CSR Bradford SolaBrite 300 User manual

Product Installation Guide

SolaBrite 300 & 400

2

Item Checklist For Installation

2

1

Acrylic Dome with Flashing 1

2Flexitube 1

3Reector Ring 1

4Ceiling Frame 1

5Diffuser 1

6Screw Pack 1

7Duct Tape 1

1

3

5

7

4

6

Included Parts: Qty:

3

Warnings and Important Notices

WARNING: Do not proceed with the installation until you have read

the entire instructions, including these warnings.

INSTALL AT YOUR OWN RISK

The installation of this product involves working at heights on a sloping sur-

face and may be dangerous which includes the potential of death, personal

injury or property damage. Please be aware of the following before installing

this product.

• Follow the state or territory regulator OH&S guidelines for working

at height (e.g. Roof work), electrical, working in elevated temperatures

(e.g. roof space in summer).

For more information on your state’s OH&S guidelines for working at

heights, please refer to: https://www.safeworkaustralia.gov.au/heights

• Installation requires climbing and working at heights. Use caution to

minimise risks by:

• Clearing the area below the workspace

• Not walking on surfaces that are slippery, wet or dusty

• Using appropriate equipment: harness, tie off ladders, enclosed

shoes, etc

• DO NOT attempt to install if you are uncomfortable with working at

heights or on sloping roof surfaces

• There are sharp edges on the ashing, cut tiles, roof sheeting etc.

Take care and wear personal protective equipment when handling

and installing products

• When installing eave vents be careful to determine that the eave

cladding material does not contain asbestos. If it does or you cannot

determine the material, then the eave vent should only be installed

using correct asbestos handling procedures by a person trained

and/or licensed to handle asbestos.

4

Warnings and Important Notices

• The SolaBrite is designed for general residential household only.

• This product is not suitable for bushre (BAL) rated areas.

• Recommended positioning (to minimise the risk of water ingress

during rain periods)

Metal Roof: Ideally at the ridge cap but no lower than 1.2m

from the ridge cap.

Tiled Roof: Minimum third row of tiles from the ridge cap to a

maximum of the fourth row of tiles from the ridge

cap.

5

Ceiling Frame Installation

STEP 1

Firstly decide approximately the location of the SolaBrite diffuser. Check

inside the roof space to ensure it is clear of obstructions such as wiring,

water pipes, structural timbers etc. Check also that there is a clear area of

roof above the ceiling, away from the valleys, hips and ridges.

STEP 2

Measure the centre between joists and tap a nail through the ceiling to mark

the centre of the installation.

STEP 3

Hold the ceiling frame up to the ceiling and mark around the outer edge of

the upstand keeping the protruding nail in the centre of the frame. Cut along

the pencil line with a suitable saw.

STEP 4

Remove the blue adhesive lm from the ceiling frame and the clear lm from

the reector tube. Insert the ceiling frame with the long screws through the

opening and secure with the plastic nuts.

upstand

6

Installation - Tiled Roof

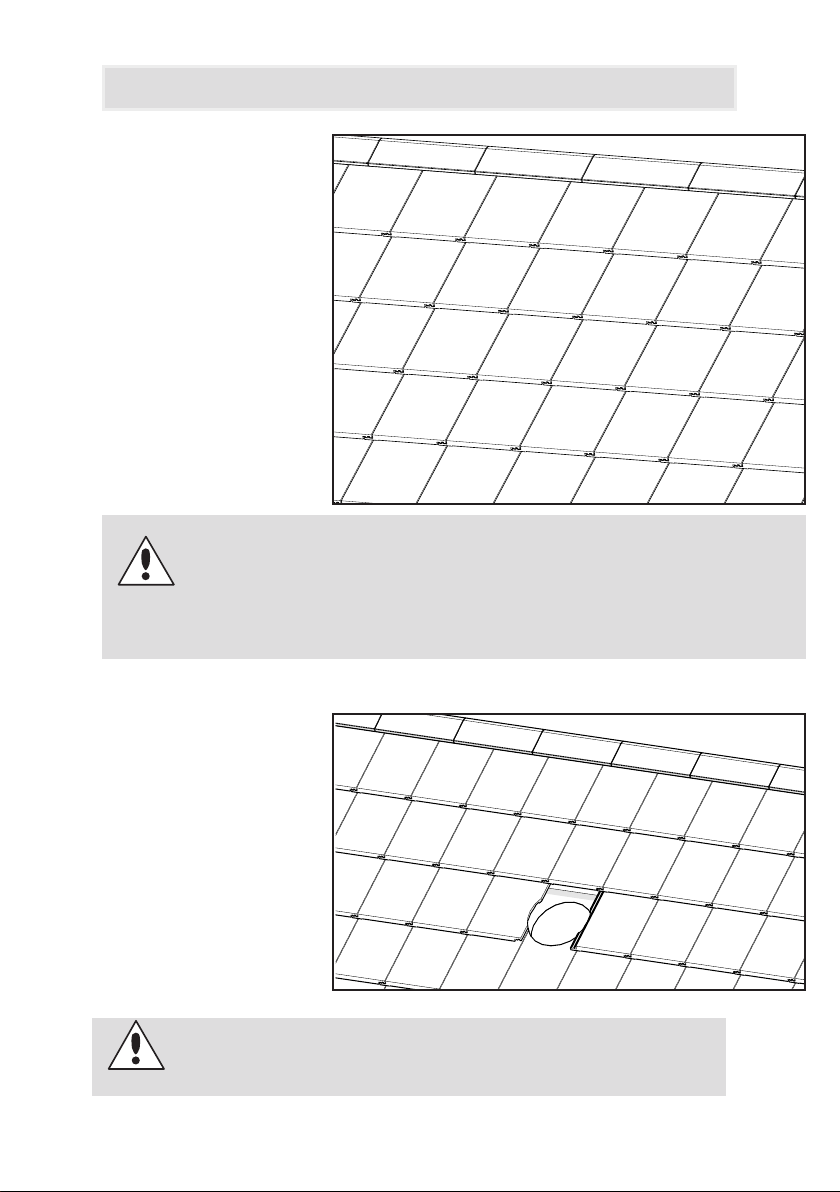

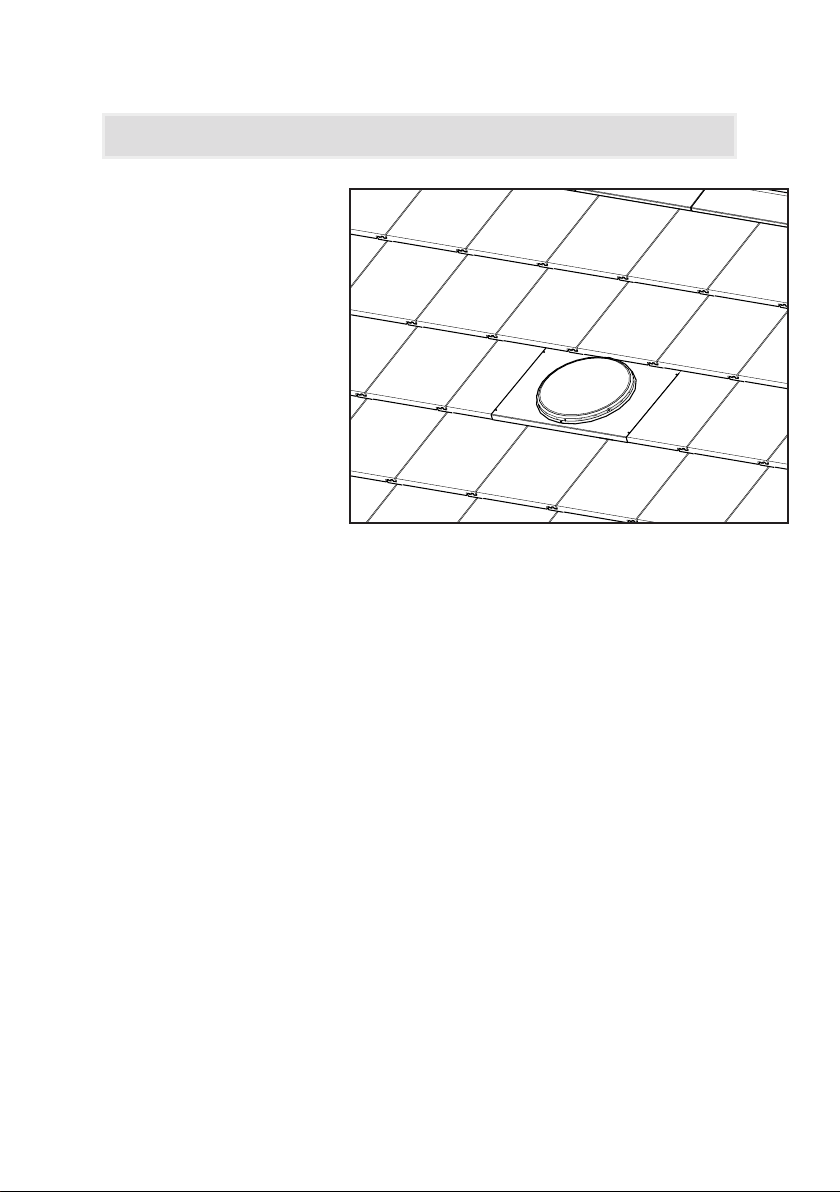

STEP 1

Directly above the

ceiling hole, select a

suitable position for

the SolaBrite on the

roof and it should be

no higher than the third

row of tiles down from

the ridge.

Take care to check

that there are no

obstructions below the

tile such as a rafter.

The removal of a tile higher than the third row down from the ridge

may damage the ridge tile pointing and is NOT recommended.

Recommended SolaBrite Positioning - Minimum third row of tiles from

the ridge cap to a maximum of the fourth row of tiles from the ridge

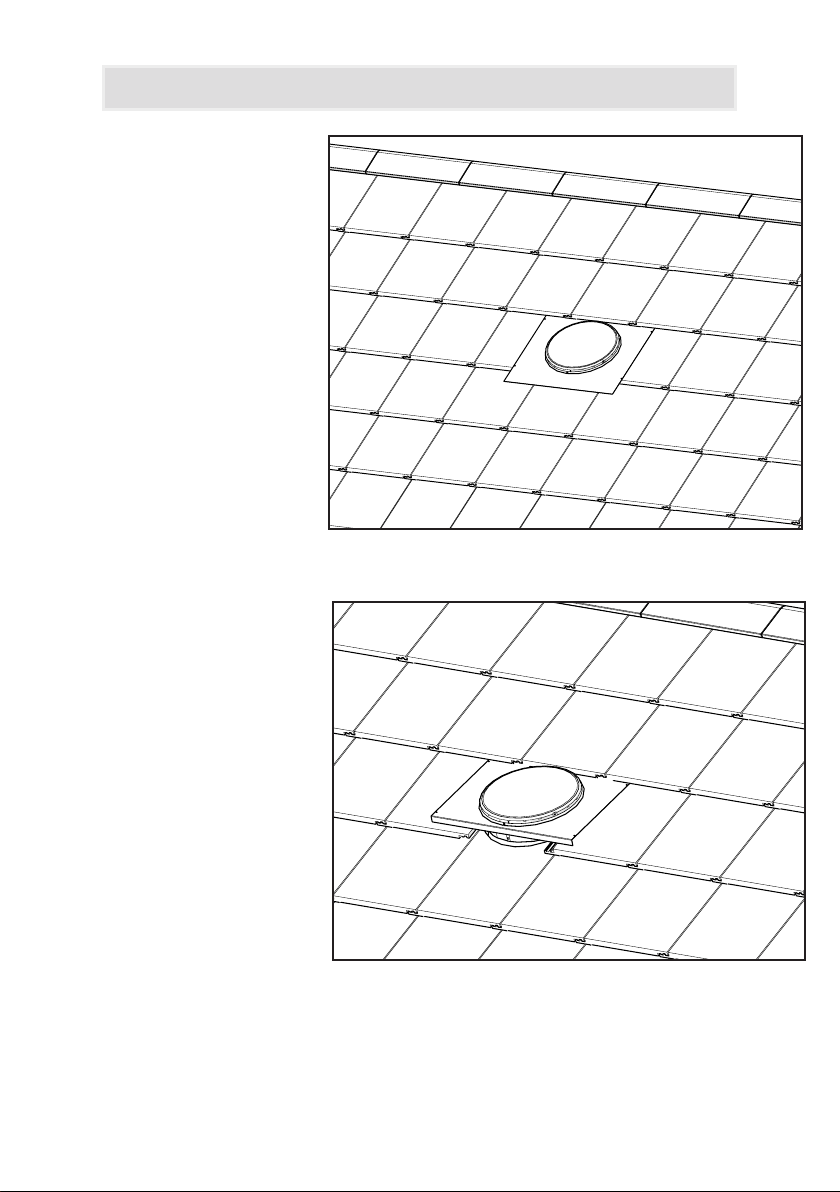

STEP 2

Position the SolaBrite in

the desired location and

mark the tile to be re-

moved and cut using the

ashing hole as template.

Ensure that the product

orientation is correct (refer

to the sticker on ashing).

If a complete tile is removed, then care must be taken to

dress the ashing to ensure a weather tight installation.

7

Installation - Tiled Roof

STEP 3

Fold up the top edge of

the ashing before tuck-

ing it into the tiles.

Fold and form the bot-

tom edge of the ashing

to seal against the tiles

below.

Using a soft hammer,

carefully dress the bottom

edge and the sides of the

ashing into the shape of

the tiles.

STEP 4

Weatherproof the ashing

by applying sealant under-

neath the ashing.

To apply, lift the formed

ashing and run a bead

3-5mm in from the edge

of the ashing edge on

the roof sheeting. Then t

the ashing.

8

Installation - Tiled Roof

STEP 5

Remove the clear protective

lm from inside of the ue.

Drop the exitube through

the hole in roof and slide

base ashing into position.

Fix the exitube to the ue

underneath the ashing us-

ing the stainless steel tabs

bent outwards. Seal with the

duct tape provided.

Fit the SolaBrite into place

and ensure surrounding tiles

are tted securely.

STEP 6

From inside the ceiling pull the exible tube tightly and cut off excess length.

Secure the tube to the reector ring on the diffuser by bending the push out tabs

and sealing with the duct tape provided.

9

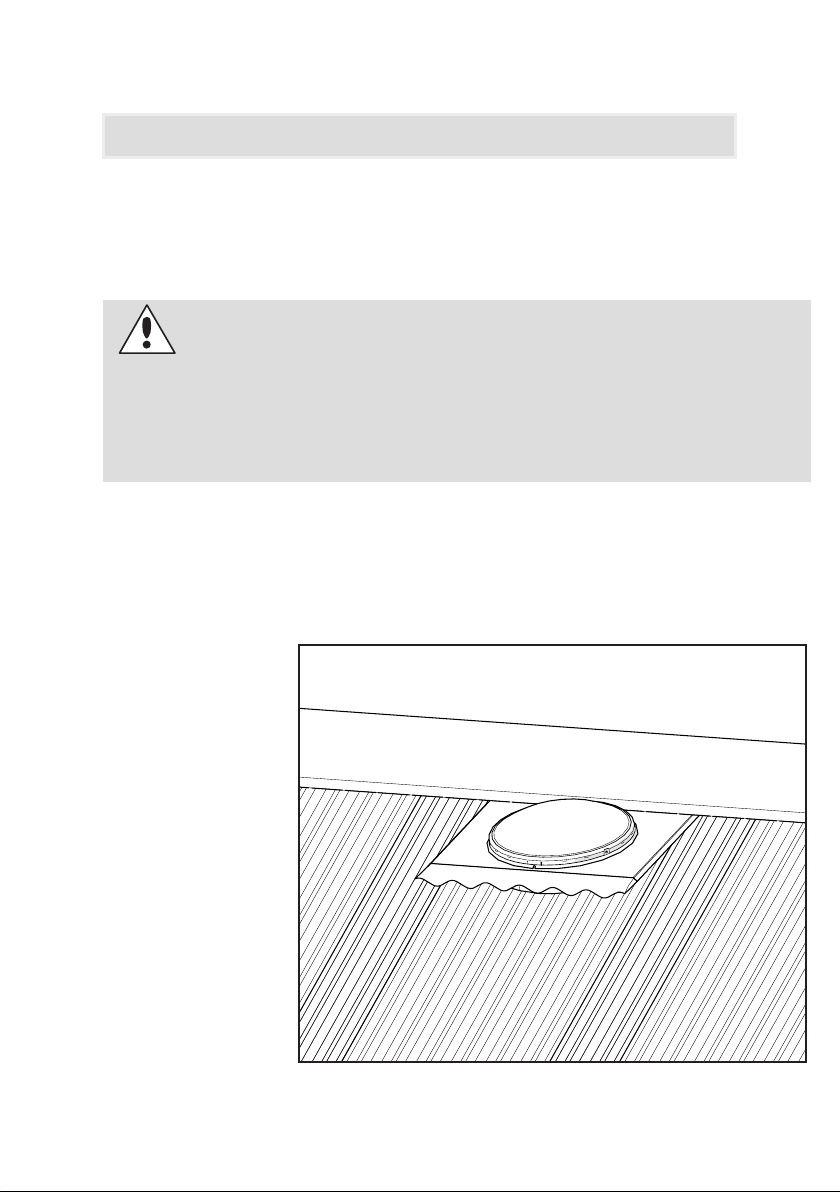

Installation - Metal Roof

STEP 2

Cut the metal roof slightly larger than exitube. Turn up the corrugations or pans on

both the low and high sides. This will help to prevent water ingress.

Ensure that the ashing covers the roof corrugations or ribs equally

and that it is located between roof rafters.

Recommended Vent Positioning - Ideally at the ridge cap but no lower

than 1.2m from the ridge cap.

Backashing required if product assembled away from the ridge cap

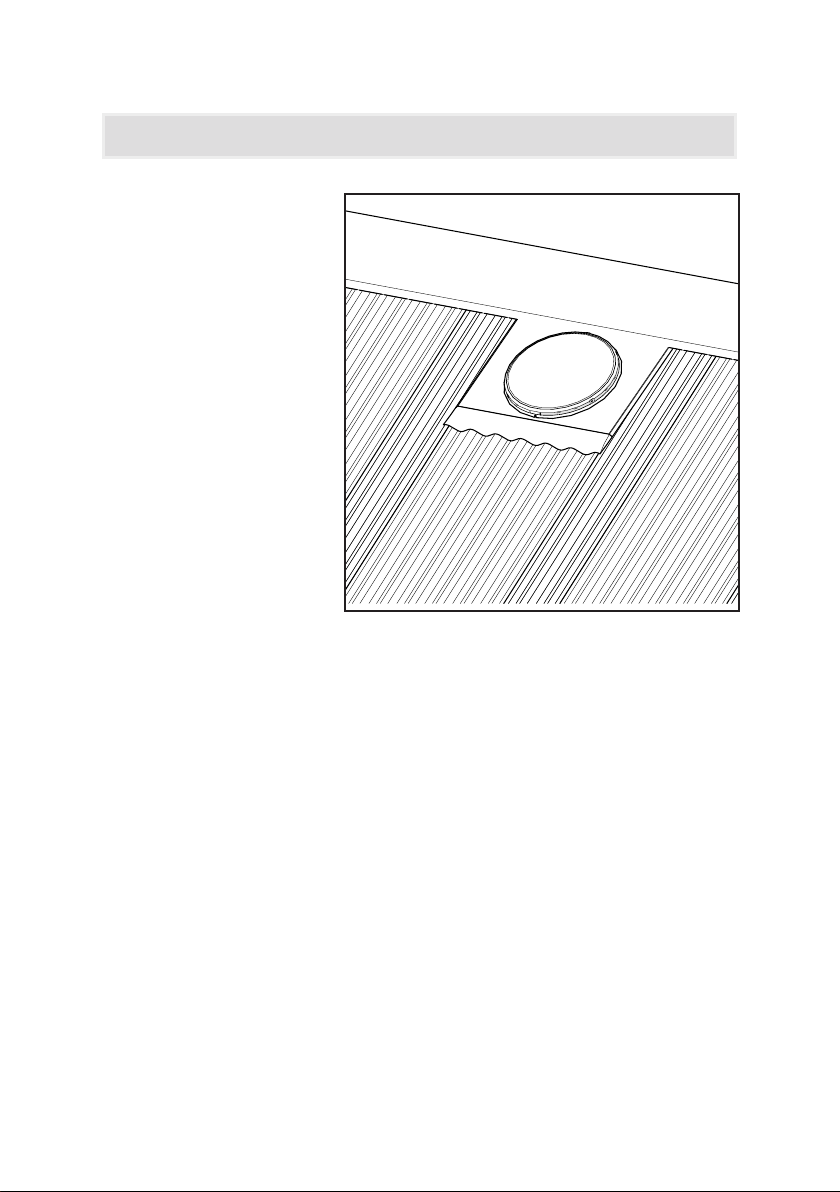

STEP 3

Return the SolaBrite

to the roof, positioning

it over the cutout.

Ensure that the top of

the ashing is slipped

under the ridge capping.

Turn up the top edge

of the ashing before

slipping under ridge

capping. This will help

prevent water ingress.

Ensure that the product

orientation is correct.

(refer to the sticker on

ashing).

STEP 1

From the underside of the metal roof decide approximately where you would

like your solabrite. Punch a hole through the center of the desired position.

10

Installation - Metal Roof

STEP 4

Using a soft rubber

hammer, carefully

work around the sides

and lower edge of the

ashing to form it into the

corrugations of the metal

sheeting prole.

STEP 5

To assist with weatherproong a bead of silicone sealant can be applied be-

tween the sheeting and the side and bottom edge of the ashing.

To apply, lift the formed ashing and run a bead 3-5mm in from the edge of

the ashing edge on the roof sheeting. Then t the ashing.

STEP 6

From inside the ceiling drop the diffuser into place and press to engage in

diffuser rest if used [see step 4 in Ceiling Frame Installation section]. Pull

exitube and cut length before securing it to the reector ring with duct tape.

11

Installation - Metal Roof

Additional Illustration

12

Bradford Ventilation SolaBrite Installation Manual 03/2021

This manual suits for next models

1

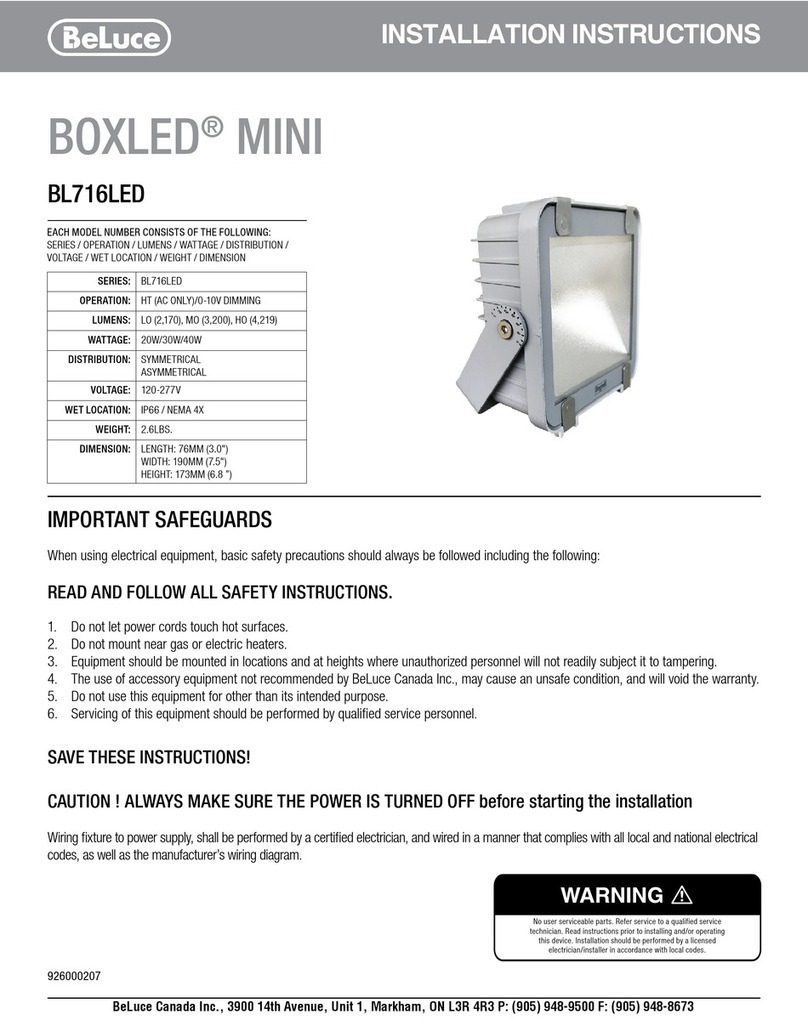

Popular Lighting Equipment manuals by other brands

Signtex

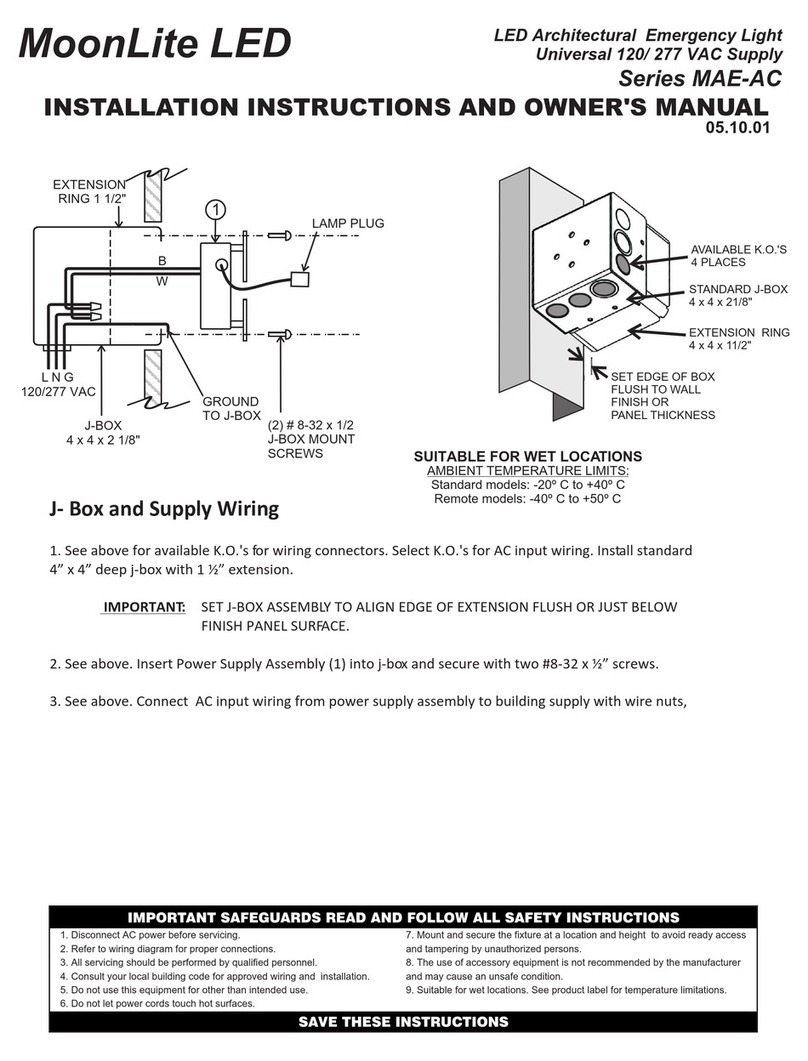

Signtex MoonLite LED MAE-AC Series Installation instructions and owner's manual

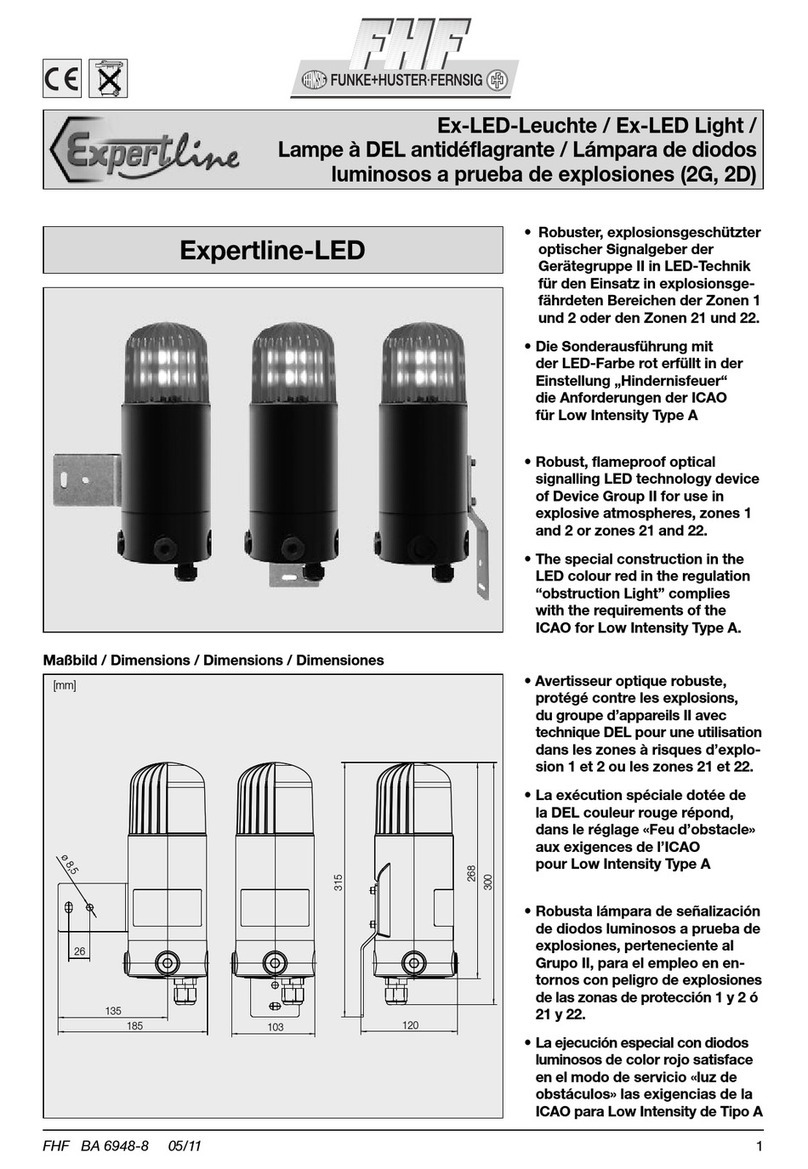

LIGHTSIDE

LIGHTSIDE LED BALL user manual

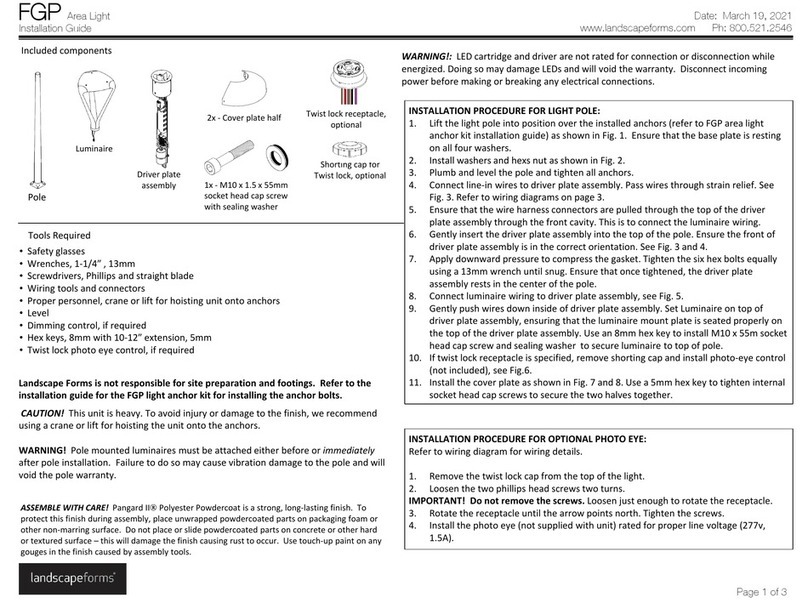

Loevschall

Loevschall F15-350E instruction manual

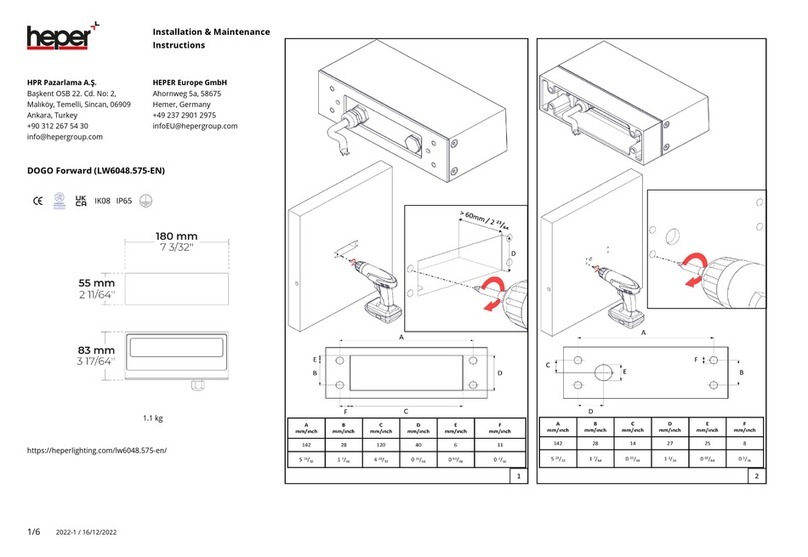

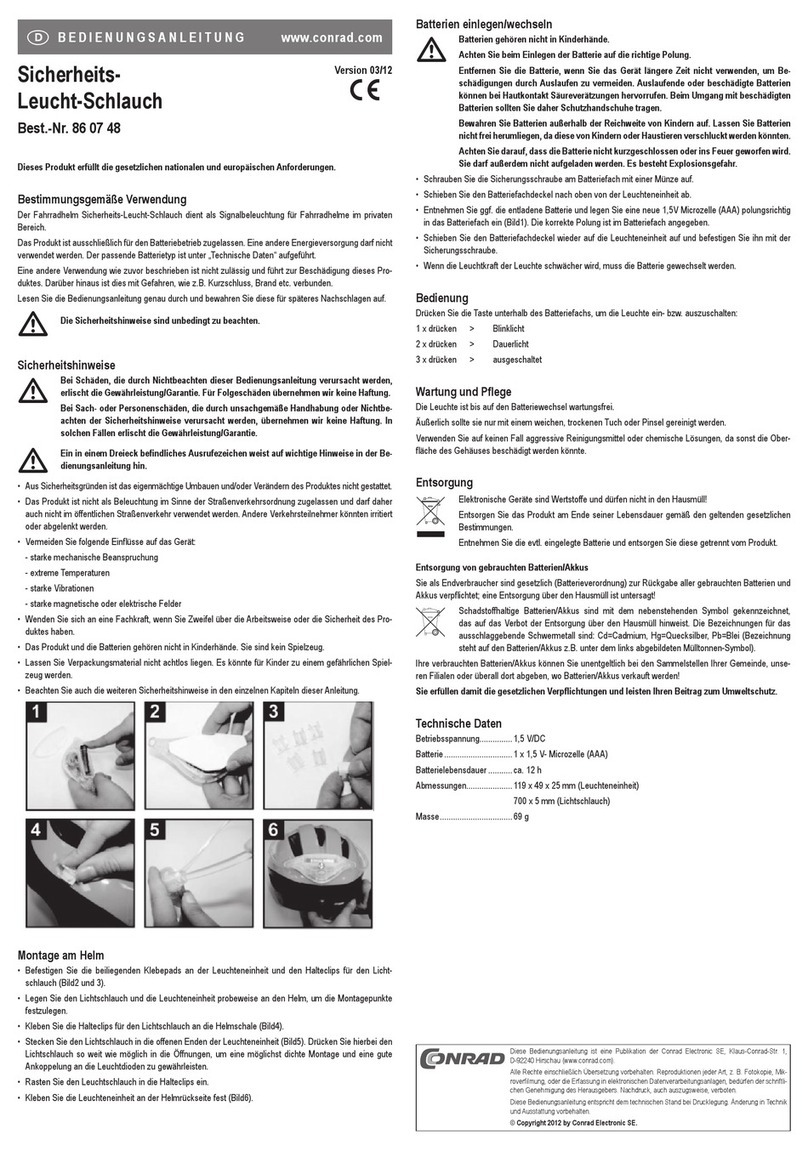

Conrad

Conrad 86 07 48 operating instructions

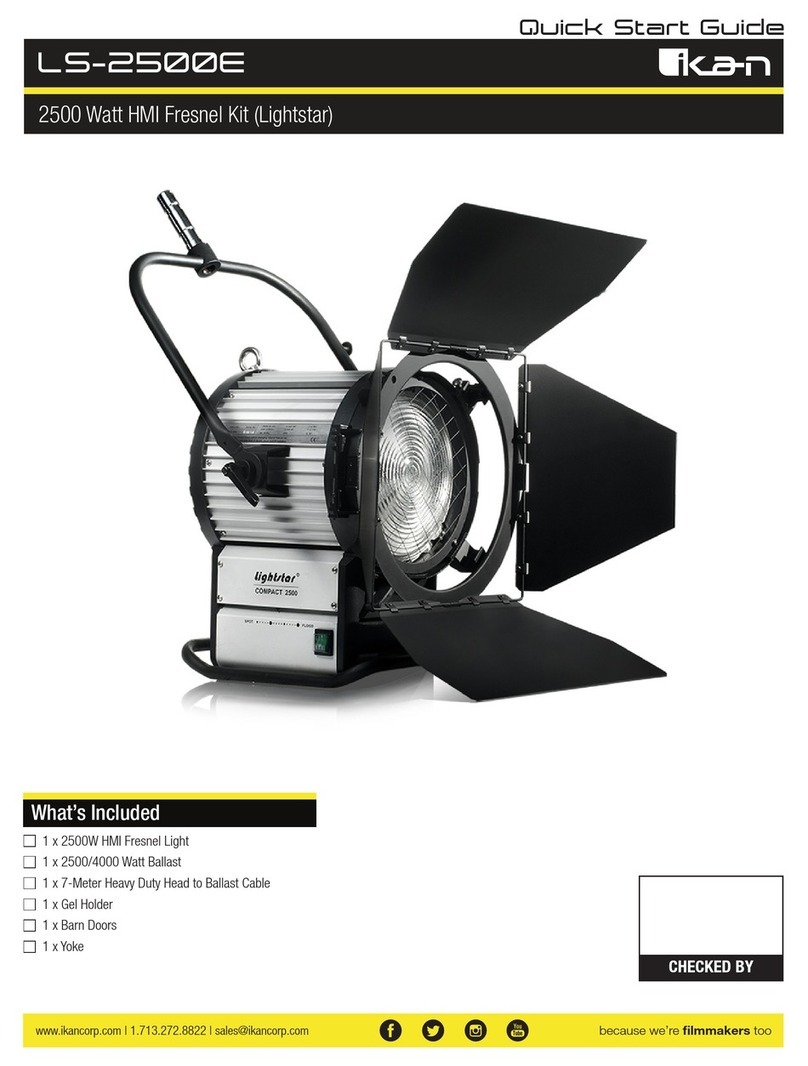

Ikan

Ikan Lightstar LS-2500E quick start guide

Fiilex

Fiilex Matrix II RGBW quick start guide

Commercial Electric

Commercial Electric 54655241 Use and care guide

hudson valley

hudson valley L1054 installation instructions

RSA Lighting

RSA Lighting C-700 Specification sheet

Light O Rama

Light O Rama SASQUATCH MEGATREE Assembly instructions

Aputure

Aputure light Dome150 product manual

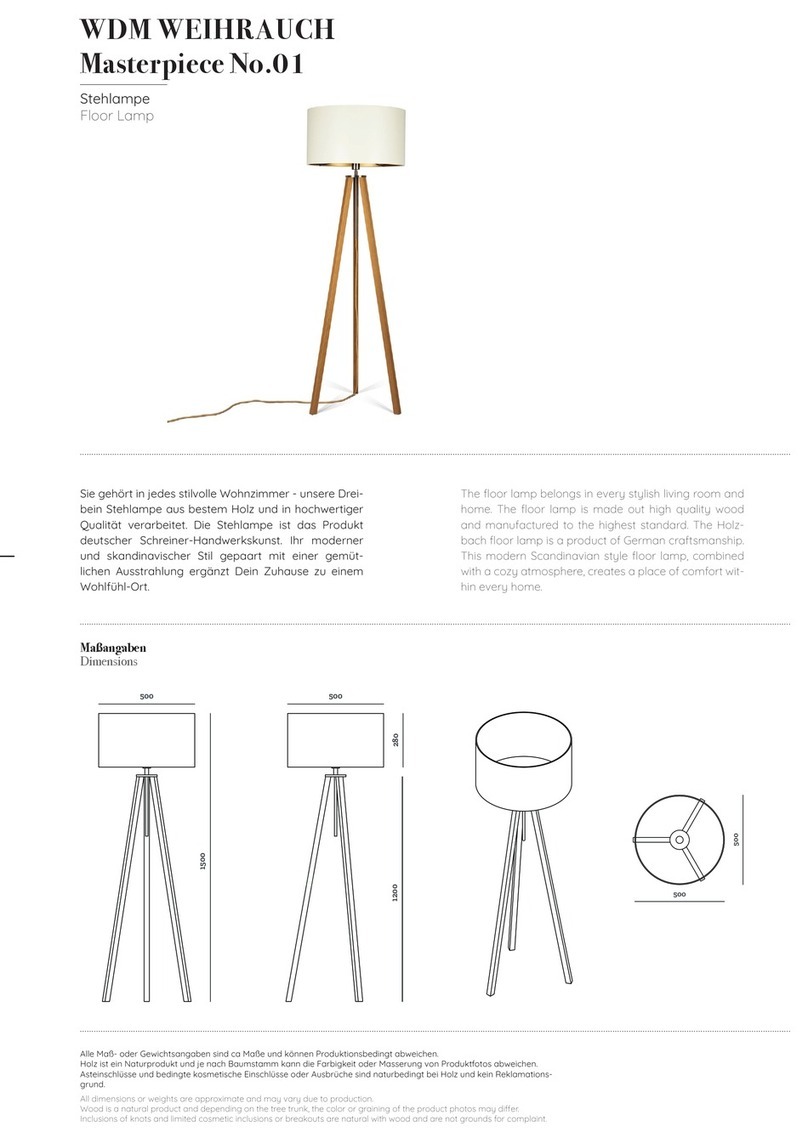

WDM

WDM WEIHRAUCH Masterpiece No.01 quick start guide