CAB INSTALLATION

9 of 29

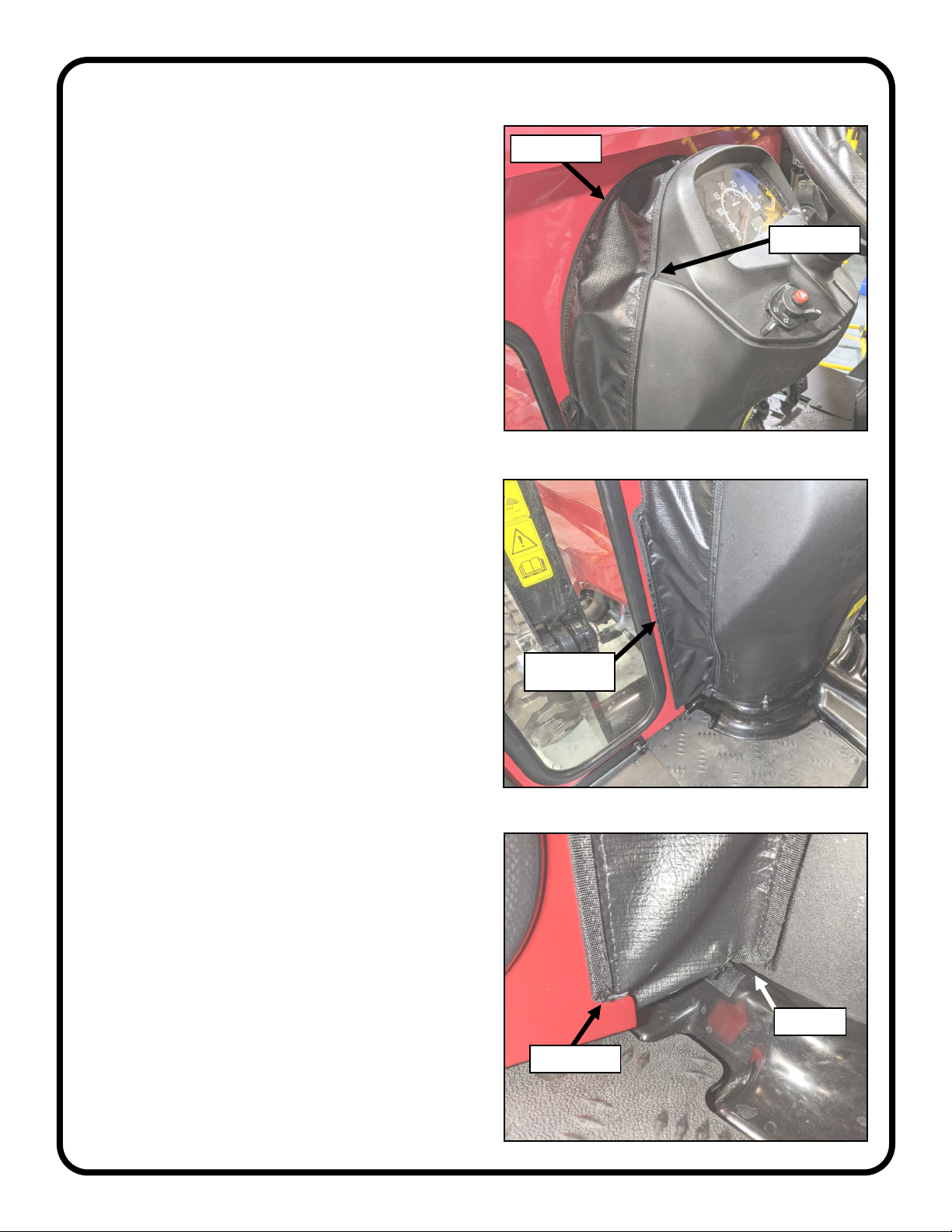

STEP 12: (TIGHTEN HARDWARE)

12.1 Tighten all hardware at this time, using the torque values

given below.

Each side frame can be pushed inward at the back to

close any gaps along the fender contour before

tightening hardware.

For 5/16” bolts that thread into factory installed threaded

inserts in the side frames without plastic washers, use

20 ft.-lbs.

For 5/16” bolts that use plastic washers, use only 12.5 ft.-lbs.

For the remaining 5/16” bolts (the vast majority on the cab)

that thread into hex nuts, use 28 ft.-lbs.

For all other bolt sizes, reference the torque tables at the end

of the manual.

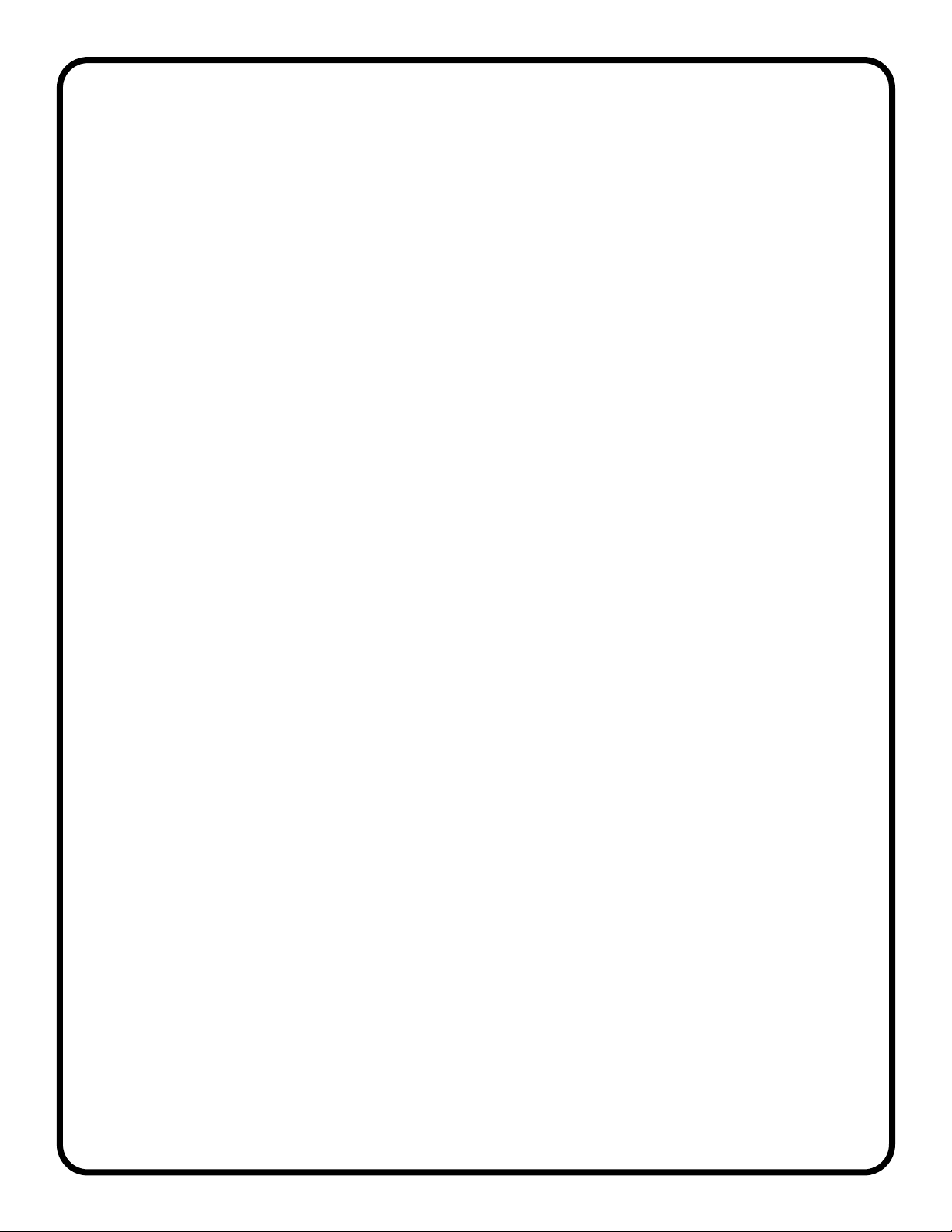

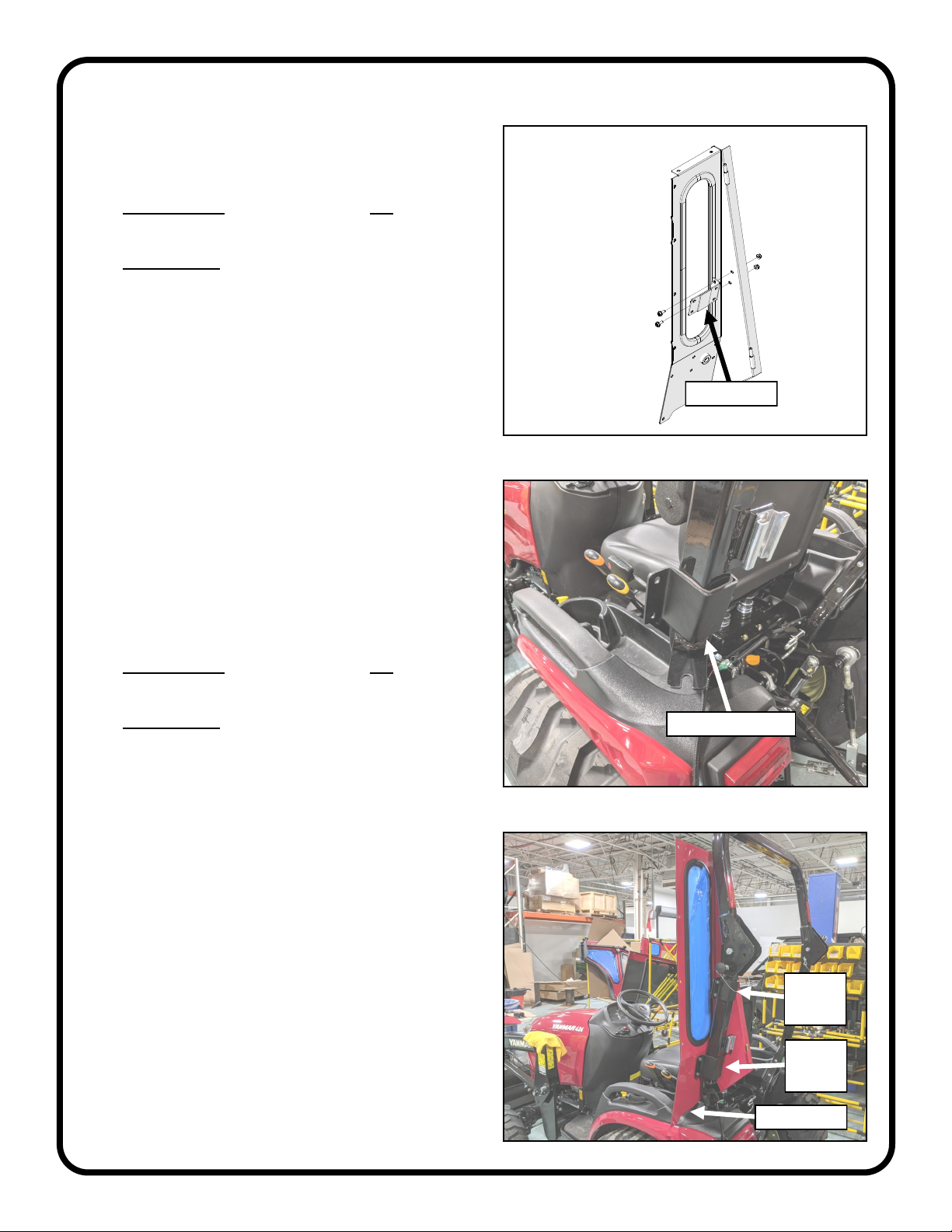

STEP 11: (REAR WINDOW)

11.1 Measure the back of the rear legs, inside to inside, and

adjust the width to 24-7/8”. Measure corner to corner

for squareness, and tighten the (8) sets of screws and

nuts that attach the rear legs to the ROPS, to lock in

this width. See figure 11.1

11.2 Grease the hinge pins for the rear window, and slide on

greased brass washers (one washer per pin). See

Figure 11.2.

11.3 Hang the rear window on the hinges.

11.4 Connect the window latches to the right rear leg by

depressing the tabs on the latch and inserting into the

receivers mounted on the rear leg. Close and check the

alignment of the window. If off, check measurements

and re-align the rear legs. Tighten the hinge hardware

to 7 ft.-lbs. Verify smooth operation of the latches.

Fig. 11.1 (Measure Rear Legs Left to Right)

24-7/8”

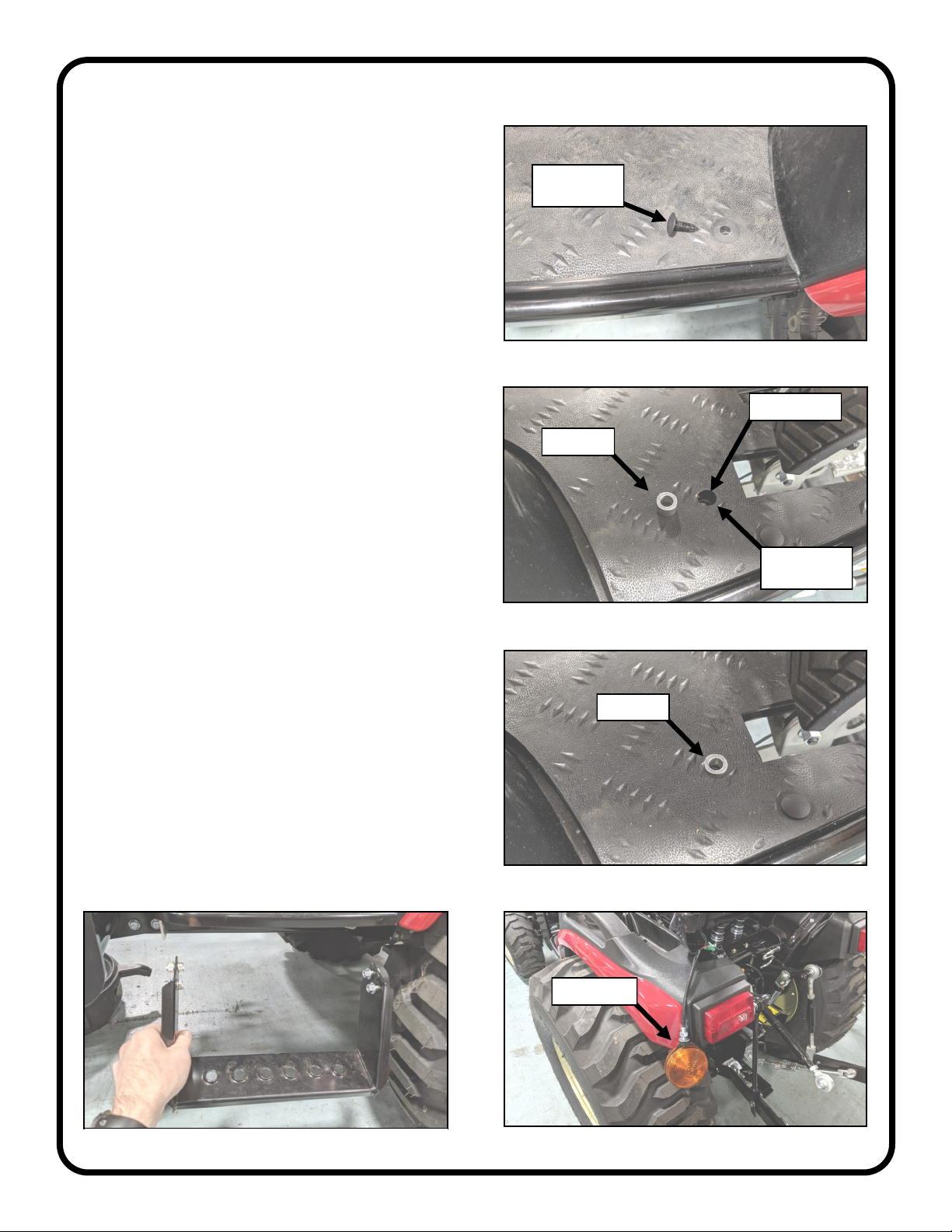

STEP 13: (LEFT STEP)

13.1 If equipped, re-install the left step to the new relocation

tabs on the side frame using the hardware saved

earlier. See Figure 13.1

Fig. 13.1 (Install Left Step)

Brass Washers

on Greased Pins

Snap Latches

into Right

Rear Leg

2 Places

Fig. 11.2 (Hang Rear Window)