Table of Contents

PNEG-2348 IR Hopper Sensor Installation 3

Contents

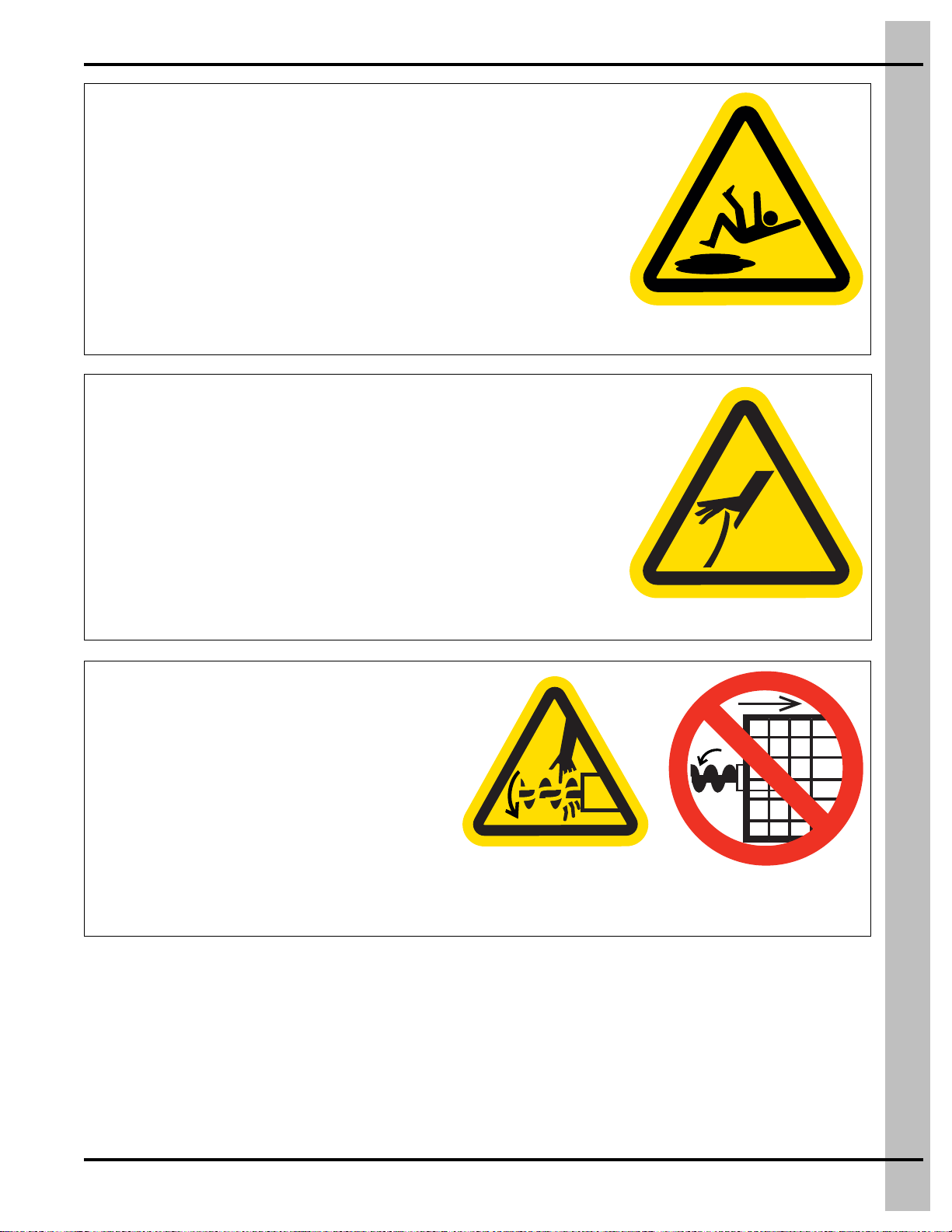

Chapter 1 Safety .....................................................................................................................................................4

Safety Guidelines ...................................................................................................................................4

Cautionary Symbols Definitions .............................................................................................................5

Safety Cautions ......................................................................................................................................6

Safety Sign-Off Sheet ............................................................................................................................8

Chapter 2 Installation ............................................................................................................................................9

Attaching the IR Sensor to the Hopper ..................................................................................................9

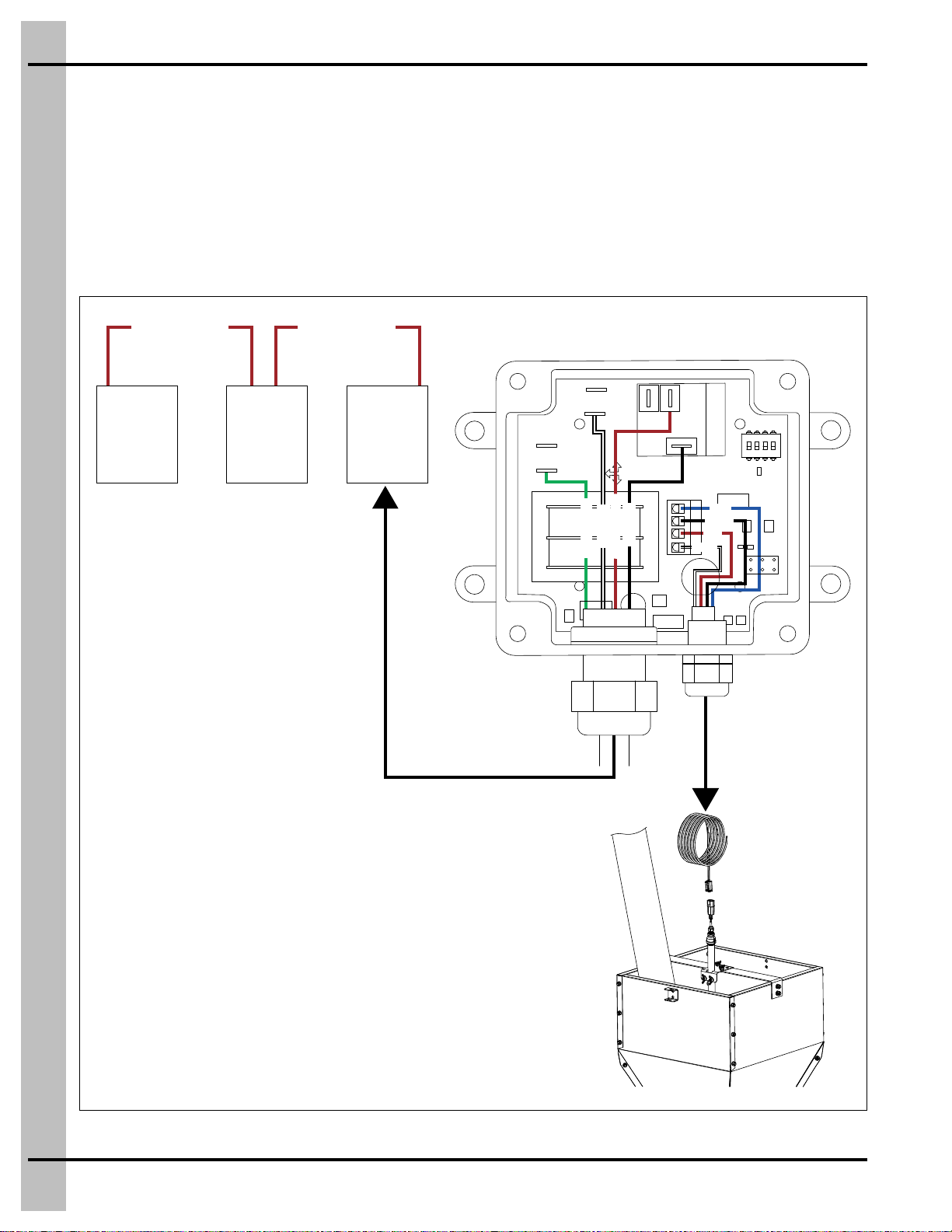

Mounting and Wiring the Control Box ..................................................................................................10

IR Plus Feed Sensor Wiring Diagram for Poultry Application ..............................................................11

Flex-Flo Control Unit (FLX-5350) Used with i-Plus3 Control Box (C2000822)

as Hopper Level Controls .....................................................................................................................12

Flex-Flo Control Unit (FLX-5350) Used with IR Plus Feed Sensor (FLX-5262)

as Hopper Level Controls .....................................................................................................................13

Wiring the IR Hopper Sensor ...............................................................................................................14

Adjusting the IR Hopper Sensor ...........................................................................................................15

Setting the Time Delay .........................................................................................................................15

Chapter 3 Parts List .............................................................................................................................................16

Poultry IR Hopper Sensor with Control (C2000829) Parts ...................................................................16

Chapter 4 Warranty ..............................................................................................................................................17