6

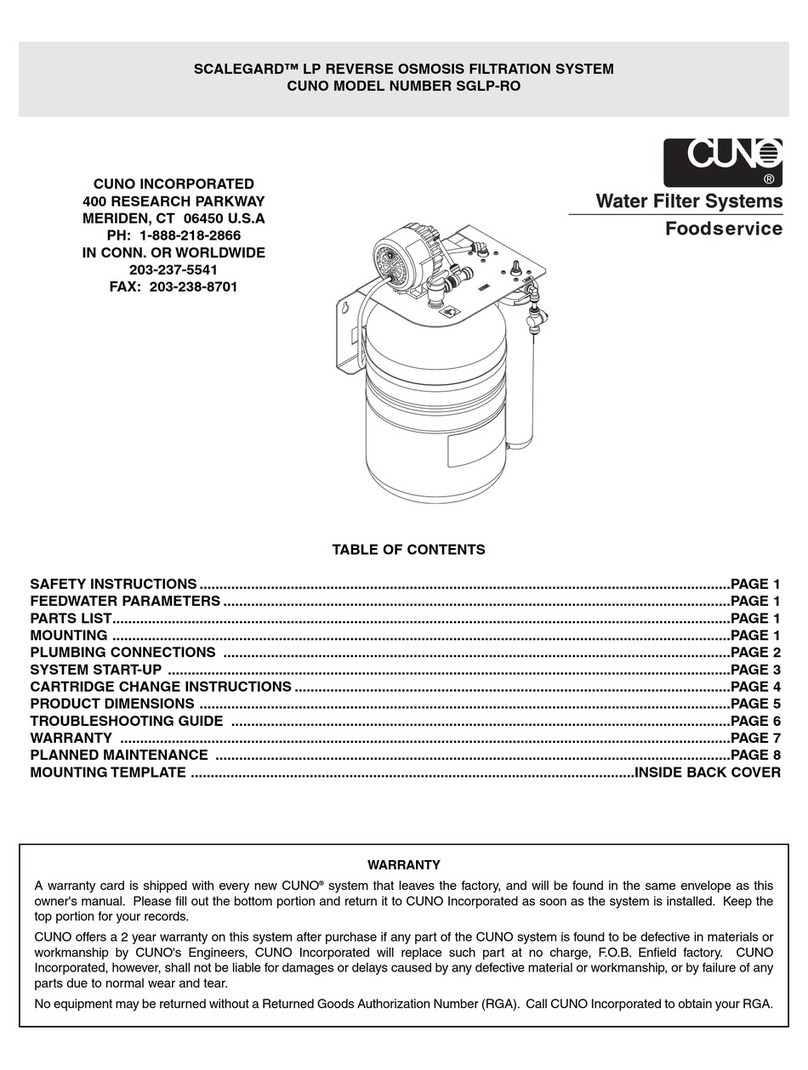

Manufacturer’s Warranty

Please read and complete the following warranty and mail the bottom half within 10 days of purchase.

Manufacturer warrants the UV system’s hardware and electrical systems, excluding wear parts, to be free from defects in

materials and workmanship for a period of two (2) years from the date of purchase by the original owner (consumer).

The warrantor will, at its option and expense, either repair or replace such systems subject to the following conditions,

exceptions and exclusions. No other warranties with respect to the systems other than those expressly included in this

one year warranty have been made by the Warrantor.

CONDITIONS, EXCEPTIONS AND EXCLUSIONS

The foregoing limited Warranty is subject to the following terms and conditions:

1. Water passed through the system must not contain:

A. Sulfur

B. Filterable solids

C. Greater than 0.3 ppm (mg/l) iron

D. Excessive hardness*

* Where total hardness is less than 7 gpg, the UV system should operate efficiently provided the quartz sleeve

and/or sensor probe is cleaned periodically. If total hardness is greater than 7 gpg, consult a CUNO

Foodservice Authorized Distributor for proper pretreatment.

IMPORTANT: To file a claim under this Warranty you must complete and mail the Warranty registration card supplied

with this Product to CUNO at the address below within ten (10) days of original retail purchase.

THIS WARRANTY DOES NOT COVER, AND IS INTENDED TO EXCLUDE, ANY LIABILITY ON THE PART OF CUNO,

WHETHER UNDER THIS WARRANTY OR UNDER ANY WARRANTY IMPLIED BY LAW, FOR ANY INDIRECT OR CONSE-

QUENTIAL DAMAGES FOR BREACH HEREOF OR THEREOF.

Note: Some states prohibit limitations on the duration of implied warranties and on the exclusion of indirect or con-

sequential damages, and so the above limitation on implied warranties and on incidental and consequential damages

may not be applicable to you.

RESPONSIBILITY OF CUNO

CUNO's responsibility under this warranty shall be to repair at its expense, and at no charge to the original purchaser-

consumer, any Product that is actually defective, malfunctioning, or otherwise in violation of this Warranty.

If CUNO, for any reason, cannot repair a Product covered hereby within two (2) weeks after receipt of the original pur-

chaser-consumer's notification of a Warranty claim, then CUNO's responsibility shall be, at its option, either to replace

the defective Product with a comparable new unit at no charge to the consumer or to refund the full purchase price.

CUNO's obligations of repair, replacement, or refund are conditioned upon the consumer's return of the defective

Product to CUNO.

If any Product covered hereby is actually defective within the terms of this Warranty, then CUNO will bear all the reason-

able and proper shipping or mailing charges actually incurred in the consumer's return of the Product set forth herein. If

the Product proves not to be defective within the terms of this Warranty, then all costs and expenses in connection with

the processing of the consumer's claim hereunder shall be borne by the consumer.

RESPONSIBILITY OF THE CONSUMER

The original purchaser-consumer's sole responsibility in the instance of a Warranty claim shall be to notify CUNO of the

defect, malfunction, or other manner in which the terms of this Warranty are violated. You may secure performance or

obligations hereunder by (in writing):

1. Identifying the Product involved (by model or serial number or other sufficient description that will allow CUNO to

determine which Product is defective).

2. Specifying where, when and from whom the Product was purchased.

3. Describing the nature of the defect, malfunction or other violation of this Warranty.

4. Sending such notification together with the defective Product and a $5.00 check or money order to cover postage

and handling to:

CUNO Incorporated, 400 Research Parkway, Meriden CT 06450 U.S.A.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH MAY

VARY FROM STATE TO STATE.