follow a typical finished wall at 4.5”. Any variation to this thickness will

offer slightly different results.

Preparation - Refer to Data Sheet for References

• Installation of Pivot Bracket is best installed while InvisiDoor is removed or during

initial installation of the InvisiDoor. Please read InvisiDoor manual first and consider

installing Pivot Bracket and modification of Wood Spacer Block when installing

Hinge Kit to InvisiDoor when door is off for ease of installation.

• Inswing application requires a minimum of 5” clearance from an adjacent wall or

obstruction above the door on the hinge side.

• Installation details regarding Pivot and Wall Bracket mounting dimensions reflect

installation of kit on a CSH manufactured Invisidoor (or like dimensions) with typical

2x4 stud wall construction. Instructions follow application into ~4.5” thick wall. Any

variations outside of those conditions regarding the InvisiDoor or surrounding wall

construction might require adjusted bracket mounting locations for the motorized

latch to work properly.

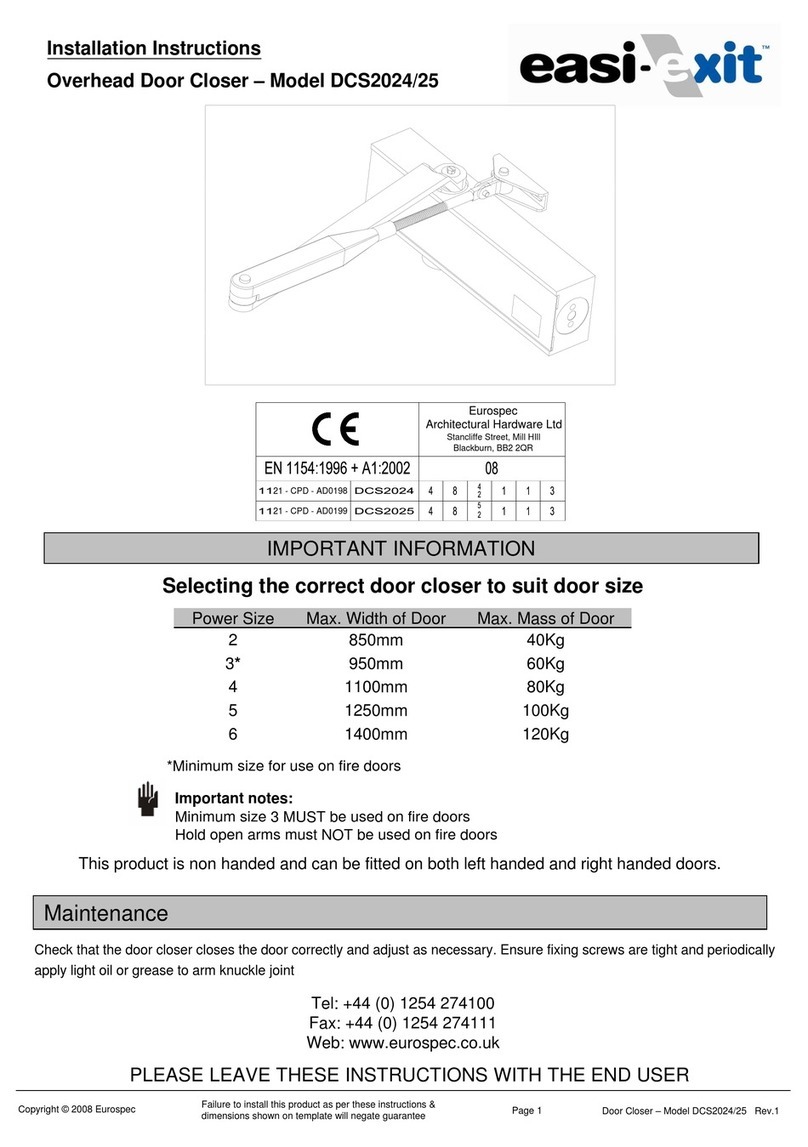

Figure 1 - Inswing Figure 2 - Outswing

4

2. Locate Pivot Bracket for installation on top of InvisiDoor.

• INSWING: The Pivot Bracket mounts on the top of the InvisiDoor roughly 5” from the Side of

cabinet and 1” off of the back of the faceframe (Fig. 3). The provided Wood Spacer block used for

the Hinge Plate would need to be trimmed back to allow for Pivot Bracket installation.

• OUTSWING: Pivot Bracket is located at an angle of roughly 35° to the back panel, with the center

bracket spine terminating flush with the Cabinet Side and the starting of the tapered outside angle

on the bracket flush with the Cabinet Back (Fig. 4). The provided Wood Spacer block used for the

Hinge Plate would need to be trimmed back to allow for Pivot Bracket installation.

3. Only (4) mounting screws are needed for bracket installation. Use the (2) slots and (2) outer holes for

mounting. Drill shallow pilot holes with 7/64” drill bit, making sure to avoid drilling through into the inside

of the cabinet. Once bracket is located, fasten with (4) #8 x ¾” Pan Head Wood Screws. Make sure the (2)

screws fastening in the slots are positioned as far out towards the pivot end for an even dispersion.

4. For the next few steps, it is important the door stays completely shut. If using the supplied InvisiDoor

adjustable Support Foot, adjust it up so that the door swings freely, then close the InvisiDoor, holding it

shut tight using a door wedge or wood shims. If you have another method to support or hold close the

InvisiDoor, remove it so there isn’t any interference in closing the door completely during installation and

testing.

5. Locate the Clevis Pin with Clip, Spacer, Soft Black Washer and Linear Motor and bring them safely to the

top back side of the InvisiDoor. Linear Motor should still be in full extension for the Outswing application,

and Inswing application with motor remaining in retracted position for installing to the InvisiDoor in the

closed door position.

6. Place the rod end of the Linear Motor (end opposite the motor) over the top of the Pivot Bracket hole

and the motor end resting safely on top of the door. Lift the Rod End off the Pivot Bracket and place

the Spacer over the bracket hole, then place the Soft Black Washer on top of the Spacer, aligning the

holes with the Rod End on top. Slide the Clevis Pin from underneath the bracket, through the pivot hole,

Spacer, Washer, and Motor Rod End, securing with the Hitch Clip on Top through the Clevis Pin Hole

(Fig. 5). Make sure Linear Motor is placed securely on top of the InvisiDoor while you get the Wall

Bracket, Clevis Pin and Clip, and wall mounting hardware.

7. Place Wall Bracket over Linear Motor (motor end) so that the Bracket’s wall mounting face is paralell to

the Wall as show in Figure 6. Make sure Soft Green Washer is between the bottom hole of the Bracket

and bottom of the motor end of the Linear Motor when sliding the Clevis Pin dropping the Pin in from the

top. Finish by clipping the Hitch Pin Clip through the Pin (Fig. 6).

8. Make sure InvisiDoor is still shut tight. Check Linear Motor is level using a small Level and mark on Wall

where Bracket height would be level when installed to Wall. With the Wall Bracket flush and snug to

wall and InvisiDoor still held tightly closed, transfer the bracket mounting holes to the Wall and pilot drill

into Door Header. Install screw to exposed outer Wall Bracket hole (Fig. 7). Remove Clevis Pin and Green

Washer to unmount Motor from Wall Bracket to expose 2nd Wall Bracket hole. Pilot drill and install 2nd

mounting screw into Door Header (Fig. 8). Reinstall Green Washer and Motor with Clevis Pin and Clip to

Wall Bracket.

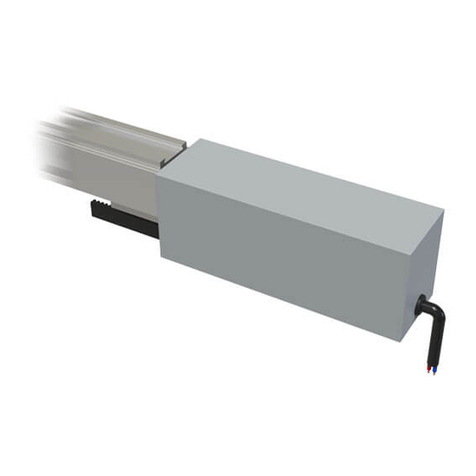

9. With motor installed, verify correct wire lengths and desired Case mounting location (Fig. 9). Use stud

finder to find studs in location where you intend to install case and mark for installation. Install enclosure

vertically with knob facing down and power wire out the top. Install on wall using (4) #8x1¾” screws

into studs or solid wood. Use drywall screws and anchors if necessary where no wood studs are located

behind Case. Use appropriate mounting hardware for concrete, or other type of wall construction.

10. Secure the wiring from the Linear Motor to the Case. It is important to securly fasten the loose wiring

using Zipties or wire clips to the wall away from the door jamb to avoid any loose wire from interfering

with the Invisidoor or motor when door is opened and closed (Fig. 10). Minimal slack is needed where

wire attaches to motor.

5

Figure 3

Figure 7

Figure 4

Figure 8

Figure 5

Figure 9

Figure 6

Figure 10

6

11. Make sure any door stop is removed and that nothing is blocking or will catch the door as you prepare

to open it. Plug in the Power Driver Plug to the outlet and grab the Key Fob Remote.

12. Climb to view the top of the InvisiDoor while it operates but make sure you are standing where the

InvisiDoor won’t interfere when opening completely. On the Key Fob, press the up button on the Key Fob

to retract (Outswing) or down button to extend (Inswing) the Linear Motor. Make sure speed controller

knob on enclosure is set to full speed for testing.

13. As the Linear Motor starts operation, watch for any chance of objects or obstacles that will interfere or

cause resistance the the door opening. Let it complete the full open operation (Fig. 11). If at any time

there the motor strains or the door stops before complete operation, hit the same button you did to

open it (which stops action), then press the opposite button to close the door. Inspect for any causes

of interference around the jamb and door to clear for proper operation. If the bracket interferes with

the door jamb during operation, reposition bracket where it can complete full operation without

interference.

14. After you test to completely open door, press opposite button to return the InvisiDoor back to its closed

position, make sure the door shuts completely and the motor completed it’s full close cycle. Motor must

run its full cycle without resistance to avoid damage to the motor or power supply. At this time make any

Wall Bracket position adjustments if door doesn’t fully close.

15. Locate the magnetic latch and catch plate with hardware. Open InvisiDoor fully and unplug the Linear

Motor Clip. For Inswing application, with door closed mark line on Face Frame with pencil where face

frame is concealed from Trim Panel when closed. Use Mortise Tool or Chisel ¼” deep into top of InvisiDoor

top Face Frame above the marked line. Allow Magnet to sit slightly inset from flush (Fig. 12). The inset

allows the Door to close completly and the Catch Plate to hit Magnet. For Outswing application, use Mortise

Tool or Chisel ¼” deep into the edge of the Jamb about 48” from the floor. Allow Magnet to sit slightly

inset from flush (Fig. 13). Install Magnet using (2) #4x⅝” screws.

16. Snap Catch Plate on the Latch with nubs facing out. Plate should sit flush with Face Frame (Inswing)

or flush with Wall surface where the Back of the Trim comes to rest when closed (Outswing). The nubs

should stick out to transfer location to the back of the Trim when door is closed for installing plate in

correct location. Close Door to transfer nub markings. Try adding a washer underneath the Plate when

closing the door to improve transferring of marks.

17. Open InvisiDoor and locate transfered marks from the Catch Plate. Line up indents with nubs on plate and

install using (1) #4x⅝” screw and install using #1 Philips Flat Head screw where the indents left the mark.

18. Test closure of the InvisiDoor using the Key Fob to confirm Magnet and Plate Latch properly when closed.

Make adjustments to the Magnet depth and/or plate location if not properly latching.

19. The InvisiDoor will still require support from the adjustable leveler to avoid the door to sag over time,

though locating the foot in the shim for closure is no longer required and could provide too much

resistance to the Motorized InvisiDoor operation. It is recommended that if you are using the InvisiDoor

provided adjustable foot leveler from the Hinge Kit, that the plastic floor shim be sanded smooth to

eliminate the locating hole for easy open and close motion avoiding any unnecessary resistance to the

motor. The foot should slide easily on and off the shim when the motor is in operation, and allow the door

to close completly. Routinely check to make sure any door sag over time doesn’t cause the adjustable

foot support to bind and interfere with full door movement. Adjust as necessary. If using an alternative

Support or Closure device, make sure it also does not interfere with intended operation. If resistance is too

strong for proper and complete open and shut operation, could cause increased wear on motor elements.

20. Provided Key Fobs (2) are for use on keychains or can be mounted to fixed locations for easy access. Key

Fobs work up to 30ft with line of sight. For example, kit provides (2) Magnet Strips for holding Key Fobs

inside and outside the InvisiDoor. One can be installed concealed under InvisiDoor Fixed Shelf or nearby in

the room to hold one Key Fob concealled from view for access from the front and another can be installed

on the wall, inside hidden room similar to a light switch application.

7

Troubleshooting:

•Motor does not respond to button activation:

Make sure speed controller knob is set to highest setting. Try to make speed adjustments during motor

operation. Sometimes lowering speed adjustments made after motor has completed a movement

sometimes causes it to delay or not respond the next time you press a button. Speeding it up

momentarily after trying to open/close will cause it to operate, allowing to correct the speed back down

while it is in operation resolves this issue.

•Motor seems to emit variable noise and inconsistant speed during operation:

Make sure there are no resistance or interference with the door opening and closing completly.

Check Adjustable Foot to see if too much resistance on the floor shim is preventing the door from

closing completely. Motor generates notable sound during normal operation. The provided Soft

Washers installed at either end of the motor help limit sound and vibration resonance through the

InvisiDoor which can amplify sound. Sound from the motor should be fairly consistant in most normal

circumstances.

•InvisiDoor does not shut completely:

Check that there is no interference in the door jamb around the door or around the motor and brackets.

Check if there is resistance with the Adjustable Foot when trying to close completely. If door seems

free of interference, try adjusting the location of the Magnet Catch or Bracket locations to see if this

adjustment makes the door shut completely.

Figure 11

Figure 13

Figure 12

Also available from CSH:

REV. 12.09.21

N169W21008 Meadow Ln.

Jackson WI, 53037

cshardware.com

(262) 365-7960

Mini Barn Door Hardware Rolling Barn Door Hardware

Rolling Library Ladder and Ladder Hardware

Table of contents

Popular Door Opening System manuals by other brands

MS Sedco

MS Sedco ID20 installation instructions

Aumuller

Aumuller FTA600 R Assembly and commissioning instructions

Dictator

Dictator DICTAMAT OpenDo Technical manual

Geberit

Geberit IDO Glow Installation instruction

Johnson Controls

Johnson Controls MC-303 PG+ Nstallation guide

Besam

Besam ASSA ABLOY Swingmaster 900 Service and installation manual