8 of 9

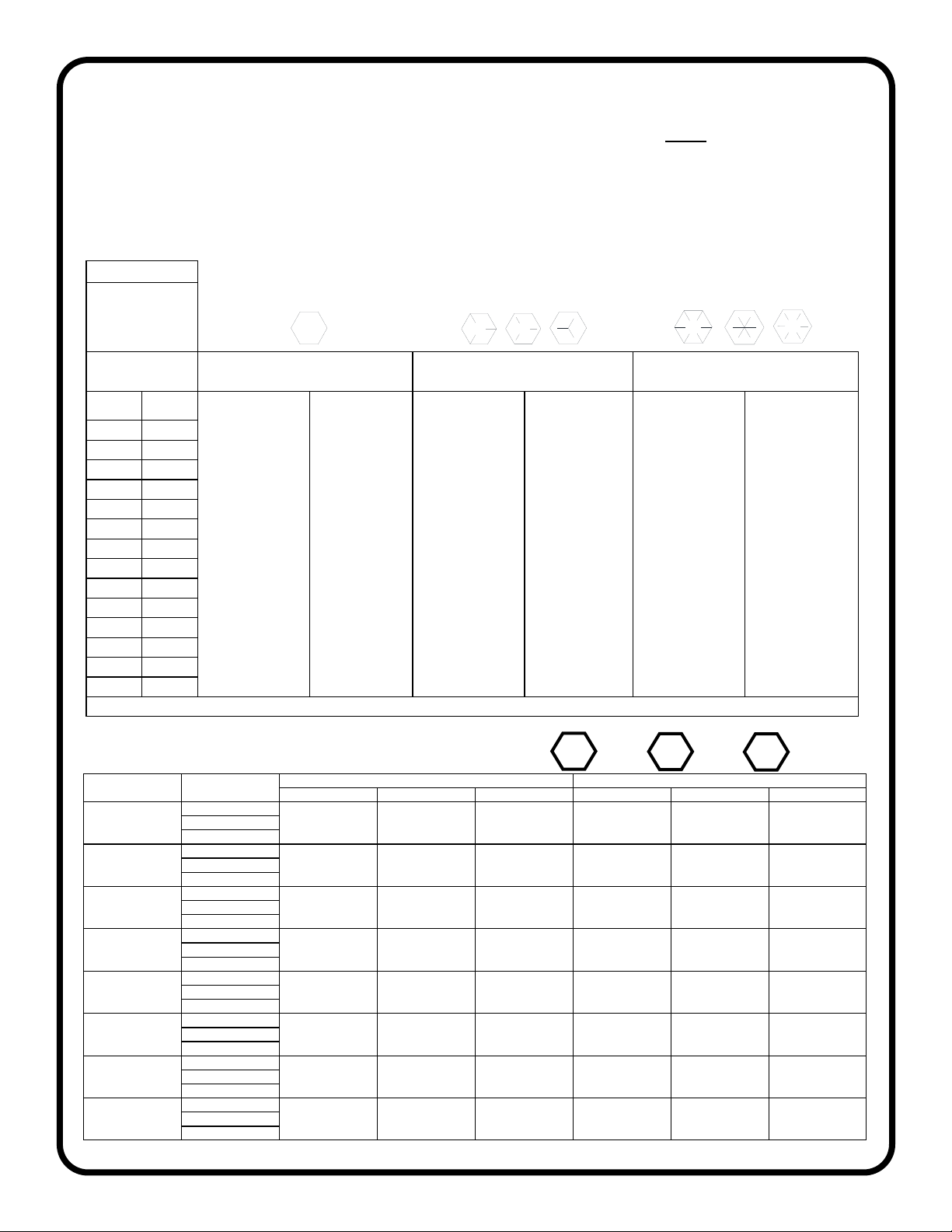

Torque Specs. for Structural Bolts

This page is for use primarily when dealing with high-strength vehicle fasteners such as ROPS hardware that hold the

structure together for safety. This page can also be used for other solid metal-to-metal joints. Do not use these high torque

values on any of the following applications involving: tubing, plastic, nylon or rubber washers, threaded inserts, etc.. See next

page regarding less critical fasteners.

The values below apply to fasteners that are dry or lubricated with normal engine oil. They do not apply if special graphited or

moly disulphide greases or other extreme pressure lubricants are used. This applies to both UNF and UNC threads.

Remember to always use the same grade or property class when replacing bolts.

IMPORTANT: on all PLATED GRADE 8 bolts, reduce torque 15% from listed bolt torque specification.

Size of Screw Property Class

Course Thread Fine Thread

Pitch (mm) Pounds Feet Newton-Meters Pitch (mm) Pounds Feet Newton-Meters

M6

5.6

1.0

3.6-5.8 4.9-7.9

-

- -

8.8 5.8-9.4 7.9-12.7 - -

10.9 7.2-10 9.8-13.6 - -

M8

5.6

1.25

7.2-14 9.8-19

1.0

12-17 16.3-23

8.8 17-22 23-29.8 19-27 25.7-36.6

10.9 20-26 27.1-35.2 22-31 29.8-42

M10

5.6

1.5

20-25 27.1-33.9

1.25

20-29 27.1-39.3

8.8 34-40 46.1-54.2 35-47 47.4-63.7

10.9 38-46 51.5-62.3 40-52 54.2-70.5

M12

5.6

1.75

28-34 37.9-46.1

1.25

31-41 42-55.6

8.8 51-59 69.1-79.9 55-68 75.9-92.1

10.9 57-66 77.2-89.4 62-75 84-101.6

M14

5.6

2.0

49-56 66.4-75.9

1.5

52-64 70.5-86.7

8.8 81-93 109.8-126 90-106 122-143.6

10.9 96-109 130.1-147.7 107-124 145-168

M16

5.6

2.0

67-77 90.8-104.3

1.5

69-83 93.6-112.5

8.8 116-130 157.2-176.2 120-138 162.6-187

10.9 129-145 174.8-196.5 140-158 189.7-214.1

M18

5.6

2.0

88-100 119.2-136

1.5

100-117 136-158.5

8.8 150-168 203.3-227.6 177-199 239.8-269.6

10.9 175-194 237.1-262.9 202-231 273.7-313

M20

5.6

2.5

108-130 146.3-176.2

1.5

132-150 178.9-203.3

8.8 186-205 252-277.8 206-242 279.1-327.9

10.9 213-249 288.6-337.4 246-289 333.3-391.6

METRIC BOLT TORQUE SPECIFICATIONS 5.6 8.8 10.9

SAE Grade No.

Bolt head identification

mark as per grade.

NOTE: Manufacturing

Marks Will Vary

TORQUE TORQUE TORQUE

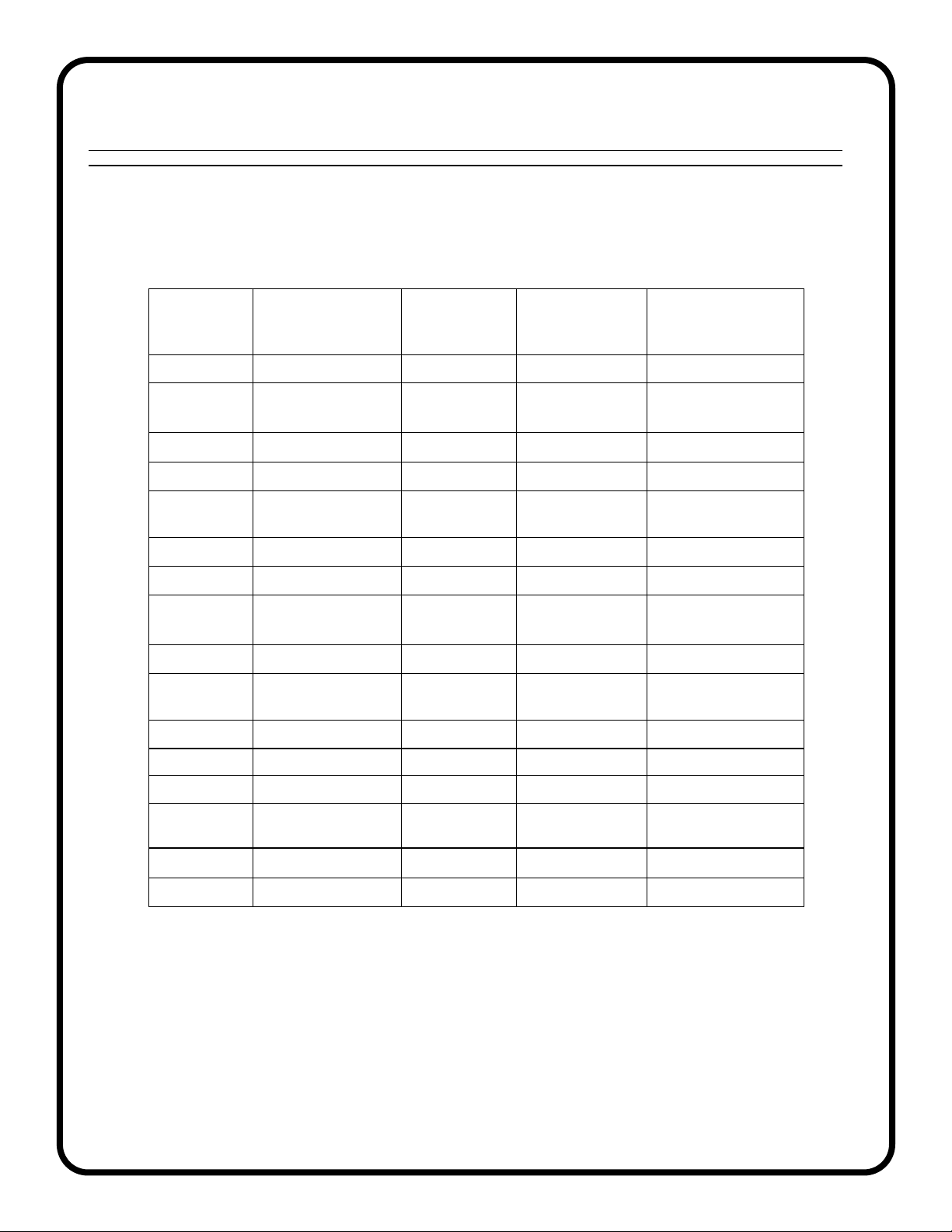

Bolt Size Pounds Feet Newton-Meters Pounds Feet Newton-Meters Pounds Feet Newton-Meters

Inches Millimeters Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max.

1/4 6.35 5678911 12 15 12 15 16 20

5/16 7.94 10 12 14 16 17 20.5 23 28 24 29 33 39

3/8 9.53 20 23 27 31 35 42 48 57 45 54 61 73

7/16 11.11 30 35 41 47 54 64 73 87 70 84 95 114

1/2 12.70 45 52 61 70 80 96 109 130 110 132 149 179

9/16 14.29 65 75 88 102 110 132 149 179 160 192 217 260

5/8 15.88 95 105 129 142 150 180 203 244 220 264 298 358

3/4 19.05 150 185 203 251 270 324 366 439 380 456 515 618

7/8 22.23 160 200 217 271 400 480 542 651 600 720 814 976

125.40 250 300 339 406 580 696 787 944 900 1080 1220 1464

1-1/8 25.58 - - - - 800 880 1085 1193 1280 1440 1736 1953

1-1/4 31.75 - - - - 1120 1240 1519 1681 1820 2000 2468 2712

1-3/8 34.93 - - - - 1460 1680 1980 2278 2380 2720 3227 3688

1-1/2 38.10 - - - - 1940 2200 2631 2983 3160 3560 4285 4827

*Thick Nuts must be used with Grade 8 bolts

58*

2