EGR EGR-3PVE-COLOUR User manual

TC0123b

page 1 of 28

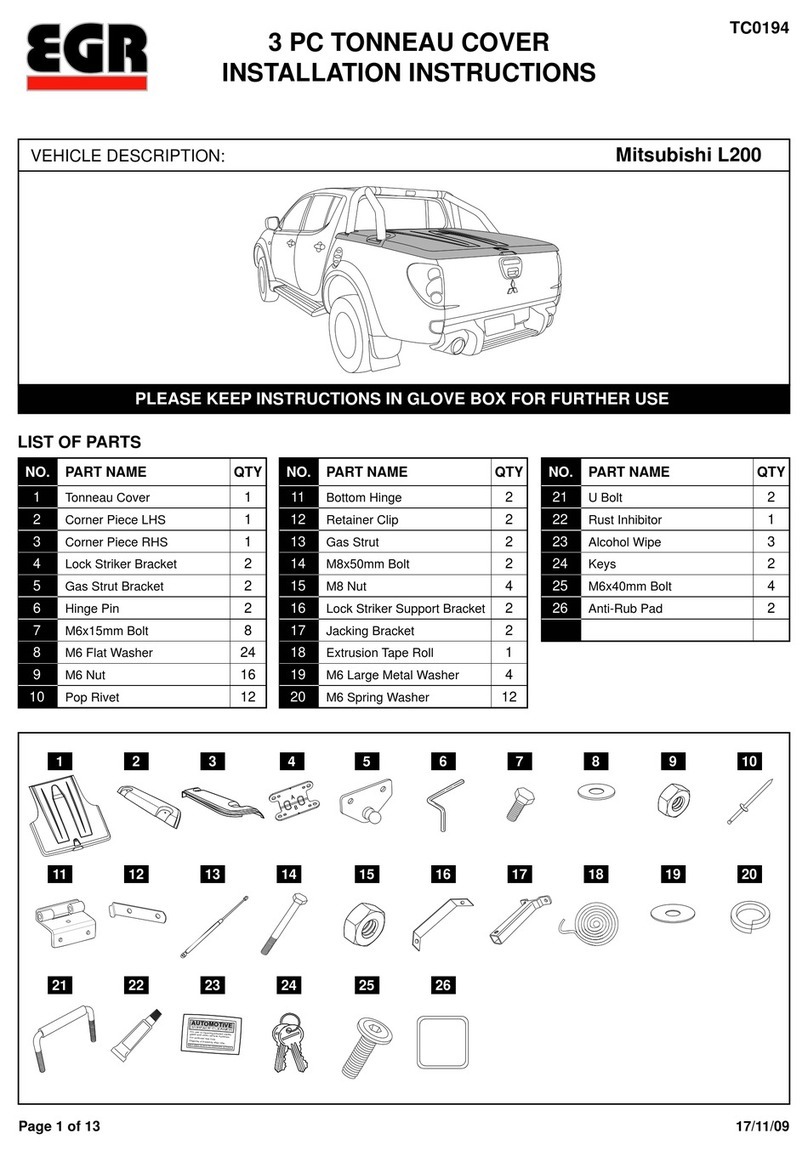

Holden VE Ute 2007

Part Number: EGR-3PVE-COLOUR

3PC TONNEAU COVER WITH

SPORTS BAR & REMOTE LOCKING

INSTALLATION INSTRUCTIONS

Item

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1

1

1

1

2

2

2

8

2

3

2

2

2

2

2

4

4

4

4

4

4

4

2

6

4

12

1

1

8

8

12

1

1

1

1

2

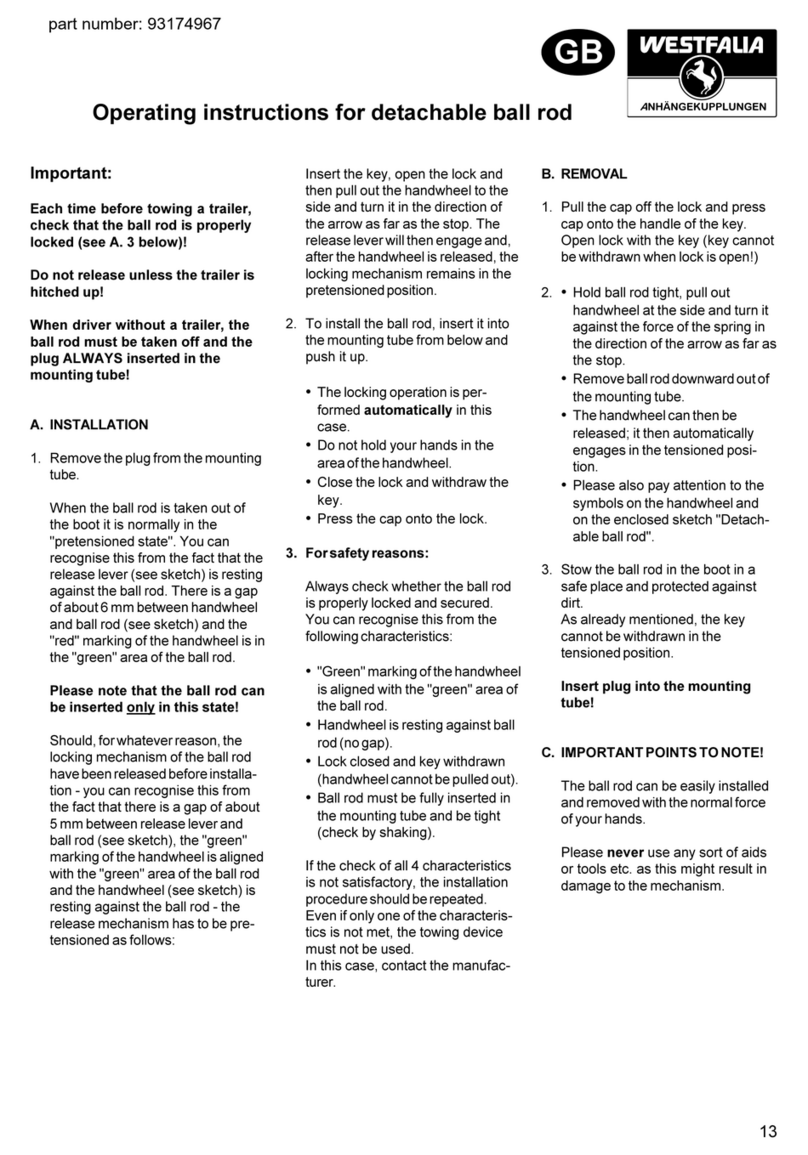

Tonneau Cover

Left Hand Corner Piece

Right Hand Corner Piece

Drill Template

Hinge Base Plates

Hinge Pins

Hinge Pin Locking Tabs

Hex Head Self-tapping Screws

Countersunk Self-tapping Screws

Rubber Extrusion (1xLong, 2xShort)

Gas Strut Brackets

Ball Stud Screws

Lock Striker Brackets

Jacking Brackets

M8 Hex Head Bolts

M8 Hex Nuts

12gx1½” Self-tapping Screws

Plastic Spacers

Component Name Qty Item

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

M6x30mm Screws

M6 Flat Washers

M6 Spring Washers

Pop Rivets

Gas Struts

Clear Protection Pads

Flat Washers (14mm x 5.5mm)

Nut Inserts (4 Spare)

Hex Head Bolt

Wizlock Nut

20mm Allen Screws

Fibre Washers

Rubber Washers

Wiring Harness

Allen Key

Alcohol Wipe

Rust Inhibitor

Keys

Component Name Qty

LIST OF PARTS - 3PC TONNEAU COVER

Drill with Ø5mm, Ø10mm & 3/16” Drill Bits

Masking Tape

Tape Measure

Allen Key Screwdriver bits to suit M8

Non-Acetic Silicon & Caulking Gun

13mm Spanner

Torx Head Screwdriver & Bits

Wrench with 10mm Socket

Non-permanent Marker

Rivet Gun

Phillips & Flat Head Screwdriver

Torque Wrench (¼” Drive)

RECOMMENDED TOOL LIST

21/05/08

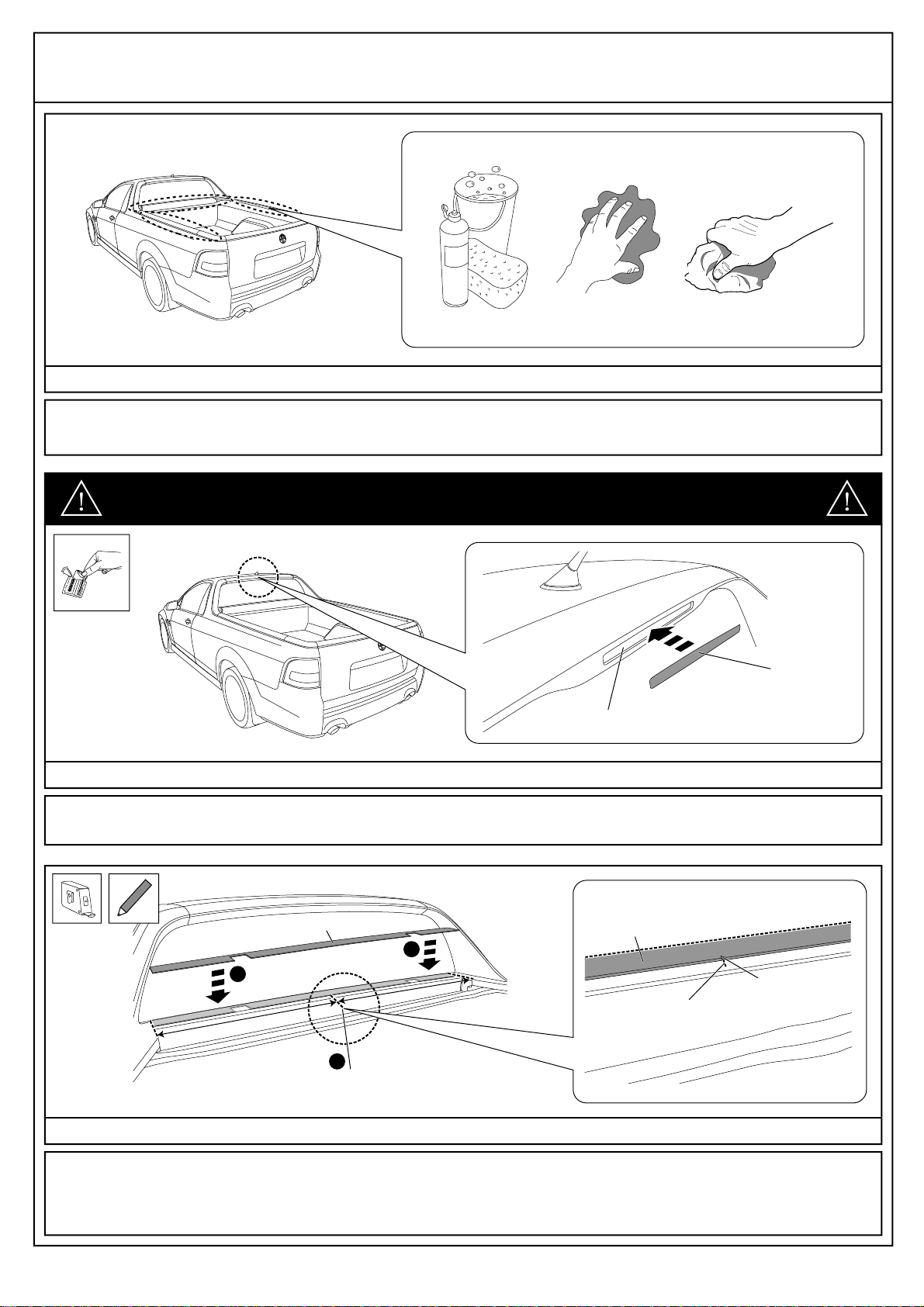

Clean Tonneau Cover & Sports Bar with

a mild detergent and water solution. Do not use abrasive

cleaners or solvents.

Care Instructions:

PLACE THESE INSTRUCTIONS IN VEHICLE’S GLOVE BOX AFTER INSTALLATION IS COMPLETE.

3PC TONNEAU COVER PARTS

TC0123b

page 2 of 28

3PC TONNEAU COVER WITH SPORTS BAR & REMOTE LOCKING

21/05/08

12345

678910

11 12 13 14 15

16 17 18 19 20

21 22 23 24 25

26 27 28 29 30

31 32 33 34 35 36

AUTOMOTIVE

SURFACE CLEANER

IMPREGNATED WITH 70% ISOPROPYLALCOHOL

For use in cleaning painted metal,

glass and other vehicle surfaces.

For external use only.

Dispose of properly after use.

SPORTS BAR PARTS

TC0123b

3PC TONNEAU COVER WITH SPORTS BAR & REMOTE LOCKING

page 3 of 28

Item

1

2

3

4

5

6

7

8

9

10

11

1

1

1

2

2

2

1

1

1

1

2

2

1

1

1

1

4

8

12

4

4

1

Sports Bar Top Tube

Sports Bar Left Hand Leg

Sports Bar Right Hand Leg

Rubber Sleeves

M8x30mm Black Screws Hex Drive

M8 Black Internal Tooth Washers

LED

LED Gasket (attached to LED)

Wiring Connector - Male

Wiring Adapter Loom

M4x30mm Screws

Component Name Qty Item

12

13

14

15

16

17

18

19

20

21

22

M4 Internal Tooth Washers

Foot Gasket Left Hand Front

Foot Gasket Left Hand Rear

Foot Gasket Right Hand Front

Foot Gasket Right Hand Rear

12Gx1½” Self Tapping Screws

M6x20mm Screws

M6 Spring Washers

Washer Plates

Clamping Plates with Tapped Holes

Black Decal

Component Name Qty

LIST OF PARTS - SPORTS BAR

21/05/08

12345

678910

11

17 18 19 20 21 22

12 13 14 15 16

TC0123b

page 4 of 28

3PC TONNEAU COVER WITH SPORTS BAR & REMOTE LOCKING

21/05/08

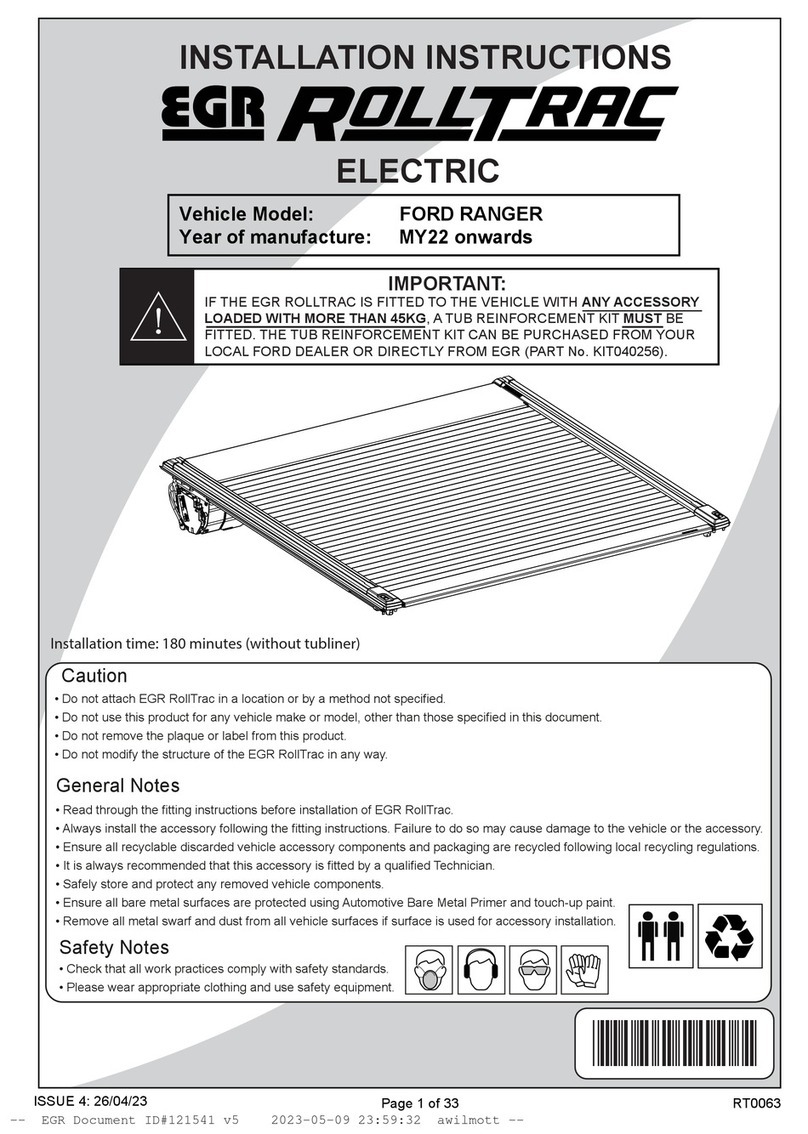

WARNING!

When in the closed position, Tonneau Cover must be locked and tailgate must be closed! Failure to do so could result in unexpected opening of the

Tonneau Cover from sudden wind gusts, which could cause damage to the vehicle and/or your Tonneau Cover!

Warranty Terms

EGR warrants that the ABS Tonneau Cover will be free from defects in material and workmanship for a period of three (3) years from the retail date of

purchase. The gas struts are warranted for one (1) year from the retail date of purchase. This warranty only applies to the original purchaser and is

nontransferable. Warranty must be claimed with original sales receipt for proof of purchase.

Exclusions

This warranty does not cover failure due to neglect, improper installation including any modifications to installation hardware, operating the vehicle

with your EGR Tonneau Cover in the open position, alterations, addition of equipment, abuse, accident, corrosion, normal wear and tear, lack of

maintenance, and exposure to chemicals that are not safe for plastics.

Incidental or consequential damage or loss of contents due to use, neglect, lack of maintenance, misuse of EGR Tonneau Cover is sole responsibility

of the vehicle owner and operator. Paint wear to the vehicle bed can happen with any Tonneau Cover and is the sole responsibility of the vehicle

owner. Paint damage to your vehicle is not covered under this warranty.

Disclaimer

In the event that your EGR Tonneau Cover is found to be defective under the terms of this warranty, it is at the discretion of EGR to repair or replace

the defective part. Transportation costs and labour are not associated with this warranty claim.

Maintenance

Your EGR Tonneau Cover only requires periodic cleaning with mild car wash soap. Only use cleaners, waxes, or products that are labeled safe for use

on plastics. Avoid the use of any chemicals to clean your EGR Tonneau Cover unless labelled safe for plastics.

The gas struts are self lubricating and should only be cleaned occasionally with a damp cloth. Premature seal failure will result if solvents or lubricants

are used to clean struts. Gas struts must be orientated in open Tonneau position with the shaft end attached to the tub.

The locking mechanisms only require occasional lubrication with lithium grease. All installation hardware and fasteners must be checked every so

often for tightness.

Do not cycle remote key fob continuously or the actuator for operation of the remote locking system will burn out.

TONNEAU COVER - IMPORTANT:

• Do not stand/sit or rest heavy objects on Tonneau Cover.

• Humans or animals are not to be under the closed Tonneau Cover at any time.

• Securely lock Tonneau Cover before operating vehicle.

• Do not carry open volatile chemicals with Tonneau Cover installed.

• If contact with volatile chemicals occurs clean Tonneau Cover with mild detergent and water solution.

• Read instructions carefully before installation. It is strongly recommended that installation is conducted by an authorized dealer.

• This product must be installed exactly as specified in these instructions. Failure to do so may result in improper fit and/or retention.

• Recommend installation by 2 people.

SPORTS BAR - IMPORTANT:

Please take care when assembling and installing this product to protect the finish and your investment. To protect your investment, wax this product after

installing. Regular waxing is recommended. Do not use any type of polish or wax that contains abrasives that could damage the finish.

Finish Protection: Our products have a high finish that must be maintained such as any other high finish product on the vehicle. Protect the finish with

a non-abrasive automotive wax. The use of soap, polish, or wax that contains abrasives is detrimental, as the compounds scratch the finish and open

it to corrosion. Use metal polishes - “Autosol” is recommended.

Disclaimer: The buyer assumes all risk and liability whatsoever from the installation and use of our products. Our products are sold as decorative

accessories and should not be relied upon as protection for the vehicle or occupants in the event of a collision or rollover. The manufacturer assumes

no liability for injury, loss, incidental or consequential damages in the event of a collision or rollover.

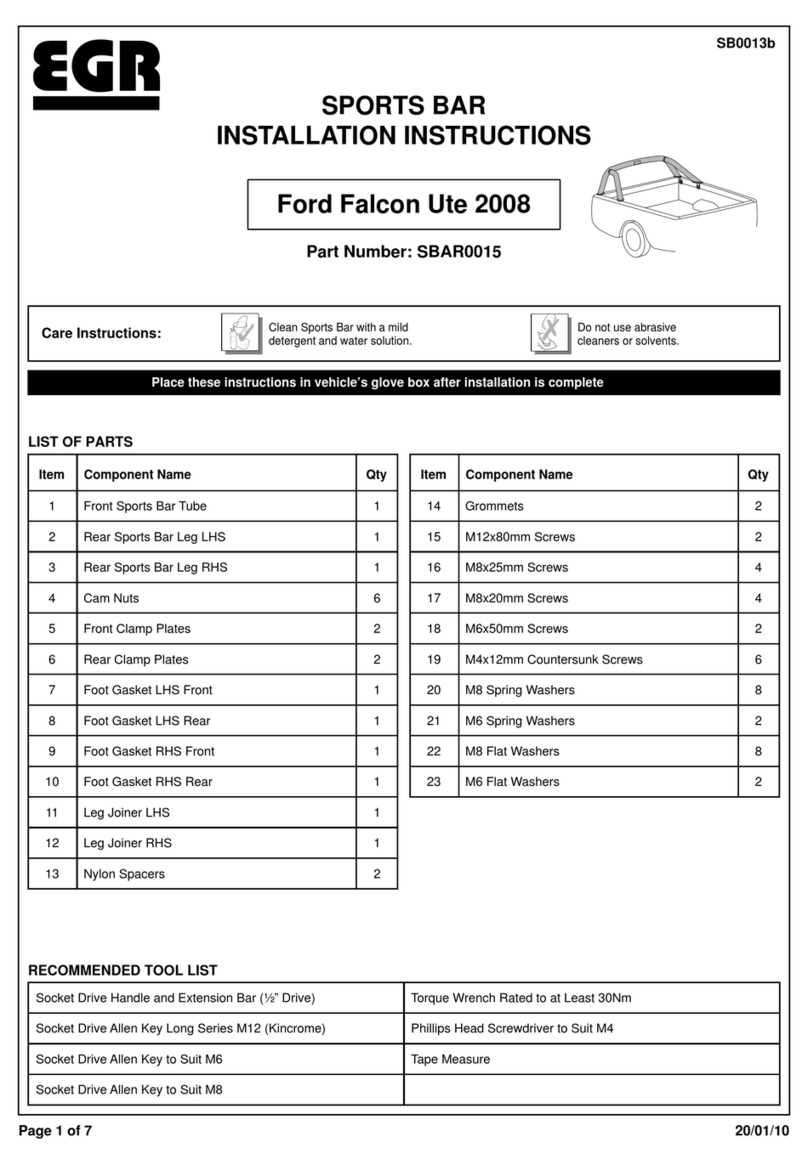

PAINTING INSTRUCTIONS (IF UNPAINTED)

• Sand Tonneau Cover prior to painting recommend 500 grit using an orbital type sander.

• Prior to painting, clean all surfaces to be painted using clean water and a mild detergent, do not use lacquer thinner or any solvent based products.

Wipe completely dry.

• Best results will be achieved by wiping the areas to be painted with a tack rag just prior to painting.

• Select a top coat and clear paint that is suitable for ABS (Acrylonitrile-Butadiene-Styrene).

• Automotive paint systems, such as Acrylics or Two Packs, can be applied directly to the components. However, some paints may require a primer.

If recommendations on paint specification are not followed, cracking of the part or degradation to the material may result. In all paint systems,

aromatic hydrocarbons and alkalies are best avoided to reduce damage to the material properties.

• If using a paint system which requires baking, do not expose the product to temperatures above 70° C (155° F).

• Allow a minimum of 8 hours after baking before installation on the vehicle.

TC0123b

page 5 of 28

3PC TONNEAU COVER WITH SPORTS BAR & REMOTE LOCKING

21/05/08

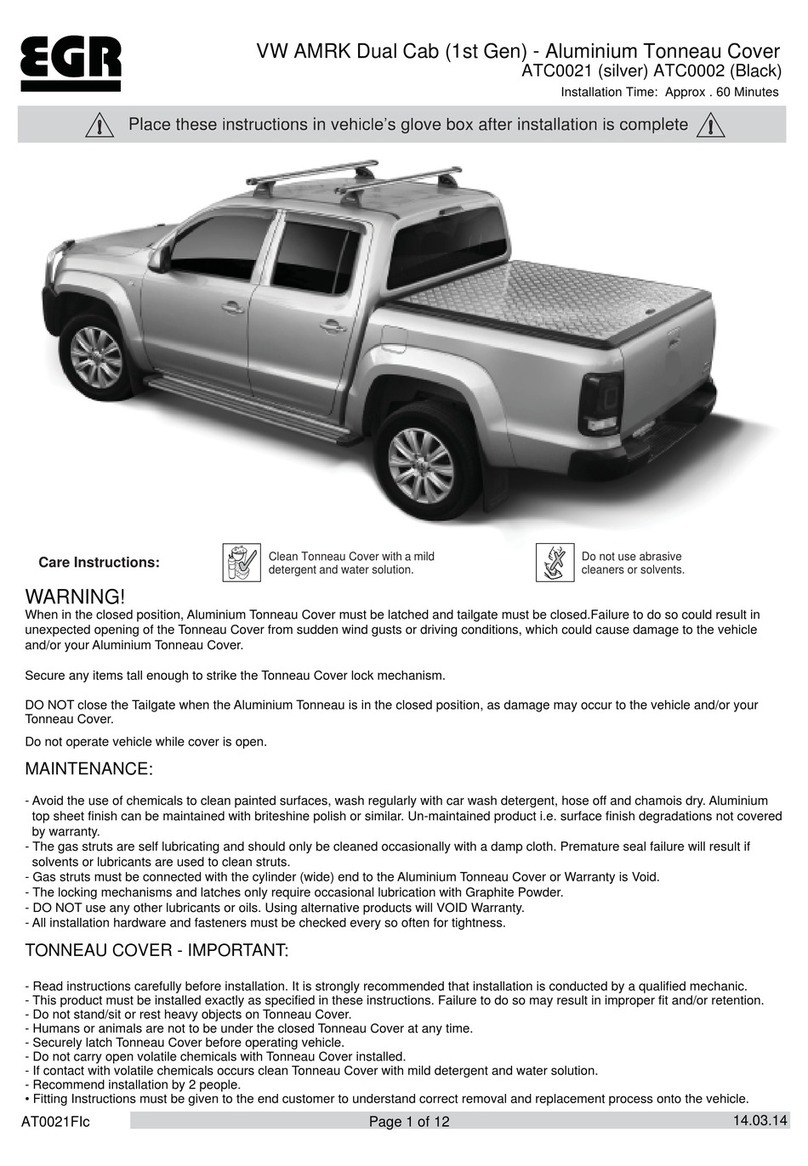

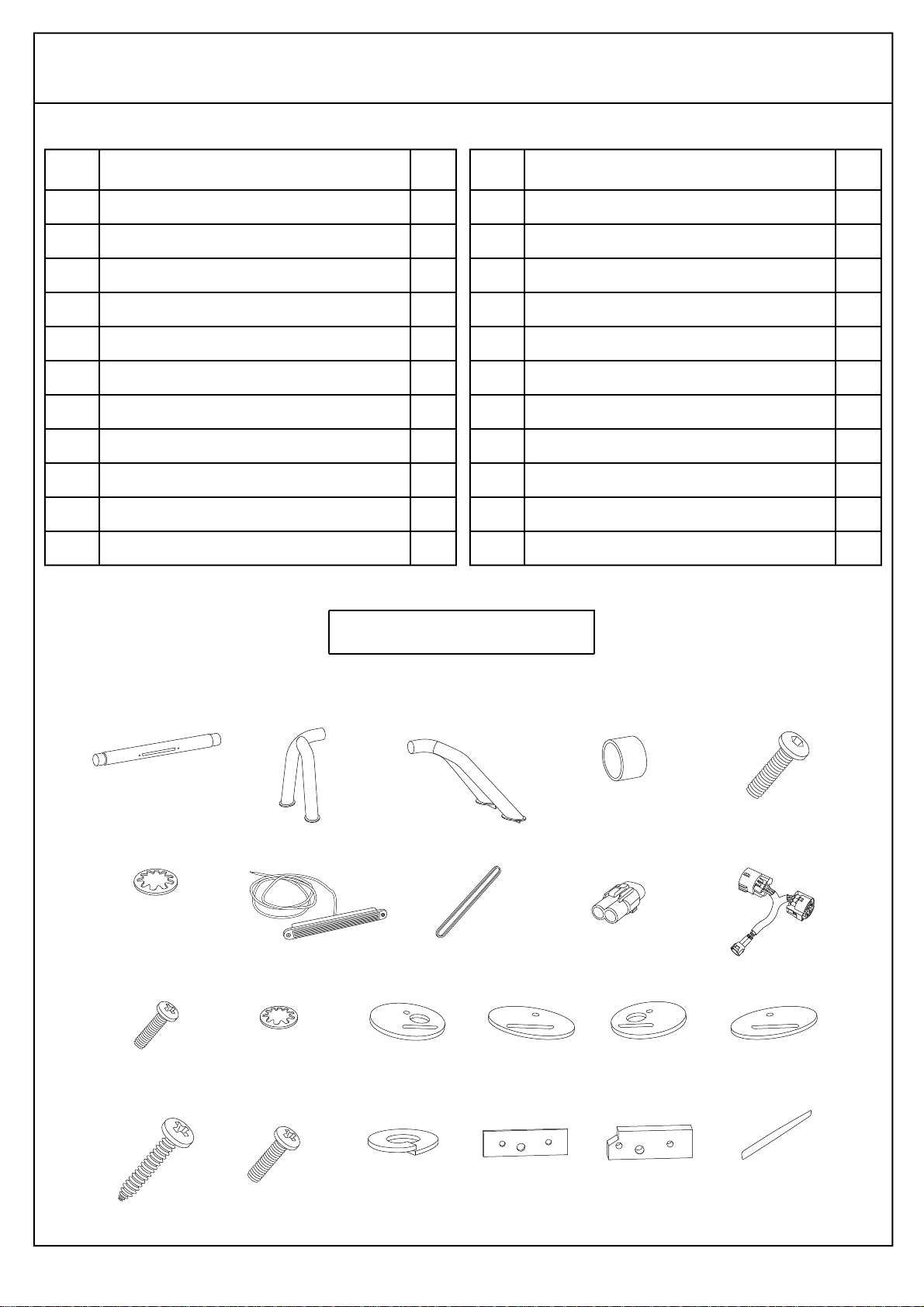

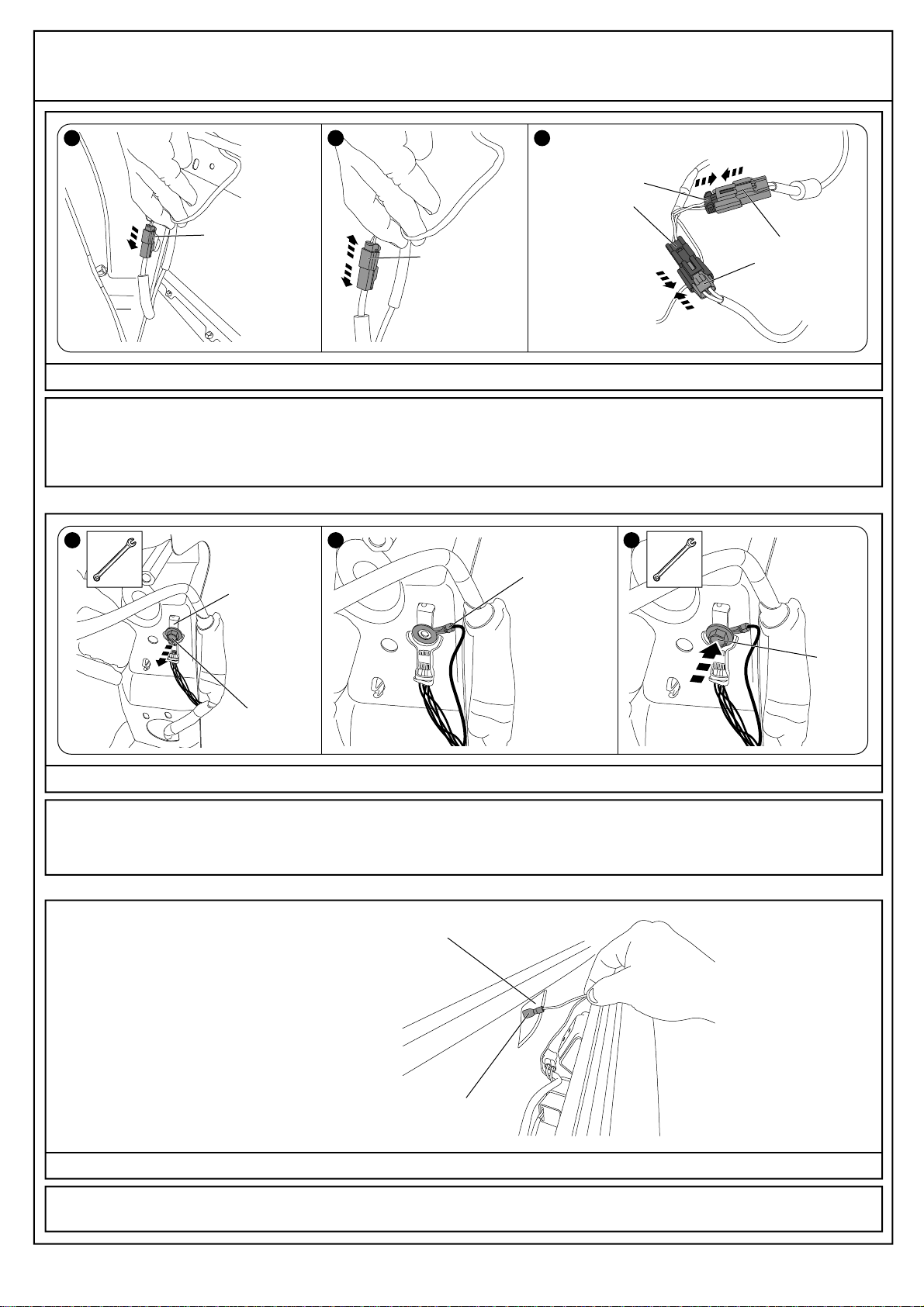

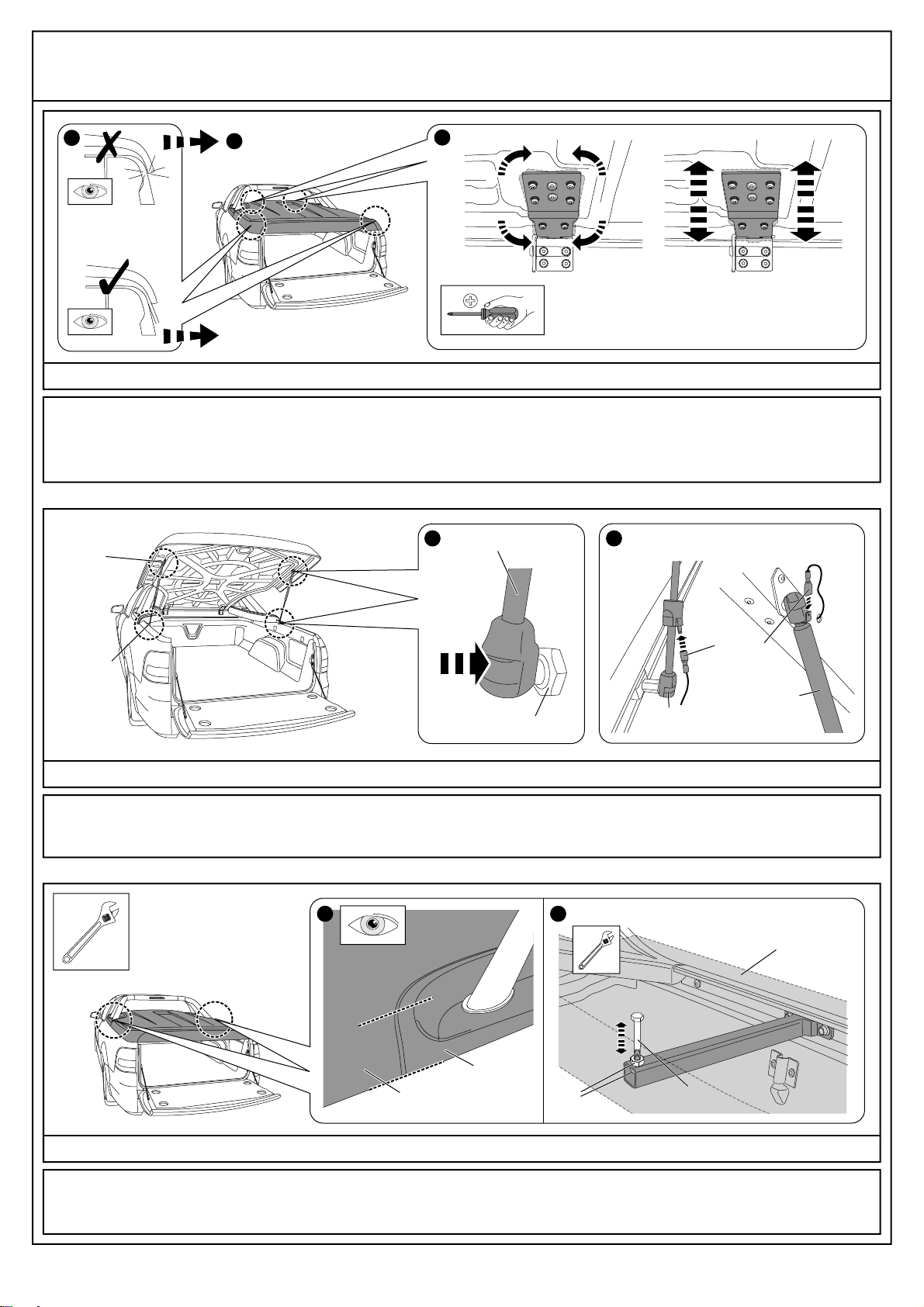

1. NOTE: Two people are required to complete installation. Thoroughly clean and dry the installation areas. See Dia #1.

Diagram #1

2. Clean the LED brake light area with the alcohol wipe provided and wipe away any residue with a dry, clean cloth.After removing the

protective lining, attach the black decal to the LED Brake light as shown, ensuring the brake light is completely covered. See Dia #2.

Diagram #2

IMPORTANT: If vehicle is fitted with an LED brake light at the top of the rear window,

proceed to Diagram #2. Otherwise, proceed to Diagram #3.

BLACK

DECAL

LED BRAKE LIGHT

3. Using a non-permanent marker, find and mark the centre point of the header rail using a tape measure. Position the drill template

on top of header rail, aligning the edge correctly with the rear window and the notch in the centre with the marked centre point on the

header rail as shown. See Dia #3. IMPORTANT: Re-check the centre point of the header rail has been marked correctly.

Drill template MUST be centre.

Diagram #3

DRILL TEMPLATE

FIND AND MARK HEADER RAIL CENTRE POINT

1

2

2

CENTRE POINT

MARKED ON

HEADER RAIL

DRILL

TEMPLATE

NOTCH IN CENTRE

OF DRILL TEMPLATE

REAR WINDOW

TC0123b

page 6 of 28

3PC TONNEAU COVER WITH SPORTS BAR & REMOTE LOCKING

21/05/08

4. Fit hinge base plates into cut-out in drill template as shown. Mark four (4) holes in front of hinge base plate. Remove hinge base

plates. Centre punch previously marked holes and drill Ø5mm holes, followed by Ø10mm holes at the eight (8) positions. Remove any

swarf and apply rust inhibitor to all the drilled holes. Do not remove drill template at this time. See Dia #4.

Diagram #4

10mm

DRILL TEMPLATE

Ø5mm

4 5

Ø10mm

6 7

FIT

1

REMOVE

32

MARK, CENTRE PUNCH,

DRILL Ø5mm THEN Ø10mm HOLES

& APPLY RUST INHIBITOR

DRILL TEMPLATE

HINGE

BASE

PLATE

THIS STEP IS VERY IMPORTANT, PLEASE TAKE THE TIME TO ENSURE THAT IT

IS DONE CORRECTLY.

NOTE: IF YOUR WORKSHOP WILL BE INSTALLING MORE OF THESE TONNEAU COVERS IT IS

RECOMMENDED THAT YOU PURCHASE A PNEUMATIC TOOL TO ASSIST WITH THIS PROCESS.

THIS PNEUMATIC TOOL WILL BOTH ENSURE THE NUTSERTSARE INSTALLED CORRECTLYAND

SUBSTANTIALLY REDUCE INSTALLATION TIME FOR THIS STEP. DETAILS FOR THE

RECOMMENDED TOOL IS AS FOLLOWS:

PRODUCT NAME: THREADED INSERT FASTENING TOOL

MODEL NUMBER: 74200

MANUFACTURER: TEXTRON FASTENING SYSTEMS PTY LTD

ADDRESS: 891 WELLINGTON ROAD, ROWVILLE, VICTORIA, 3178.

CONTACT: PH 03 9764 3877 FAX 03 9755 7352

5. Attach the hex head bolt, wizlock nut and rubber washer to a nut insert as shown. Insert nut insert assembly through drilled hole in

header rail. While holding the wizlock nut in place with a 13mm spanner, tighten the bolt until the nut insert collapses completely in the

drilled hole (the nut insert is collapsed when the bolt starts to become tight, at approx torque 6Nm). Remove bolt, wizlock nut and

rubber washer. Repeat process for the remaining seven (7) drilled holes. See Dia #5.

NOTE: Replace rubber washer during each installation.

Diagram #5

NUT

INSERT

RUBBER

WASHER

WIZLOCK

NUT

NUT

INSERT

HEX

HEAD BOLT

REMOVE

HEX HEAD

BOLT

REMOVE

WIZLOCK NUT

REMOVE

RUBBER

WASHER

1 2 3 4

NUT INSERT

ASSEMBLY

HEADER RAIL

13MM

SPANNER

(HOLD NUT)

WIZLOCK NUT

ROTATE

BOLT

UNTIL TIGHT

(WITH 10MM

SOCKET)

HEADER RAIL

13mm

10mm 10mm10mm

7. Drive the countersunk self-tapping screw through the hole in the top surface both of the hinge base plates. Tighten to torque 3Nm.

See Dia #7.

Diagram #7

8.Attach the LED and the LED gasket to the Sports Bar top tube using the M4x30mm screws and M4 internal tooth washers as shown.

Tighten to torque 2Nm. Ensure the wiring connected to the LED is fed through the Sports Bar top tube and out the end as shown.

See Dia #8. NOTE: Ensure the warning label is orientated correctly. If wording is upside-down flip bar 180º, but ensure LED

wiring loom comes out the right hand end of the Sports Bar top tube.

Diagram #8

TC0123b

page 7 of 28

3PC TONNEAU COVER WITH SPORTS BAR & REMOTE LOCKING

21/05/08

COUNTERSUNK

SELF-TAPPING

SCREWS

HINGE

BASE

PLATE

TORQUE 3Nm

TOP TUBE

LED WIRING

LED

M4 INTERNAL

TOOTH

WASHERS

M4x30 SCREWS

TORQUE 2Nm

LED GASKET

6.Apply non-acetic silicon to the underside of the hinge base plates and position on the vehicle, aligning the four (4) holes on the hinge

with those on the header rail as well as inside the cut-out of the drill template. Position hinge pin locking tabs with the tabs to the left

hand of the hinge base plate across the top two fixing holes. Use the allen screws and fibre washers supplied to secure the hinges.

Tighten to torque 8Nm. See Dia #6.

Diagram #6

1

NON-ACETIC

SILICON &

CAULKING GUN

HINGE

BASE

PLATE HINGE BASE

PLATES

DRILL TEMPLATE

22

3HINGE BASE

PLATE

HINGE PIN

LOCKING TAB

ALLEN SCREWS

FIBRE WASHERS

TORQUE 8Nm

10. Loosely attach the Sports Bar top tube to the Sports Bar left hand and right hand leg using the M8x30mm black screw and M8 black

internal tooth washer as shown. Do not tighten yet. See Dia #10.

Diagram #10

9. Slide the rubber sleeves over the ends of the Sports Bar left hand leg and right hand leg and then slide the Sports Bar top tube in

as shown. Ensure that all holes are aligned with each other, and that the LED wiring is fed through the large hole in the bottom of the

Sports Bar right hand front leg. See Dia #9. NOTE: Ensure the warning label is orientated correctly. If wording is upside-down

flip bar 180º.

Diagram #9

11. Note the protective lining on back of Sports Bar foot gaskets. Trial fit the gaskets to the Sports Bar to determine which foot they are

fitted to. Remove the lining before attaching in next step. See Dia #11.

Diagram #11

TOP TUBE

RUBBER

SLEEVE

LEFT HAND

LEG

RIGHT HAND

LEG

RUBBER

SLEEVE

LEG

LEG

RUBBER

SLEEVE

RUBBER

SLEEVE

TOP

TUBE

TOP

TUBE

RIGHT

HAND

FRONT

LEG

LED

WIRING

NO POWER

TOOLS

M8 INTERNAL

TOOTH WASHER

M8x30 BLACK SCREW

FOOT GASKET

RIGHT HAND FRONT

FOOT GASKET

RIGHT HAND REAR

FOOT GASKET

LEFT HAND FRONT

FOOT GASKET

LEFT HAND REAR

TC0123b

page 8 of 28

3PC TONNEAU COVER WITH SPORTS BAR & REMOTE LOCKING

21/05/08

TC0123b

page 9 of 28

3PC TONNEAU COVER WITH SPORTS BAR & REMOTE LOCKING

21/05/08

14. Open the vehicle’s tailgate. Remove the two (2) push rivets and peel back the rubber tailgate seal as far as the base of the tailgate

as shown. See Dia #14.

Diagram #14

12. Attach the foot gaskets to their correct Sports Bar foot as shown, ensuring the holes in the Sports Bar feet remain accessible.

Repeat process for the other side of the vehicle. See Dia #12.

Diagram #12

13. Remove the three (3) tie-down brackets on the right hand of the bed using a torx-head screwdriver as shown. See Dia #13.

Diagram #13

RIGHT HAND SHOWN

FOOT GASKET

RIGHT HAND REAR

LED WIRING

SPORTS BAR

RIGHT HAND LEG

FOOT GASKET

RIGHT HAND FRONT

12

2

3

PUSH

RIVETS

TAILGATE

SEAL

TORX HEAD SCREWS

TIE-DOWN BRACKETS RIGHT HAND VIEW INSIDE VEHICLE TUB

15. Lift and pull the bedliner as shown to gain access to the wiring located in the side panel of the vehicle. Disconnect the stop light

wiring plug located behind the bedliner, by pushing down on the tag on the connector using you finger or a flat blade screwdriver.

See Dia #15. NOTE: This connector is located above the wheel arch towards the rear of the vehicle.

Diagram #15

16. The hardware kit contains both the wiring adapter loom and the wiring harness. As only the wiring harness is required for this

installation, do not use the wiring adapter loom. See Dia #16.

Diagram #16

TC0123b

page 10 of 28

3PC TONNEAU COVER WITH SPORTS BAR & REMOTE LOCKING

21/05/08

17. Insert the wiring harness supplied in hardware kit between the two stop light wiring plugs as shown. See Dia #17.

Diagram #17

BEDLINER STOP LIGHT

WIRING PLUG

BEDLINER

TAILGATE

SEAL

1 2

DISCONNECT

WIRING ADAPTER

LOOM WIRING

HARNESS

DISCARD KEEP

STOP LIGHT

WIRING PLUG

STOP LIGHT

WIRING PLUG

WIRING HARNESS

SUPPLIED IN

HARDWARE KIT

CONNECT

CONNECT

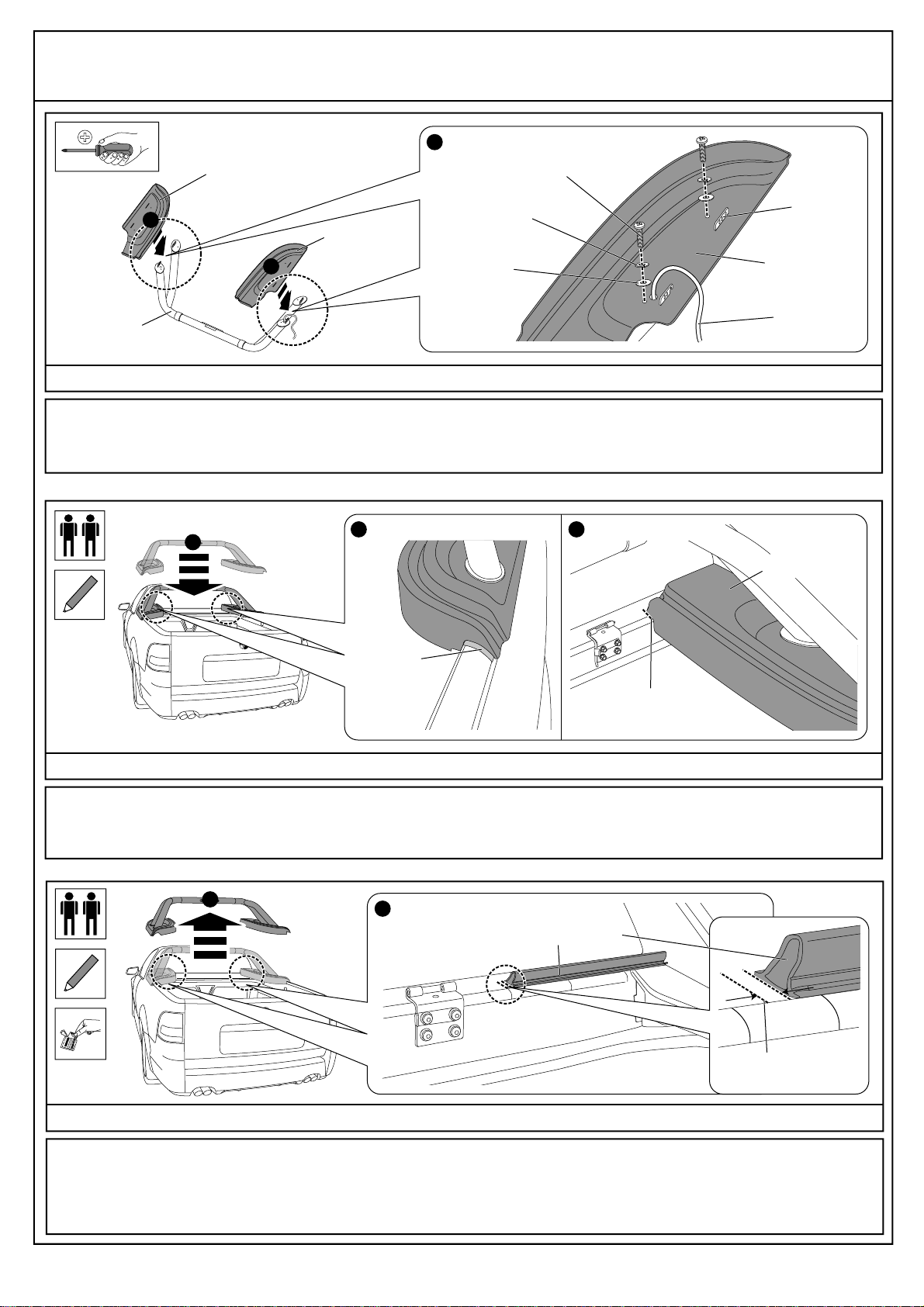

18. Find the white 2-way connectors on the vehicle (directly behind the wheel arch) and unclip them from the vehicle as shown.

Disconnect the white 2-way connectors. Connect the white 2-way connectors on the wiring harness to the white 2-way connectors from

the vehicle as shown. Finally clip either of the white 2-way connectors back to where they were previously unclipped from the vehicle.

See Dia #18.

Diagram #18

2-WAY

CONNECTORS

(VEHICLE)

EARTH WIRE

TERMINAL

(VEHICLE)

EARTH WIRE

TERMINAL

(WIRING

HARNESS)

BOLT

BOLT

RE-ATTACH

BOLT

UNCLIP FROM

MOUNT DISCONNECT

TC0123b

page 11 of 28

3PC TONNEAU COVER WITH SPORTS BAR & REMOTE LOCKING

21/05/08

19. Find the earth wire terminal behind the bedliner near the vehicle’s tailgate and remove the bolt holding the terminal together as

shown. Locate the earth wire from the wiring harness and locate it over the hole that the bolt was just removed from. While holding

everything in place, re-attach the bolt to the earth wire terminal on the vehicle as shown. See Dia #19.

Diagram #19

20. Find the middle tie down bracket hole and push the spade terminal from the wiring harness through it as shown. See Dia #20.

Diagram #20

1

1

2-WAY

CONNECTORS

(VEHICLE)

2-WAY

CONNECTORS

(VEHICLE)

2-WAY

CONNECTORS

(WIRING HARNESS)

CONNECT

CONNECT

2 3

3

REMOVE

BOLT

2

MIDDLE TIE DOWN BRACKET HOLE

PUSH SPADE TERMINAL THROUGH

HOLE IN BEDLINER

SPADE TERMINAL

(WIRING HARNESS)

23. Centre punch and drill Ø5mm holes at the two (2) outer hole positions marked in the previous Diagram. Remove any drill swarf and

apply rust inhibitor. Repeat process for the other side of the vehicle. Attach the M8 hex head bolt and M8 hex nuts to the jacking

brackets as shown. Do not install the jacking bracket at this time. See Dia #23.

Diagram #23

22. Trial-fit the jacking bracket by sliding it into the side rail and aligning it with the bedliner fixture as shown. Mark the two (2) outer hole

positions on the jacking bracket. Remove the jacking bracket from the side rail. Repeat process for the other side of the vehicle.

See Dia #22.

Diagram #22

RIGHT HAND SHOWN

FRONT VIEW

JACKING

BRACKET LINER

FIXTURE

LINER

FIXTURE

x2

JACKING

BRACKET

SIDE RAIL

MARK HOLES

ALIGN

RIGHT HAND SHOWN

1

SIDE VIEW

2

Ø5mm

CENTRE PUNCH,

DRILL Ø5mm HOLES &

APPLY RUST INHIBITOR

M8 HEX

HEAD BOLT

JACKING BRACKET

M8 HEX

NUTS

TC0123b

page 12 of 28

3PC TONNEAU COVER WITH SPORTS BAR & REMOTE LOCKING

21/05/08

4-WAY GREY

CONNECTOR

WIRING HARNESS

(BEHIND BEDLINER)

21. Run the grey 4-way connector from the wiring harness all the way to the front of the tub behind the bedliner as shown. At the front

of the tub, pull the grey 4-way connector 200mm out from behind the bedliner as shown. See Dia #21.

Diagram #21

4-WAY GREY CONNECTOR

(WIRING HARNESS)

WIRING HARNESS

200mm

TC0123b

page 13 of 28

3PC TONNEAU COVER WITH SPORTS BAR & REMOTE LOCKING

21/05/08

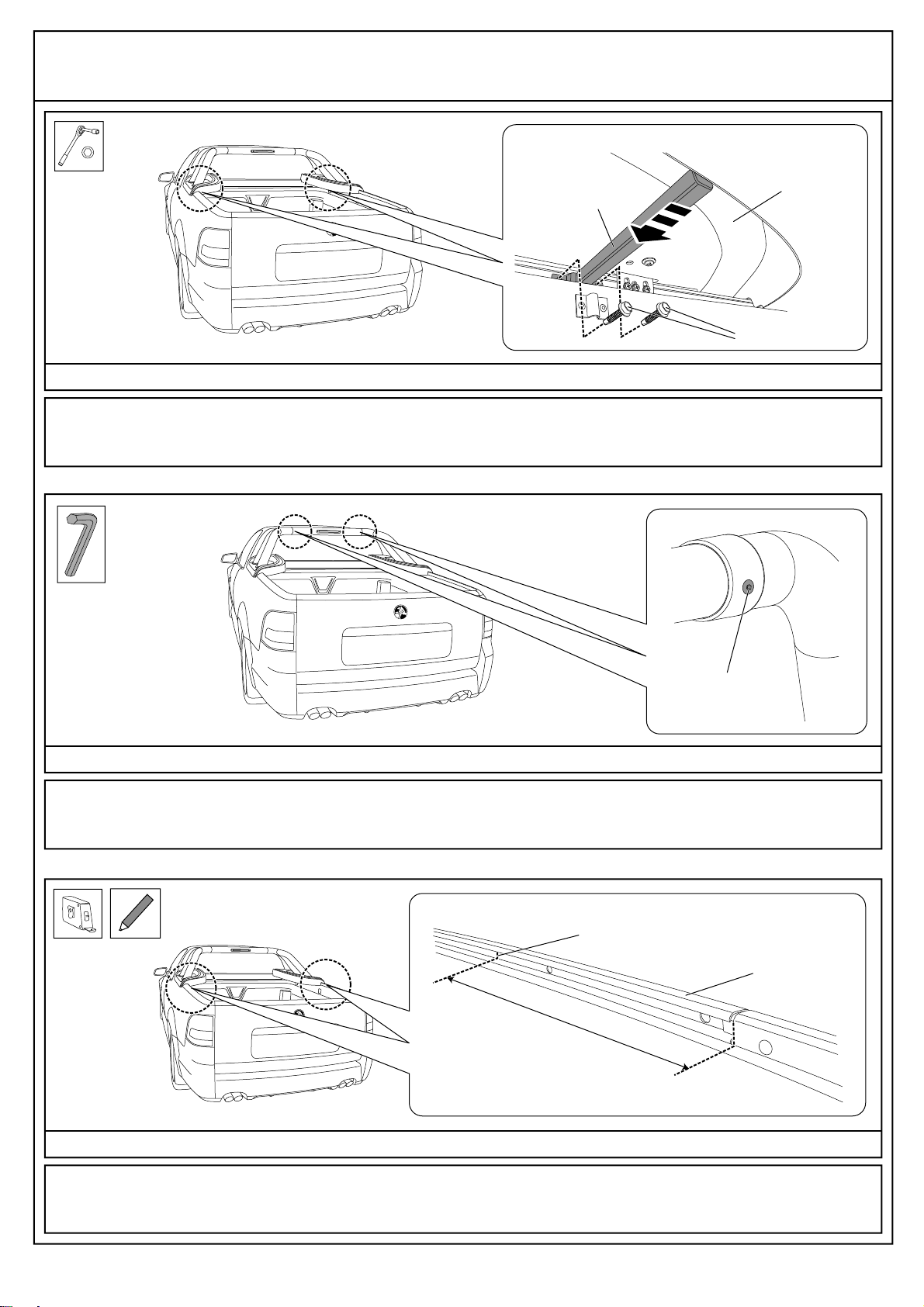

24. Fit the corner pieces to the Sports Bar feet as shown. Fasten the corner pieces in place using the M6x30mm screws, M6 spring

washers, and M6 flat washers as shown. Leave the screws loose - do not tighten yet. See Dia #24.

Diagram #24

25. Trial-fit Sports Bar onto vehicle. To protect the vehicle’s paint work, attach a clear protection pad where the corner piece meets the

side rail as shown. Draw a line along the edge of the corner piece where it meets the header rail as shown. Repeat process for the

other side of the vehicle. See Dia #25.

Diagram #25

RIGHT HAND

CORNER PIECE

LEFT HAND

CORNER PIECE

SPORTS

BAR

1

1

RIGHT HAND SHOWN

2

LED WIRING

LOOM

RIGHT HAND

CORNER PIECE

SPORTS

BAR

M6x30mm SCREWS

M6 SPRING

WASHER

M6 FLAT

WASHER

1

DRAW LINE

AGAINST EDGE

CLEAR

PROTECTION

PAD

RIGHT HAND SHOWNRIGHT HAND SHOWN

26. Remove the Sports Bar from the vehicle. Draw a parallel line 3mm to the RIGHT of the original line. Clean the header rail with

alcohol wipe provided and wipe away any residue with a clean cloth. Remove the protective liner from the rubber extrusion and attach

it to the header rail as shown. Rub down firmly to ensure good adhesion. Repeat process for the other side of the vehicle, ensuring the

parallel line is drawn 3mm to the LEFT of the original line. See Dia #26. IMPORTANT: Ensure the slant in the rubber extrusion is facing

towards the rear of the vehicle and the rubber extrusion is positioned as close to the front face of the header rail as shown.

Diagram #26

12RIGHT HAND SHOWN

RUBBER EXTRUSION

3mm

LINE DRAWN IN

PREVIOUS STEP

RIGHT HAND

CORNER PIECE

32

TC0123b

page 14 of 28

3PC TONNEAU COVER WITH SPORTS BAR & REMOTE LOCKING

21/05/08

27. Trial-fit the rubber extrusion to the header rail, aligning it with the back of the hinge base plates as shown and to the first previously

marked line. Using a non-permanent marker, draw a line along the length of the rubber extrusion. Clean the header rail with alcohol

wipe provided and wipe away any residue with a clean cloth. Remove the protective lining from the extrusion and attach it to the header

rail, aligning it with the drawn line. Rub down firmly to ensure good adhesion. See Dia #27.

IMPORTANT: Ensure the slant in the rubber extrusion is facing towards the rear of the vehicle.

Diagram #27

29. Slide the clamping plates with tapped holes into the side rail and locate centrally over the top of the previously drilled holes. Repeat

process for the other side of the vehicle. See Dia #29.

Diagram #29

28. Using a torx head screwdriver, remove and discard the torx screws from the front two (2) holes on the side rail as shown. Repeat

for the other side of the vehicle. Drill out all four (4) holes with a Ø3/16” drill. Clean away swarf from drill and drilled holes. See Dia #28.

NOTE: Be careful not to drill through the outside rail. Use 10mm drill stop as shown.

Diagram #28

10mm

SIDE RAIL

REMOVE

RIGHT HAND SHOWN RIGHT HAND SHOWN SIDE RAIL

1 2

SIDE RAIL

CLAMPING PLATES

WITH TAPPED HOLES

RIGHT HAND SHOWN

Ø3/16”

RUBBER

EXTRUSION

DRAWN LINE

TRIAL-FIT RUBBER EXTRUSION

1MARK LINE ALONG EXTRUSION

2CLEAN WITH ALCOHOL WIPES

3REMOVE PROTECTIVE LINING

4ATTACH RUBBER EXTRUSION

5

FIRST MARKED LINE

DRILL OUT HOLES

WITH 3/16” DRILL

TC0123b

page 15 of 28

3PC TONNEAU COVER WITH SPORTS BAR & REMOTE LOCKING

21/05/08

30. Fit the Sports Bar to the vehicle as shown. Note the corner piece positions over the top of the previously installed rubber extrusion.

Ensure the corner pieces are tightly fitted around the vehicle sail-plane panels, then tighten the M6 screws as shown. Tuck the LED

wiring loom up under the side rail and behind the bedliner as shown. See Dia #30.

Diagram #30

31.Attach the male wiring connector to the wiring adapter loom as shown. Feed the LED wiring loom along the inside of the side panel

and attach it to the male wiring connector. Ensure the male wiring connector is orientated correctly when attaching. See Dia #31.

* IMPORTANT: CHECK THE WIRING ADAPTER LOOM AND THE CORRECT LOCATION OF THE RED BRAKE SIGNAL WIRE TO

ENSURE THEY MATCH WHEN THE WIRES ARE INSERTED INTO THE MALE CONNECTOR. IF THE WIRES DO NOT MATCH,

THE SPORTS BAR LED WILL NOT FUNCTION.

Diagram #31

1

LED WIRING

LOOM

BEDLINER

BULB SEAL

ENSURE

TIGHT

FIT

TIGHTEN

M6 SCREWS

SPORTS BAR

RIGHT HAND LEG

CLAMPING

PLATE

2

WHITE LED

CONNECTOR

WIRING

HARNESS

LED

WIRING

LOOM

RIGHT HAND ONLY

3

WHITE LED

CONNECTOR

RED

“CLICK”

*

MALE WIRING CONNECTOR

!

“CLICK”

1

2

32. Re-attach the bedliner by lifting it back into position, re-installing the tie-down brackets (torque 10Nm), the push rivets and the

tailgate seal as shown. Ensure there is at least 150mm of the spade terminal protruding through the bedliner and that it is positioned

at the rear of the bracket and half way up the edge of the bracket. See Dia #32.

Diagram #32

TORX HEAD

SCREWS

(TORQUE 10Nm)

TIE-DOWN

BRACKETS

2

1

1

1

2

3

PUSH

RIVETS

TAILGATE

SEAL

RIGHT HAND VIEW INSIDE

VEHICLE TUB

150mm

SPADE

TERMINAL

TC0123b

page 16 of 28

3PC TONNEAU COVER WITH SPORTS BAR & REMOTE LOCKING

21/05/08

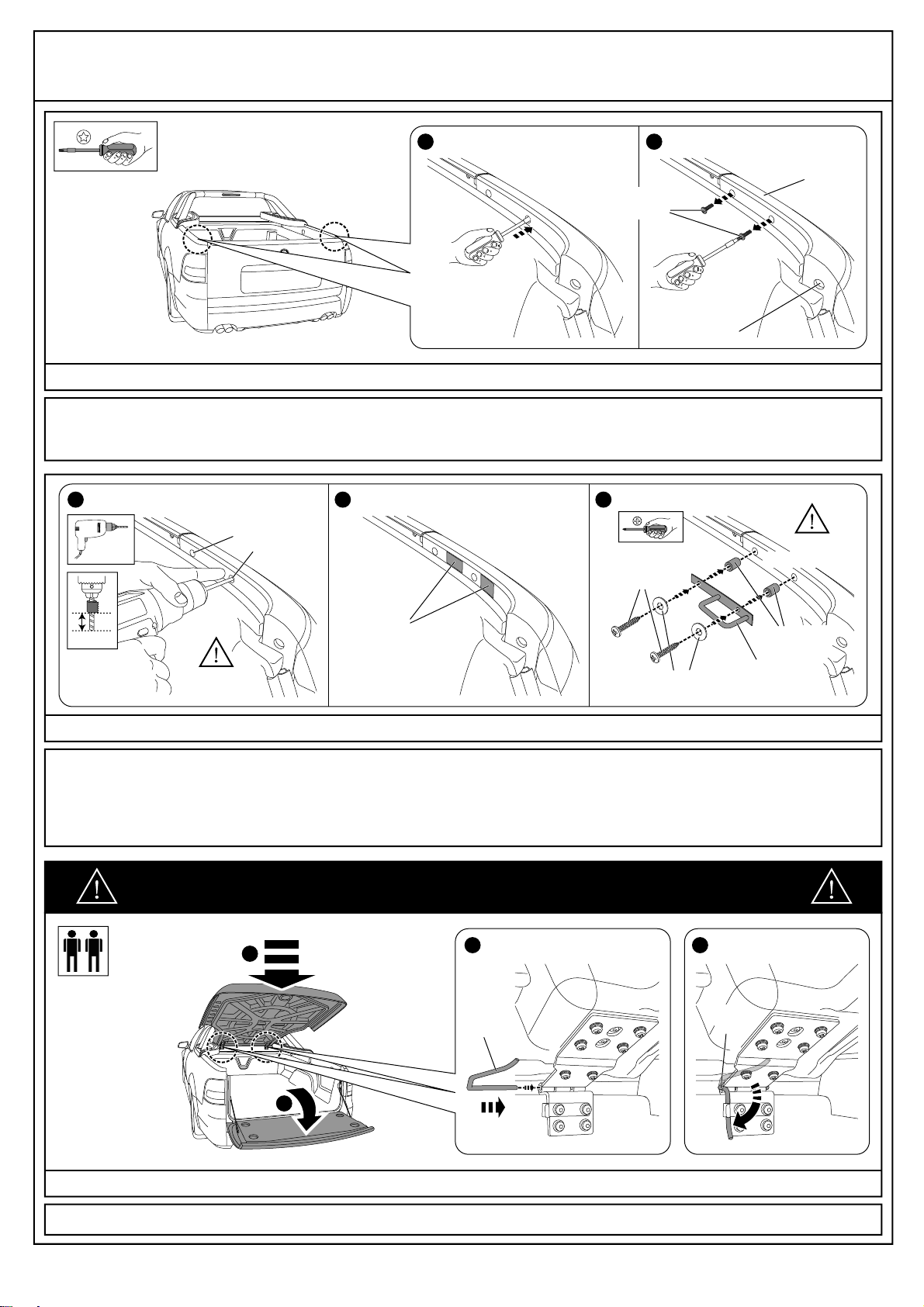

33. Attach the Sports Bar front legs to the clamping plates and side rails using the 12Gx1½” self tapping screws, M6 spring washers

and washer plates as shown. Do not tighten yet. Repeat process for the Sports Bar rear legs. See Dia #33.

Diagram #33

34. Attach the Sports Bar front legs to the clamping plates using the M6x20mm screws and M6 spring washers as shown. Do not

tighten yet. Repeat process for the Sports Bar rear legs. See Dia #34.

Diagram #34

35. Tighten all the screws on the Sports Bar right hand leg in the order A - B - C - D - E - F. TightenA, B, D & E to torque 12Nm. Tighten

C & F to torque 10Nm. Repeat process for the Sports Bar left hand leg. Visually check that all scews are home and all spring washers

are compressed. See Dia #35.

Diagram #35

CLAMPING

PLATE

M6 SPRING

WASHER

12Gx1½” SELF

TAPPING

SCREW

WASHER

PLATE

CLAMPING

PLATE

RIGHT HAND SHOWN RIGHT HAND SHOWN

RIGHT HAND

FRONT LEG RIGHT HAND

REAR LEG

M6 SPRING

WASHER

12Gx1½” SELF

TAPPING

SCREW

1 2

WASHER

PLATE

CLAMPING

PLATE

M6 SPRING

WASHER

M6x20 SCREW

M6x20 SCREW

WASHER

PLATE

CLAMPING

PLATE

RIGHT HAND SHOWN RIGHT HAND SHOWN

M6 SPRING

WASHER

WASHER

PLATE

1 2

RIGHT HAND

FRONT LEG RIGHT HAND

REAR LEG

TIGHTEN

TORQUE 12Nm

RIGHT HAND SHOWN RIGHT HAND SHOWN

1

DE

F

TIGHTEN

TORQUE 12Nm

TIGHTEN

TORQUE 10Nm

TIGHTEN

TORQUE 12Nm

C

AB

2

RIGHT HAND

FRONT LEG

RIGHT HAND

REAR LEG

TIGHTEN

TORQUE 10Nm

TIGHTEN

TORQUE 12Nm

TC0123b

page 17 of 28

3PC TONNEAU COVER WITH SPORTS BAR & REMOTE LOCKING

21/05/08

37. Tighten the M8x30mm black screws in the Sports Bar Top Tube as shown. Tighten to torque 7Nm. See Dia #37.

Diagram #37

TIGHTEN

TORQUE 7Nm

36. Attach the jacking bracket to the side rail using the hex head self-tapping screws as shown. Tighten to torque 3Nm. Repeat the

process for the other side of the vehicle. See Dia #36.

Diagram #36

38. Using a non-permanent marker, measure and mark (on the inside of the side rail), 500mm from the end of the vehicle’s rear side

rail panel as shown. Repeat process for the other side of the vehicle. See Dia #38.

Diagram #38

RIGHT HAND SHOWN

SIDE RAIL

MARK HERE

(ON INSIDE OF SIDE RAIL)

500mm

RIGHT HAND SHOWN

TORQUE

3Nm

FIT

HEX HEAD SELF-

TAPPING SCREWS

UNDERSIDE

OF CORNER

PIECE

JACKING

BRACKET

TC0123b

page 18 of 28

3PC TONNEAU COVER WITH SPORTS BAR & REMOTE LOCKING

21/05/08

40. Attach the gas strut bracket to the side rail using the hex head self-tapping screws as shown. Tighten to torque 3Nm. Attach ball

stud screw to the gas strut bracket as shown. Tighten to torque 4Nm. Repeat process for the other side of the vehicle. See Dia #40.

Diagram #40

41. Drill Ø5mm holes through the plastic plugs located in the rear of the side rail as shown. Remove the plugs using a screwdriver.

Repeat process for the other side of the vehicle. See Dia #41.

Diagram #41

GAS STRUT

BRACKET

SELF-TAPPING

SCREW

TORQUE 3Nm

SELF-TAPPING

SCREW

TORQUE 3Nm

BALL STUD

SCREW

TORQUE 4Nm

RIGHT HAND SHOWN

1

12

10mm

Ø5mm RIGHT HAND SHOWN RIGHT HAND SHOWN

REMOVE

DRILL

PLASTIC

PLUGS

1 2

39. Fit the gas strut bracket into the side rail, aligning it with the previously drawn mark as shown. Centre punch and drill Ø5mm holes

at the two (2) outer hole positions on the gas strut bracket. Clean away drill swarf and apply rust inhibitor to the drilled holes and repeat

process for the other side of the vehicle. See Dia #39.

Diagram #39

10mm

Ø5mm

1 2 3

GAS STRUT

BRACKET

ALIGN BRACKET

WITH MARK

CENTRE PUNCH,

DRILL Ø5mm HOLES &

APPLY RUST INHIBITOR

RIGHT HAND

SHOWN

TC0123b

page 19 of 28

3PC TONNEAU COVER WITH SPORTS BAR & REMOTE LOCKING

21/05/08

44. Open vehicle’s tailgate. Fit Tonneau Cover and secure hinges with hinge pins as shown. See Dia #44.

Diagram #44

IMPORTANT: Ensure vehicles’s tailgate is opened before installing Tonneau Cover,

as locking mechanism may not function until adjusted correctly.

“CLICK”

RIGHT HAND SHOWN

4

HINGE

PIN

HINGE

PIN

RIGHT HAND SHOWN

3

2

1

43. Drill the threads in the side rail panel using a Ø3/16” drill with a 10mm drill stop as shown. Clean away drill swarf. To prevent paint

scratching, attach two (2) clear protection pads to the side rail panel as shown.Attach the lock striker bracket to the side rail panel using

the 12g self-tapping screws, flat washers (14mm x 5.5mm) and plastic spacers as shown. DO NOT OVERTIGHTEN! Repeat process

for the other side of the vehicle. See Dia #43. NOTE: Plastic spacers fit inside the side rail panel between the thread nut and lock

striker bracket.

Diagram #43

RIGHT HAND SHOWN RIGHT HAND SHOWN

ATTACH

RIGHT HAND SHOWN

DRILL THREAD

WITH Ø3/16”

DRILL 12gx1½”

SELF-TAPPING

SCREWS

CLEAR

PROTECION

PADS

FLAT WASHERS

(14mm x 5.5mm)

1 32

USE 10mm

DRILL STOP

LOCK STRIKER

BRACKET

PLASTIC

SPACERS

DO NOT

OVER-TIGHTEN

10mm

Ø3/16”

42. Using a torx head screwdriver, retrieve the torx head screws from inside the side rail panel as shown. If you drop one of the torx

head screws inside the panel, simply remove the 3rd screw and slide the panel upwards to retrieve it. Repeat process for the other side

of the vehicle. See Dia #42.

Diagram #42

RIGHT HAND SHOWN RIGHT HAND SHOWN

1 2

TORX HEAD

SCREWS

3RD SCREW

SIDE RAIL

PANEL

45. Check Tonneau Cover is central to vehicle and the sides of Tonneau Cover do not contact the vehicle bed rail. Adjust position if

necessary by loosening the top hinge screws and re-positioning Tonneau Cover to fit centrally on vehicle. Re-tighten hinges to torque

5Nm. See Dia #45.

Diagram #45

46. Attach the gas struts by clipping them into place as shown. ENSURE THE NARROW END MOUNTS TO THE VEHICLE. Connect

the wiring harness to the terminals on the driver’s side gas strut as shown. See Dia #46. NOTE: Attach gas strut with terminals to

the driver’s side of the vehicle.

Diagram #46

TC0123b

page 20 of 28

3PC TONNEAU COVER WITH SPORTS BAR & REMOTE LOCKING

21/05/08

NEXT STEP

RE-TORQUE 5Nm

ENSURE

CLEARANCE

TO TUB

LOOSEN HINGE SCREWS

TO ADJUST TONNEAU

POSITION IF NECESSARY

122

GAS STRUT DRIVER’S SIDE ONLY

47. Adjust jacking bolts until corner pieces are level with the main surface of the Tonneau Cover. Once in the correct position, lock the

M8 nuts into position against the bracket using a spanner. Repeat for other side of vehicle. See Dia #47.

Diagram #47

RIGHT HAND SHOWN

CORNER

PIECE

TONNEAU

COVER

1 2

M8

NUTS

M8 HEX

HEAD BOLT

CORNER

PIECE

LARGE

END

NARROW

END

1 2

GAS STRUT

BOTTOM

GAS

STRUT

TOP

WIRING

HARNESS

Table of contents

Other EGR Automobile Accessories manuals