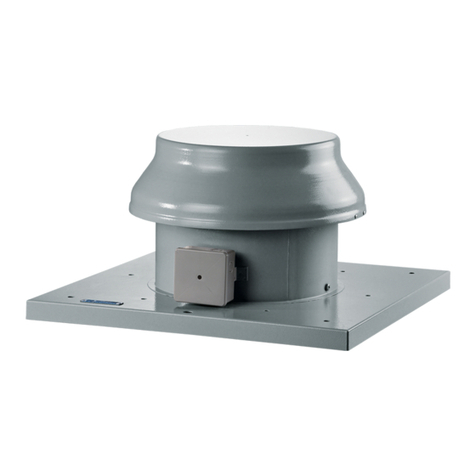

CSR Bradford EcoPower 400 User manual

Industrial Ventilators Installation

Instructions

EcoPower®and Hurricane®

Non-Cyclonic

PRINT IN COLOUR

V3.0 | 08/22

2

The contents of this install guide are copyright protected and may not be reproduced in any form without prior written consent of CSR. Recommendations and

advice regarding the use of the products described in this guide are to be taken as a guide only, and are given without liability on the part of the company or

its employees. We reserve the right to change product specifications without prior notification, please refer to the CSR website for the latest version of this

document. The purchaser should independently determine the suitability of the product for the intended use and application.

SYSTEM PRE-REQUISITES – Check Before Commencing

Before attempting to start the installation, please ensure that the following allowable roof pitch and

make-up air requirements can be met.

Product Make-up air* per ventilator - 100%

open, evenly distributed open area

Allowable Roof Pitch

EcoPower 400

Hurricane 100 - 400

≥0.3m² up to 45°

EcoPower 600

Hurricane 450 - 600

≥ 0.5m² up to 45°

EcoPower 900

Hurricane 700 - 900

≥ 0.9m² up to 22.5°

* Performance values are based on a 5Pa pressure loss across the make-up air opening.

Additional make-up air can be provided as per the recommendations in AS1668.2.

DO NOT PROCEED TO INSTALL THIS PRODUCT IF THE ABOVE REQUIREMENTS ARE NOT

MET

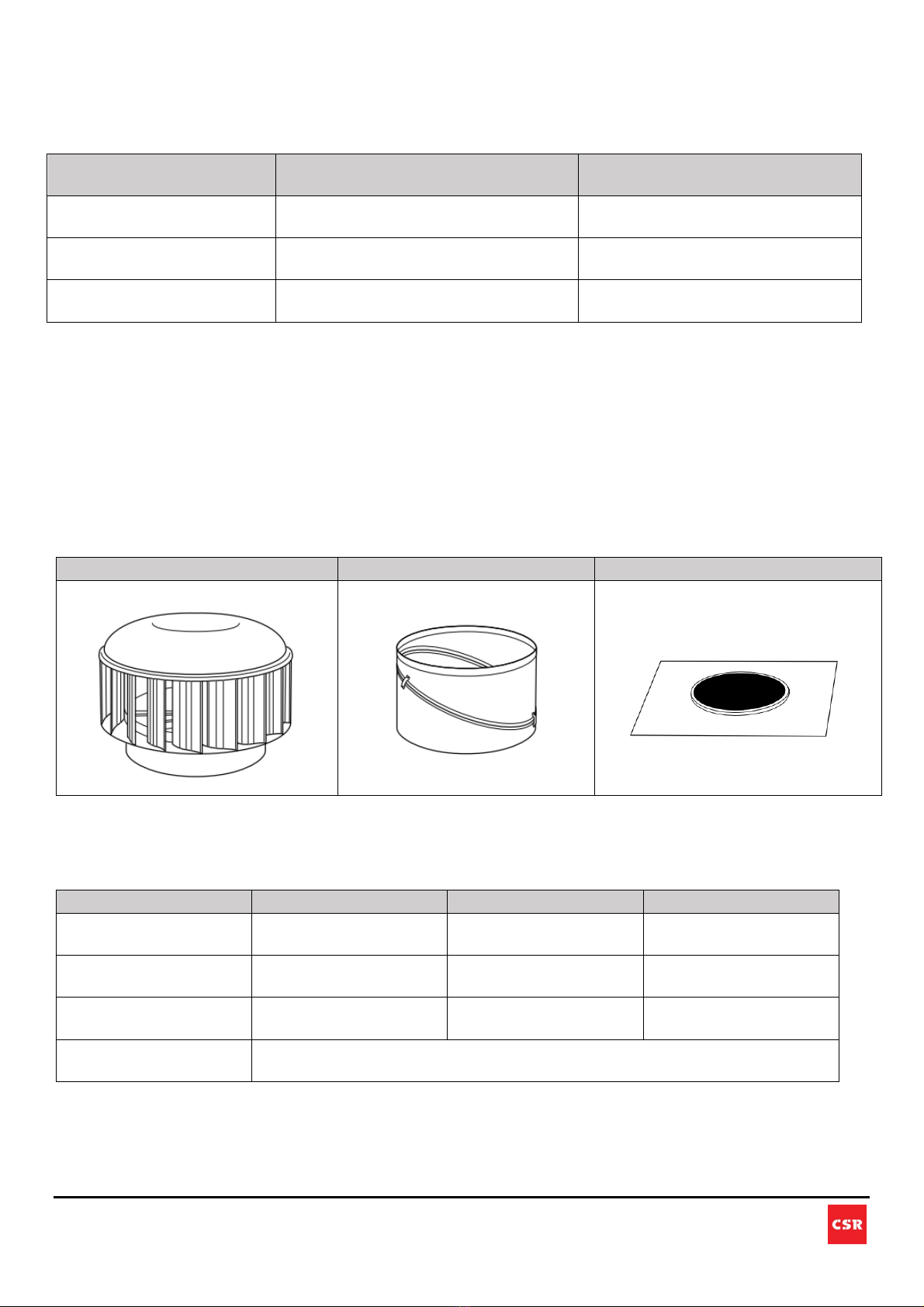

1. PACKING LIST (for a standard complete product) – Check Before Commencing

Included Parts

Additional Materials Required - Not Supplied

a. FASTENERS (Quantity and Type)

Product

Head to Varipitch

Varipitch to Flashing

Flashing to Roof

EcoPower 400

Hurricane 100 - 400

6 6 12

EcoPower 600

Hurricane 450 - 600

9 9 16

EcoPower 900

Hurricane 700 - 900

12 12 26

Fasteners

Use 10G X 16MM Galvanised Self Drilling TEK Screws with Neoprene

Washer or 5/32" (4.0mm) Rivets Aluminium/Steel Sealed

Ventilator Head

Varipitch

Flashing

3

The contents of this install guide are copyright protected and may not be reproduced in any form without prior written consent of CSR. Recommendations and

advice regarding the use of the products described in this guide are to be taken as a guide only, and are given without liability on the part of the company or

its employees. We reserve the right to change product specifications without prior notification, please refer to the CSR website for the latest version of this

document. The purchaser should independently determine the suitability of the product for the intended use and application.

b. SUPPLEMENTARY FLASHING required for installation away from the ridge – refer to section 4

for details.

c. PESTGUARD (if required) to provide protection against the entry of vermin.

IMPORTANT: Note regarding lifting this product

Lift the product in its original packaging using a crane or similar equipment to the roof mounting location,

prior to handling the product.

Caution During Lifting:

The ventilator top surface/dome can be easily scratched or deformed when placed upside down so always

place it on a soft/smooth surface such as cardboard or a soft-foam mat.

4

The contents of this install guide are copyright protected and may not be reproduced in any form without prior written consent of CSR. Recommendations and

advice regarding the use of the products described in this guide are to be taken as a guide only, and are given without liability on the part of the company or

its employees. We reserve the right to change product specifications without prior notification, please refer to the CSR website for the latest version of this

document. The purchaser should independently determine the suitability of the product for the intended use and application.

SAFETY AND WARNINGS

a. The installation of this product involves working at heights on a sloping surface and may be dangerous,

including the potential of death, personal injury, or property damage.

b. Follow the state or territory regulator OH&S guidelines for working at heights, electrical, working in

elevated temperatures (e.g. roof space in summer). For more information on your State OH&S

guidelines for working at heights, please refer to: https://www.safeworkaustralia.gov.au/heights

c. All ventilation products must be installed by a qualified installer and all electrical wiring (where

applicable) must be undertaken by a qualified electrician.

d. EcoPower Hybrid Ventilators use 220V-240V AC power for the electrically powered components and

electrical connections must only be undertaken by a qualified electrician.

e. EcoPower Hybrid Ventilators are supplied with either a Smart Controller or Interface Box - these devices

must not be tampered with and the hybrid ventilator must not be operated without either of these

devices.

f. Do not attempt to power up EcoPower Hybrid Ventilators when the product is not suitably roof mounted

as the turbine will rotate without warning and may create a hazard.

g. Due to the size and weight of the turbine, it is recommended that it is always lifted by 2 people or a

crane. Refer to the lifting instructions.

h. Damaged parts must be replaced with a genuine replacement part from CSR Bradford Ventilation.

i. The turbine head of this product can rotate without warning (even during installation) – always keep

body parts away from moving components.

j. Please read this manual carefully before installing this product and keep it for future reference or

provide it to the building owner/maintenance manager.

LIMITATIONS

Not suitable for use in cyclonic regions.

5

The contents of this install guide are copyright protected and may not be reproduced in any form without prior written consent of CSR. Recommendations and

advice regarding the use of the products described in this guide are to be taken as a guide only, and are given without liability on the part of the company or

its employees. We reserve the right to change product specifications without prior notification, please refer to the CSR website for the latest version of this

document. The purchaser should independently determine the suitability of the product for the intended use and application.

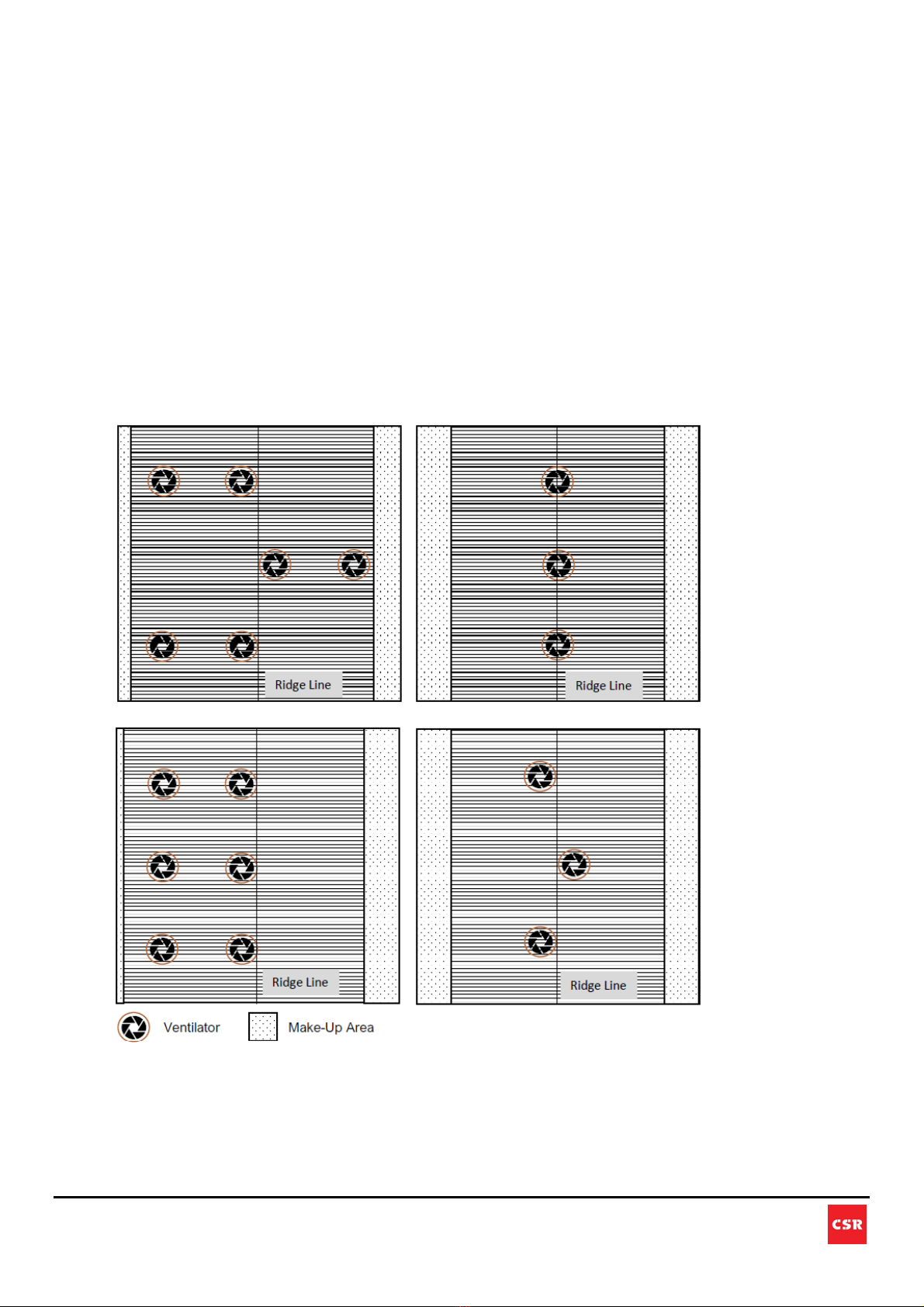

2. VENTILATOR POSITIONING & PROVISION FOR MAKE-UP AIR

CSR Bradford Ventilation recommends that ventilators are positioned 4m to 6m away from each other in all

directions for effective and efficient performance. It is also recommended that ventilators of the same size

are used together to prevent replacement air from being drawn between ventilators of different sizes.

Ensure that the ventilators are not sheltered from the wind by surrounding objects, the shadow angle

created by the roof ridge or by each other.

Make-up air is required for this ventilator to replenish the exhausted air. As a general guide, the largest

make-up air entry should be positioned on the opposite side of the building to the largest ventilator demand.

The make-up air location should be positioned at optimum height to provide efficient sweeping of the floor

area.

The illustrations below provide a number of generic ventilator and make-up air layouts but it should be

noted that a whole-of-building assessment, as per AS1668.2, should be conducted by a suitably qualified

person prior to deciding upon site-specific ventilator and make-up air placement.

IMPORTANT: If external make-up air is insufficient, the ventilators will draw make-up air from each other –

this will both diminish the effectiveness of the system and increase the risk of the system drawing external

water into the building during periods of rain. It is also recommended that ventilators of the same size are

used together to prevent replacement air from being drawn between ventilators of different sizes.

6

The contents of this install guide are copyright protected and may not be reproduced in any form without prior written consent of CSR. Recommendations and

advice regarding the use of the products described in this guide are to be taken as a guide only, and are given without liability on the part of the company or

its employees. We reserve the right to change product specifications without prior notification, please refer to the CSR website for the latest version of this

document. The purchaser should independently determine the suitability of the product for the intended use and application.

3. INSTALLATION UNDER THE RIDGE

Note: See Section 4 for installation away from the ridge.

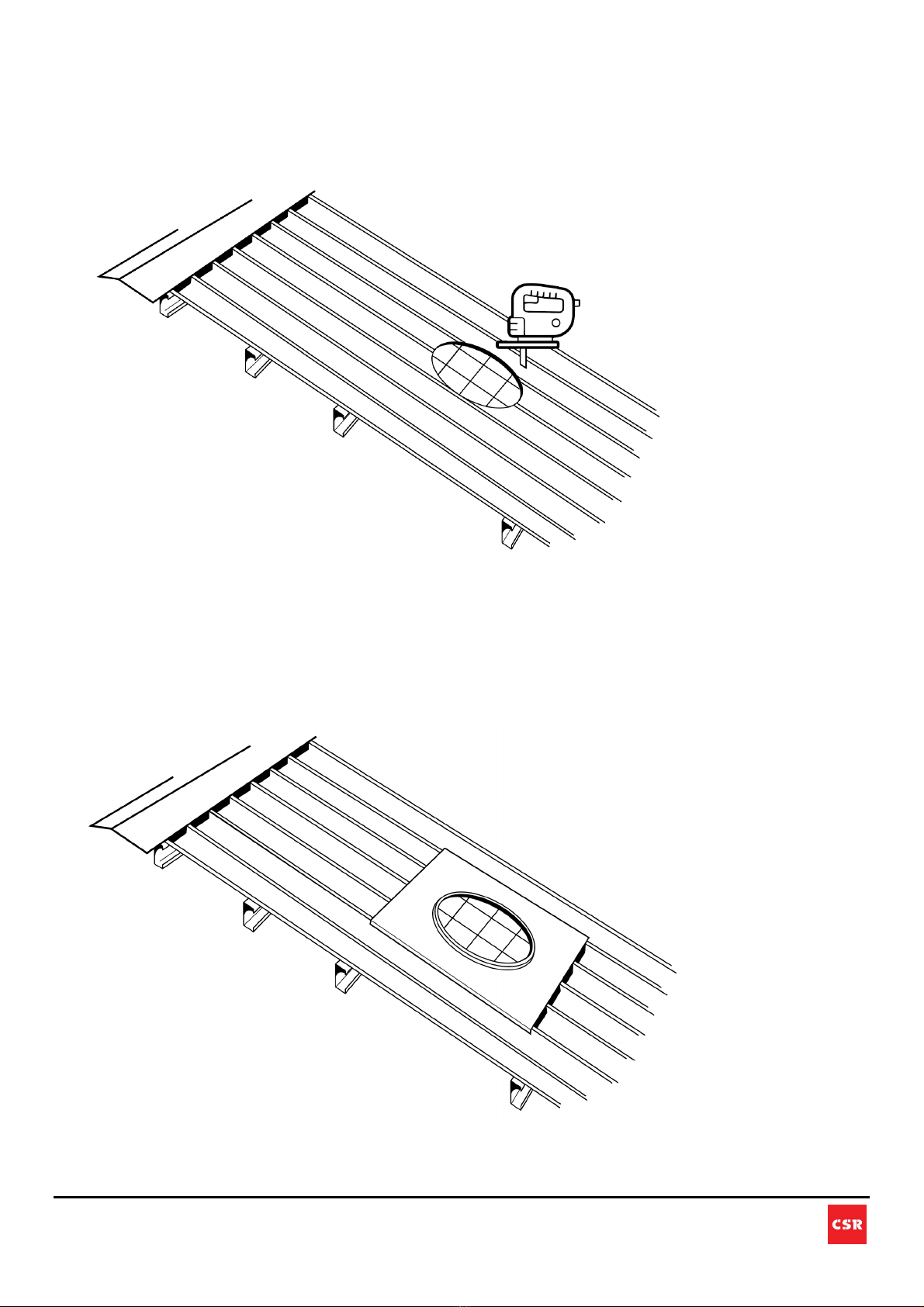

a. Set Position: Place the base flashing under the ridge cap at the required position and adjust the

position to avoid structural roof members below the roof sheet. Ensure the flashing covers the

corrugation or ribs equally on each side of the flashing, then mark a circle on the roof using the hole in

the flashing as a template.

7

The contents of this install guide are copyright protected and may not be reproduced in any form without prior written consent of CSR. Recommendations and

advice regarding the use of the products described in this guide are to be taken as a guide only, and are given without liability on the part of the company or

its employees. We reserve the right to change product specifications without prior notification, please refer to the CSR website for the latest version of this

document. The purchaser should independently determine the suitability of the product for the intended use and application.

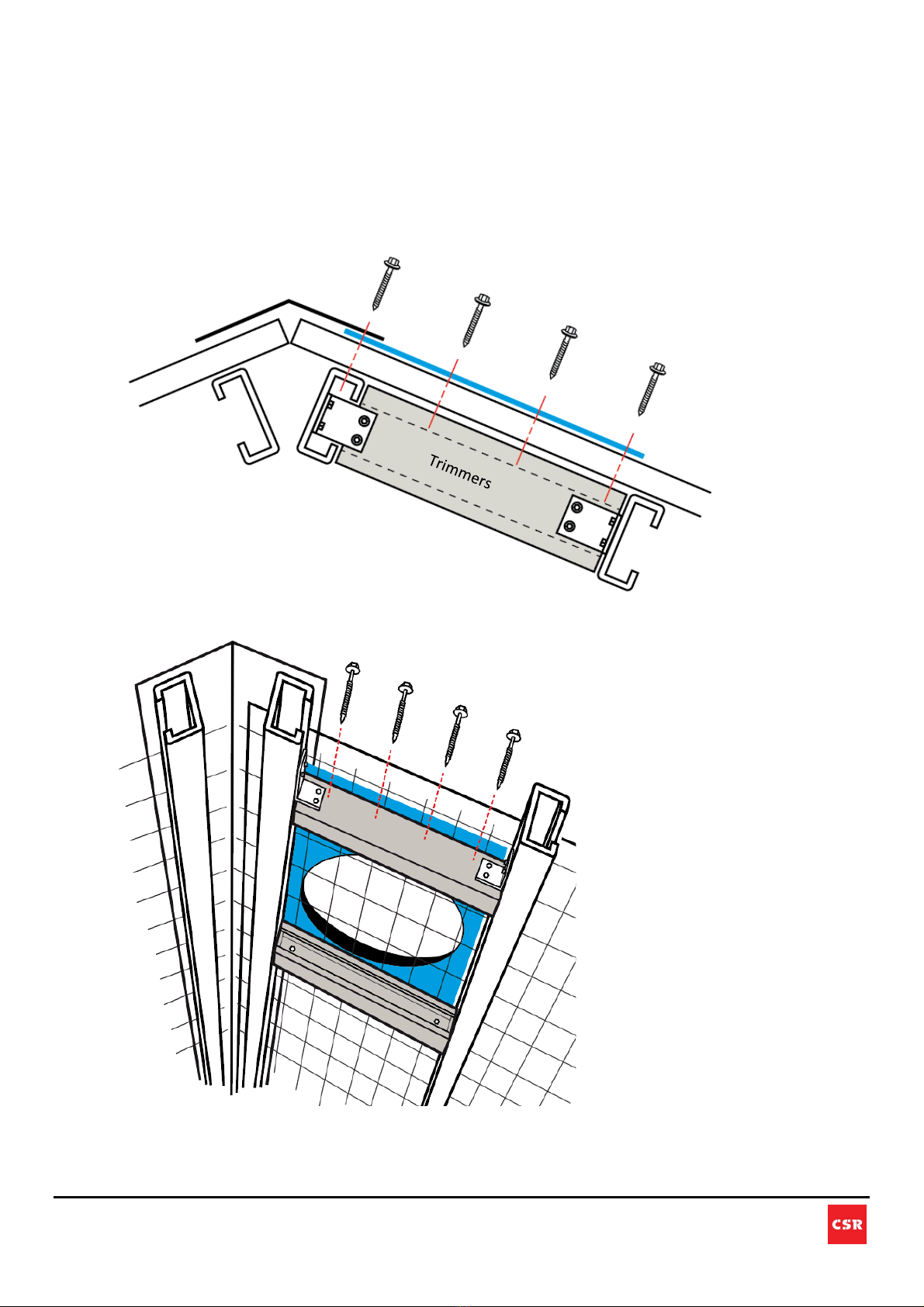

Important Note Regarding Roof Structural Support:

EP400 - EP600 & H100 – H600 – If the purlin spacing is larger than 600mm, trimmers are

required. Install the trimmers between the purlin on either side of the opening. Do not cover the

openings.

EP900 & H700 – H900 – If the purlin spacing is larger than 1000mm, trimmers are required.

Install the trimmers between the purlin on either side of the opening. Do not cover the opening.

Purlin

Flashing

8

The contents of this install guide are copyright protected and may not be reproduced in any form without prior written consent of CSR. Recommendations and

advice regarding the use of the products described in this guide are to be taken as a guide only, and are given without liability on the part of the company or

its employees. We reserve the right to change product specifications without prior notification, please refer to the CSR website for the latest version of this

document. The purchaser should independently determine the suitability of the product for the intended use and application.

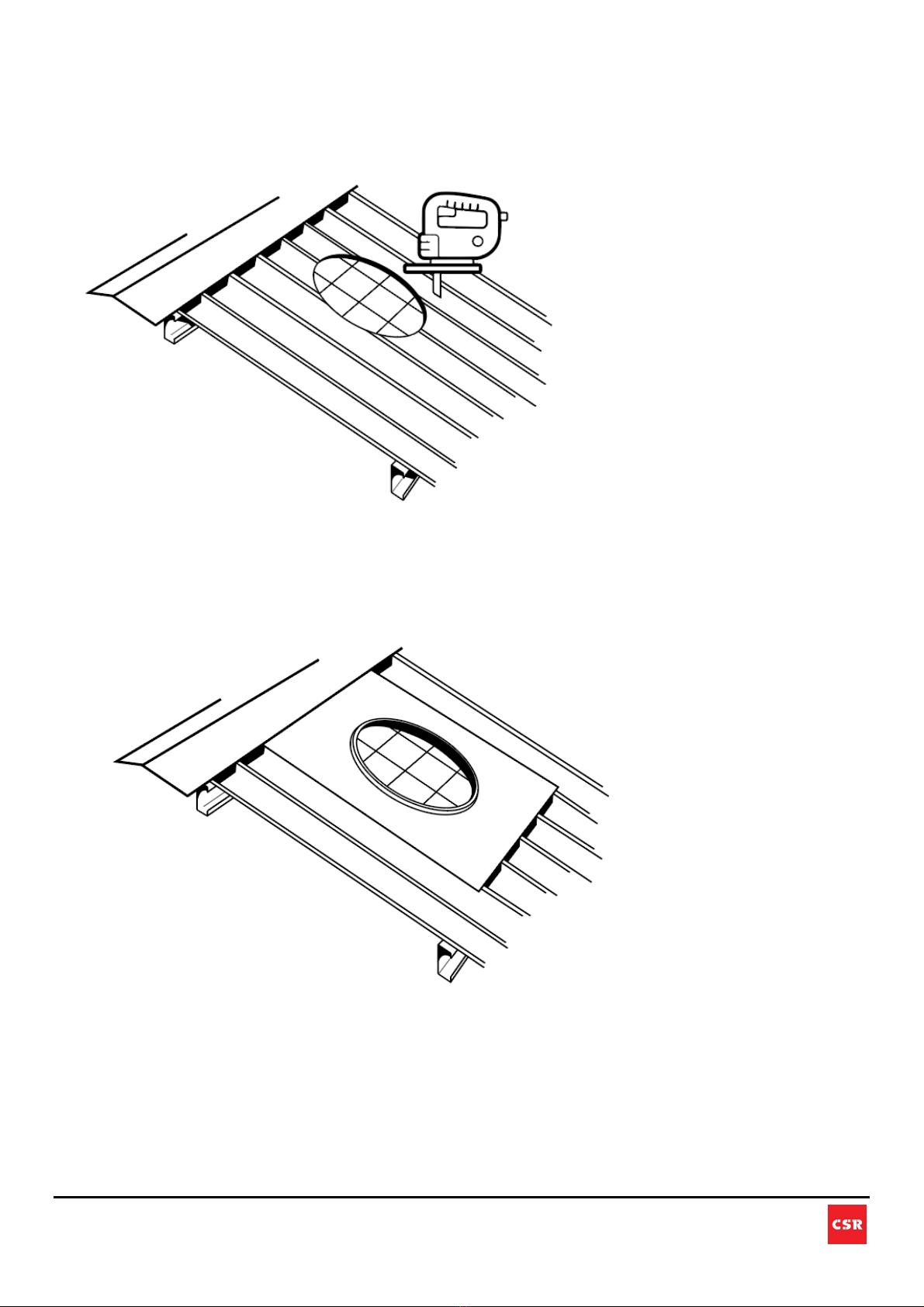

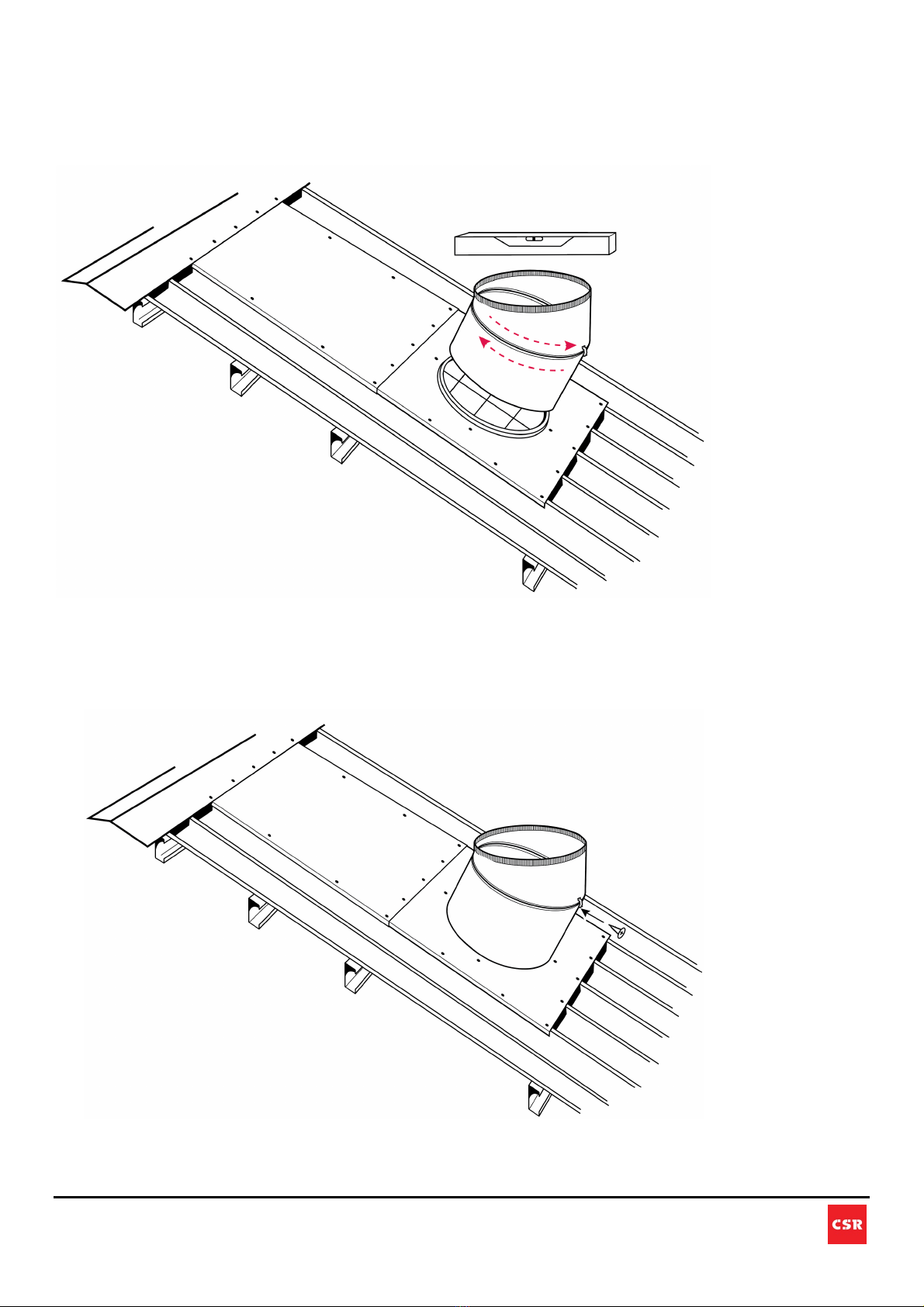

b. Cut Hole: Carefully cut the hole, remembering that there may be insulation and other roof

members under the roof sheet. Once the hole has been cut, fold up the edge of the

corrugations or pans. Ensure the roofing safety mesh/net integrity is maintained after the

installation.

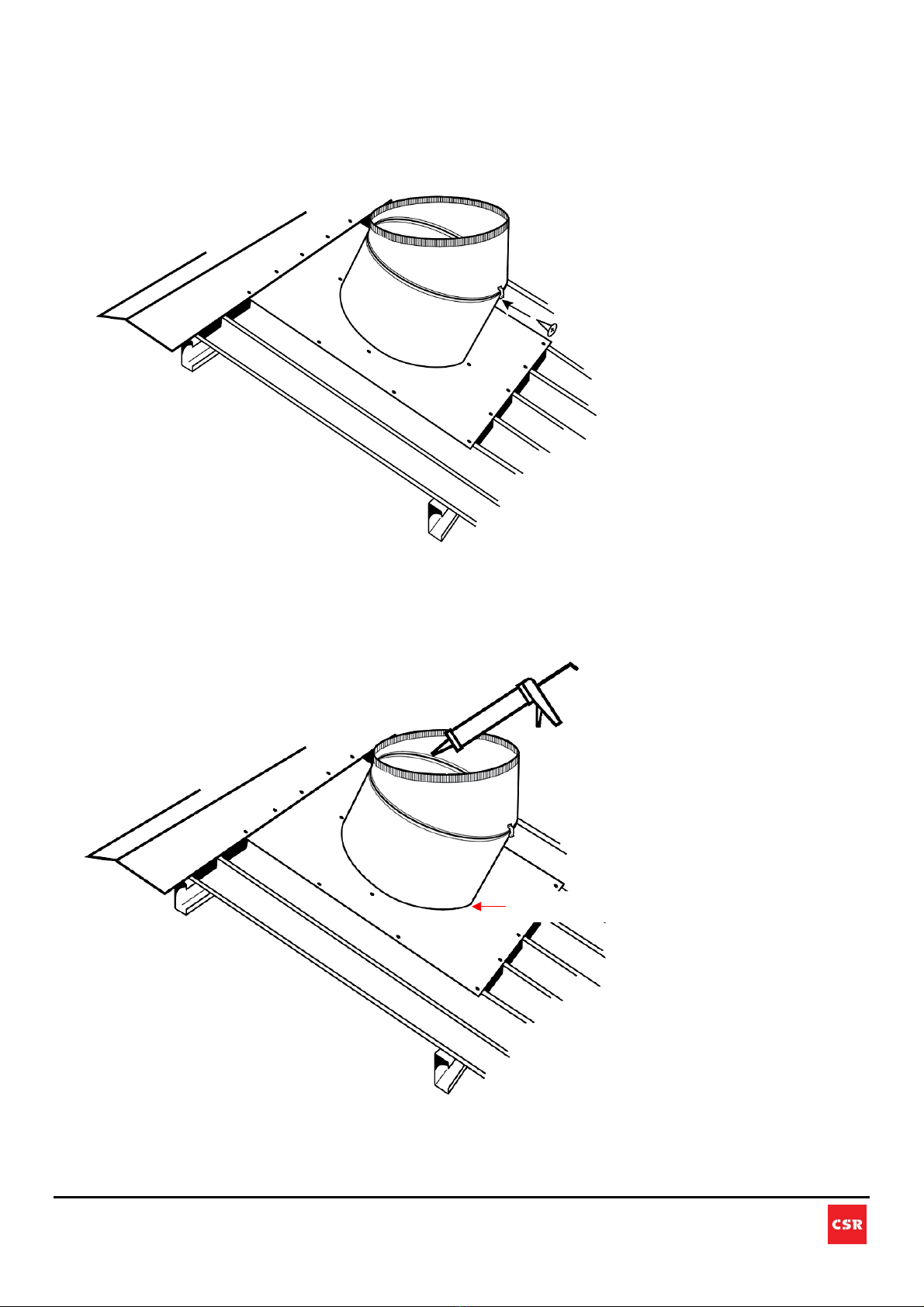

c. Secure Flashing: Attach the flashing under the ridge cap and apply sealant prior to final fixing

(refer to the table below for the required number of fasteners). If trimmers are used ensure the

flashing is secured to the trimmers. Seal all fasteners with a suitable sealant to ensure they are

weatherproof.

9

The contents of this install guide are copyright protected and may not be reproduced in any form without prior written consent of CSR. Recommendations and

advice regarding the use of the products described in this guide are to be taken as a guide only, and are given without liability on the part of the company or

its employees. We reserve the right to change product specifications without prior notification, please refer to the CSR website for the latest version of this

document. The purchaser should independently determine the suitability of the product for the intended use and application.

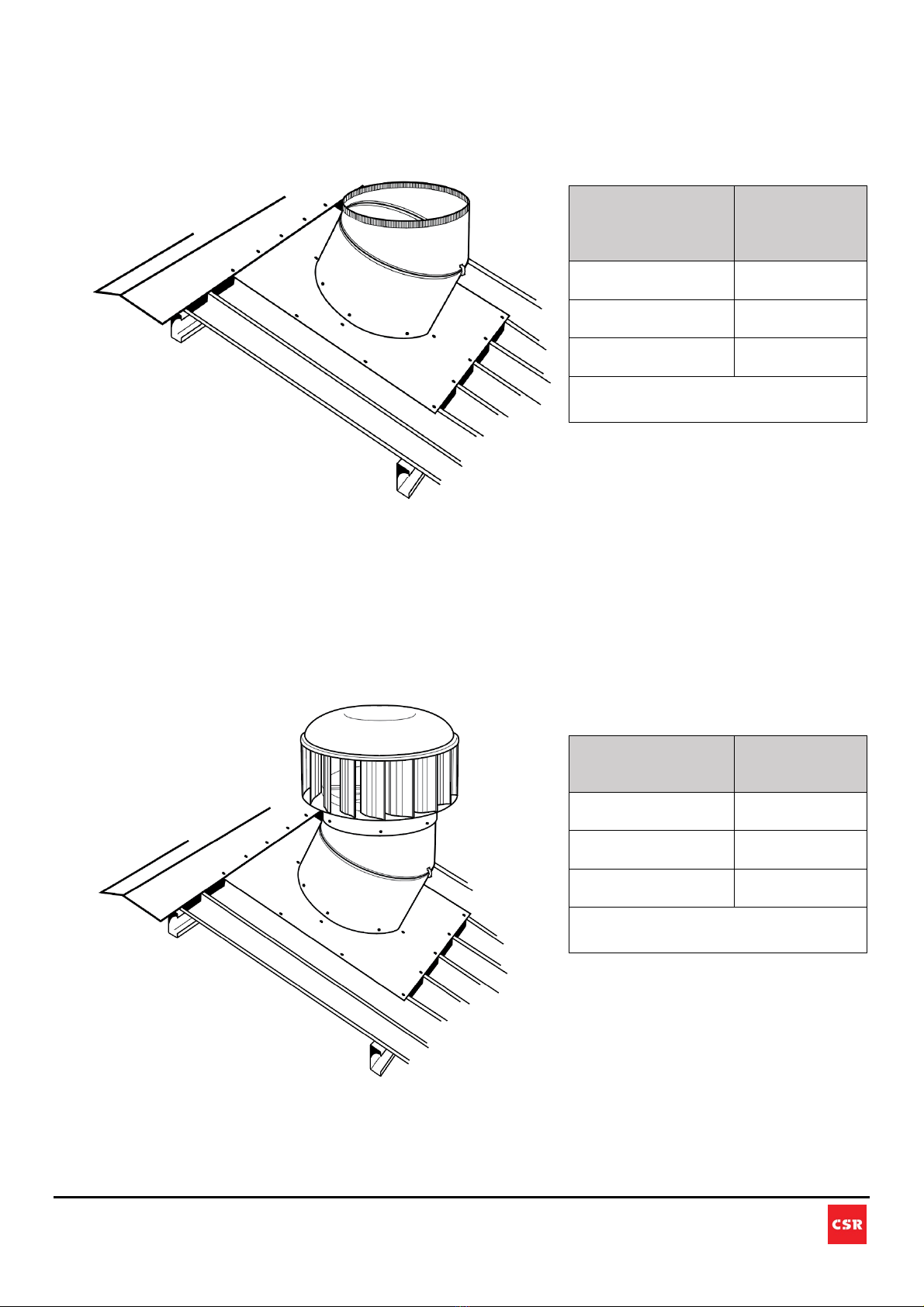

d. Assemble the Varipitch: When a Varipitch throat is being used, position the Varipitch on the

flashing and rotate the top and bottom halves until the top of the Varipitch is level (horizontal) -

it is recommended that an electronic or spirit level is used to ensure that the top edge of the

throat is horizontal in all directions.

Model

Fasteners to

secure flashing

to roof

EcoPower 400

Hurricane 100 -

400

12 (4 near throat)

EcoPower 600

Hurricane 450 -

600

18 (4 near throat)

EcoPower 900

Hurricane 700 -

900

26 (4 near throat)

Use 10G X 16MM Galvanised Self Drilling TEK

Screws with Neoprene Washer or 5/32"

(4.0mm) Rivets Aluminium/Steel Sealed

10

The contents of this install guide are copyright protected and may not be reproduced in any form without prior written consent of CSR. Recommendations and

advice regarding the use of the products described in this guide are to be taken as a guide only, and are given without liability on the part of the company or

its employees. We reserve the right to change product specifications without prior notification, please refer to the CSR website for the latest version of this

document. The purchaser should independently determine the suitability of the product for the intended use and application.

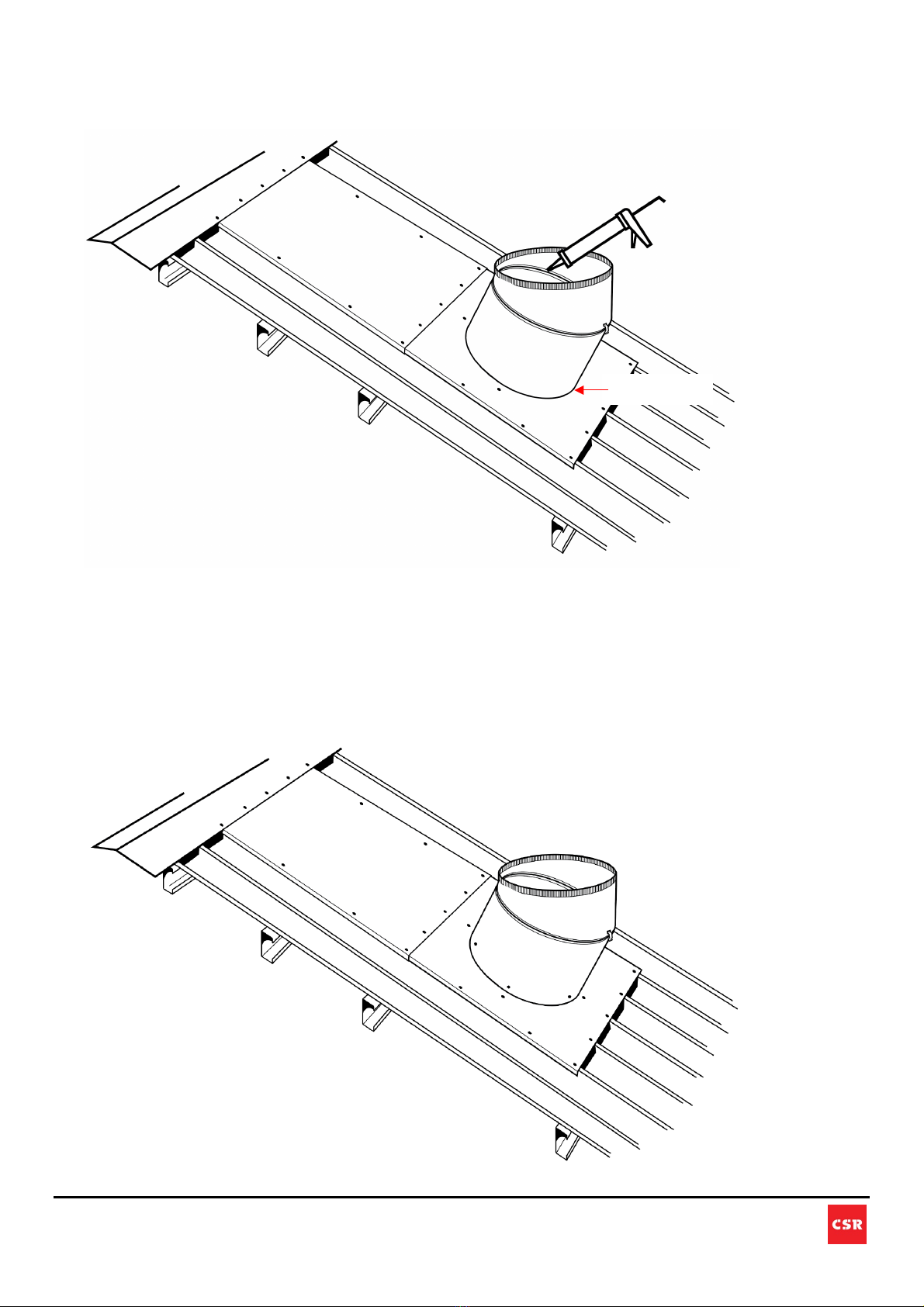

e. Secure the Varipitch Angle: With the Varipitch upper throat positioned horizontally, lock it into

position using the supplied Varipitch clip. Use either self-tapping screws or blind rivets to

secure all the clips between the two halves of the Varipitch.

f. Weather Sealing: Seal the Varipitch seam on the inside with a bead of weather-resistant

suitable sealant.

NOTE: DO NOT apply sealant to the joint between the flashing and Varipitch. This is a natural

gutter to release any trapped condensation. See details in section (i) below.

Do Not Seal

11

The contents of this install guide are copyright protected and may not be reproduced in any form without prior written consent of CSR. Recommendations and

advice regarding the use of the products described in this guide are to be taken as a guide only, and are given without liability on the part of the company or

its employees. We reserve the right to change product specifications without prior notification, please refer to the CSR website for the latest version of this

document. The purchaser should independently determine the suitability of the product for the intended use and application.

g. Secure Varipitch to Flashing: Reposition the Varipitch on the Flashing and check it is

horizontal - secure the Varipitch to the flashing using the recommended number of screws

shown in the table below – DO NOT SEAL this connection.

h. Assemble Turbine: Assemble the turbine head to the Varipitch. Re-check if the assembly is

level (horizontal) and adjust the turbine by tilting the throat slightly if required. Ensure the

knurling (the tapered section of the Varipitch) is fully inside the ventilator throat and secure the

ventilator throat by fastening it to the top of the Varipitch with the number of fasteners shown in

the table below.

NOTE: DO NOT apply sealant to the joint between the turbine and Varipitch. This is a natural

gutter to release any trapped condensation. See details in section (i) below.

Model

Fasteners to

secure

varipitch to

flashing

EcoPower 400

Hurricane 100 - 400

6

EcoPower 600

Hurricane 450 - 600

9

EcoPower 900

Hurricane 700 - 900

12

Use 10G X 16MM Galvanised Self Drilling TEK

Screws with Neoprene Washer or 5/32" (4.0mm)

Rivets Aluminium/Steel Sealed

Model

Fasteners to

secure turbine

to varipitch

EcoPower 400

Hurricane 100 - 400

6

EcoPower 600

Hurricane 450 - 600

9

EcoPower 900

Hurricane 700 - 900

12

Use 10G X 16MM Galvanised Self Drilling TEK

Screws with Neoprene Washer or 5/32" (4.0mm)

Rivets Aluminium/Steel Sealed

12

The contents of this install guide are copyright protected and may not be reproduced in any form without prior written consent of CSR. Recommendations and

advice regarding the use of the products described in this guide are to be taken as a guide only, and are given without liability on the part of the company or

its employees. We reserve the right to change product specifications without prior notification, please refer to the CSR website for the latest version of this

document. The purchaser should independently determine the suitability of the product for the intended use and application.

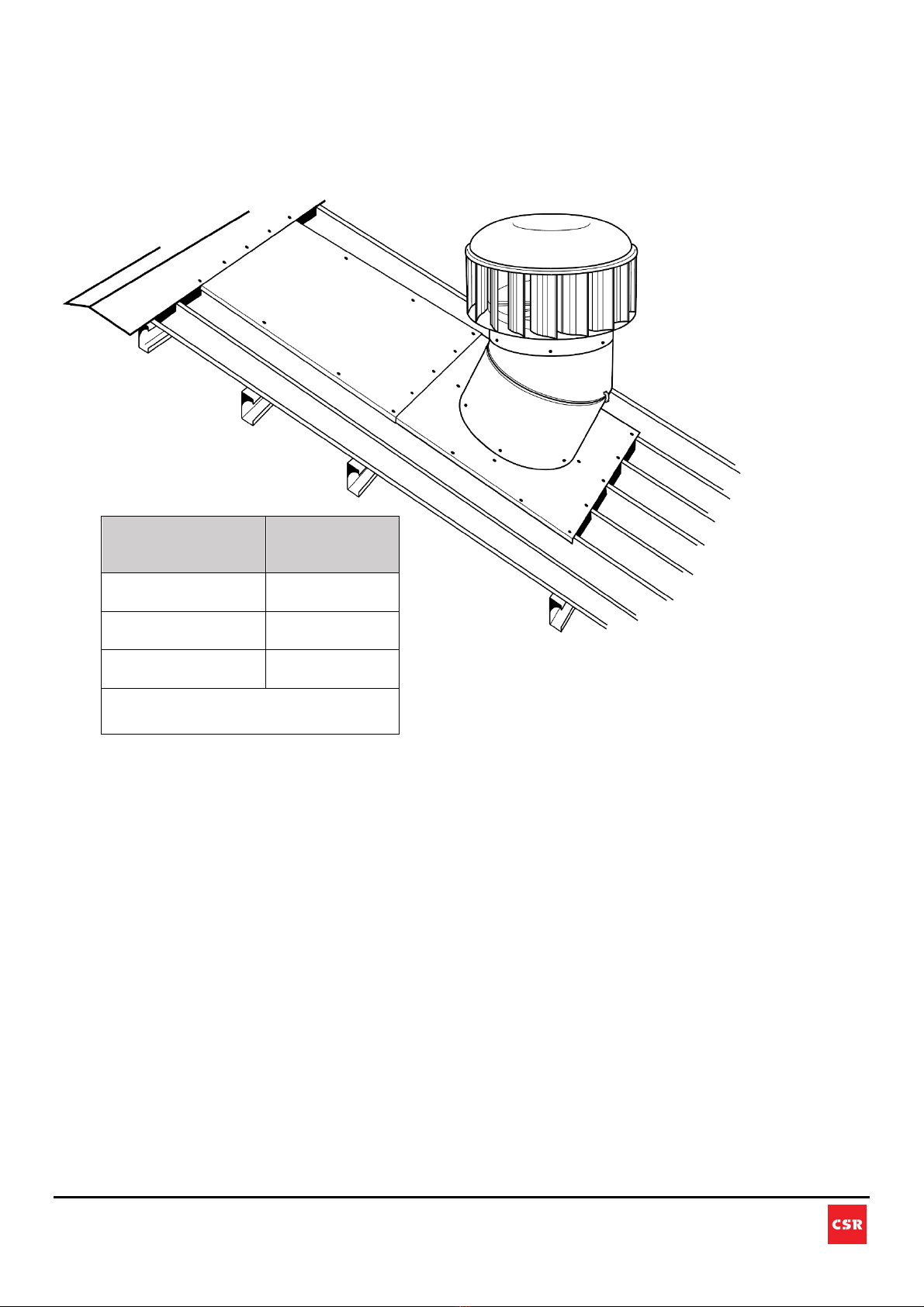

i. Sealing is crucial for this product to ensure no leaking occurs during its lifespan, but there is

also a requirement for drainage. To ensure that only the required areas are sealed and the

drainage path is left open, follow this guide carefully:

Location Area Sealing Requirement

All fasteners Seal

Flashing perimeter to roof Seal

Varipitch seam (inside throat) Seal

Turbine to varipitch Do Not Seal

Varipitch to flashing Do Not Seal

Flashing bottom edge to roof Do Not Seal

Do Not Seal

Do Not

Seal

Do Not Seal

13

The contents of this install guide are copyright protected and may not be reproduced in any form without prior written consent of CSR. Recommendations and

advice regarding the use of the products described in this guide are to be taken as a guide only, and are given without liability on the part of the company or

its employees. We reserve the right to change product specifications without prior notification, please refer to the CSR website for the latest version of this

document. The purchaser should independently determine the suitability of the product for the intended use and application.

4. INSTALLATION AWAY FROM RIDGE

a. Set Position: Place the base flashing at the required position and adjust the position to avoid structural

roof members below the roof sheet. Ensure the flashing covers the corrugation or ribs equally on each

side of the flashing, then mark a circle on the roof using the hole in the flashing as a template.

14

The contents of this install guide are copyright protected and may not be reproduced in any form without prior written consent of CSR. Recommendations and

advice regarding the use of the products described in this guide are to be taken as a guide only, and are given without liability on the part of the company or

its employees. We reserve the right to change product specifications without prior notification, please refer to the CSR website for the latest version of this

document. The purchaser should independently determine the suitability of the product for the intended use and application.

Important Note Regarding Roof Structural Support:

EP400 - EP600 & H100 – H600 – If the purlin spacing is larger than 600mm, trimmers are

required. Install the trimmers between the purlin on either side of the opening. Do not cover the

openings.

EP900 & H700 – H900 – If the purlin spacing is larger than 1000mm, trimmers are required.

Install the trimmers between the purlin on either side of the opening. Do not cover the opening.

Purlin

Flashing

15

The contents of this install guide are copyright protected and may not be reproduced in any form without prior written consent of CSR. Recommendations and

advice regarding the use of the products described in this guide are to be taken as a guide only, and are given without liability on the part of the company or

its employees. We reserve the right to change product specifications without prior notification, please refer to the CSR website for the latest version of this

document. The purchaser should independently determine the suitability of the product for the intended use and application.

b. Cut Hole: Carefully cut the hole, remembering that there may be insulation and other roof

members under the roof sheet. Once the hole has been cut, fold up the edge of the

corrugations or pans. Ensure the roofing safety mesh/net integrity is maintained after the

installation.

c. Secure Flashing: Attach the flashing over the roof hole and back flashing tray to extend the

ridge to the ventilator’s flashing. Apply sealant prior to final fixing (refer to the table below for

the required number of fasteners). If trimmers are used ensure the flashing is secured to the

trimmers. Seal all fasteners with a suitable sealant to ensure they are weatherproof.

16

The contents of this install guide are copyright protected and may not be reproduced in any form without prior written consent of CSR. Recommendations and

advice regarding the use of the products described in this guide are to be taken as a guide only, and are given without liability on the part of the company or

its employees. We reserve the right to change product specifications without prior notification, please refer to the CSR website for the latest version of this

document. The purchaser should independently determine the suitability of the product for the intended use and application.

Model

Fasteners to

secure turbine

flashing to roof

EcoPower 400

Hurricane 100

- 400

12 (4 near throat)

EcoPower 600

Hurricane 450

- 600

18 (4 near throat)

EcoPower 900

Hurricane 700

- 900

26 (4 near throat)

Use 10G X 16MM Galvanised Self Drilling

TEK Screws with Neoprene Washer or

5/32" (4.0mm) Rivets Aluminium/Steel

Sealed

Extended Flashing

(not supplied)

Overlap requirement between extended

flashing and turbine flashing is 100mm to

250mm.

17

The contents of this install guide are copyright protected and may not be reproduced in any form without prior written consent of CSR. Recommendations and

advice regarding the use of the products described in this guide are to be taken as a guide only, and are given without liability on the part of the company or

its employees. We reserve the right to change product specifications without prior notification, please refer to the CSR website for the latest version of this

document. The purchaser should independently determine the suitability of the product for the intended use and application.

d. Assemble the Varipitch: When a Varipitch throat is being used, position the Varipitch on the

flashing and rotate the top and bottom halves until the top of the Varipitch is level (horizontal) -

it is recommended that an electronic or spirit level is used to ensure that the top edge of the

throat is horizontal in all directions.

e. Secure the Varipitch Angle: With the Varipitch upper throat positioned horizontally, lock it into

position using the supplied Varipitch clip. Use either self-tapping screws or blind rivets to

secure all the clips between the two halves of the Varipitch.

18

The contents of this install guide are copyright protected and may not be reproduced in any form without prior written consent of CSR. Recommendations and

advice regarding the use of the products described in this guide are to be taken as a guide only, and are given without liability on the part of the company or

its employees. We reserve the right to change product specifications without prior notification, please refer to the CSR website for the latest version of this

document. The purchaser should independently determine the suitability of the product for the intended use and application.

f. Weather Sealing: Seal the Varipitch seam on the inside with a bead of weather-resistant

suitable sealant.

NOTE: DO NOT apply sealant to the joint between the flashing and Varipitch. This is a natural

gutter to release any trapped condensation. See details in section (i) below.

g. Secure Varipitch to Flashing: Reposition the Varipitch on the Flashing and check it is

horizontal - secure the Varipitch to the flashing using the recommended number of screws

shown in the table below – DO NOT SEAL this connection.

Do Not Seal

19

The contents of this install guide are copyright protected and may not be reproduced in any form without prior written consent of CSR. Recommendations and

advice regarding the use of the products described in this guide are to be taken as a guide only, and are given without liability on the part of the company or

its employees. We reserve the right to change product specifications without prior notification, please refer to the CSR website for the latest version of this

document. The purchaser should independently determine the suitability of the product for the intended use and application.

h. Assemble Turbine: Assemble the turbine head to the Varipitch. Re-check if the assembly is

level (horizontal) and adjust the turbine by tilting the throat slightly if required. Ensure the

knurling (the tapered section of the Varipitch) is fully inside the ventilator throat and secure the

ventilator throat by fastening it to the top of the Varipitch with the number of fasteners shown in

the table below.

NOTE: DO NOT apply sealant to the joint between the turbine and Varipitch. This is a natural

gutter to release any trapped condensation. See details in section (i) below.

Model Fasteners to

secure turbine

to varipitch

EcoPower 400

Hurricane 100 - 400

6

EcoPower 600

Hurricane 450 - 600

9

EcoPower 900

Hurricane 700 - 900

12

Use 10G X 16MM Galvanised Self Drilling TEK

Screws with Neoprene Washer or 5/32" (4.0mm)

Rivets Aluminium/Steel Sealed

20

The contents of this install guide are copyright protected and may not be reproduced in any form without prior written consent of CSR. Recommendations and

advice regarding the use of the products described in this guide are to be taken as a guide only, and are given without liability on the part of the company or

its employees. We reserve the right to change product specifications without prior notification, please refer to the CSR website for the latest version of this

document. The purchaser should independently determine the suitability of the product for the intended use and application.

i. Sealing is crucial for this product to ensure no leaking occurs during its lifespan, but there is

also a requirement for drainage. To ensure that only the required areas are sealed and the

drainage path is left open, follow this guide carefully:

Location Area Sealing Requirement

All Fasteners Seal

Back Flashing perimeter Seal

Turbine Flashing perimeter to roof Seal

Varipitch Seam (inside throat) Seal

Turbine to Varipitch Do Not Seal

Varipitch to Flashing Do Not Seal

Flashing bottom edge to roof Do Not Seal

Do Not Seal

Do Not Seal

Do Not Seal

This manual suits for next models

8

Table of contents

Other CSR Fan manuals

Popular Fan manuals by other brands

LF

LF Harbor Breeze FLORENCE 42127 manual

Home Decorators Collection

Home Decorators Collection BROUGHTON Use and care guide

Fanimation

Fanimation Windpointe FP7500 manual

Vortice

Vortice VORT PRESS 110 I LL Instruction booklet

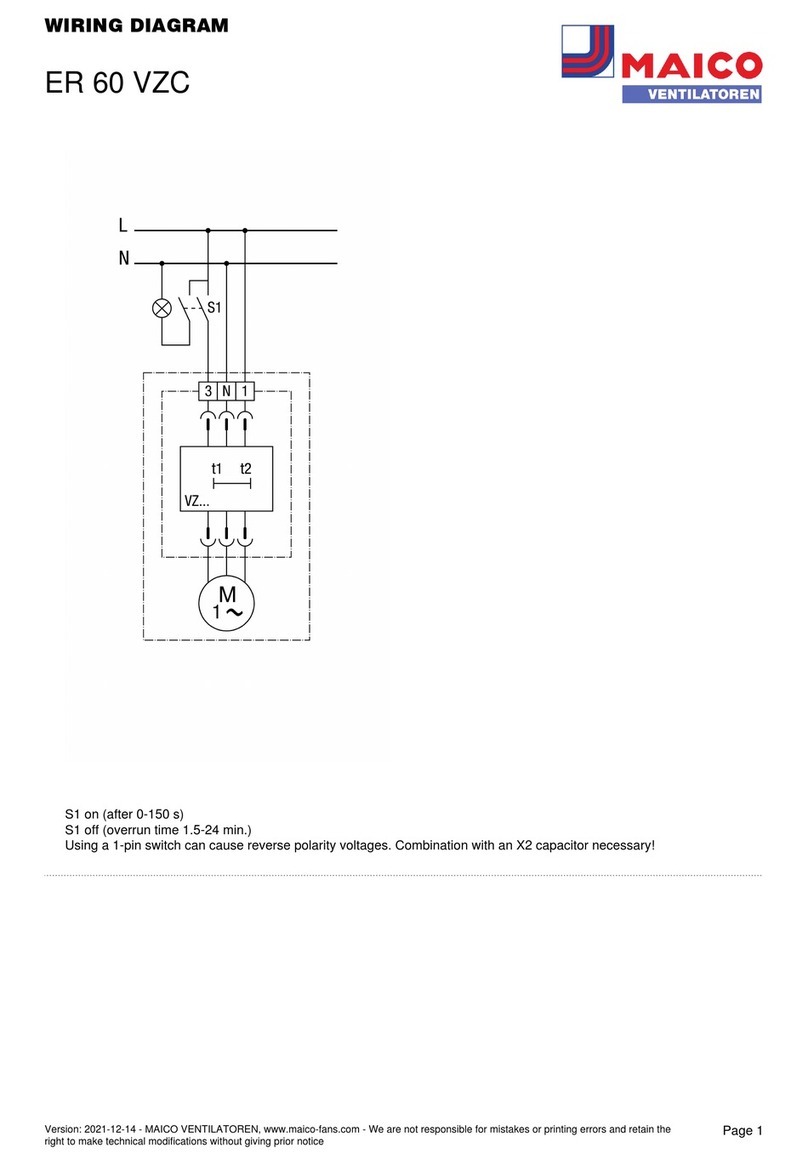

Maico

Maico ER 60 VZC Wiring diagram

Quest Engineering

Quest Engineering F9 Installation, operation and maintenance instructions

Schwank

Schwank MonsterFans MF-C12 Use instruction

Munters

Munters VX Series instruction manual

BLAUBERG Ventilatoren

BLAUBERG Ventilatoren Tower A Series user manual

Fisher & Paykel

Fisher & Paykel HBD600I INSTALLATION GUIDE/USER GUIDE

Vallox

Vallox A3712-1 manual

mercor

mercor mcr Monsun Series Technical manual