Installation Procedure

SAFETY

Always follow these safety precautions when

installing and operating the water filter system:

DO NOT use with water that is microbiologically

unsafe or of unknown quality without adequate

disinfection before or after the system.

DO NOT use a torch or other high temperature

sources near filter or cartridge.

DO NOT install on line pressures above 125 psi

(862 kPa).

DO NOT install on hot water line. Maximum

temperature allowed is 100°F (38°C).

DO NOT install in direct sunlight.

DO NOT reverse connections. The system must

be installed with the inlet and outlet as labeled.

DO NOT install filter system in locations where it

can be damaged by other freestanding equipment.

DRAIN filter system at temperatures below 40°F

(4.4°C). Protect from freezing.

INSTALLATION must comply with existing state

or local plumbing codes.

This piece of equipment is made in America and

has American sizes on hardware. All metric

conversions are approximate and vary in size.

FEEDWATER PARAMETERS

Be sure to confirm that the feedwater falls within

the limits shown below. If you’re not sure if this has

been done, check with your distributor before

installing the system. This is important because

failures caused by water related problems are not

covered under the system warranty.

Feed TDS . . . . . . . . .Up to 2,000 ppm (mg/L)

Hardness* . . . . . . . . . . .<10 grains (171 mg/L)

Iron (Fe) . . . . . . . . . . . . . . . . . . . . . .<0.1 mg/L

Hydrogen Sulfide . . . . . . . . . . .none allowable

Feed pH . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Free chlorine . . . . . . . . . . . . . . . . . . . .<2 mg/L

Manganese (Mn) . . . . . . . . . . . . . .<0.05 mg/L

Turbidity . . . . . . . . . . . . . . . . . . . . . . . .<5 NTU

* NOTE: For waters over 10 grain hard, a CUNO water

softener is recommended for pretreatment. Consult

CUNO technical services for correct sizing.

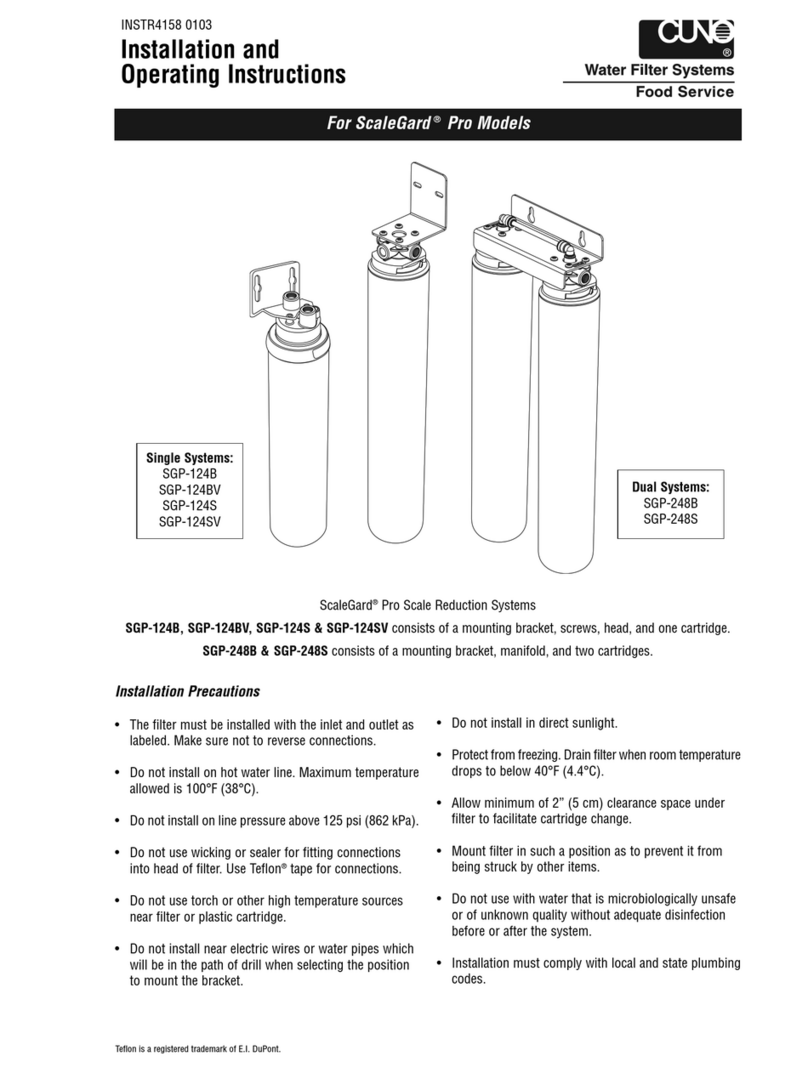

PARTS LIST (SEE FIGURE 1, PAGE 2)

THE FOLLOWING PARTS ARE INCLUDED WITH

THE SCALEGARD REVERSE OSMOSIS WATER

FILTRATION SYSTEM. PLEASE UNPACK THE

CONTENTS FROM THE PRODUCT BOX AND

CHECK TO VERIFY THAT ALL OF THE PARTS

LISTED BELOW ARE INCLUDED. SHOULD ANY

PARTS BE MISSING, PLEASE CONTACT CUNO

AT 1-888-218-2866.

QTY DESCRIPTION

1 TANK & BRACKET ASSEMBLY

1 PREFILTER CARTRIDGE

1 REVERSE OSMOSIS MEMBRANE

CARTRIDGE

1 WATER SAMPLE VALVE ASSEMBLY

(SEE FIGURE 1)

1 1’ LENGTH OF 3/8” BLUE TUBING

1 10’ LENGTH OF RED TUBING

1 ADAPTER - STEM X BARB (1/4X1/4”)

1 ADAPTER - STEM X BARB (3/8 X 1/4”)

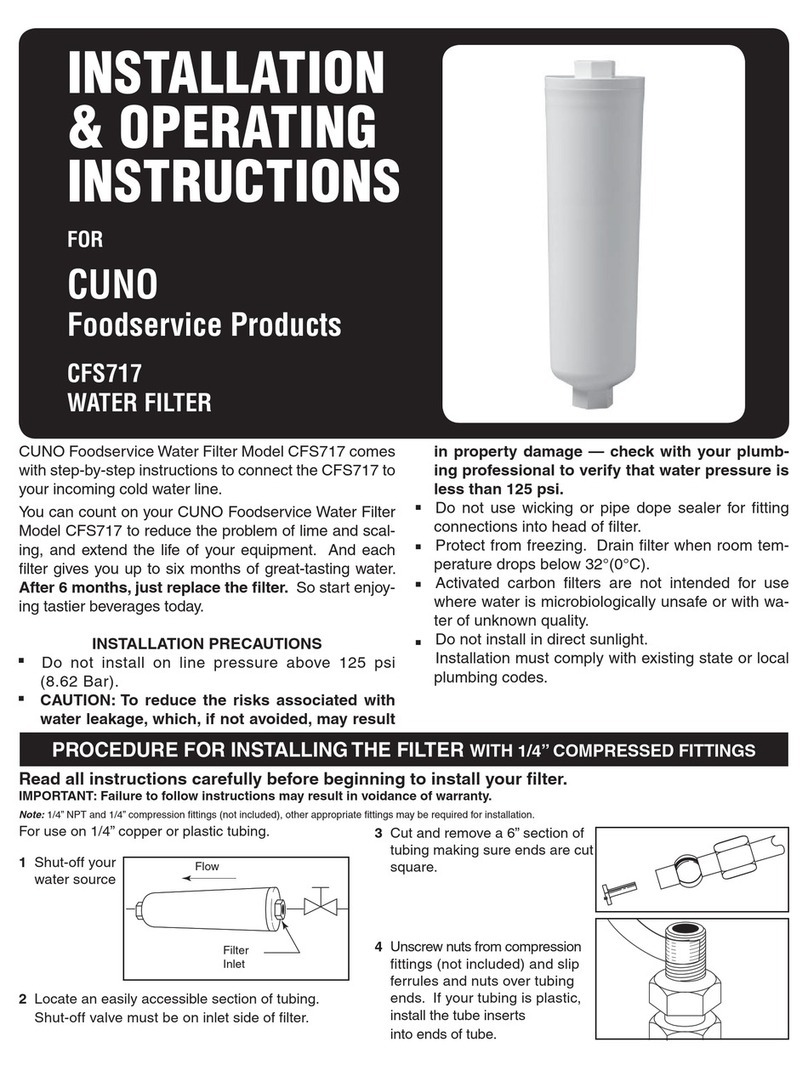

MOUNTING

1) Remove the mounting bracket template from

this manual. Tape it to the wall where the

mounting bracket is to be installed.

2) Install mounting screws (not included) into

each of the keyhole locations on the template.

Be sure to leave a 1/8" to 1/4" space between

the bottom of the screw head and the wall so

that the bracket can be hung.

NOTE: Mounting hardware must be

capable of supporting a minimum of 50 lbs

(22.7 kg).

3) Hang the Bracket/Tank Assembly from the

mounting screws.

4) Once the bracket is hung, tighten the

mounting screws so that the bracket is snug

between the screw and the wall.

Note: Make sure that the bracket is securely

mounted to a wall stud or other appropriate

wall structure.

1