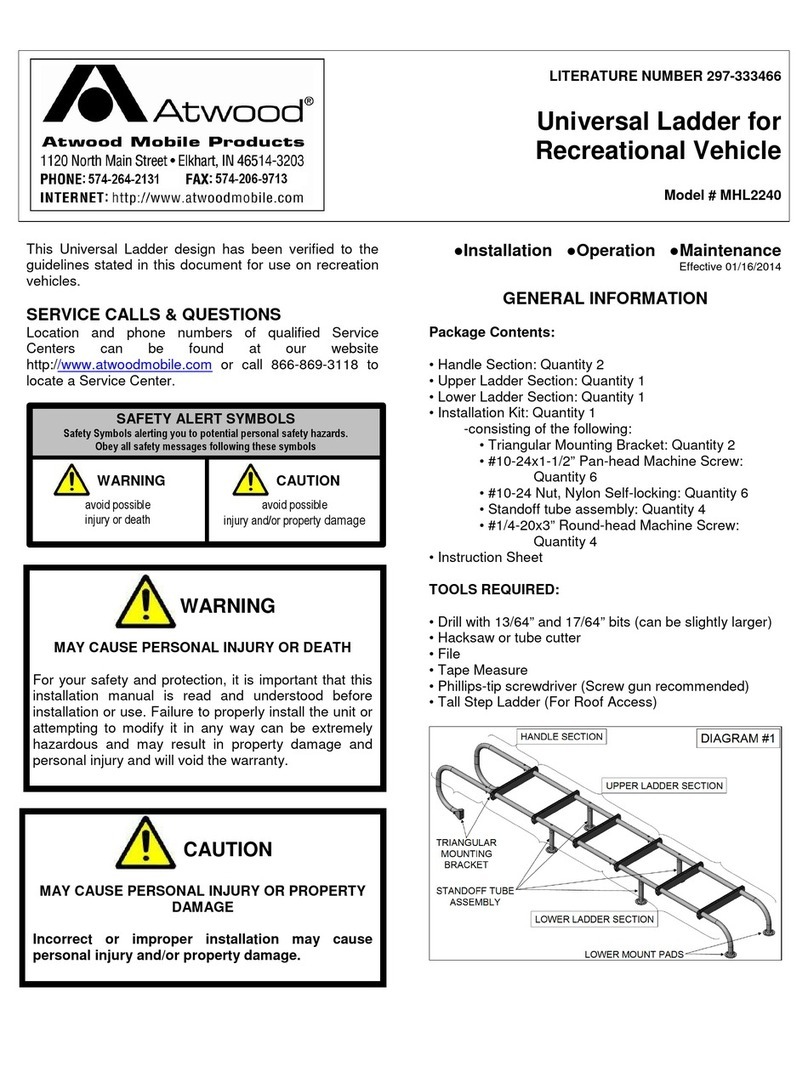

CSH QUIET GLIDE QG.200 Series User manual

QUIET GLIDE ROLLING

LADDER INSTRUCTION

MANUAL

QG.200-300-500-700 Series Hardware

•7" clearance is required above the track's centerline when the ladder is in the storage position

(to avoid contacting ceiling or crown molding), and at least 3" is needed when the ladder is

fully angled for climbing. (Figure 1a-b)

GENERAL INSTALLATION/SPECIFICATION GUIDE

For QG.200, 500, 700 Series Hardware Kits

Step 1: Track Installation Special Application Notes/Cautions:

2

Figure 1a Figure 1b

If NOT using a Splice Kit to connect multiple tracks or installing

End Caps, skip to page 4 for Track Installation.

•Do not mount track brackets directly onto a

drywall surface, even if there is solid wood behind.

Track brackets will eventually crush the drywall,

potentially causing the track system to fail. Track

brackets need to be installed directly onto a solid

wood surface.

•If installing a Standard Double Roller or Swivel

Roller (200 or 700 Series), ladder will need to be

placed onto the track before fastening to wall

and adding End Caps.

3

•Slide all the brackets onto the track (brackets should be no more than 32" apart).

•Install the end caps to the rail.

•

Using a ¼”-20 tapping tool, tap the ends of the track (see Figure 3b).

•

Secure the end cap to the track using the supplied ¼”-20 KD bolt and a 4mm

Allen wrench (see Figure 3c). End result is Figure 3d.

Figure 3a Figure 3c

Figure 3b Figure 3d

Figure 1a

Figure 1b

•If installing a Standard Double Roller or Swivel Roller (200 or 700 Series), ladder will need to be

placed onto the track before adding End Caps.

1. To connect track rails using the Quiet Glide Splice Kit (QG.41), follow these steps:

·

Insert half the length of the roll pin into one of the tracks. (Figure 1a).

·

Slide the steel bar halfway into the track and tighten one of the set screws. (Figure 1b).

•

Line up the other track and slide it over the pin and bar, ensuring

a snug connection. (Figures 2a & b).

•

Complete the splice by tightening the remaining set screw.

Figure 2a Figure 2b

Splice and End Cap Installation Special Application Notes/Cautions

4

2. Slide all of the brackets into the

channel in the metal track (if not

done from Splice Kit steps),

approximating the spacing on your

mounting surface. Brackets should

be no more than 32" apart.

(Figure 2a-b)

3.Determine the center track

installation height and mark the

location for the bottom of the

mounting brackets. Hold the metal

track up to the mounting surface-

lining up your brackets with the

planned locations marked. Mark the

center of both the fastener holes.

(Figure 3a-b)

Figure 2a

Figure 3a

Figure 4

4. Pre-drill your marked

locations using 1/8" bit

for soft wood and

13/64" for hard wood.

(Figure 4)

5. Bring your metal

track with brackets to

your mounting surface

and fasten each bracket

to the wood surface with

the included screws.

(Figure 5)

Figure 5

Please note: If installing a Standard Double

Roller or Swivel (200 or 700 Series), ladder

will need to be placed onto the track before

fastening to wall.

6. Use an accurate leveling device to ensure that the

horizontal locations of the bracket and track are properly

aligned. (Figure 6).

Figure 6

Figure 2b

Figure 3b

5

Step 2: Ladder Assembly (if applicable)

Storage:

•Store the ladder in its original packaging in a humidity-controlled

environment until ready to finish/assemble.

•Lay the stored ladder on a dry, level surface, preferably off the floor (do not

lean against wall for any extended period, this can cause bowing/warping of

the ladder).

Surface prep:

•After removing from shipping packaging, allow the ladder parts to

acclimate to the temperature/humidity of the area where the ladder will be

installed. (Acclimation times vary by species and product, a guide is to

acclimate the wood ladders for at least three days. The goal is to reach an

equilibrium between the moisture content of the wood materials and the air

where the product is being installed)

•Sand all wooden parts with a 220-grit sanding pad just prior to finishing.

(This opens the wood pores creating a more uniform and consistent finish

on the ladder)

•Remove all dust from the ladder prior to finishing.

•It is highly recommended that a high-quality top-coat finish is applied to

the raw, stained, or painted wood ladder to protect and preserve the beauty

of the wood.

Ladder Assembly:

Critical note: A flat, level surface is required. Use 3/4"

plywood spacers under the ladder sides. (See Step 4 below):

1. Lay out the parts to be assembled on the table

(Figure 1)

2. Install the nut caps for the truss rods, use a rubber

mallet if necessary (Figure 2)

3. Install the truss rods loosely into the nut caps using a

5mm Allen wrench, allowing room to slide the steps

into the dados

(detailed in Step 5). For ladders with top

turned rungs, install by gluing the top turned rung in

the side rails (Figure 3-4).

4. Slide 2 plywood spacers under the ladder side rails

(Figure 5-6 below). (Only use 2 spacers for this

operation, additional spacers can result in uneven

side rails)

Figure 1

Figure 2

Figure 3Figure 4

6

5. Slide the steps into the dados, verifying

that the compound miter is lined up in the proper

orientation with the dado. (Figure 7-8). Confirm

that the ladder side rails are all lying flat in contact

with the spacers and the bottom of the ladder side

rails are even with each other and perpendicular to

the sides.

6. Begin tightening the truss rods. (Do not tighten

securely at this time, need to be able to adjust the

height of the steps to align with the dados while

fastening with the supplied screws).(Figure 9-10)

Truss rods should be spaced evenly between the

ladder side rails. The amount of exposed threads

on the truss rods, as viewed on the inside, should

be relatively even.

Figure 5 Figure 6

Figure 7 Figure 8Figure 9 Figure 10

Figure 11 Figure 12

Figure 7 Figure 8

7. Align the compound miter of the step to

the dado. Begin fastening, pushing the side

rail down in tight contact with the plywood

spacers (Figure 11). Completely fasten

each step (both sides) before moving onto

the next step. (Figure 12)

7

8. When all the steps have been

installed, tighten the truss rods

completely. (Figure 13) If assembled

properly, the ladder side rails will be in

tight contact with the plywood spacers

(all 4 contact points). There will also be

a slight, even gap between the table and

the edge of the steps. (Figure 14)

9. For ladders with top turned rungs, clamp the ladder side rails

together and secure the top turned rung with a mechanical

fastener. (Figure 15). Acceptable fasteners:

o18-gauge brad nail, 1-1/2” long, or

o1-1/2” finish nail (4d), need to predrill using a 1/16” drill

bit.

Figure 13Figure 14

Figure 15

Step 3 Ladder Hardware Installation

Upper Hardware Assembly

1. Align the Upper Hardware Assembly on the beveled portion of the ladder by measuring down

1-1/2” from the tip of the ladder (Figure 16) (the top turned rung will be centered between the bolt

holes on the side of the hardware)

2. Using a Vix bit or similar self-centering drill guide, drill a pilot hole into the edge of the ladder for

the (2) #10 x ¾” flat-head, Phillips-drive screws. Secure each Upper Hardware Assembly to the

top of the ladder (Figure 17-18)

Figure 16 Figure 17Figure 18

8

3. Using a ¼” drill bit, drill the holes for the ¼-20 KD bolts on the sides of the ladder (Figure 19-21)

Recommended procedure for this:

•Using the holes in the top roller guide as a drill guide, drill a ¼” hole half way through the

thickness of the ladder slide rail.

•Drill the same hole on the opposite side of the top roller guide, producing a ¼” through

hole in the ladder side rail.

•Follow this same procedure for all 4 through holes and complete the assembly by securing

the top roller guide with the supplied ¼-20 KD bolts and acorn nuts.

Bottom Hardware Assembly

1. Place the bottom roller housing onto the bottom of the ladder using the “U” bracket portion of the

housing. Verify that the bracket is flush with the bottom of the ladder.

(Because of the 12-degree angle of the bottom of the ladder this will align the housing diagonally

across the ladder side rail).

Figure 19Figure 20 Figure 21

2. Mark the location of the “U” bracket

on the bottom of the ladder, approximately

1-1/2” from the front edge of the

ladder (Figure 22). At the same time

mark on the side of the ladder the

location of the top mounting hole of

the bottom roller housing. Measure

these marks and transfer these

measurements to the other ladder side

rail so that the hardware will mount

identically on both ladder side rails.

3. Using a ¼” drill bit, drill a through

hole in the ladder side rail for the ¼-20

KD bolt (Figure 23)

4. Predrill the ladder side rail for the #10

x ¾” screw using a 1/8” drill bit. (This is

critical step to help avoid splitting the

wood, which can lead to failure of the

ladder when weight is applied)

5. Install both the bottom roller guides

using the included screws and KB bolts

and acorn nuts.

Figure 22Figure 23

9

Bottom Wheel Locking Adjustment

(Breaking Wheels only) (Figure 24-25)

The amount of weight needed to engage the

breaking mechanism on the breaking

bottom wheel assemblies is adjustable, the

unit is preset for approximately 70 lbs.

1. Steps for adjustment (Use a 7/32” Allen

wrench for adjustments)

2. Locate the Allen drive screw in the

bottom of the wheel housing (see blue

box below)

3. To decrease sensitivity (need more

weight to engage breaking mechanism),

turn screw clockwise.

4. To increase sensitivity (need less weight

to engage breaking mechanism), turn

screw counterclockwise.

(Be careful not to loosen too much to

prevent the spring from falling out)

Figure 24Figure 25

Hook your ladder onto the track.

Congratulations on

completing your Quite Glide

Ladder!

Please consider leaving a review on

Google Reviews or cshardware.com!

Any questions? Please call CSH

Customer Service at 262-375-7960

M-F 8:00am-4:30pm CST

or email [email protected]

10

1.

Dimensional Specifications

Top Ladder Hardware

CC 6-1/2”

4”

5-1/2”

5-1/2” 1-3/4”

2-1/8” dia

Top Roller 7/8”

4” CC

5-1/2”

4” 1-3/4”

Rolling Hook

6-1/2”

2-1/2” 2” dia

7/8”

6-1/2”

4” CC

5-1/2”

5-1/2” 1-3/4”

Top Swivel Roller 7/8”

4-13/16”

1-3/16”

4-13/64”

3-5/16” 27/32”

53/64”

DoDouble Hook *

*Designed For Loft Applications

6-1/2”

4” CC

5-1/2”

3-7/8” 1-3/4”

Adjustable Hookdj *7/8”

Bottom Ladder Hardware

8”

5-9/16”

Standard Wheel 1-3/8”

7/8”

8-1/4”

6-1/8”

Standard Brake Wheel 1-3/4”

7/8”

6-1/4”

5-9/16”

Contemporary

Wheel 1-3/8 ”

7/8”

6-1/8”

6-1/8”

Contemporary Brake Wheel

1-3/4”

7/8”

3”

Non - Skid Foot

1-1/4"

Protrusion

2-3/8”

Vertical Rail Brackets

For Roller and Swivel Top Guides

3/4”

1-

23/32” 23/32”

2-1/16”CC

15/16”

2-11/16”

1-7/8”

3/4”1-

For Hook and Rolling Hook Top Guides

7/8”

2”CC 2-5/8”

Protrusion

Horizontal Rail Brackets

For Roller and Swivel Top Guides

7/8”

2-3/8”

7/8”

15/16”

1-3/4”

For Hook and Rolling Hook Top Guides

1”

CC

5/8”

1-7/8”

1”

Center of Rail

Bottom of

Horizontal Bracket

11/16”

1-3/4”

11

47”

7”

45°angle

(approximately)

5” radius

Stock = 1-1/4” x 1-1/4”

with 3/16” radius corners

5/8” radius ends

2- Predrilled holes 3/8”

2-1/8”CC on each end

located 3/4” from end

2-1/8”CC

3/4”

Hand Rail dimensions

* +/- 1"

(10’ ladder)

Approximate Distance from wall (ladder in climbing position)

(8’ ladder)

Rail Height and Distance

for 8’, 9’, 10’ standard ladders

114"*

102"*

(9’ ladder)

92.5"*

8' l8' ladder = 25"adder = 25"

10' ladder = 29"

9' ladder = 27"

Bracket

Splice kit

14 -1/2”

1-3/8”

6”

Bracket

38”

30” Radius

90°

Straight section

of curved rail

3 -7/8”

30” Radius

28-3/4”

Bracket

Bracket

Splice kit

21”

135°

Straight section

of curved rail

Bracket

Splice kit

1-3/8”

17”

Bracket

35-1/2”

16” Radius

9”

90°

Straight section

of curved rail

Curved rail radius dimensions

Hook top Hardware cannot be used with curved rails!

Rail Diameter = 1”

Revised 6.20.23

This manual suits for next models

2

Other CSH Ladder manuals

Popular Ladder manuals by other brands

fakro

fakro LWS-P 22/47 Installation instruction

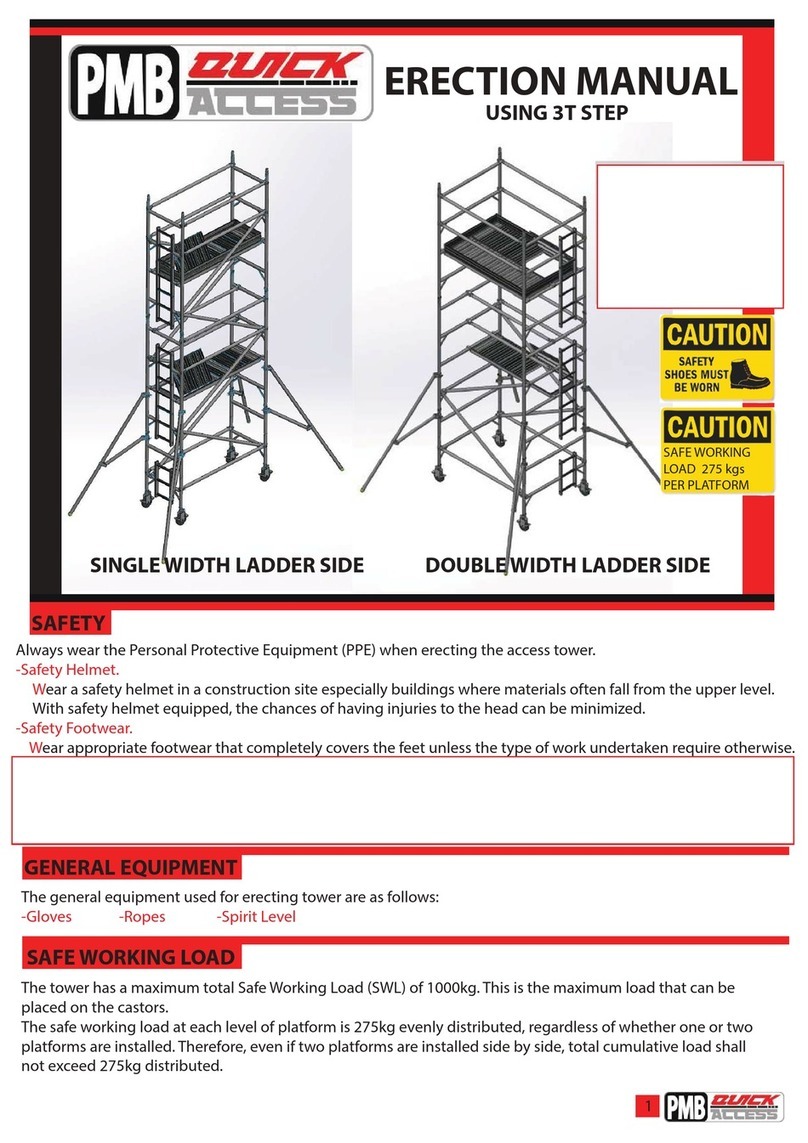

PMB

PMB Quick Access Erection Manual

Confer Plastics

Confer Plastics ROLLGUARD 7200 Assembly and installation manual

Werner

Werner WH2200 SERIES installation instructions

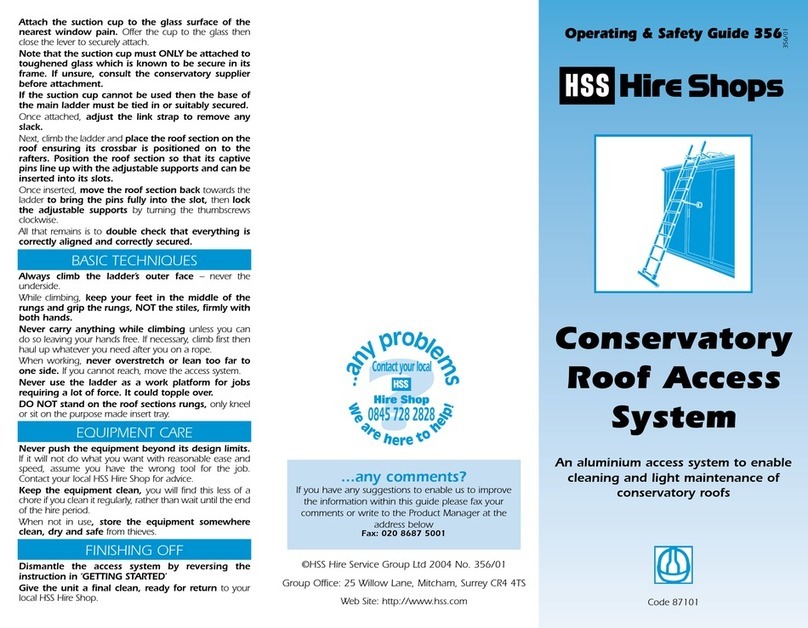

HSS Hire

HSS Hire Conservatory Roof Access System Operating & safety guide

X-Stand

X-Stand MAX XL Assembly and Safe Use Manual