Installation Procedure

- Water Supply Connection and Bypass Valve -

To allow for filter servicing, swimming pool filling or lawn sprinkling, a manual Bypass Valve has been installed at the

factory. The Bypass allows raw water to be manually routed around the filter.

1. Position filter at desired location for installation. If a water softener is to be installed, the filter should be positioned first

and then the softener.

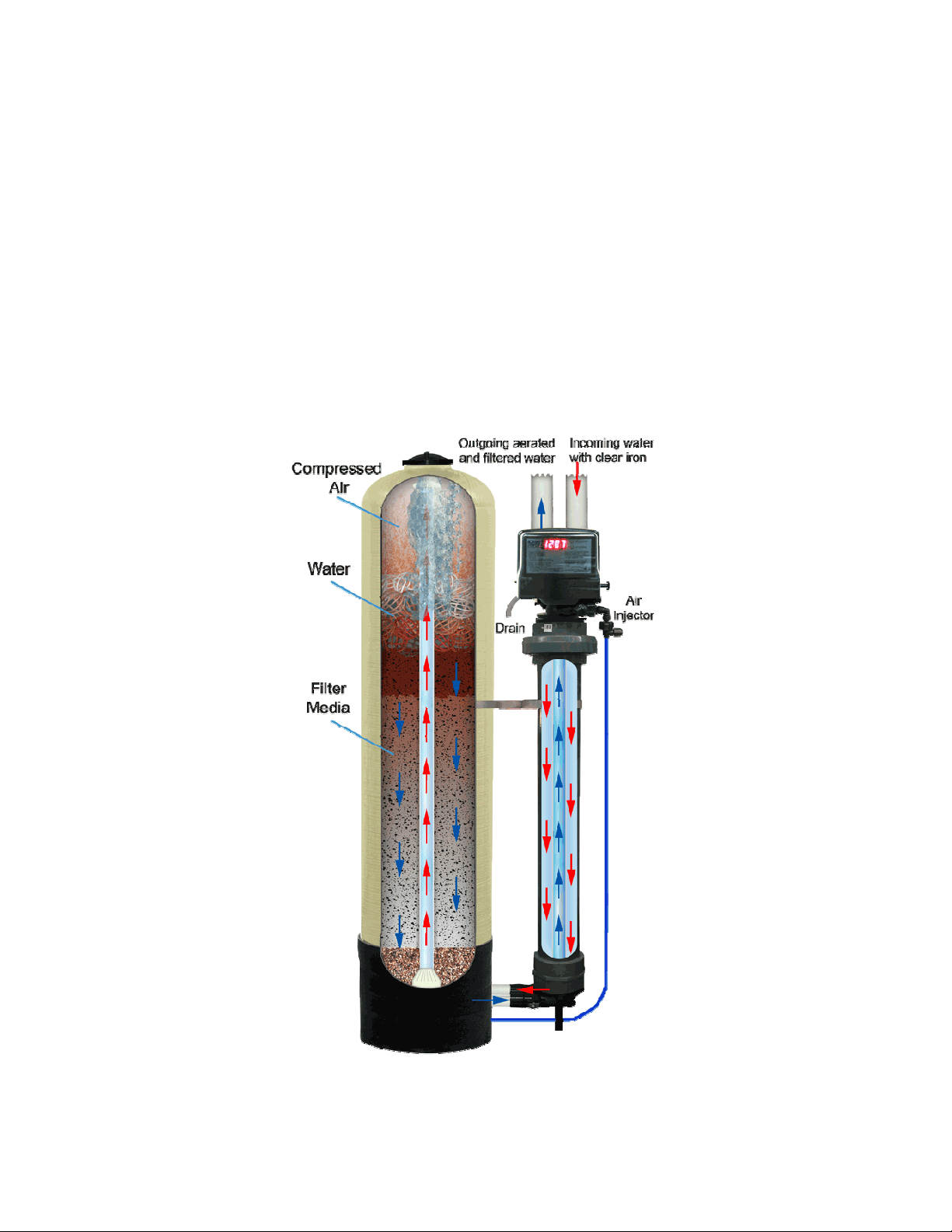

2. The filter material is shipped separately from the mineral tank with the exception of gravel. The 20# gravel is already

in the filter tank. The tank must be loaded with material after tank has been placed at the desired location.

A. Remove the tank cap from the media tank.

B. Use a cork or tape to place over top of distributor tube to prevent material from entering tube while filling.

C. Place media funnel provided in hole on top of tank.

D. Pour several gallons of water in the tank. (Fill tank about 1/3 full.)

E. Pour in the required filter media. The required quantity & type of media is listed in the filter specifications.

F. After installing filter media, add the included pack of aeration balls.

G. After filling the tank with material, use a garden hose or several buckets to fill the tank with water.

Note: This will permit the filtering media to become soaked while preparing the installation and will prevent the

control valve from being plugged with floating material on initial backwash.

H. Remove funnel and clean filter media from tank threads.

I. Remove cork or tape from distributor tube.

J. Replace tank cap on mineral tank.

3. Turn OFF main water supply and OPEN nearest faucet to relieve pressure.

4. Cut main line and install appropriate elbows and extensions.

Caution: Raised arrows located on the sides of control valve body and bypass valve indicate proper direction of water

flow. Install inlet and outlet piping in direction of arrows.

- Drain Line Connection -

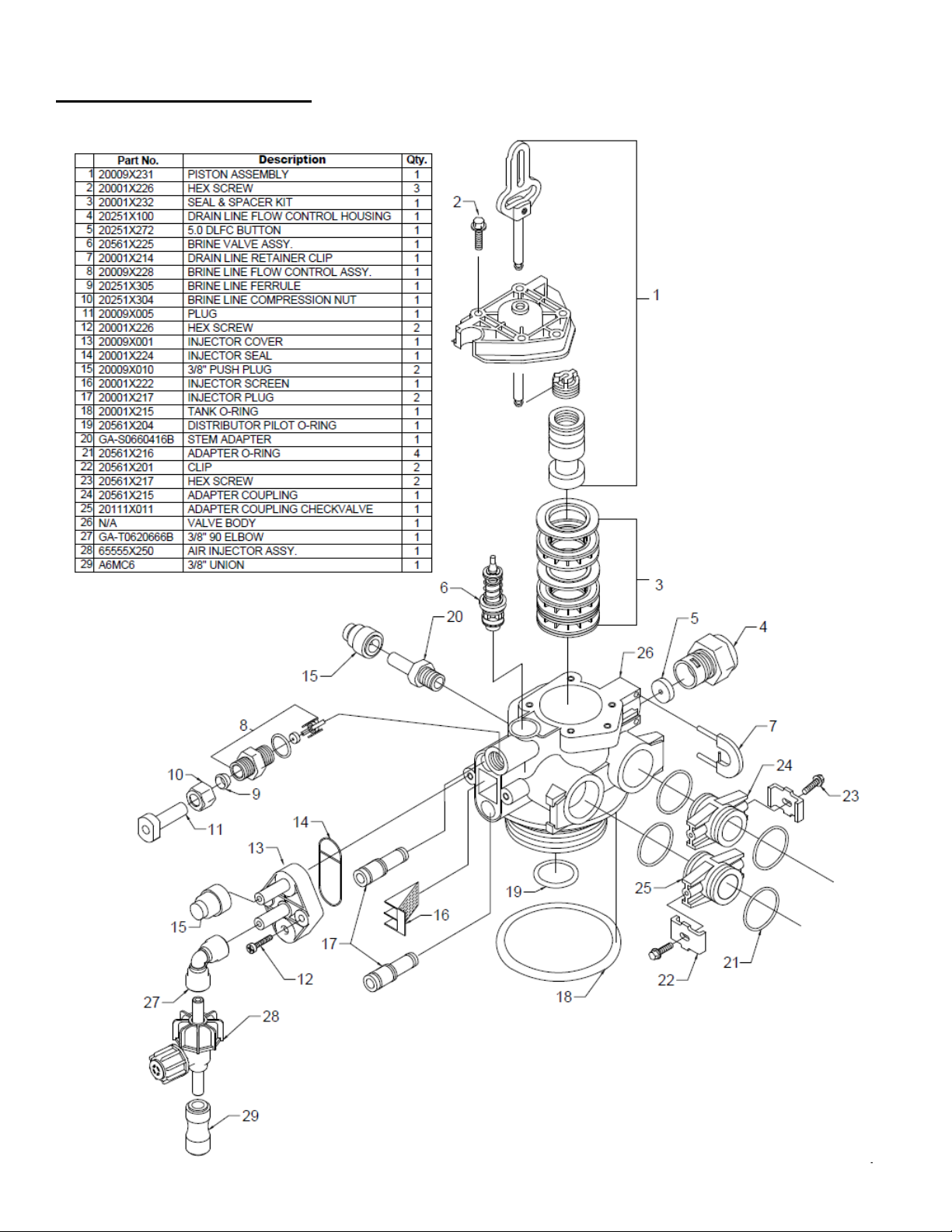

1. Pull out clip and remove drain line assembly located on the left side of control valve. Remove drain line hose elbow

and wrap threads with Teflon tape. Reinstall drain line hose elbow. Replace drain line assembly and reinstall clip.

Caution: Hand tighten only!

2. Install 1/2" I.D. drain line tubing (not included) from hose elbow to an open drain. A 4" gap between end of the drain

line and the open drain is required to prevent waste water backflow. Keep the drain line as short as possible. An

overhead drain line can be used if necessary, but should discharge below the control valve. A syphon trap (taped loop)

at the outlet of the drain line is advisable to keep the drain line full and assure correct flow during backwash. Elbows or

other fittings must be kept at a bare minimum.

Note: Where the drain line is elevated above the control valve or exceeds 20 feet in length, 3/4" I.D. drain line tubing

should be used.