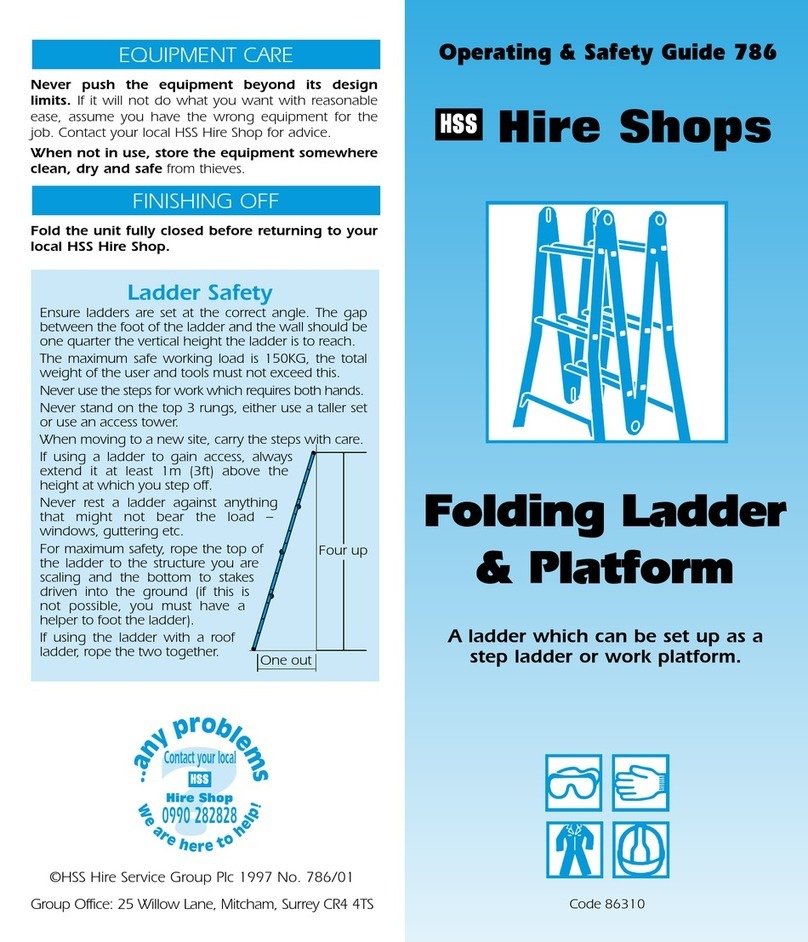

Never overload the scaffold. The work platform’s

maximum safe working load is 275kg and MUST

NOT BE EXCEEDED.

Never lean anything against the scaffold and never

use it for jobs that exert repetitive or excessive

force. Lateral forces over 198N – equivalent to a

20kg weight – make it unstable.

Never use boxes, steps etc to gain extra height and

never reach too far out to one side.

Never move a scaffold with personnel, tools or

material, always clear the platform.

Ensure the ground over which the scaffold is to be

moved is flat, level, firm enough to bear its weight,

and well away from hazards.

Once in place, re-lock the brakes.

Don’t take chances. If the scaffold cannot be moved

safely for any reason, dismantle it and rebuild in the

new location.

Never use the scaffold for anything other than its

intended purpose – as a light-duty work platform. If

it won’t do what you want contact your local HSS

Hire Shop for advice.

Keep the scaffold clean, paying special attention to

the deck. You will find this easier if you clean up

regularly.

When not in use, store everything somewhere

clean, dry and safe from thieves.

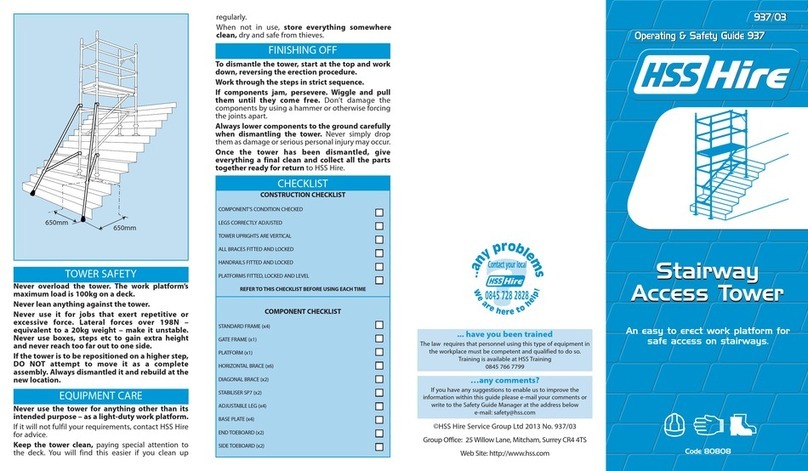

To dismantle the scaffold, simply reverse the

erection procedure.

If components jam, persevere. Wiggle and pull

them until they come free. Don’t damage the

components by using a hammer or otherwise

forcing the joints apart.

FFIINNIISSHHIINNGGOOFFFF

EEQQUUIIPPMMEENNTTCCAARREE

SSCCAAFFFFOOLLDDSSAAFFEETTYY

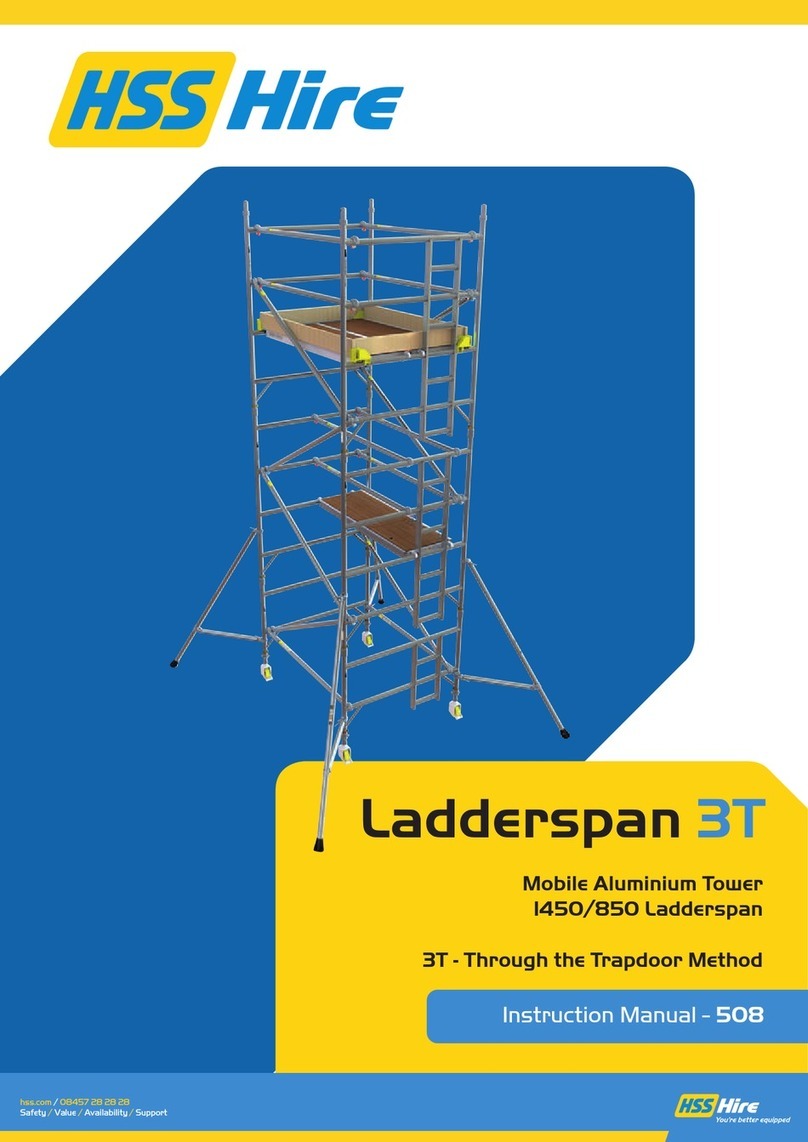

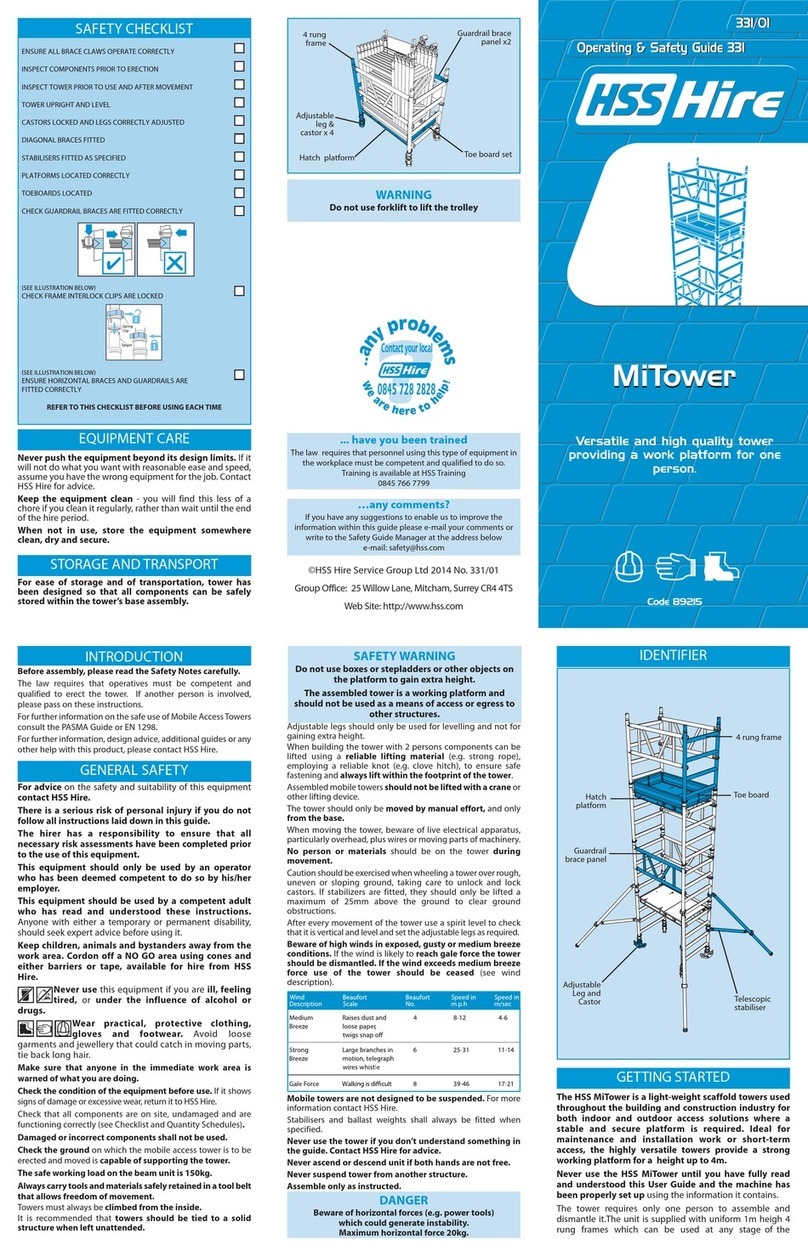

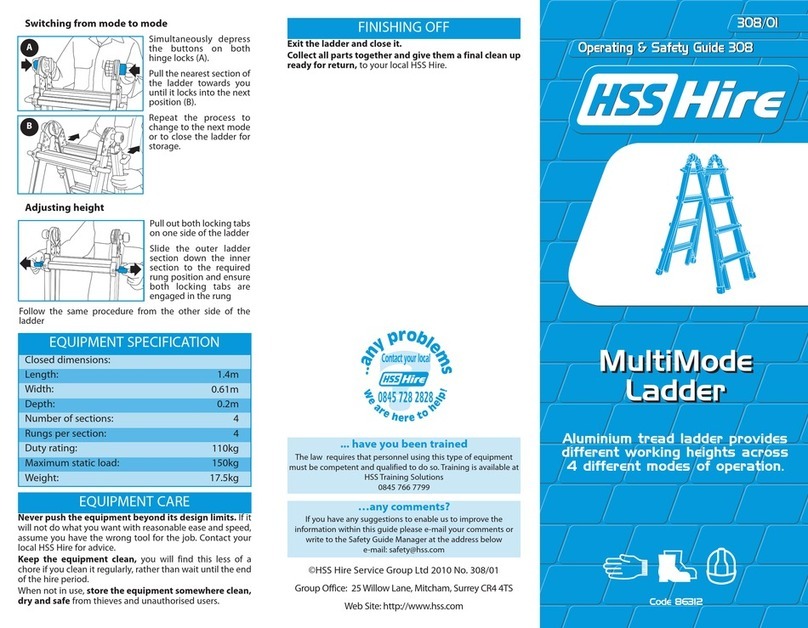

Folding Indoor

Scaffold

Designed to the European

Standard HD1004, the Folding

Room Scaffold provides the ideal

platform for interior decorating

and maintenance.

Operating & Safety Guide 509

Code 80860

509/02

509/02

Folding Indoor

Scaffold

Operating & Safety Guide 509

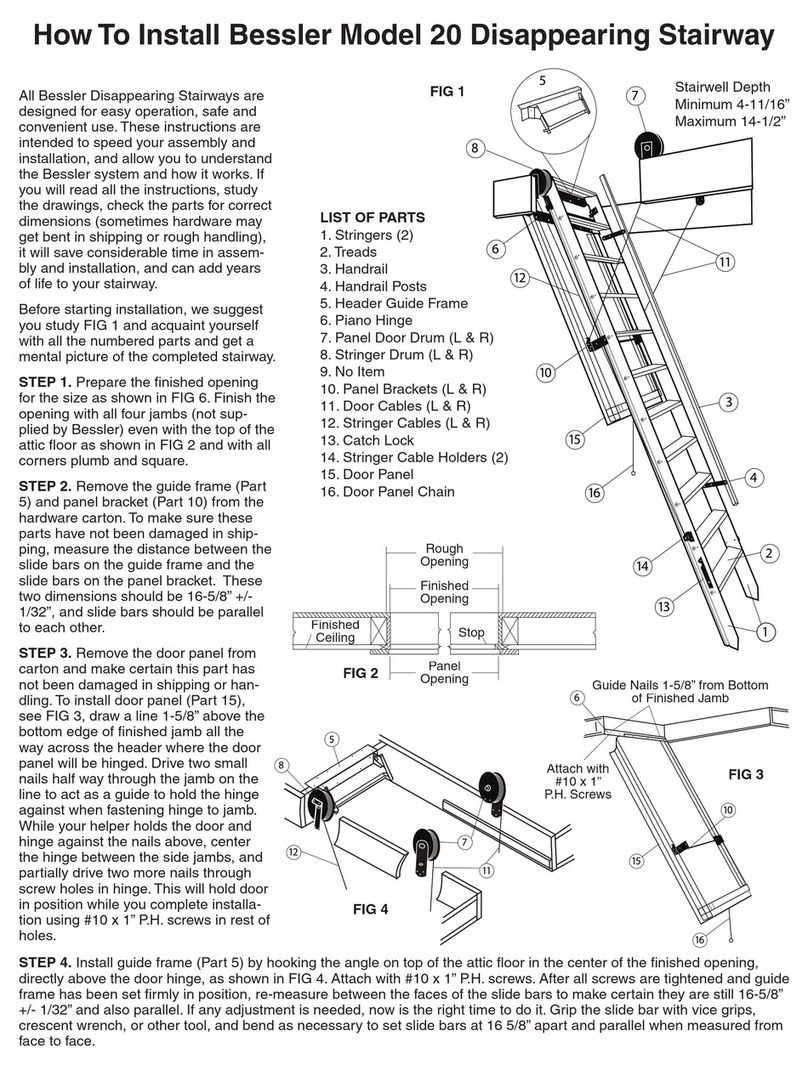

ASSEMBLY PRINCIPLES

USAGE ADVICE

ERECTION

Check that all components are on site and that they

are functioning correctly.

Check if the ground on which the mobile access tower

is to be erected and moved, is capable of supporting

the tower.

The safe working load is 275 kgs (606 Ibs) uniformly

distributed up to a maximum of 950 kgs (2100 Ibs) per

tower (including self weight). This must not be

exceeded.

Do not use boxes or step ladders on the platform to

gain additional height.

MOVEMENT

The tower should only be moved by manual effort,

and only from the base.

When moving the tower, beware of live electrical

apparatus, particularly overhead, plus wires or moving

parts of machinery.

No personnel or materials should be on the tower

during movement.

DURING USE

Beware of open ended buildings which can cause funneling

effect.

Do not abuse equipment. Damaged or incorrect

components should never be used.

The assembled tower is a working platform and should

not be used as a means of access to other structures.

Beware of horizontal forces (eg power tools) which could

generate instability. Maximum horizontal force 20 kg.

Mobile towers are not designed to be suspended - please

refer to your supplier.

MAINTENANCE

All components and their parts should be regularly

inspected to identify damage, particularly to welds. Lost or

broken parts should be replaced, and any tubing with

indentations greater than 5mm should be put to one side

for manufacture repair. Adjustable leg threads should be

cleaned and lightly lubricated to keep them free running.

©HSS Hire Service Group Ltd 2007 No. 509/02

Group Office: 25 Willow Lane, Mitcham, Surrey CR4 4TS

Web Site: www.hss.com

WHEN BUILDING A BOSS TOWER:

To comply with the Work at Height Regulations we

show procedures with additional platforms and the

locating of single Guardrails when building in advance

of climbing onto a platform to reduce the risk of a fall.

This involves moving components, but is an important

procedure for your safety.

Always stand on a Boss Platform, never on the rungs of

a Frame.

Install temporary single Guardrails prior to climbing

onto platforms, from the platform staggered below.

Working platforms require double Guardrails. All

working levels require toeboards.

Stagger platforms to the left or right at 1 metre

intervals,which will limit the potential height of fall.

Locate single Guardrail (Horizontal Braces) from below

in advance of climbing onto the platform.

... have you been trained

The law requires that personnel using folding indoor

scaffold must be competent and qualified to do so.

Training available at HSS Training Solutions

0088445577666677779999

…any comments?

If you have any suggestions to

enable us to improve the

information within this guide

please e-mail your comments or

write to the Safety Guide Manager

at the address below