10

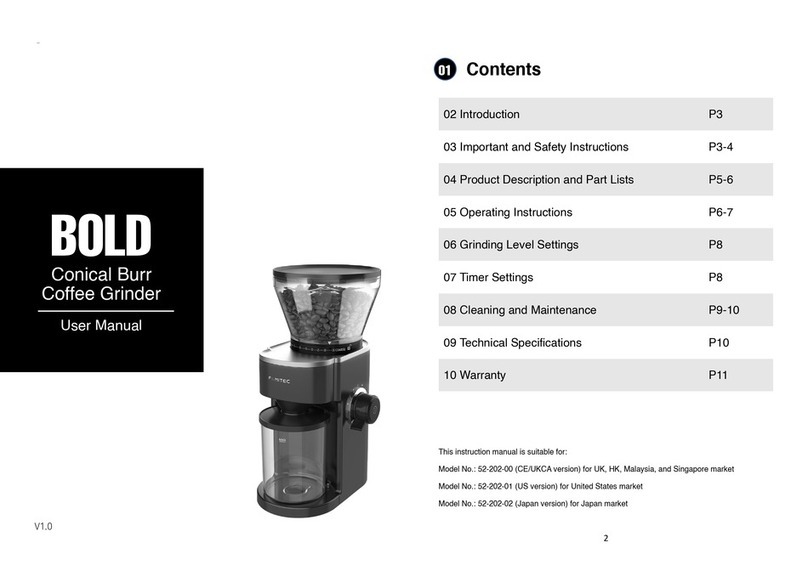

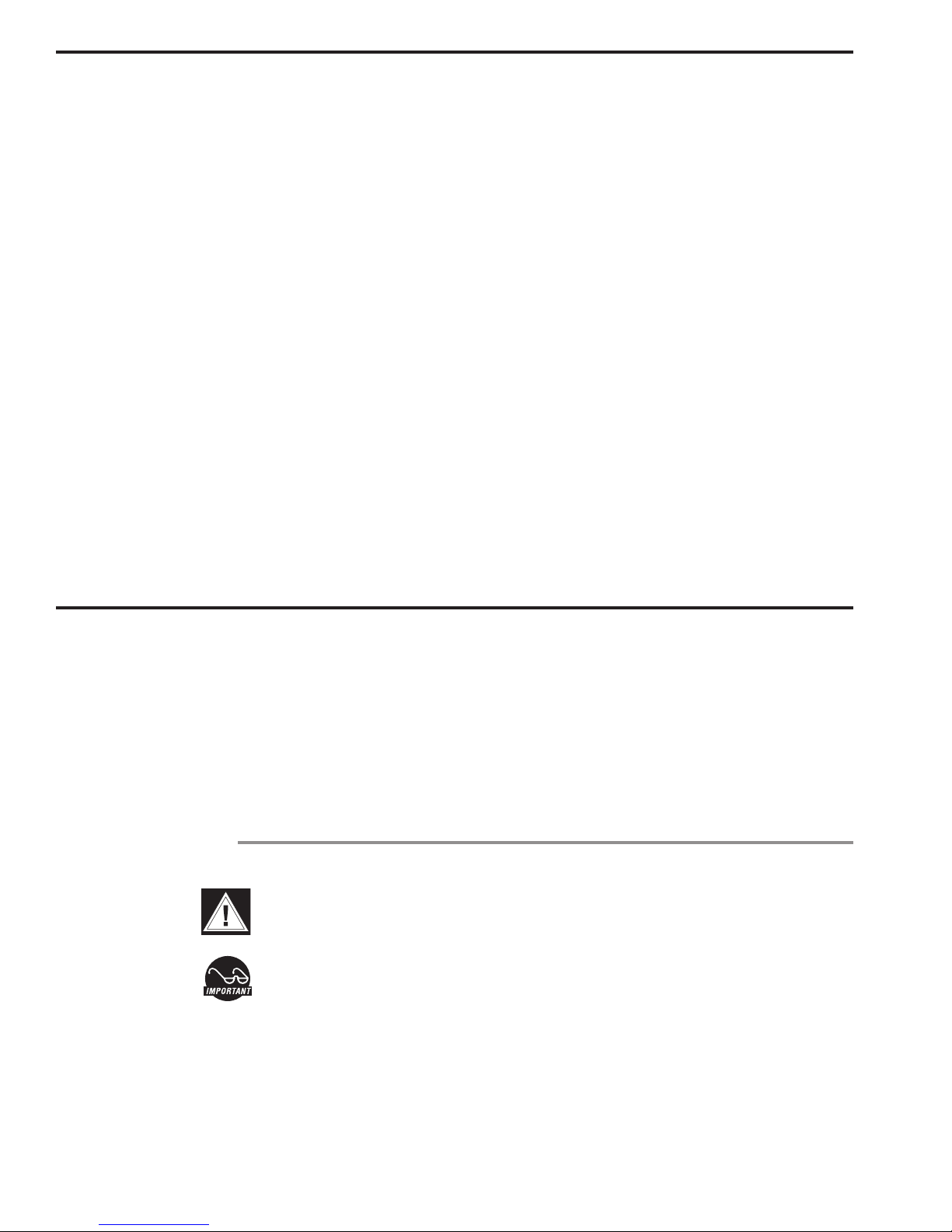

PARTS LIST

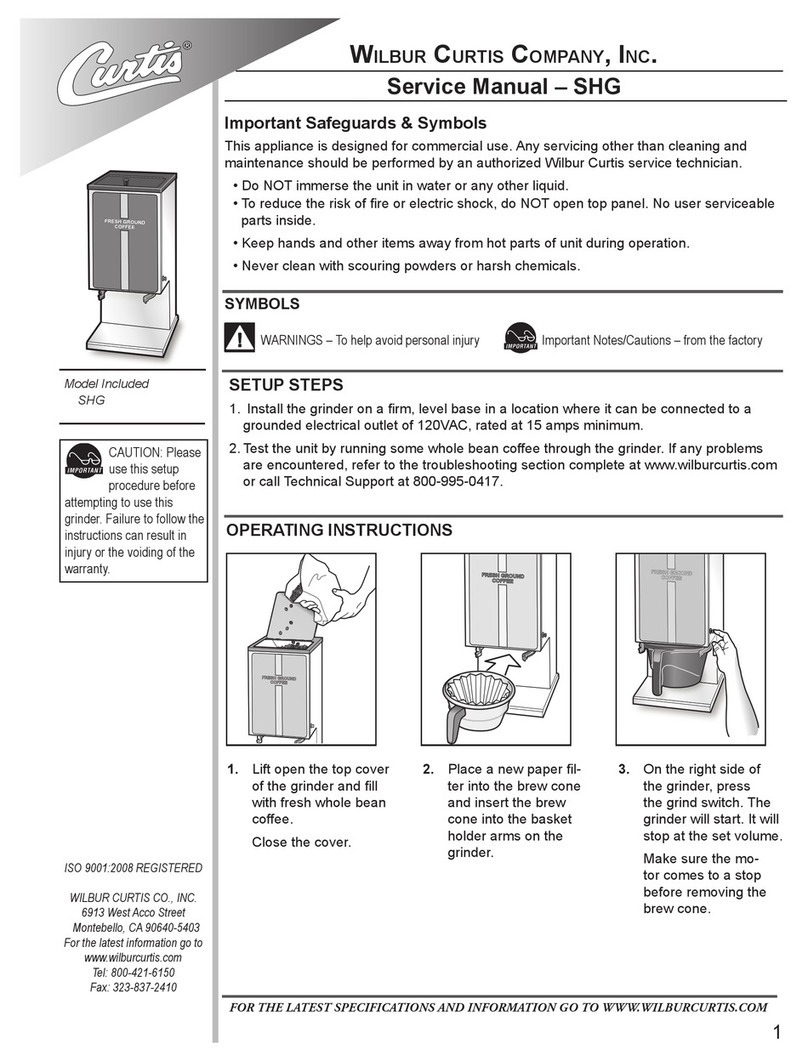

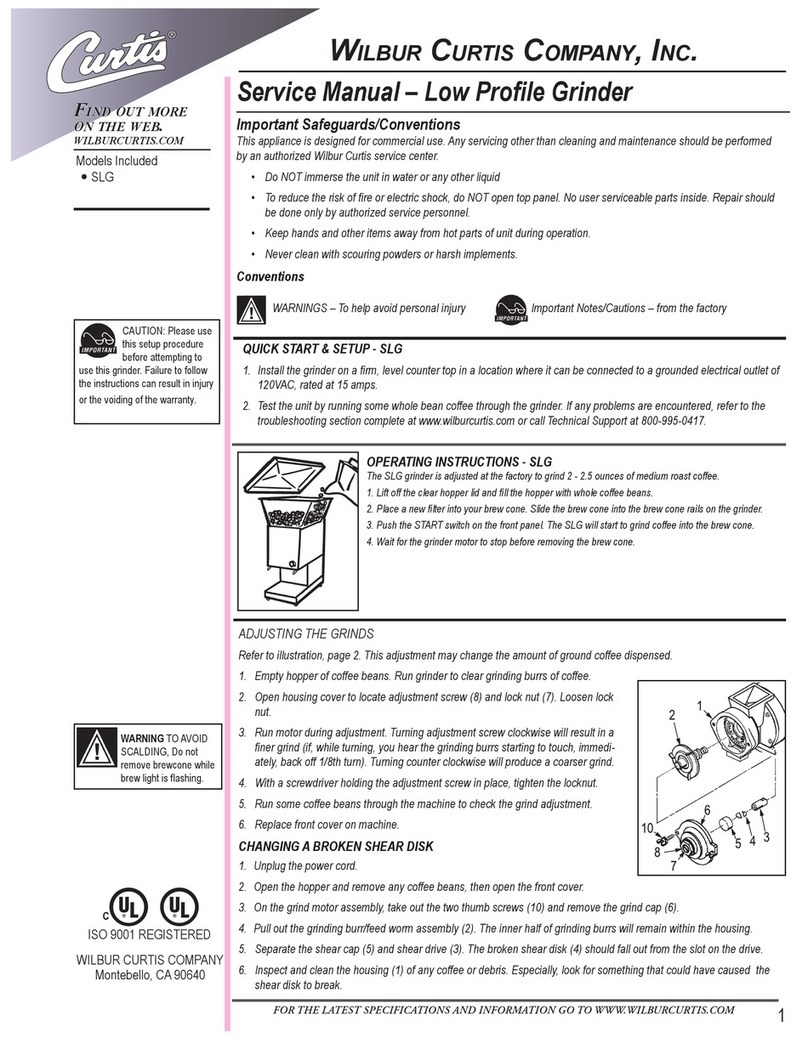

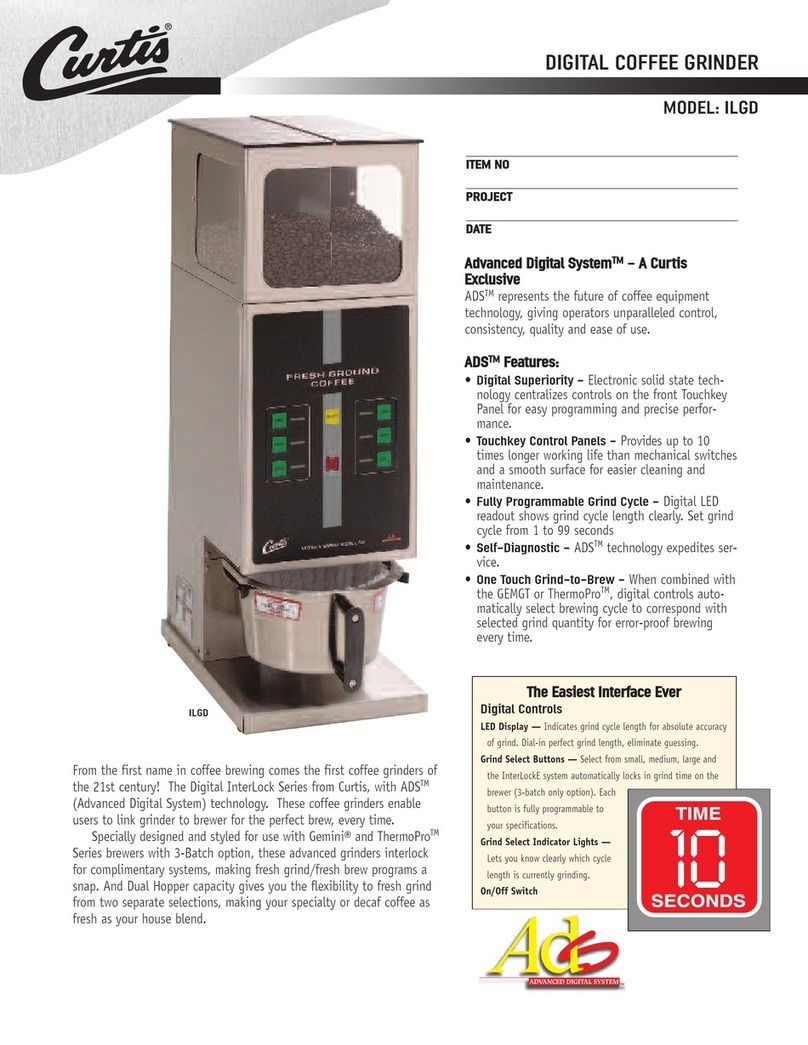

COVER, HOPPER DUAL GRINDER ASSY

WINDOW, ACRYLIC DUAL GRINDER

DIVIDER, W/HOLE ILG-11/DHG-11

DUAL HOPPER GRINDER ASSY

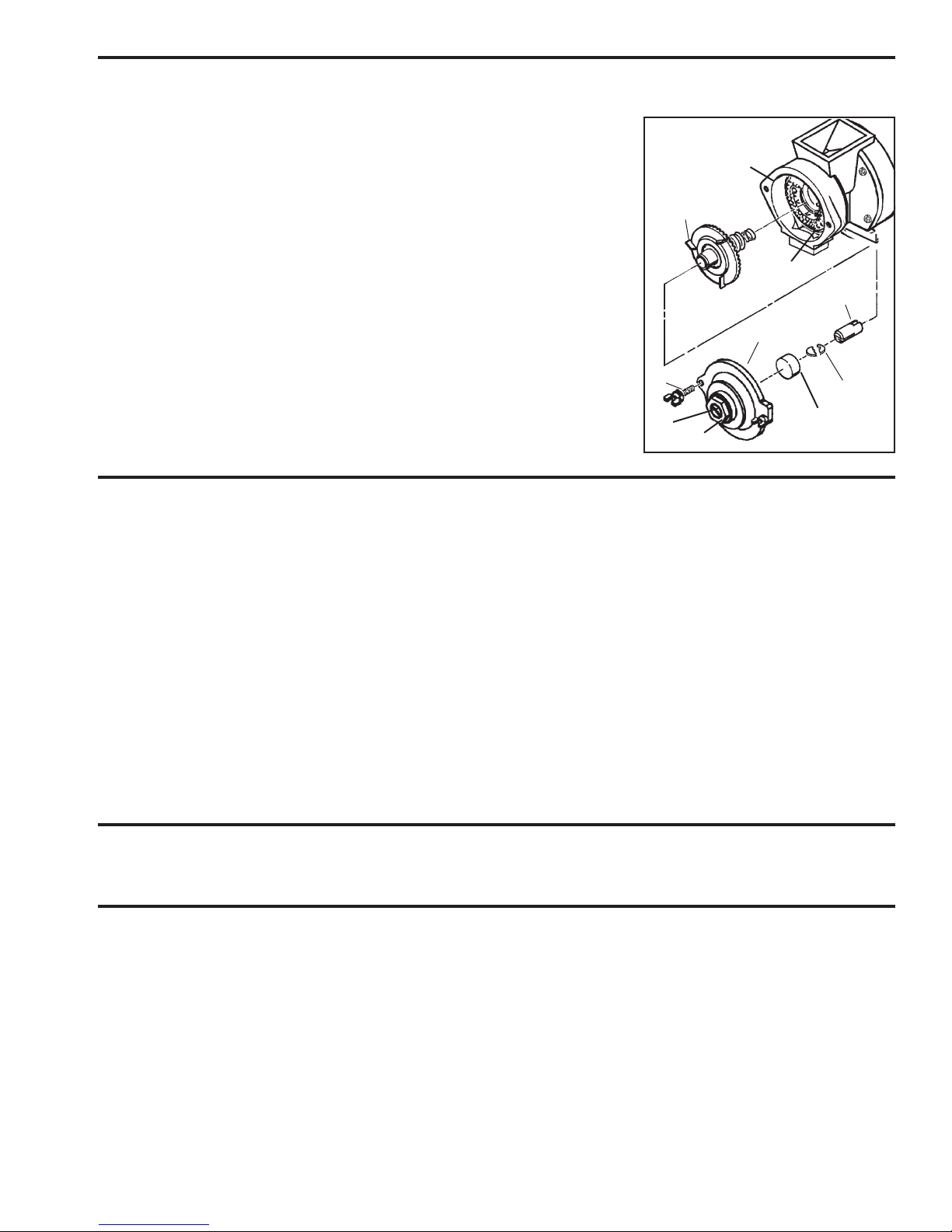

AUGER ASSY DHG/ILG/ILGD

BEARING, AUGER BR

WRAP, DUAL HOPPER ILGD

FUNNEL, DHG/ILGD

SHEILD, HOUSING, ILGD/ILG/SHG/DHG

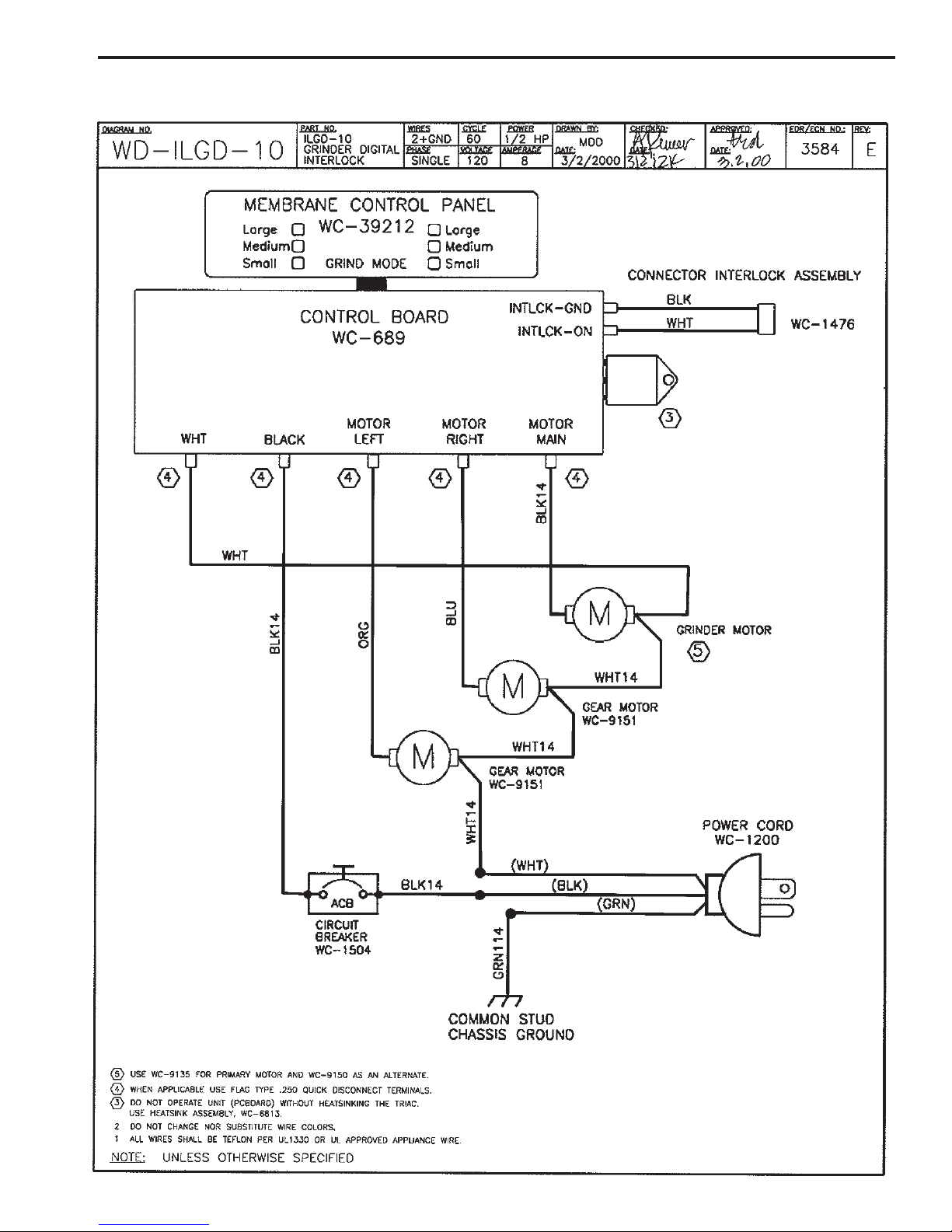

MOTOR, GEAR 115V DUAL GRINDER

CONTROL BOARD, ILGD, DHGILD

GUIDE, SPOUT W/A SHG DHG ILGD

MEMBRANE CONTROL PANEL, ILGD

MEMBRANE CONTROL PANEL, TL-ILGD

LABEL, ADJUSTMENT INFO SHG, DHG

LEG, 3/8"-16 STUD SCREW BUMPER

LEG, GLIDE 3/8"-16 STUD SCREW

MOTOR, CRUSHING GRINDER ASSY 120VAC SHG/DHG/ILGD

NUT, HEX ADAPTER GRINDER

WC-1504

WC-37283

WC-3503

WC-3502

WC-3518

WC-4813

1

2

* 3

* 4

* 5

6

6A

* 7

8

10

11

12

13

14

15

16

17

17A

18

18A

20

21

22

22A

23

24

25

26

27

28

ITEM

Nº

PART

Nº DESCRIPTION