I.B. 48004

Page 8

Effective 11/97

THE CONTACTOR (Continued)

The kickout spring is adjustable and occupies the space

above the operating magnet. The kickout spring must be

removed before the magnet coil can be changed if that

becomes necessary. The normal position of the kickout

spring lever is vertical. The lever can be loosened to

unload the kickout spring (after loosening the set screw

that locks the adjusting screw). Unscrew the 0.313-inch

adjusting screw immediately below the kickout spring

itself. Although it can be loosened, the lever is captive.

As the screw is loosened, the kickout spring will reach its

relaxed, free length and can be removed easily. To re-

install it, reverse the procedure. Insert the

uncompressed, free spring into position; then apply load

by tightening the adjusting screw on the lever until the

lever is approximately vertical. See specific instructions

later. Because the spring forces exceed 100 pounds (45

kilograms), place a free hand over the kickout spring as a

precaution while turning the adjusting screw in either

direction. Tighten the set screw to lock the adjusting

screw.

The operating magnet (see Figure 12) is on the front of

the contactor. The coil has a “figure-eight” shape and is

really two coils in series, with a connection to their

common point. Both coils are encapsulated in one

environmentally-immune coil shell, which also contains a

full-wave silicon diode rectifier. An AC or DC source can

be connected to terminals A and B on the coil shell.

When an AC source is applied, the rectifier converts the

AC to unfiltered DC to excite the magnet. When a DC

source is applied, only two legs of the full-wave rectifier

are active and pass DC current for magnet excitation.

The magnet will not chatter as AC magnets sometimes

do but at less than rated voltage, it may hum slightly. A

normally-closed auxiliary contact, set to open slightly

before the armature fully closes, is connected to termi-

nals C and D on the coil shell. When adjusted correctly,

this auxiliary contact allows a relatively high current

through the pick-up winding, and as the contactor closes,

the auxiliary contact inserts the holding winding, which

reduces the coil current to a low value, sufficient to hold

the magnet closed without overheating.

In the description of the bottles, it was mentioned that no

arc boxes are required. However, because of electrical

clearance requirements, four phase barriers must be

installed before the contactor is energized.

CONTACTOR-MOUNTED COMPONENTS

To simplify installation and servicing, a number of related

components are mounted on the Type SJD contactor

chassis: a control power transformer with test plug and

fuses, instrument-quality potential transformers with

secondary fuses (when furnished), primary fuses for the

control power and potential transformers, and load side

fuse clips for the power circuit fuses. See Figures 7 and

13. The test-run plug is used to connect to an auxiliary

source of control voltage when it is not inserted into the

receptacle that is the output from the secondary of the

control power transformer. This male test plug can be

plugged into a standard polarized 120-volt (or 240-volt,

depending on coil voltage rating) extension cord socket

for testing the control circuit and any sequence without

energizing the medium-voltage controller at power circuit

voltage. When the male plug is transferred to the exten-

sion cord, it automatically disconnects from the control

power transformer to prevent feedback of high voltage

into the power circuits. Check to be sure no inadvertent

bypass of this arrangement has been made in the wiring

before relying on this safety feature.

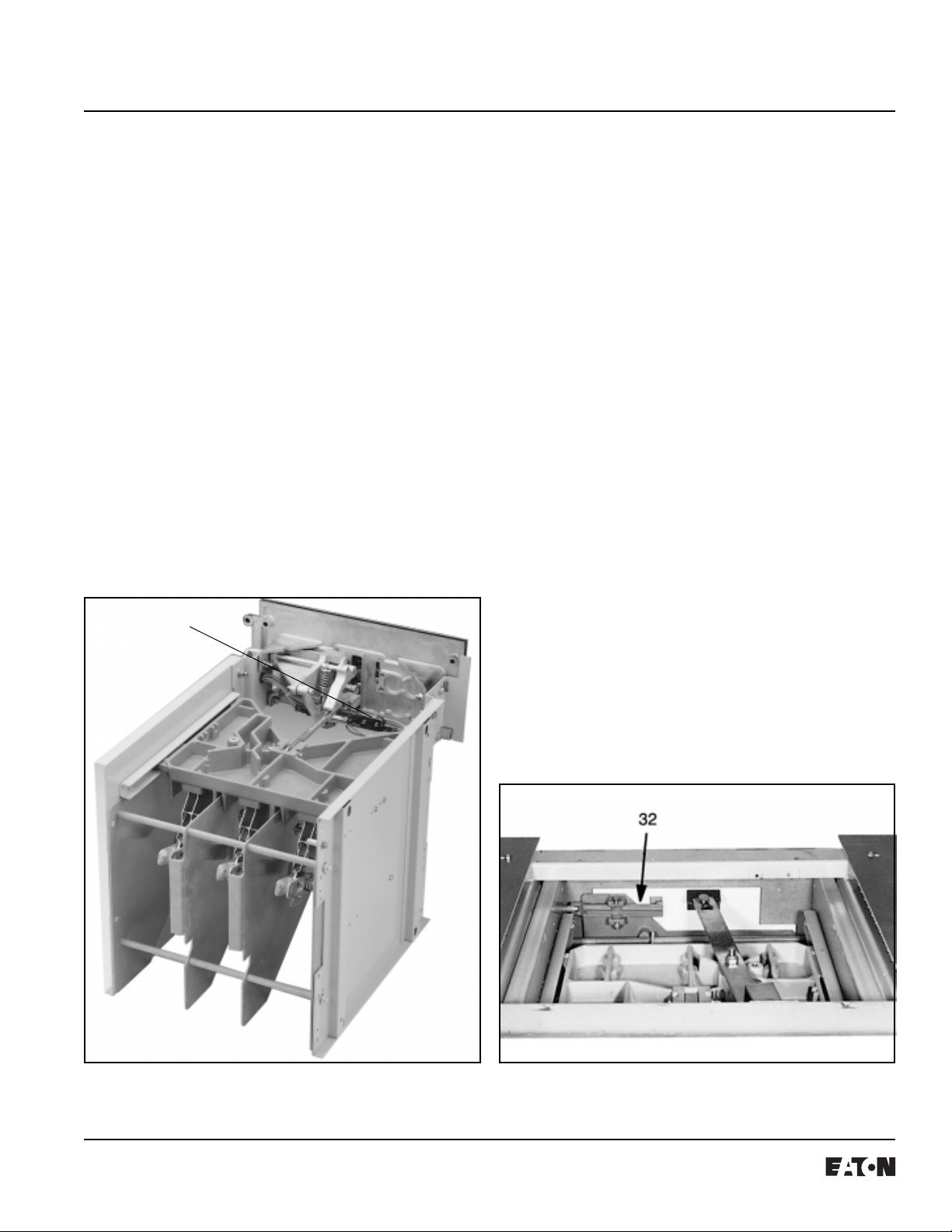

CONTACTOR HANDLING

Each contactor weighs about 160 pounds (73 kilograms). An

oblong hole is provided in each sidesheet for lifting if desired.

A horizontal bar is provided at the front for pulling the

contactor out of its cell, or for pushing it back into place.

When a type SJD contactor is installed in a medium-

voltage controller it can be moved to a drawout position

or removed from the enclosure as follows:

DANGER

WARNING: ALL WORK ON THIS CONTACTOR SHOULD

BE DONE WITH THE MAIN DISCONNECT DEVICE

OPEN.AS WITHANY CONTACTOR OF THIS VOLTAGE,

THERE IS DANGER OF ELECTROCUTION AND/OR

SEVERE BURNS. MAKE CERTAIN THAT POWER IS

OFF. CHECK FOR THE PRESENCE OF DANGEROUS

VOLTAGE WITH AVOLTAGE SENSOROFTHE

APPROPRIATE RANGE.

1. If removal is planned, provide a lift truck or suitable

platform to receive the contactor as it comes out.

2. Make sure all circuits are deenergized.

3. Remove the three power circuit fuses using the fuse

puller supplied with the starter.

4. Disconnect the pull-apart terminal blocks connecting

the contactor to the low-voltage compartment and

stow them so that the cable will not be damaged.