Pub 49004

Effective 9/00

Page 6

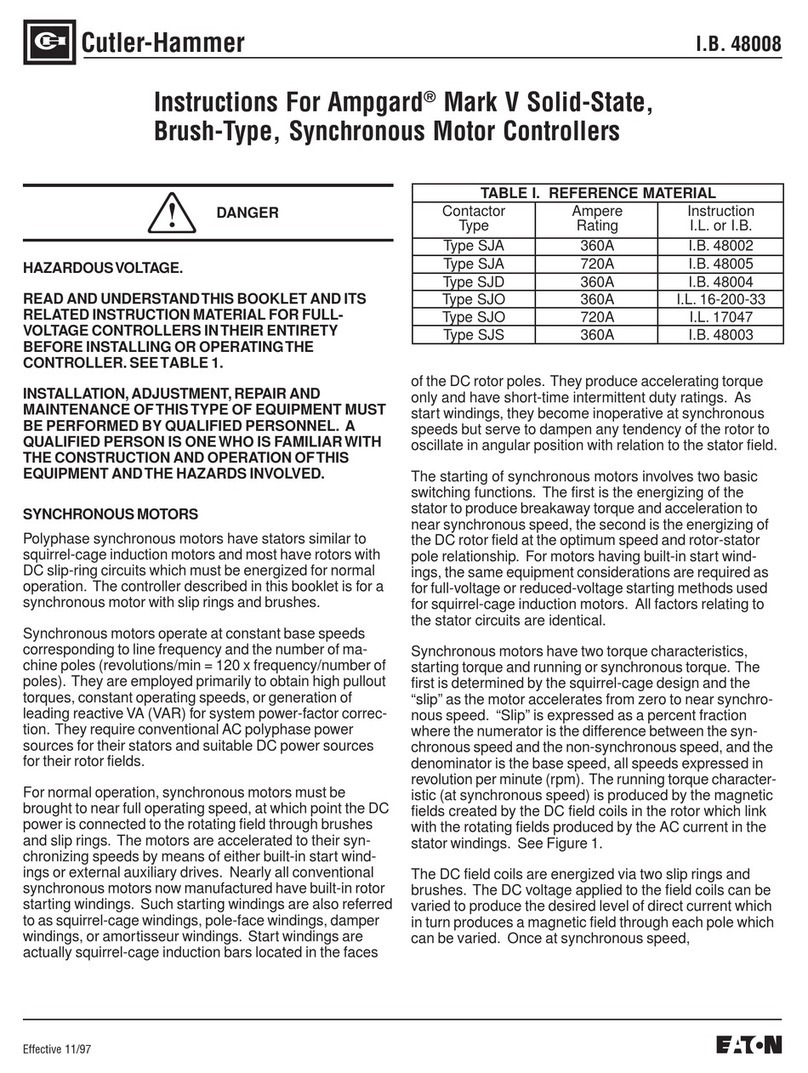

Catalog Steady State Inrush Input

Number Wattage Wattage Voltage

PSS55A 55W 250W 115VAC

PSS55B 55W 250W 230VAC

PSS55C 55W 250W 360 - 480VAC

Protective Features, Cont’d

timer. If 24VDC power is removed, the soft starter remem-

bers the remaining cool-down time and will not reset until

the total cool-down time has elapsed.

The unit monitors these conditions for overload:

Thermal (current) Overload - monitors RMS, with a

5, 10, 20, or 30-second dela time based on Trip

Class setting.

Protective Setting Factory

Feature Default

Overload 32% - 100% of rated current 32%

(FLA Dial Range)

Trip Class 5, 10, 20, 30 5

Fault Reset Auto, Manual Manual

Jam On, Disable On

Stall On, Disable On

Phase Loss On, Disable On

Phase Reversal On, Disable On

Overload On, Disable On

Programming Settings

General

To program and operate the IT Soft Starter, a Control

Interface Module (CIM) is required (see Fig. 6). The CIM

(Catalog No. EMA71) is for use with all models: S801N,

S801R, S801T, and S801V. The CIM (Catalog No. EMA72)

is used with all model S801N, S801R, S801T and S801V

with the pump control option (see Fig. 7). The CIM serves

as the interface between the operator and the Soft Starter

control circuitr to program the Soft Starter. The CIM dip

switches and rotar controls are used to select the Soft

Starter settings. When making adjustment to the CIM

under normal operation, the LEDs will function as follows:

A change to an dip switch will cause all LEDs to flash

momentaril .

An adjustment to an POT will cause all LEDs to light

and sta lit until adjustment of POT has been completed.

While selecting these parameters, 24VDC power ma be

applied to the Soft Starter, but it is not required.

NOTE: The IT Soft Starter does not have to be powered

to make adjustment to the control interface module. Once

the unit is energized, it will communicate with the CIM

and load the program into the Soft Starter. Allow the unit

2 seconds to ensure communication checks complete

and values are set. To verif CIM is operational, press

Fault Reset. If the CIM is powered and communicating,

all LEDs will momentaril flash.

See the user manual for additional detail on the standard

and pump control option.

Procedure for Starting

Application Note - Permissive (P)

(P) must be held high (24VDC) in order to START the

Soft Starter.

Remove 24VDC from terminal P to initiate a stop.

Run inputs (terminals 1 through 4) are a momentar

high (24VDC).

If the inputs (Input 1, 2, 3, 4) are high when the Per-

missive opens, the Soft Starter will STOP.

The Soft Starter will not start when 24VDC is applied

to the Permissive (P) until Input 1 changes from 0 volts

(open) to a high (+24V) condition. (Once P is at 24

volts, Input 1 must c cle from 0 volts to 24 volts to

start.)

On the larger soft starters when the b pass contactors

close, a sound similar to contactor chattering can be

heard. This sound is caused b more than one contactor

closing in a staggered manner over a ver short period

of time. This is part of normal operation and should not

be misinterpreted as a dirt pickup.

For two-wire control, jumper permissive (P) and Input

1, together.

24VDC Power Requirements

When sizing a 24VDC power suppl for our IT soft starter,

it must meet the following stead state and inrush charac-

teristics.

Stead State Minimum = 25 watts

Inrush Minimum = 240 watts for 150 msecs

Voltage on the unit cannot exceed 30VDC. The soft starter

will turn off at approximatel 20.9VDC.

It is recommended that power supplies from Cutler-Hammer

be used.

The following C-H power supplies are available:

Table 5

Table 6

NOTE: A minimum of #14 AWG should be used between

the power suppl and the 24V (+) and (-) terminals of the

soft starter.

Protective Features

The soft starter cannot be restarted until the calculated

cool-down time has passed. C cling power does not reset