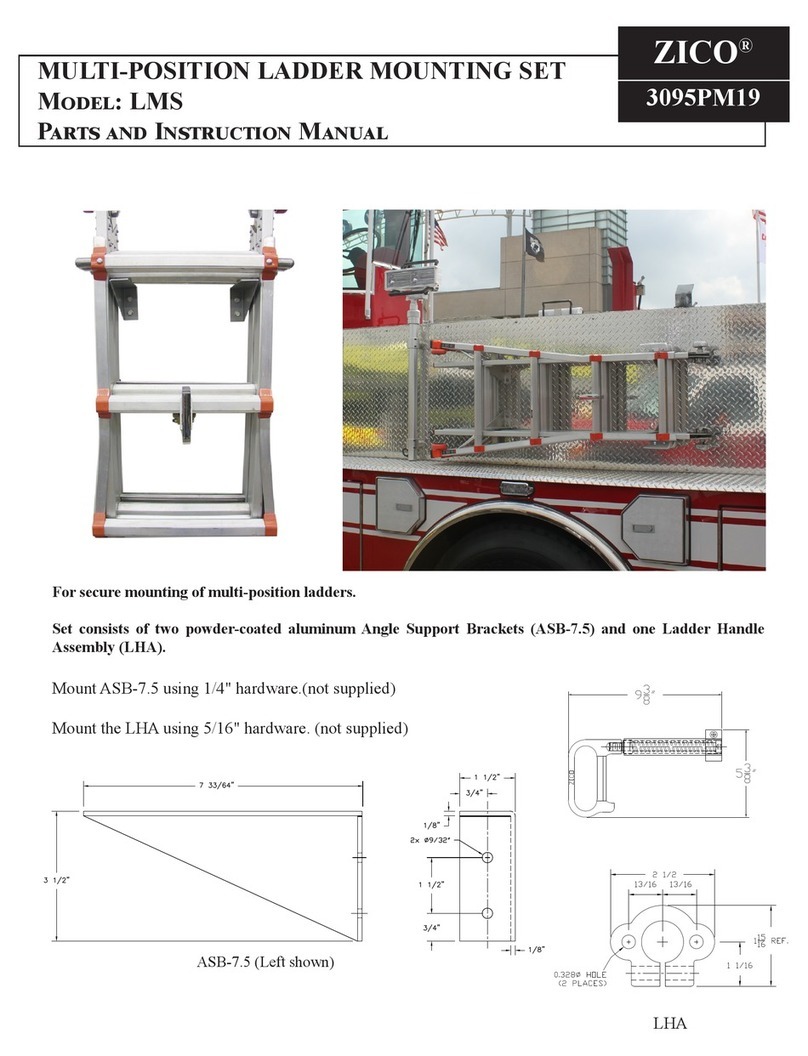

CSH PUTNAM User manual

INSTRUCTION MANUAL

for Installing

NO.1 PUTNAM ROLLING

LADDERS AND HARDWARE

PL.210, PL.230 (Top Guide Assemblies)

PL.270-S, PL.270-C (Bottom Wheel Assemblies)

Hardware Kits vary. See Page 10 for different hardware components.

2

Instruction Manual for No.1 Putnam Rolling

Ladders and Hardware

Step 1: Rail Installation

Special application notes/cautions:

• Leave at least 7” of clearance between

the center of the rail and the ceiling, crown

molding or other overhanging protrusions

when the ladder is in the stored position

(close to the wall/cabinet/bookshelf). In the

climbing position, a minimum 3” clearance

between the center of the rail and any upper

cabinet doors is required to be able to open

the upper cabinet doors (see figure 1).

• Do not mount rail brackets directly onto a

drywall surface. Always mount these brackets

to solid wood, pre-drilling the holes in the

wood is advisable to avoid splitting the wood.

• Do not use rail brackets as a splice between

2 rails (instead, use the supplied wooden

dowels for this purpose)

• Do not use hook-style ladder hardware with

curved rails.

1. Establish the height where the center of the rail is to be installed, then mark the

location where the mounting bracket will be located. Verify with a quality leveling

device that the horizontal locations of the brackets are level and true.

Figure 1

2

Instruction Manual for Installing E-Glide Ladder Hardware

Hardware Included:

Step 1: Rail Installation

Special application notes:

• Do not mount rail brackets directly onto a drywall

surface. Always mount these brackets to solid

wood, predrilling the holes is advisable to avoid

splitting the wood.

• Clearance requirements:

• Ladder in the stored position (close to the

wall/cabinet/bookshelf). Leave at least

2 ½” of clearance between the top of the

rail and the ceiling, crown molding or other

overhanging protrusions (figure 1).

• Ladder in the climbing position, a minimum 1”

clearance between the top of the rail and any

upper cabinet doors is required to be able to

open these doors (figure 2).

Figure 1 Figure 2

Installation Tools Needed:

Pre installation-

TOOLS REQUIRED

2

x4

x4

x1 x7

x28

H

x1 x1

x1

x14

x2 x2

M5x18

x2

M6x30

(x1)

2mm 4mm

(x1)

3mm

A

x2

B

x1

C

DEF

G

x2

x7

x4

HARDWARE INCLUDED

1. Rail height determination: Distance from the floor to the location on the header board

where the screw for the rail bracket will be fastened.

• For the 92” ladder = 88 1/4” to 89 1/4”

• For the 107” ladder = 103 1/4” to 104 1/4”

5/16” Drill Bit

10mm Wrench

Drill

Tape

Measure

Level

#2 Phillips

Screwdriver

Stored Position Climbing Position

Pre installation-

TOOLS REQUIRED

2

x4

x4

x1 x7

x28

H

x1 x1

x1

x14

x2 x2

M5x18

x2

M6x30

(x1)

2mm 4mm

(x1)

3mm

A

x2

B

x1

C

DEF

G

x2

x7

x4

HARDWARE INCLUDED

Pre installation-

TOOLS REQUIRED

2

x4

x4

x1 x7

x28

H

x1 x1

x1

x14

x2 x2

M5x18

x2

M6x30

(x1)

2mm 4mm

(x1)

3mm

A

x2

B

x1

C

DEF

G

x2

x7

x4

HARDWARE INCLUDED

Pre installation-

TOOLS REQUIRED

2

x4

x4

x1 x7

x28

H

x1 x1

x1

x14

x2 x2

M5x18

x2

M6x30

(x1)

2mm 4mm

(x1)

3mm

A

x2

B

x1

C

DEF

G

x2

x7

x4

HARDWARE INCLUDED

Pre installation-

TOOLS REQUIRED

2

x4

x4

x1 x7

x28

H

x1 x1

x1

x14

x2 x2

M5x18

x2

M6x30

(x1)

2mm 4mm

(x1)

3mm

A

x2

B

x1

C

DEF

G

x2

x7

x4

HARDWARE INCLUDED

Pre installation-

TOOLS REQUIRED

2

x4

x4

x1 x7

x28

H

x1 x1

x1

x14

x2 x2

M5x18

x2

M6x30

(x1)

2mm 4mm

(x1)

3mm

A

x2

B

x1

C

DEF

G

x2

x7

x4

HARDWARE INCLUDED

Pre installation-

TOOLS REQUIRED

2

x4

x4

x1 x7

x28

H

x1 x1

x1

x14

x2 x2

M5x18

x2

M6x30

(x1)

2mm 4mm

(x1)

3mm

A

x2

B

x1

C

DEF

G

x2

x7

x4

HARDWARE INCLUDED

Pre installation-

TOOLS REQUIRED

2

x4

x4

x1 x7

x28

H

x1 x1

x1

x14

x2 x2

M5x18

x2

M6x30

(x1)

2mm 4mm

(x1)

3mm

A

x2

B

x1

C

DEF

G

x2

x7

x4

HARDWARE INCLUDED

Pre installation-

TOOLS REQUIRED

2

x4

x4

x1 x7

x28

H

x1 x1

x1

x14

x2 x2

M5x18

x2

M6x30

(x1)

2mm 4mm

(x1)

3mm

A

x2

B

x1

C

DEF

G

x2

x7

x4

HARDWARE INCLUDED

Pre installation-

TOOLS REQUIRED

2

x4

x4

x1 x7

x28

H

x1 x1

x1

x14

x2 x2

M5x18

x2

M6x30

(x1)

2mm 4mm

(x1)

3mm

A

x2

B

x1

C

DEF

G

x2

x7

x4

HARDWARE INCLUDED

Pre installation-

TOOLS REQUIRED

2

x4

x4

x1 x7

x28

H

x1 x1

x1

x14

x2 x2

M5x18

x2

M6x30

(x1)

2mm 4mm

(x1)

3mm

A

x2

B

x1

C

DEF

G

x2

x7

x4

HARDWARE INCLUDED

x2 x2

3/8”

#3 Philips bit

8

114-116”

(10’ ladder)

102-104”

(9’ ladder)

Distance from wall

(ladder in climbing position)

31”

90-92”

(8’ ladder)

47”

7”

45°angle

(approximately)

5” radius

Stock

= 1-1/4” x 1-1/4”

with 3/16” radius corners

5/8” radius ends

2- Predrilled holes 17/64”

2-1/8”CC on each end

located 3/4” from end

47”

7”

2-1/8”CC

3/4”

6-1/2”

4” CC

5-1/2”

5-1/2”

1-3/4”

2-1/8” dia

Top Roller

7/8”

6-1/2”

4” CC

5-1/2”

4” 1-3/4”

Rolling Hook

2-1/2” 2” dia

7/8”

8-1/4”

6-1/8”

Brake Wheel 1-3/4”

7/8”

8-1/4”

6-1/8”

Brake Wheel

1-3/4”

7/8”

8”

5-7/8”

Standard Wheel 1-3/8”

7/8”

8”

5-7/8”

Standard Wheel 1-3/8”

7/8”

5”

5-3/8”

Contemporary Wheel

1-7/16”

7/8”

5”

5-3/8”

Contemporary Wheel

1-7/16”

7/8”

3”

Non - Skid Foot

1-1/4

6-1/2”

4” CC

5-1/2”

5-1/2” 1-3/4”

Top Swivel Roller

7/8”

Top Ladder Clearance

Rail Height and Distance for 8’, 9’, 10’ standard ladders

Hand Rail Dimensions

TOP LADDER HARDWARE BOTTOM LADDER HARDWARE

* Designed For Loft Applications

6-1/2”

4” CC

5-1/2”

3-7/8”

1-3/4”

Adjustable Hook

7/8”

*

4-13/16”

1-3/16”

4-13/64”

3-5/16”

27/32”

Double Hook 53/64”

*

*also comes

available as a

Brake Wheel

(measurements

are the same)

*

8

114-116”

(10’ ladder)

102-104”

(9’ ladder)

Distance from wall

(ladder in climbing position)

31”

90-92”

(8’ ladder)

47”

7”

45°angle

(approximately)

5” radius

Stock

= 1-1/4” x 1-1/4”

with 3/16” radius corners

5/8” radius ends

2- Predrilled holes 17/64”

2-1/8”CC on each end

located 3/4” from end

47”

7”

2-1/8”CC

3/4”

6-1/2”

4” CC

5-1/2”

5-1/2”

1-3/4”

2-1/8” dia

Top Roller

7/8”

6-1/2”

4” CC

5-1/2”

4” 1-3/4”

Rolling Hook

2-1/2” 2” dia

7/8”

8-1/4”

6-1/8”

Brake Wheel 1-3/4”

7/8”

8-1/4”

6-1/8”

Brake Wheel

1-3/4”

7/8”

8”

5-7/8”

Standard Wheel 1-3/8”

7/8”

8”

5-7/8”

Standard Wheel 1-3/8”

7/8”

5”

5-3/8”

Contemporary Wheel

1-7/16”

7/8”

5”

5-3/8”

Contemporary Wheel

1-7/16”

7/8”

3”

Non - Skid Foot

1-1/4

6-1/2”

4” CC

5-1/2”

5-1/2” 1-3/4”

Top Swivel Roller

7/8”

Top Ladder Clearance

Rail Height and Distance for 8’, 9’, 10’ standard ladders

Hand Rail Dimensions

TOP LADDER HARDWARE BOTTOM LADDER HARDWARE

* Designed For Loft Applications

6-1/2”

4” CC

5-1/2”

3-7/8”

1-3/4”

Adjustable Hook

7/8”

*

4-13/16”

1-3/16”

4-13/64”

3-5/16”

27/32”

Double Hook 53/64”

*

*also comes

available as a

Brake Wheel

(measurements

are the same)

*

3

3. Install rail brackets

a. For vertical brackets (PL.14 series): Drive the brackets into the slotted rail and

align them with the vertical uprights/stiles on the shelving unit. Mark the fastener

locations and pre-drill the holes in the wood to avoid splitting. Secure the brackets

using the supplied screws (be sure to use the tapped and threaded brackets for

the ends of the rails,

(see vertical brackets below

).

Wooden dowel Rail

2. Splice the sections of rails

together using the supplied

wooden dowels. Do not put

rail brackets in the area where

the splices will be located

(see

figure 2)

.

b. For horizontal brackets (PL.27 series): Separate the bracket and fasten the back

plate to the shelving unit or horizontal trim board in the desired location, no more

than 36” from center to center (pre-drill the holes in the wood to avoid splitting).

Drive the bracket fronts into the track and align with the mounted backs, then

reassemble the brackets with the rail attached (use the left and right brackets

with the attached end caps for the ends of the rails).

To install a PL.210 roller type ladder onto the rail when using the horizontal brackets:

• Separate one of the outside brackets with end cap attached.

• Slide the front portion of the bracket off the rail.

• Install ladder onto the rail and reinstall the end bracket.

PL.14

PL.27

Vertical Brackets

PL.14H

PL.27H

Figure 2

Horizontal Brackets

Left/Right

End Bracket

(Non-handed)

Left and Right

End Brackets

(Handed)

Adjustable

Bracket

Adjustable

Bracket

Vertical Hook

Bracket

Horizontal

Hook Bracket

4

Step 2: Ladder Assembly (if applicable)

It is recommended that the unfinished ladder rail sides and steps are lightly hand sanded with a

220 grit sanding pad just prior to finishing the ladder (stain, paint, clear coat sealer).

It is also much easier to finish the ladder prior to assembly.

1. Stand on edge one of the ladder side rails on a flat surface, dados facing away from you.

2. Insert one of the steps into the dado, aligning the compound miter of the step flush with

the dadoed surface of the side rail. If not flush, flip and/or rotate the step until it lines up

properly with the side rail

(see the following page)

.

c. For the Corner Brace/Bracket (PL.40CRVBKT series) used in conjunction with the 90º, 30” radius curved rails

(see diagrams below)

• Install the Corner Brace/Bracket by measuring from the inside corner of the 90-degree trim boards out 23 ¼” for

both sides.

• Attach the brace to the shelving unit at the desired height from the floor.

• Remove the top piece on the horizontal rail bracket that is attached to the Corner Brace.

• On the curved rail, mark the halfway point on the rail, this is where the horizontal bracket on the corner brace will

be located.

• On the trim, measure from the inside corner out approximately 42” on both sides, this will be the location of the

two additional rail brackets.

• Follow Steps 3a or 3b above to install these additional rail brackets.

• Reattach the center rail bracket and add two additional brackets towards each end of the curved rail, secure

these brackets to the shelving unit.

• Additional rails can then be added to the curved rail as needed by using the wooden dowel to connect them.

PUTNAM

ROLLING LADDER CO. INC

CORNER BRACE ASSEMBLY

No. 27

Bracket

MACHINE

SCREW

MACHINE

SCREW

WOOD

SCREW

WOOD

SCREW

NUT

NUT

WASHER

WASHER

PUTNAM

ROLLING LADDER CO. INC

CORNER BRACE INSTALLED W/ 90° CURVED RAIL

BRACKET

BRACKET

WALL/SHELVING

UNIT

CORNER

BRACE

ASSEMBLY

EQUAL

(APPROX.

23-1/4”)

EQUAL

(APPROX.

23-1/4”)

APPROX.

45-1/2”

TO END OF

CURVED RAIL

APPROX. 45-1/2”

TO END OF

CURVED RAIL

APPROX.

42” TO

CENTER OF

BRACKET

APPROX.

42” TO CENTER OF

BRACKET

5

6. Install the Truss Rods

a. Drive in the threaded insert using a rubber mallet

(see figure 4)

.

b. Slide the threaded rod through the hole in the ladder side rail and tighten with a

⅜” socket or open-end wrench.

3. Using the supplied #14 x 2½” round-head screws, secure the step to the side rail

through the predrilled holes on the side rails. Assemble the remaining steps in the

same manner

(see figure 3a)

.

4. Once all the steps are assembled onto one of the side rails, position the side rail on

its side with the steps pointing up and insert the top turned rung

(see figure 3b)

.

5. Properly align each step as well as the top turned rail into its corresponding dado/

hole, use the supplied screws to fasten the steps into place

(see figure 3c)

.

Incorrect Correct

Figure 4a

Figure 3a

Figure 4b

Figure 3b

Figure 4c

Figure 3c

6

Step 3: Attaching the Hardware to the Ladder

1. Install the upper roller and hook assemblies (Straight Side Rails).

a. Center the upper assembly around the top turned dowel. Measure down from the

top of the ladder to the top of the Upper Assembly hardware (approx. 1½”). This

measurement should be the same on both wood side rails

(see figure 5)

.

PLEASE NOTE:

Pre-drilling is essential to prevent splitting the wood.

~1½”~1½”

2. Install the upper roller and hook

assemblies (Top Bent Side Rails).

a. See diagram for location of the

upper assembly hardware.

1. Using a Vix bit or similar self-

centering drill guide, drill a pilot hole

into the edge of the ladder for the

(2) #10 x ¾” Flat-head, Phillips-

drive screws and secure each Upper

Assembly to the top of the ladder

(see figure 6)

.

Figure 6a Figure 6b Figure 6c

Figure 5a Figure 5b

7

b. Mark the location of the “U” bracket on the bottom of the ladder, this will be

approximately 2” in from the front of the rail. At the same time, mark the location

on the side of the ladder for the top and middle mounting holes of the bottom

wheel assembly. Measure these marks and transfer these measurements to the

other ladder side rail so that the hardware will mount identically on both ladder

side rails

(see figure 8)

.

c. Using a ¼” drill bit, drill through holes in the ladder side rail for the ¼-20 pan-

head bolts

(see figure 8).

2. Install the bottom wheel assemblies

a. Place the bottom wheel assembly onto

the bottom of the ladder using the “U”

bracket portion of the housing. Verify

that the bracket is flush with the bottom

of the ladder. (Because of the 12-degree

angle of the bottom of the ladder, this will

align the housing diagonally across the

ladder side rail).

2. Using a ¼” drill bit, drill out the through holes for the ¼-20 Phillips, pan-head 1 ⅜”

long bolts. We recommend this procedure:

• Using the holes in the upper assembly as a drill guide, drill a ¼” hole halfway

through the thickness of the ladder slide rail.

• Drill the same hole on the opposite side of the Upper Assembly, producing a

straight ¼” through hole in the ladder side rail.

• Follow this same procedure for all 4 through holes and finish by securing the upper

assemblies with the supplied ¼-20 Phillips drive, pan-head bolts and acorn nuts.

Note: For the PL.210 series Upper Roller Assembly, the larger diameter wheel is on

the top (see figure 7).

Figure 7a Figure 7cFigure 7b Figure 7d

8

d. Pre-drill the ladder side rail for the #10 Flat-head, Phillips drive ¾” screw

(see

figure 9)

. PLEASE NOTE:

Pre-drilling is essential to prevent splitting the wood.

e. Install the bottom wheel assemblies using the included screws, bolts, and

acorn nuts.

...and your Putnam Ladder

is complete!

Figure 9a Figure 9c

Figure 9b

Figure 8b

Figure 8c Figure 8d

Figure 8a

9

Putnam Ladder Application Images

Hardware Dimensions

10

•Length - 2 1⁄4”

• Width - 3 3⁄8”

• Height - 3⁄4”

Corner Bracket Measurements

3⁄4”

11 1⁄4”

16”

1”

2 3⁄4”

6 1⁄8”

8 1⁄8”

2 1⁄4”

7⁄8”

• Length - 6 1⁄8”

• Width - 2 1⁄4”

• Height - 8 1⁄8”

Bottom Wheel Measurements

PL.270-C

• Length - 6 3⁄16”

• Width - 2 1⁄2”

• Height - 8 1⁄4”

Bottom Wheel Measurements

6 3⁄16”

8 1⁄4”

2 1⁄2”

7⁄8”

PL.270-S

• Length - 4”

• Width - 1 3⁄4”

• Height - 6”

Upper Hook Measurements

4”

6”

1 3⁄4”

1 3⁄4”7⁄8”

PL.230

• Length - 3 1⁄4”

• Width - 1 3⁄4”

• Height - 6”

Upper Wheel Measurements

7⁄8”

3 1⁄4”

6”

1 3⁄4”

2

3

⁄

4

”

PL.210

PL.40CRVBKT

Hardware Dimensions

11

• ¼-20 Partially Threaded Rod, 15.875”long

• Hex Head with Flat to Flat ⁄” wide, ¼”Dia. Shaft

• Last ⁄” of bolt threaded

Truss Rod

• ¼-20 x ½” Propel nut

Nut

• ¼” x ⁄” Dia. Flat Washer

Washer

15.875”

⁄”

¼”

⁄8”

⁄”

⁄”

7⁄8”

• Length - 1 5⁄8”

• Width - 1 1⁄4”

• Height - 3 3⁄4”

Vertical Hook Bracket Measurements

3 3⁄4”

1 5⁄8”1 1⁄4”

PL.14H

3 1⁄2”

2 1⁄8”

3 1⁄2”

• Length - 3 1⁄2”

• Width - 2 1⁄8”

• Height - 3 1⁄2”

Horizontal Hook Bracket Measurements

PL.27H

• Length - 1 5⁄8”

• Width - 1 1⁄4”

• Height - 5”

Vertical Bracket Measurements

5”

1 5⁄8”1 1⁄4”

PL.14

3 3⁄8”

3⁄4”

2 1⁄4”

• Length - 2 1⁄4”

• Width - 3 3⁄8”

• Height - 3⁄4”

Horizontal Bracket Measurements

PL.27

Also available from CSH:

REV. 5.26.21

1170 Wauwatosa Rd.

Cedarburg, WI 53012

cshardware.com

(262) 365-7960

Mini Barn Door Hardware Rolling Barn Door Hardware

InvisiDoor

Table of contents

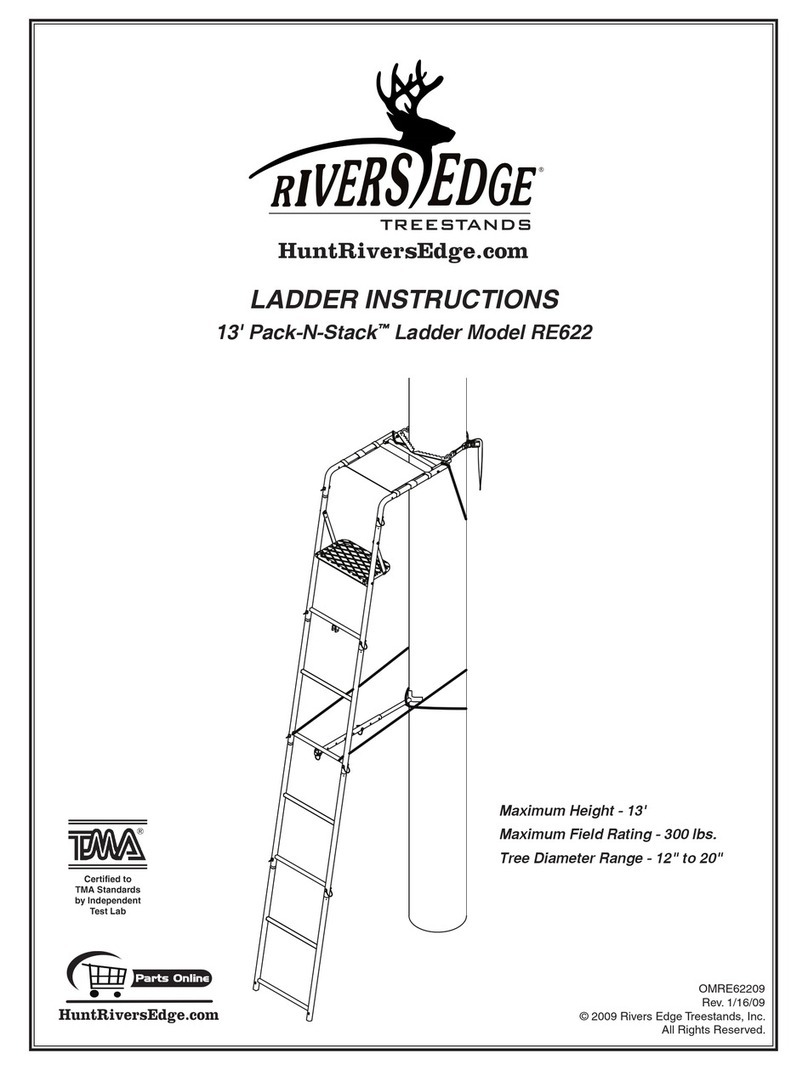

Other CSH Ladder manuals

Popular Ladder manuals by other brands

Centaure

Centaure 203 1 Series instruction manual

Colombo

Colombo S107 Use and Operating Instructions

Vorel

Vorel 17730 instructions

Westfalia

Westfalia 67 87 89 instruction manual

SCALANT

SCALANT SCARLO 1000 Assembly instructions

Piristeel

Piristeel Pisko SafeLine Instructions for installation, use and maintenance manual